Document

Laboratory Biosafety Practices

A. I. Bhat

Indian Institute of Spices Research

Calicut 673012, Kerala

Why Biosafety Practices?

Protection

:

• workers

• “products”

• co-workers

• lab support personnel

• environment

What are the general hazards in a laboratory?

• Fire

• Breakage of glassware

• Sharps

• Spillages

• Pressure equipment & gas cylinders

• Extremes of heat & cold

• Chemical hazards

• Biological hazards

• Radiation

And many more!

worldwide literature search from 1979-2004

• 1,141 overt infections, 24 deaths

• Most common causative agents of overt infection include:

1. M. tuberculosis 6. HBV

2. Arboviruses 7. Shigella spp.

3. C. burnetti 8. Salmonella spp

4. Hantavirus 9. HCV

5. Brucella spp. 10. N. meningitidis

• Many asymptomatic infections

• Many newer agents, e.g. SARS-CoV,

Cryptosporidium, etc.

• No specific exposure event in most cases

_________________________

_________________________

________WSLH

4

What were the predominant means of exposure?

– As mentioned before no specific exposure event identified in most cases

– Those identified included:

• Inhalation of aerosols generated by work practices or procedures or spills

• Percutaneous inoculation

• Contamination of mucous membranes

• Ingestion

_________________________

_________________________

________WSLH

5

• Objective of biosafety is containment of potentially harmful biological agents

• Purpose of containment is to reduce/eliminate exposure of lab workers, other persons and outside environment to biohazardous agents

• Key elements of containment include:

– Laboratory practice and technique

– Safety equipment (primary barriers and PPE)

– Facility design and construction (secondary barriers)

• Risk Assessment of the work to be done with a specific agent or under specific circumstances determines the appropriate combination of these elements to employ

_________________________

_________________________ 6

________WSLH

General Lab Requirements: Safety

• Knowledgeable supervisor

• Knowledgeable personnel

– Aware of potential hazards

– Proficient in practices &

– techniques

• Lab specific biosafety manual

Laboratory safety

Special procedures

•

Decontaminate work surfaces

•

Report spills and accidents

•

No animals in laboratories

Common Sense Rules

• Wash hands & remove protective clothing before eating, drinking, smoking, handling contact lenses, applying lip balm or cosmetics

• Keep hands away from eyes, nose, mouth while cleaning

• Frequent hand washing is best defense against spreading infection

Elements of Containment

Safety Equipment (Primary barriers and PPE)

• Available for each possible route of exposure

– Aerosol: BSCs, covered centrifuge carriers, loop incinerators or disposable loops, PPE

– Percutaneous: sharps disposal; retractable needles

– Mucous membrane contact: goggles or safety glasses, face shields, gloves

– Ingestion: automatic pipetting devices

_________________________

_________________________

________WSLH

19

Elements of Containment

The Biological Safety Cabinet

The single most important piece of safety equipment in the laboratory!

• Importance of the Biological Safety Cabinet

– The principal device used to provide containment of infectious splashes or aerosols generated by many microbiological procedures

– Provides protection to the operator, the laboratory environment and work materials

• Which type is for you?

_________________________

_________________________

________WSLH

20

Biosafety Levels

• 4 biosafety levels

– Consist of combinations of lab practices and techniques, safety equipment and lab facilities

• Purpose: To categorize risk associated with infectious agent and define the appropriate safety practices, equipment and facilities for handling the agent safely

• Appropriate BSL determined by:

– Microbiological agent Risk Group

– Mode of transmission

– Procedural protocols

– Experience of staff

– Likelihood of aerosol generation

– Work involves use of amplified agent

– Other?

_________________________

_________________________

________WSLH

21

Risk group classification

Risk

Group

1

2

3

4

Individual risk no, low moderate high high

Community risk no, low low low high

Risk Group 1

• Unlikely to cause animal or human disease

• Non pathogenic agent

Risk Group 2

Pathogenic for humans

Unlikely a serious hazard

Treatment and preventive measures available

Limited risk of spread of infection

Risk Group 3

Pathogenic, cause serious disease

Effective treatment and preventive measures usually available

Little person-to-person spread

Risk Group 4

Lethal, pathogenic agent

Readily transmittable

– direct, indirect

Effective treatment and preventive measures not usually available

Risk groups, biosafety levels, practices and equipment

BSL Laboratory type Safety equipment

1 Basic teaching, research

Laboratory practices

Good microbiological techniques

None

Open bench work

2 Primary health services; diagnostic services, research

Good microbiological techniques, protective clothing, biohazard sign

Open bench PLUS biological safety cabinet for potential aerosols

3 Special diagnostic services, research

Biological safety cabinet and/or other primary devices for all activities

4 Dangerous pathogen units

As BSL 2 PLUS special clothing, controlled access, directional airflow

As BSL 3 PLUS airlock entry, shower exit, special waste

Class III biological safety cabinet, positive pressure suits, double ended autoclave (through the wall), filtered air

BSL

1

2

Recommended Biosafety Levels for Infectious Agents

Agents Microbiology

Practices

Safety Equipment

(Primary Barriers)

Standard Microbiological

Practices

None required

Facilities

(Secondary Barriers)

Open bench top sink required

Not known to consistently cause disease in healthy adults

Associated with human disease, hazard equals percutaneous injury, ingestion, mucous membrane exposure

BSL-1 plus: Limited access, biohazard warning signs, “sharps” precautions, biosafety manual defining waste decontamination & medical surveillance policies

Class I or II BSCs or other physical containment for manipulations of agents that cause splashes or aerosols of infectious materials, PPE: lab coats, gloves, face protection as needed

BSL-1 plus: Autoclave

3

4

Indigenous or exotic agents with potential aerosol transmission; may have serious or lethal consequences

BSL-2 plus: Controlled access;

Decontamination of all waste & lab clothing before laundering;

Baseline serum

Class I or II BCSs or other physical containment for all manipulations; PPE: protective clothing; gloves; respiratory protection as needed

BSL-2 plus: Physical separation from corridors; Self-closing, double-door access;

Exhausted air not recirculated; Negative airflow into laboratory

Dangerous/exotic agents with high risk of life-threatening disease, aerosoltransmitted infections; or related agents with unknown risk of transmission

BSL-3 practices plus:

Clothing change before entering, shower on exit, all material decontaminated on exit

All procedures in Class

III BSCs or Class I or II

BSCs in combination with full-body, airsupplied, positive pressure personnel suit

__________________________________________________________WSLH

BSL-3 plus: Separate building or isolated zone, dedicated supply, exhaust, vacuum, & decon systems; other requirements.

28

Disinfection

Disinfection requirements depend on the experimental work and nature of the agents being handled

Contact time and concentration for disinfectants are specific for each material and manufacturer

Efficacy is a function of surface, contact time, product, dilution

Using detergents

• Use licensed detergents/disinfectants

• Follow manufacturers’ recommendations

• Wear adequate personal protective equipment

• Perform hand hygiene

• Avoid difficult to clean surfaces/ materials

(carpet, wood)

• Apply disinfectant to a large area - wiping, soaking

• Avoid aerosolizing specimens while handling

Disinfection with household bleach

Work areas

-disinfect with 0.5% bleach after every procedure

Contaminated supplies

-soak with 0.5 % household bleach for 30 minutes

-wash in soapy water

-sterilize as necessary

Photo: WHO

Risk Assessment

• Whose responsibility?

– Technically, the lab director

– Practically, the bench microbiologist

• Primary factors to consider:

– Agent hazards

– Laboratory procedures planned

• Potential for aerosol generation

• Consider facility, equipment needed; appropriate PPE

– Capability of the staff

• Training, technical proficiency, good habits

• Known vs. unknown agent risk

– For known or suspected agent, consult BMBL agent summary statements, other references

– For unknown agent…

_________________________

_________________________

________WSLH

32

General Safety Rules

1. Listen to or read instructions carefully before attempting to do anything.

2. Wear safety goggles to protect your eyes from chemicals, heated materials, or things that might be able to shatter.

3. Notify your teacher if any spills or accidents occur.

33

General Safety Rules

4. After handling chemicals, always wash your hands with soap and water.

5. During lab work, keep your hands away from your face.

6. Tie back long hair.

34

General Safety Rules

7. Roll up loose sleeves.

8. Know the location of the fire extinguisher, fire blanket, eyewash station, and first aid kit.

9. Keep your work area uncluttered. Take to the lab station only what is necessary.

35

General Safety Rules

10. It is suggested that you wear glasses rather than contact lenses.

11. Never put anything into your mouth during a lab experiment.

12. Clean up your lab area at the conclusion of the laboratory period.

13. Never “horse around” or play practical jokes in the laboratory.

36

Glassware Safety

1. Chipped or cracked glassware should not be used. Show it to the teacher.

2. Broken glassware should not be disposed of in a classroom trashcan.

There is a special glass disposal container for it.

3. When pouring liquids into glassware, make sure the container you are pouring into is resting on a table at least a hands breadth from the edge.

37

Glassware Safety

4. If a piece of glassware gets broken, do not try to clean it up by yourself.

Notify the teacher.

5. Do not place hot glassware in water.

Rapid cooling may make it shatter.

38

Chemical Safety

1. Wear protective goggles whenever heating or pouring hazardous chemicals.

2. Never mix chemicals together unless you are told to do so (and then only in the manner specified).

3. Never taste any chemicals (you should never taste anything in the lab).

39

Chemical Safety

4. If you need to smell the odor of a chemical, waft the fumes toward your nose with one hand. Do not put your nose over the container and inhale the fumes.

40

Chemical Safety

5. Follow the instructions of your teacher when disposing of all chemicals.

6. Wash your hands after handling hazardous chemicals.

41

Heating Safety

1. Use tongs and/or protective gloves to handle hot objects.

2. Never reach across an open flame or burner.

42

Heating Safety

3. Always point the top ends of test tubes that are being heated away from people.

4. When heating a test tube, move it around slowly over the flame to distribute the heat evenly.

43

Heating Safety

5. Only glassware that is thoroughly dry should be heated.

6. Heat glassware by placing it on a wire gauze platform on a ringstand.

Do not hold it in your hand.

44

First Aid

Injury: Burns

To Do: Immediately flush with cold water until burning sensation is lessened.

45

First Aid

Injury: Cuts, bruises

To Do: Do not touch an open wound without safety gloves. Pressing directly on minor cuts will stop bleeding in a few minutes. Apply cold compress to bruises to reduce swelling.

46

First Aid

Injury: The eyes

To Do: Flush eyes immediately with plenty of water for several minutes. If a foreign object is lodged in the eye, do not allow the eye to be rubbed.

47

Spillages

• Clear up spillage promptly

• You will already have determined how to do this as part of your risk assessment

• Dispose of any hazardous material as toxic waste

Messy workers are usually poor workers!!

Unacceptable Lab Clothing

•

Skirts

• Shorts

•

Open-toed shoes

• Sandals

• Jackets

•

Bulky shirts or sweaters

• Floppy or loose sleeves

Laboratory Equipment

• Never use any laboratory equipment unless you are trained & have been authorised to do so

• As well as injuring yourself you may cause very costly damage

Laboratory hygiene

• Never eat, drink or smoke in a laboratory

• Never apply cosmetics

• Never touch your face, mouth or eyes

• Never suck pens or chew pencils

• Always wash your hands before you leave and especially before eating

First Aid

• All laboratory workers should undergo simple first aid training

– For ALL chemical splashes, wash with plenty of water for 10 minutes

– Control bleeding with direct pressure, avoiding any foreign bodies such as glass

• Report all accidents to your supervisor or departmental safety officer

MSDS

Material Safety Data Sheets

• These are data sheets that tell you the chemical and safety properties of the various chemicals we will use in the lab.

• You must look up MSDS information for the safety section of your Pre-Lab in order to:

– Know how to use the chemicals safely.

– Know what to do if there is a spill or accident.

– Be able to do the lab.

MSDS

Diamond

• The MSDS information is put into a short-hand form for quick and easy reference on labels and posters.

• You also see MSDS Diamonds on transport vehicles and containers.

• Red: Flammability

• Yellow: Reactivity

• White: Specific Hazard

• Blue: Health Hazard

MSDS Diamond

MSDS Diamond

• Test your Knowledge by writing in your notes what you think this MSDS Diamond is telling you about a chemical:

MSDS Diamond

• Answers:

– Red: Flammability

• A 4 in the flammability diamond = VERY Flammable

– Yellow: Reactivity

• A 2 in the reactivity diamond = Reacts Violently with Water

– White: Specific Hazard

• No Water in specific hazard diamond = Don’t use water, this also corresponds with the Reactivity diamond

– Blue: Health Hazard

• A 1 in the health hazard diamond = slightly hazardous to your health

When in doubt – ASK!!!

• Do not carry out a new or unfamiliar procedure until you have been fully trained & understand the precautions necessary for safe working

• DO NOT GUESS!!!!

When Accidents Happen:

1. REMAIN CALM!

This sounds like common sense, but when accidents happen remaining calm is crucial!

2. Report ALL accidents

IMMEDIATELY, no matter how small.

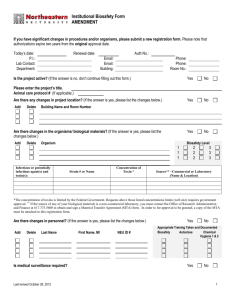

Indian biosafety rules and regulations to advice, facilitate and regulate modern biotechnology work at different stages to achieve the objectives of protecting environment including human and animal health from the unintended adverse effects of GMOs and products thereof.

Recombinant DNA Advisory Committee

(RDAC)

Review developments in Biotechnology at National and

International level.

Recommend suitable and appropriate safety regulations for

India in r-DNA research, use and applications.

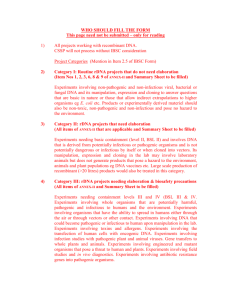

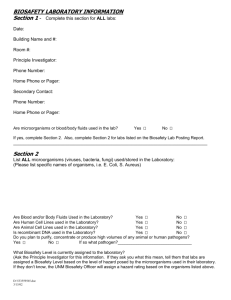

Institutional Biosafety Committee (IBSC)

To note, examine and approve proposals involving r-DNA work; to ensure adherence of r-DNA Safety Guidelines- 1990 of Government; inspection of containment facilities at R&D and production units and to inform the RCGM about the facilities;

To prepare emergency plan according to guidelines;

To approve experiments utilizing the organisms and genetic elements from

Risk Group-I and II organisms up to laboratory fermentation 20 ltrs capacity with intimation to RCGM; for using organisms falling in Risk Group III & above, recommend to RCGM for approval to conduct laboratory studies;

To recommend for import/ exchange of GMOs/LMOs/Transgenic seeds, vectors, gene constructs, plasmids, etc., for research purposes;

To inform DLC and SBCC as well as GEAC about the experiments where ever needed; to act as a nodal point for interaction with statutory bodies; to ensure experimentation at designated location taking into account of approved protocols etc.

IBSC contd...

To examine the description of the target gene and source; nucleotide sequence and amino acid sequence of target gene and the target protein; the composition of the vector used; schematic diagram of the expression cassette; restriction map of vector indicating the location of the target gene; cloning strategy; description of the host cell line including genera and species; risks involved in handling of cell line; methods of maintenance of cell line; classification of the host cell line as per the guidelines;

To approve category I & II experiments, as per the Guidelines 1998 of

DBT, up to green house level with intimation to RCGM in category III

& above experiments, RCGM to approve conduct lab & green house studies. To recommend all open field experiments in any of the category, for any purpose (biosafety studies, seed increase experiments, agronomic studies, etc) for the approval of RCGM.

To examine protocols for toxicity/allergenicity studies as per national and international guidelines and their recommendations to RCGM

Review Committee on Genetic Manipulation (RCGM)

Monitor safety aspects of ongoing rDNA projects involving Genetically Engineered (GE) organisms/ hazardous microorganisms. All ongoing projects including high risk category and confined field experiments shall be reviewed by RCGM to ensure that adequate precautions and containment conditions are complied with as per the Guidelines and

Standard Operating Procedures (SOPs) issued by DBT from time to time.

The RCGM shall lay down procedures restricting or prohibiting production, sale, importation and use of such GE organisms or products thereof for research and applications as mentioned in the schedule of Rules, 1989.

RCGM shall bring out manuals and guidelines specifying procedure for regulatory processes with respect to activities involving GE organisms in research, use and application including industry with a view to ensure safety to human, animal and environment health.

The RCGM would issue the clearance letters/permits for import or exchange of genes,

DNA fragments, vectors, plasmids, cosmids, etiologic agents and transgenic organisms or germplasm(s) including transformed calli, seeds, plants and plant parts for research use only. It will also take note of all such commercially available agents which are acquired from commercial sources through Institutional Biosafety Committee (IBSC)

The RCGM shall be the regulatory body for receiving and reviewing the applications to conduct confined field trials

(such as event selection trials, Biosafety Research Level I trials (BRL I), pollen flow studies, strip trials or any other trial involving GE organisms) and recommend appropriate studies to be conducted for data generation for biosafety assessment as per clause 4, as per the decision of the Genetic Engineering Approval Committee (GEAC) or its authorization.

The RCGM, on case-by-case basis, can authorize applicants to use bioreactors to produce sufficient material/endproducts of GE organisms required for conducting pre-clinical studies and other relevant data generation including the use of capacity over and above as specified by Recombinant DNA Safety Guidelines, 1990. It will authorize to produce sufficient quantities of GE organism/plant product(s) for generating safety data in appropriate animals as per National and International Guidelines, as appropriate on case by case basis.

The RCGM, if required, can generate, examine or invite the research projects, proposals for capacity building and training courses in biosafety, creation of information systems/ data banks in electronic media, websites etc. for financial support and recommend the same to the DBT of specific projects for furthering the cause of generating specific biosafety data related to use of GMOs and strengthening infrastructure facilities & dissemination of biosafety rules, regulations and guidelines in the country.

The RCGM may also invite, induct or appoint special experts in their individual capacities on a case by case basis.

The RCGM may constitute subgroups of its members or subcommittees involving experts for specific functions or seek advice on specific matters from other external experts.

The RCGM or its constituted subgroups/subcommittees may visit periodically the experimental sites where r-DNA projects and activities involving GE organisms/ hazardous microorganisms are being pursued to ensure that adequate safety measures have been taken as per the guidelines and compliance of SOPs

Genetic Engineering Appraisal Committee (GEAC)

Statutory Body under the Ministry of Environment & Forests for approval of activities involving large-scale use of hazardous living microorganisms and recombinants in research and industrial production from the environmental angle

Responsible for approval of proposal relating to release of genetically engineered organisms and products Into the environment including experimental field trials as per the provisions of Rules 1989.

Responsible for approval of proposals involving the use of living modified organism falling in the risk category III and above in the manufacture/import of recombinant Pharma products or where the end product of the recombinant Pharma products per se is a living modified organism.

State Biotechnology Co-Ordination Committee (SBCC)

Powers to inspect, investigate and to take punitive action in case of violations of statutory provisions through the State Pollution Control Board or the

Directorate of Health etc.

To review periodically the safety and control measures in various institutions handling GMOs.

To act as nodal agency at State level to assess the damage, if any, due to release of GMOs and to take on site control measures.

District Level Committee (DLC)

Have powers to inspect, investigate and report to the SBCC or the GEAC about compliance or non compliance of r-DNA guidelines or violations.

To act as nodal agency at District level to assess the damage, if any, due to release of GMOs and to take on site control measures.

Monitoring - cum - Evaluation Committee (MEC)

To undertake field visits at the experimental site(s) approved by the RCGM for the purpose of collecting scientific information on the comparative agronomic advantages of the transgenic plants.

To advise, time to time, the RCGM on the risks and benefits from the use of the transgenic plants put into evaluation. The committee to suggest new experimental design(s) to RCGM and also assist in collecting, consolidating and analyzing the field data for evaluating the environmental risks emanating from the transgenic plants.

To apprise the RCGM on those transgenic crops which would find environmentally safe and economically viable for recommending the same to Genetic Engineering Approval

Committee (GEAC) for consideration for release into the environment.

To undertake field visits at the experimental site(s) approved by the GEAC for the purpose of collecting scientific information, based on specific request made by the GEAC. The

Committee to submit its report to GEAC directly with information to RCGM.

APPLICATION FORMATS

P roforma for submitting application to IBSC/RCGM for Import/Exchange of GMOs/LMOs and products thereof for research and development purposes

P roforma for submitting application to IBSC/RCGM for Import/Exchange of GMOs/LMOs and products thereof for research and development purposes

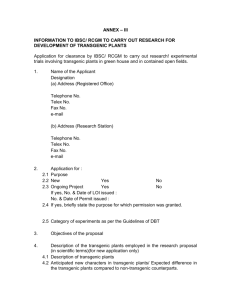

P roforma for submitting application to IBSC/RCGM to carry out research for development of transgenic plants

Application to GEAC under Rules 1989 seeking approval for environmental release of transgenic crops, as per DBT Guidelines 1998

Application to GEAC seeking approval to conduct large scale field trials on transgenic crops

Proforma for submitting application to IBSC/RCGM to conduct confined field trials of regulated genetically engineered plants