13.42 Lecture: Vortex Induced Vibrations

advertisement

13.42 Lecture:

Vortex Induced Vibrations

Prof. A. H. Techet

18 March 2004

Classic VIV Catastrophe

If ignored, these vibrations can prove catastrophic to

structures, as they did in the case of the Tacoma

Narrows Bridge in 1940.

Potential Flow

U(q) = 2U sinq

P(q) = 1/2 r U(q)2 = P + 1/2 r U2

Cp = {P(q) - P }/{1/2 r U2}= 1 - 4sin2q

Axial Pressure Force

Base

pressure

(i)

(ii)

i) Potential flow:

-p/w < q < p/2

ii) P ~ PB

p/2 q 3p/2

(for LAMINAR flow)

Reynolds Number Dependency

Rd < 5

5-15 < Rd < 40

40 < Rd < 150

150 < Rd < 300

Transition to turbulence

300 < Rd < 3*105

3*105 < Rd < 3.5*106

3.5*106 < Rd

Shear layer instability causes

vortex roll-up

• Flow speed outside wake is much higher than inside

• Vorticity gathers at downcrossing points in upper layer

• Vorticity gathers at upcrossings in lower layer

• Induced velocities (due to vortices) causes this

perturbation to amplify

Wake Instability

Classical Vortex Shedding

l

h

Von Karman Vortex Street

Alternately shed opposite signed vortices

Vortex shedding dictated by

the Strouhal number

St=fsd/U

fs is the shedding frequency, d is diameter and U inflow speed

Additional VIV Parameters

• Reynolds Number

UD inertial effects

Re

v

viscous effects

– subcritical (Re<105) (laminar boundary)

• Reduced Velocity

U

Vrn

fn D

• Vortex Shedding Frequency

SU

fs

D

– S0.2 for subcritical flow

Strouhal Number vs. Reynolds

Number

St = 0.2

Vortex Shedding Generates

forces on Cylinder

Uo

Both Lift and Drag forces persist

on a cylinder in cross flow. Lift

is perpendicular to the inflow

velocity and drag is parallel.

FL(t)

FD(t)

Due to the alternating vortex wake (“Karman street”) the

oscillations in lift force occur at the vortex shedding frequency

and oscillations in drag force occur at twice the vortex

shedding frequency.

Vortex Induced Forces

Due to unsteady flow, forces, X(t) and Y(t), vary with time.

Force coefficients:

Cx =

D(t)

1/

2r

U2

d

Cy =

L(t)

1/

2r

U2 d

Force Time Trace

DRAG

Cx

Avg. Drag ≠ 0

LIFT

Cy

Avg. Lift = 0

Alternate Vortex shedding causes

oscillatory forces which induce

structural vibrations

Heave Motion z(t)

z (t ) zo cos wt

z (t ) zow sin wt

z (t ) zow 2 cos wt

LIFT = L(t) = Lo cos (wst+)

Rigid cylinder is now similar

to a spring-mass system with

a harmonic forcing term.

DRAG = D(t) = Do cos (2wst+ )

ws = 2p fs

“Lock-in”

A cylinder is said to be “locked in” when the frequency of

oscillation is equal to the frequency of vortex shedding. In this

region the largest amplitude oscillations occur.

Shedding

frequency

Natural frequency

of oscillation

wv = 2p fv = 2p St (U/d)

wn = m +k m

a

Equation of Cylinder Heave due

to Vortex shedding

mz bz kz L(t )

z(t)

L(t ) La z (t ) Lv z (t )

m

mz (t ) bz (t ) kz (t ) La z (t ) Lv z (t )

k

b

(m La ) z (t ) (b Lv ) z (t ) k z (t ) 0

Added mass term

Restoring force

Damping

If Lv > b system is

UNSTABLE

Lift Force on a Cylinder

Lift force is sinusoidal component and residual force. Filtering

the recorded lift data will give the sinusoidal term which can

be subtracted from the total force.

LIFT FORCE: L(t ) Lo cos(wt o )

if w wv

L(t ) Lo cos wt cos o Lo sin wt sin o

L(t )

Lo cos o

Lo sin o

z

(

t

)

z (t )

2

zow

zow

where wv is the frequency of vortex shedding

Lift Force Components:

Two components of lift can be analyzed:

Lift in phase with acceleration (added mass):

M a (w , a)

Lo

2 cos o

aw

Lift in-phase with velocity:

Lv

Lo

sin o

aw

Total lift:

L(t ) M a (w, a) z (t ) Lv (w, a) z (t )

(a = zo is cylinder heave amplitude)

Total Force:

L(t ) M a (w, a) z (t ) Lv (w, a) z (t )

p

2

r

d

Cma (w, a) z (t )

4

1

r dU CLv (w , a) z (t )

2

2

• If CLv > 0 then the fluid force amplifies the motion

instead of opposing it. This is self-excited

oscillation.

• Cma, CLv are dependent on w and a.

Coefficient of Lift in Phase with

Velocity

Vortex Induced Vibrations are

SELF LIMITED

In air: rair ~ small, zmax ~ 0.2 diameter

In water: rwater ~ large, zmax ~ 1 diameter

Lift in phase with velocity

Gopalkrishnan (1993)

Amplitude Estimation

Blevins (1990)

a/ =~ 1.29/[1+0.43 S ]3.35

G

d

_

_

^ 2 2m (2pz ; f^ = f /f ; m

*

=

m

+

m

SG=2 p fn

n

n

s

a

r d2

b

z=

2 k(m+ma*)

ma* = r V Cma; where Cma = 1.0

Drag Amplification

VIV tends to increase the effective drag coefficient. This increase

has been investigated experimentally.

~

Cd

|Cd|

Gopalkrishnan (1993)

3

a

= 0.75

d

2

1

0.1

0.2

0.3

fd

U

Fluctuating Drag:

Mean drag:

Cd = 1.2 + 1.1(a/d)

~

Cd occurs at twice the

shedding frequency.

Single Rigid Cylinder Results

1.0

a)

One-tenth highest

transverse

oscillation amplitude

ratio

b)

Mean drag

coefficient

c)

Fluctuating drag

coefficient

d)

Ratio of transverse

oscillation frequency

to natural frequency

of cylinder

1.0

Flexible Cylinders

Mooring lines and towing

cables act in similar fashion to

rigid cylinders except that

their motion is not spanwise

uniform.

t

Tension in the cable must be considered

when determining equations of motion

Flexible Cylinder Motion Trajectories

Long flexible cylinders can move in two directions and

tend to trace a figure-8 motion. The motion is dictated by

the tension in the cable and the speed of towing.

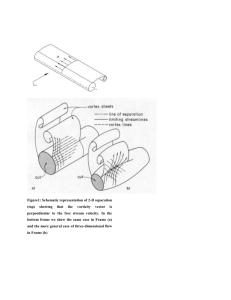

Wake Patterns Behind

Heaving Cylinders

f,A

U

f,A

‘2S’

U

‘2P’

• Shedding patterns in the wake of oscillating

cylinders are distinct and exist for a certain range

of heave frequencies and amplitudes.

• The different modes have a great impact on

structural loading.

Transition in Shedding Patterns

Vr = U/fd

f* = fd/U

Williamson and Roshko (1988)

A/d

Formation of ‘2P’ shedding pattern

End Force Correlation

Hover, Techet, Triantafyllou (JFM 1998)

Uniform Cylinder

Tapered Cylinder

VIV in the Ocean

• Non-uniform currents

effect the spanwise vortex

shedding on a cable or

riser.

• The frequency of shedding

can be different along

length.

• This leads to “cells” of

vortex shedding with

some length, lc.

Oscillating Tapered Cylinder

U(x) = Uo

x

Strouhal Number for the tapered

cylinder:

St = fd / U

d(x)

where d is the average

cylinder diameter.

Spanwise Vortex Shedding from

40:1 Tapered Cylinder

Techet, et al (JFM 1998)

Rd = 400;

St = 0.198; A/d = 0.5

Rd = 1500;

St = 0.198; A/d = 0.5

Rd = 1500;

St = 0.198; A/d = 1.0

No Split: ‘2P’

dmax

dmin

Flow Visualization Reveals:

A Hybrid Shedding Mode

• ‘2P’ pattern results at

the smaller end

• ‘2S’ pattern at the

larger end

• This mode is seen to

be repeatable over

multiple cycles

Techet, et al (JFM 1998)

z/d = 7.9

z/d = 22.9

DPIV of Tapered Cylinder Wake

Digital particle image

‘2S’ velocimetry (DPIV)

in the horizontal plane

leads to a clear

picture of two distinct

shedding modes along

‘2P’

the cylinder.

Rd = 1500; St = 0.198; A/d = 0.5

Vortex Dislocations, Vortex Splits & Force

Distribution in Flows past Bluff Bodies

D. Lucor & G. E. Karniadakis

Techet, Hover and Triantafyllou (JFM 1998)

Objectives:

•

Confirm numerically the existence of a stable,

periodic hybrid shedding mode 2S~2P in the

wake of a straight, rigid, oscillating cylinder

Approach:

•

VORTEX SPLIT

•

•

DNS - Similar conditions as the MIT experiment

(Triantafyllou et al.)

Harmonically forced oscillating straight rigid

cylinder in linear shear inflow

Average Reynolds number is 400

Methodology:

•

NEKTAR-ALE Simulations

Parallel simulations using spectral/hp methods

implemented in the incompressible Navier- Stokes

solver NEKTAR

Principal Investigator:

Results:

•

•

Prof. George Em Karniadakis, Division of Applied

Mathematics, Brown University

Existence and periodicity of hybrid mode

confirmed by near wake visualizations and spectral

analysis of flow velocity in the cylinder wake and

of hydrodynamic forces

VIV Suppression

•Helical strake

•Shroud

•Axial slats

•Streamlined fairing

•Splitter plate

•Ribboned cable

•Pivoted guiding vane

•Spoiler plates

VIV Suppression by Helical Strakes

Helical strakes are a

common VIV suppresion

device.

Oscillating Cylinders

Parameters:

y(t)

d

y(t) = a cos wt

.

y(t) = -aw sin(wt)

Vm = a w

n m/ r ; T 2p/w

Re = Vm d / n

b=

d2

/ nT

Reynolds #

Reduced

frequency

KC = Vm T / d

KeuleganCarpenter #

St = fv d / Vm

Strouhal #

Reynolds # vs. KC #

Re = Vm d / n

wad/

n

2p

a/

d 2/

( d)(

nT

)

KC = Vm T / d = 2p a/d

Re = KC * b

b = d2

/ nT

Also effected by roughness and ambient turbulence

Forced Oscillation in a Current

y(t) = a cos wt

q

w = 2 p f = 2p / T

U

Parameters: a/d, r, n, q

Reduced velocity: Ur = U/fd

Max. Velocity: Vm = U + aw cos q

Reynolds #: Re = Vm d / n

Roughness and ambient turbulence

Wall Proximity

e + d/2

At e/d > 1 the wall effects are reduced.

Cd, Cm increase as e/d < 0.5

Vortex shedding is significantly effected by the wall presence.

In the absence of viscosity these effects are effectively non-existent.

Galloping

Galloping is a result of a wake instability.

Y(t) .

y(t), y(t)

U

a

V

.

-y(t)

m

Resultant velocity is a combination of the

heave velocity and horizontal inflow.

If wn << 2p fv then the wake is quasi-static.

Lift Force, Y(a)

Y(t)

V

a

Cy =

Y(t)

1/

2r

U2

Ap

Cy

Stable

a

Unstable

Galloping motion

L(t) .

z(t), z(t)

U

a

V

.

-z(t)

a

m

b

k

..

.

mz + bz + kz = L(t)

L(t) =

1/

2

r

U2

Cl (0)

Cl(a) = Cl(0) +

+ ...

a

Assuming small angles, a:

.

z

Cl (0)

a ~ tan a = b=

U

a

..

a Clv - ma y(t)

V~U

Instability Criterion

..

(m+ma)z + (b +

1/

2

r

U2

b+

1/

2

r

U2

If

a

b

U

a

b

<0

U

.

)z + kz =~ 0

Then the motion is unstable!

This is the criterion for galloping.

b is shape dependent

Cl (0)

a

Shape

1

1

-2.7

1

0

2

U

2

-3.0

1

4

1

-10

-0.66

Instability:

b=

b

Cl (0)

< 1/ r U a

a

2

Critical speed for galloping:

b

U >

1/

2

r a

(

Cl (0)

a

)

Torsional Galloping

Both torsional and lateral galloping are possible.

FLUTTER occurs when the frequency of the torsional

and lateral vibrations are very close.

Galloping vs. VIV

• Galloping is low frequency

• Galloping is NOT self-limiting

• Once U > Ucritical then the instability occurs

irregardless of frequencies.

References

• Blevins, (1990) Flow Induced Vibrations,

Krieger Publishing Co., Florida.