Power/Bloc for Circuit Breaker Lockout/Tagout

advertisement

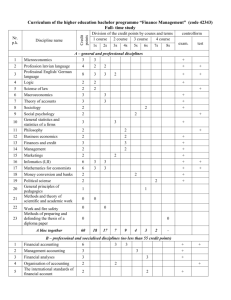

“Power/Bloc for Circuit Breaker Lockout/Tagout” Applications and Product Review Overview – Measurement - Installation 2008 Power/Bloc • PERMANENT - Permanently mounted in panels, load centers, free-standing breakers (with 3M DP805 adhesive – no penetrating fasteners) • UNIVERSAL - Fits any manufacturer – domestic, foreign, custom-fabricated - of any age • SIMPLE - Materials retained at the point of use (except lock and/or tags) • Patent #6,266,231 • Made in the USA Power/Bloc • Allows lockout of each individual breaker with no restriction of access to other breakers • Will lock out any length • Fits any panel up to 600 volts and main breakers up to 1600 amps • Use with standard ¼″ shank diameter lock • Use with group multi-lock hasp • Use with small three tumbler lock and closed door adapter for closed door operation Power/Bloc Meets or exceeds: • • • • • • • • • OSHA Standard 29 CFR 1910.147 OSHA Standard 29 CFR 1910.269 NFPA 70E ANSI Z244.1 MSHA Standard 30 CFR 56.12016 MSHA Standard 30 CFR 56.12017 MSHA Standard 30 CFR 57.12016 MSHA Standard 30 CFR 57.12017 CSA Z460 Power/Bloc Kits • Color-coded, T-slotted anodized aluminum channel • Color-coded, non-conductive, adjustable polymer bars (T or Hook design) • Non-metallic holder(s) for T and Hook bars to retain materials at point of use • Label Power/Bloc Design Lock fits in slotted channel above T or Hook Bar providing lockout until removal 5-inch T Bar 3 ½-inch Hook Bar (bars are trimmed to fit for breaker throw and panel center measurement) Power/Bloc Kit – High Profile (for panels with depth of ¾″ or greater) High Profile Panels Power/Bloc Kit – Low Profile (for panels with depth of less than 9/16″) Low Profile Panels Power/Bloc Ordering Options • May be ordered as stock kit (21″ length) to be field cut by facility staff • May be provided as pre-cut kits, labeled for specific panels/locations, based upon measurements from site survey Measurement/review of Panels • Option to schedule facility survey by Safety Design representative resulting in sitespecific quote and custom labeled and fabricated kits (at no additional charge) • Facility staff may survey and submit to Safety Design representative for sitespecific quote Ordering Protocol • Orders accepted as Purchase Order, VISA, MasterCard, or American Express • Terms: Net 30 • Shipping: UPS Ground (unless specified otherwise), Prepay and Add, FOB Factory • Estimated Shipping Schedule: 2-3 weeks ARO, contact representative for current lead times Panel Measurement and Review Measure length, top to bottom of breakers Measure width of center between breakers Measure depth of panel – panel face to door Power/Bloc Measurement/Observations • Does the panel have a ridge down the center? Wide or narrow ridge? • Does the panel have a V-shaped valley down the center? • Is there a metal holder attached to the door that would encroach into the panel depth? • Note: Power/Bloc is provided as a High Profile model for panels with a depth of ¾″ or more or a Low Profile model for panels with a depth of 9/16″ or less. *This measurement is critical. Power/Bloc Measurement/Observations • Does the level of the breakers sit above the panel dead front or does the breaker design have a rim that would require a shim to allow the Power/Bloc channel to mount level with the breaker? How high is the elevation? • Are the breakers recessed below the panel dead front? How deep is the depression? • Does the panel have a Main Breaker? I-Line Panels Power/Bloc Installation • Installation with 3M DP-805 two-part acrylic adhesive • Installation materials include dual adhesive tube assembly, installation gun (or conversion kit to allow use with a standard caulking gun), and mixing tubes Power/Bloc Installation Materials Power/Bloc Kit and Installation Materials Power/Bloc Kit Notes • If a facility survey has been conducted and a site-specific proposal prepared, you will receive custom fabricated kits as ordered • Each kit will be labeled with the appropriate panel (or location) designation and contain all materials for that panel or load center Panel Preparation • Use of DP-805 adhesive allows installation without removal of panel cover • Scuff panel to bare metal for optimum bonding and wipe area clean • Use of solvents is not normally required but wiping with isopropyl alcohol or commercial de-greaser is recommended Place 3M DP-805 in installation gun, remove cap (retain for future use) Dispense small amount of adhesive until two part adhesive feeds evenly prior to adding mixing tube; attach mixing tube to adhesive firmly and twist for secure fit Place 1/8″ bead of adhesive on entire back of Power/Bloc channel Alternate Installation with Conversion Kit for Caulking Gun I/ON O/OFF I/ON I/ON O/OFF O/OFF I/ON I/ON O/OFF O/OFF I/ON O/OFF I/ON O/OFF I/ON I/ON O/OFF O/OFF I/ON I/ON O/OFF O/OFF O/OFF I/ON I/ON I/ON O/OFF I/ON O/OFF I/ON O/OFF Align mid-point of first two slots in Power/Bloc channel with mid-point of top breaker; center Power/Bloc channel in panel O/OFF Power/Bloc Installation Place Power/Bloc channel in panel and hold until set in place – 2-3 minutes working time – full cure in 24 hours (follow placement instructions supplied with kit) Quick release painters tape or masking tape may be used to hold channel in place until adhesive is set. If there is more than one Power/Bloc channel to accommodate the length of a panel, attach the longest part on top and place the additional piece adjacent to the first piece. Release pressure, discard mixing tube and recap adhesive at end of installation or during significant time delay in installation process. Adhesive setting up in mixing tube may be delayed by wrapping in a damp cloth and placing on ice pack during multiple kit installation process. Replace mixing tube when adhesive begins to harden in tube. Dual Power/Bloc Channels for Wide Center Panel (> 3″) Place 1/8″ bead of adhesive on bar holders Mount bar holder(s) in panel Placement may be horizontal or vertical Trim Stop/Loc bars to fit specific panel and breaker throw Before trimming – T-bars are 5″ long Hook bars are 3½″ long Place Stop/Loc bars in panel to provide materials at point of use. Place identification label on panel, if desired Small Main (where applicable) Attach small strip in proper location for Stop/Loc bar to push against small main Power/Bloc with Individual Lock Power/Bloc with Multi-Lock Hasp Closed Door Bar for Use With Tag or Small Lock Power/Bloc with Small Lock for Closed Door Operation Power/Bloc Lockout/Tagout Procedure Notes • All appropriate electrical testing procedures must be followed. • The procedure detailed in this tutorial is designed to refer only to the portion of the lockout or tagout process that includes manipulation of the components of the Power/Bloc system and is not designed to be used as a comprehensive internal procedure. Power/Bloc Procedure for Lockout • De-energize selected breaker • Remove Stop/Loc bar from holder (hook bar or Tbar), place in slotted channel and adjust to restrain movement of breaker. Place individual lock, multi-lock hasp with locks, or closed door bar with small three tumbler lock in space above Stop/Loc bar. Make sure all locks and tags are attached securely. Power/Bloc Procedure for Tagout • Power/Bloc is designed as a system for tagout that provides the added protection of a restraint device with the simplicity and accessibility of a tagout procedure, where allowed. • The standard Power/Bloc kit is mounted in the panel according to installation instructions. • Remove Stop/Loc bar from holder (hook bar or Tbar), place in slotted channel and adjust to restrain movement of breaker. Place closed door bar in space above Stop/Loc bar. Attach tag to closed door bar according to site procedure. Power/Bloc Procedure for Tagout • A Stop/Loc bar is used with a closed door bar and tag assembly as specified by owner’s procedure to prevent the selected circuit from being reenergized until the tag, closed door bar, and Stop/Loc bar are removed. * Note: Materials will be in place to allow future conversion to a full lockout procedure, if desired. Tag for ID of Critical Circuits • Some facilities choose to use Power/Bloc with a closed door bar and tag for ID and assistance in prevention of accidental disconnection of a few critical circuits. • NOTE: Energized circuits should NEVER be locked on. LMHP for Large Breakers Standard bar length is 8″ Available in other lengths upon request. Shims may be required. LMHP for Large Breakers Wide Center Panels Panels with center width over 3″ requiring (2) Power/Bloc channels Individual Molded Case Breaker Power/Bloc may be attached directly to molded case circuit breaker with 3M DP-805 adhesive Multiple Circuit Lockout Multiple circuits may be locked out with minimal locks, if desired. Contact factory for details. Other Applications DIN Rail Mounting bracket to raise Power/Bloc channel to level of breaker may be required Other Applications Rotary Operator Other Applications • You are invited to present other electrical lockout challenges for review; we are frequently able to assist with solutions. • Digital pictures are helpful for review. Training Materials Power/Bloc training board is supplied (at no charge) to our clients to use in their training program. This training board may be used with this tutorial. Power/Bloc by Safety Design, Inc. • Consult website at www.powerbloc.com for measurement survey forms. • Contact Betty Wayman, Strategic Accounts Manager, Safety Design, Inc. with questions or comments. • E-mail: waymanbw@powerbloc.com • Mobile: 615-310-9793 • TEL: 615-292-8744 • FAX: 615-297-0842