Group Five

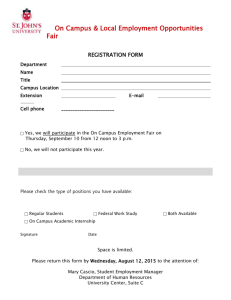

advertisement

Background / Introduction The Soweto Campus of the then Vista University was incorporated into the Rand Afrikaans University (RAU) in 2004. The following year, 2005 a merger took place between the then RAU and the Technicon Witwatersrand (TWR). Immediately after the merger, there were fears, especially from the former Vista University staff that the Soweto Campus might be discontinued or closed down. Two years later, plans to develop the campus into a bigger and better campus were accepted and approved by the National Department of Education. To this, the Chairperson of Council of the University of Johannesburg, Prof. Roy Marcus, said: “Perhaps the most important development has been the final approval for the establishment of the Soweto Campus and the turning of the soil for the commencement of building activities. The Council was delighted to have received a significant financial contribution from the National Department of Education and support from the Gauteng Provincial Government towards the establishment of a premier campus located in the South of Gauteng. The most important feature of the Soweto Campus has been the planning process that has been steered towards the creation of a suite of differential offerings. This is designed not only to serve the local community of Soweto and its surrounds, but also to create a place where people from all sectors of South Africa and Africa would want to come and gain new insights into differentiated fields of expertise” (UJ Annual Report: 2008:6). The City of Johannesburg also contributed greatly to this venture by the land-swap deals entered into with the University. From a campus occupying 19.011 hectares the completed new campus will be in 33.767 hectares of land. Background / Introduction The announcement of this development was made on the 16th of June 2008 with the theme “Soweto Campus Rising”, by the then Minister of Education Ms. Naledi Pandor. This theme was a direct response to the following: Complementing the rising of the whole of Soweto which is in the process of being renewed, Responding to the previous year’s theme (2007) – 16th of June, “Sowhereto”. To achieve these, first the university brought Turner and Townsend to be the Project Managers of the project. LVM Design Group was contracted to be the architects and PD Naidoo and Associates as the engineers of the project. Group Five were contracted as the main contractor. Group Five brought on board Inkanyeli Construction for the community involvement portion. This presentation is mainly divided into two. Firstly, it highlights the Soweto Campus development with pictures to illustrate and support the facts. It also reflects the innovations and lessons learned from the architect, the project managers and the main contractor. Development Project The aim/objective of the development project was to create an “African world-class premier” campus of the University of Johannesburg in Soweto. To attract more students from all walks of life and to turn the Soweto Campus to be on par or more than the other UJ campuses, surely the university had to do something about it. Hence the university’s request for funding to the National Department of Education. The budget for this creation was made up of the National Department of Education’s contribution of R300m and the University of Johannesburg’s R100m. To realize or achieve such a dream of such a creation, there were a number of teams or committees dealing with a number of issues like planning, design and monitoring the development. The first was a design consultant’s team which comprised of the Project Managers, Turner and Townsend, the cost managers from T&T, the Engineering Services from PD Naidoo and Associates which met every Monday afternoon. There was an OPS team which comprised of a number of relevant stakeholders from UJ, the UJ project manager, T&T Project Managers and cost managers which met every Thursday morning, to discuss the following: Recommendations for additions to scope, The finance, if we were still within budget, The progress of the project, Community involvement, Land issues/transfers, and Any other related issues and challenges to the project. Development Project This committee made recommendations to the much more executive committee, called the SWC Development Exco. This committee met every second week. It approves any alterations, additions/scope-creep. The variation/change orders were approved by this committee. It was made up of the following members: • • • • • • • • The Vice-Chancellor, The DVC: Finance, DVC: Strategic Services, UJ Project Manager, Executive Director: UJ OPS T&T Project Manager T&T QS, and T&T Cost Manager. Development Project The SWC Development Exco reported to the Project and Resource Committee of Council (PRCC) on the progress and the finances of the project and ultimately, the PRC reported to the UJ Council on the development. The renewal process was split into the following phases: • The refurbishment of the existing buildings, • New Generic buildings and • The sport facilities. The refurbishment of the existing buildings The refurbishment of the existing buildings was to change the façade (of the existing buildings) to match the new buildings. The difficulty here was that all existing buildings on campus, in fact the whole campus was in face bricks. The internal of all these buildings (also) needed more attention. The biggest task in these (refurbishment of the existing buildings) was the library which was to be extremely extended. This, together with the refurbishment of the lecture halls and the computer lab presented a huge challenge because it was impossible to hand these over, when students were still on campus. New Generic Buildings The Generic buildings are totally new structures. These house: ±85 academic offices, 14 lecture theatres, 10 computer labs with ±1 000 computers, and Parking for over 300 cars The sport facilities The sport facilities have the following: A pavilion to sit 2 000 people Three soccer fields, 2 for practice and one for matches, even for night games. The main soccer field, matches all the FIFA requirements. 5 cricket ovals/pitches, Athletic tracks, Netball courts, Sport Centre which has: Gym, Aerobics class, Spinning class, and Multipurpose hall for indoor games Latest additions to scope • Legal Clinic, from the existing huge tower resulted the legal clinic, which is now complete, Latest additions to scope • Grade R School – complete, Latest additions to scope • Club house – December 2010, and • The first residences to the SWC – these only started in February 2010 after the realization that this campus development will have more savings. That, together with the interest on the National Department of Education money made it possible to start this project. The completion date for these is the 22 November 2010 for placement in the beginning of 2011. The challenges – from UJ side Community involvement – has been a big challenge from the first day. The UJ tender documents (Soweto) stipulated the areas around the campus as places to source the labourers and subcontractors. The tender documents also stated that 20% of the domestic portion of R100m will go to the community involvement. We managed this challenge well as UJ is also part of the community structures which handle this. The refurbishment side: Moving staff from one block to another during refurbishments; The library, lecture halls and computer labs were to be done only during student recess. For instance, phase 2 of the library was only handed over to the contractor after the 2009 end of the year exams, Noise and dust to the campus community, Signage – as the contractor’s work, they tempered and misplaced the signage, Misplacement of equipment during refurbishment. For instance, some lecture halls ended up without data projectors after the work. The contractors had to replace these at their cost. Closure of the main entrance/gate for refurbishment. A temporary entrance was availed, but not adequate. Heavy rains. Lessons learnt from UJ side Outside project managers works well - huge savings and well managed of the project, Usage of the same architect for both new buildings and existing structures, served well, Should have handled the movement of staff better, Constant contact with the community is vital, Keeping both staff and students informed timeously helps. Design Innovations THE FOLLOWING SECTION PRESENTS INNOVATIONS AND LESSONS LEARNED FROM THE CONSTRUCTION FROM THE ARCHITECT, THE PROJECT MANAGERS AND THE MAIN CONTRACTOR LVM – Architects The existing campus and new facilities are linked to each other by a new pedestrian boulevard, running along the entire length of the campus, An environmentally friendly campus is achieved by incorporating energy efficient mechanisms, such as orientation, sun screening, natural ventilation, energy efficient lighting, and optimization of natural light and structural insulation, The building materials are generally low in maintenance. For example, instead of conventional ceilings in Generic A and B double volume areas, Pre-cool insulation panels were used. These are normally utilized in the construction of cold rooms and have excellent insulation and sound properties. The polystyrene sheets, sandwiched between chromodek sheeting are low in maintenance and allowed the designers to span greater distances, simplifying the roof construction, Landscaping in general is indigenous and low in maintenance. An Ecological corridor or “green” belt running all along the Southern boundary fence acts as an ecological corridor linking Sontonga Hill to the wetland precinct flanking the compass to the West. Design Innovations PDNA – Electrical Engineering In the offices, lecture theatres and labs we used recessed florescent fittings with T5 lamps to achieve the required lux levels as per SANS 10114-1. We made used of electronic ballasts which allowed us to install dimmers in the lecture theatres with pre-set scenes. This was part of the drive to make the project "greener", On the smoke detection system we have made use of the fibre optic backbone to link the various buildings to the main fire panel. Whilst this may not be entirely an innovation, it is relatively new in the industry. In terms of UJ specific, we have placed 3 PCs on a breaker in the computer labs, with timer/contactor controls in a ripple formation. Previously the practice was to have one/two PCs per breaker. The result was smaller boards and cost reduction. The UPS units used on the new sections in Generics A and B as well as the Sports Centre have been the Modular type UPS units. The major difference between this UPS and the monolithic type is the fact that it can provide the same back-up that two monolithic types would provide. It does this by allowing the maintenance department to replace modules on line should one of the modules fail. The replacement does not have to be done by a qualified UPS technician but by a standard electrical technician employed by UJ. The faulty module can then be sent back to the suppliers for repairs/replacement. The net effect is that there would be no down-time should there be a fault on the UPS. The traditional monolithic type would require a qualified UPS technician to come to site and would entail some down-time. The above UPS unit were installed at a very small premium to the monolithic type and was done within the budget. Design Innovations PDNA – Mechanical Engineering VRF (Variable Refrigerant Flow), Multi V, VRV (Variable Refrigerant Volume), Systems: The system is designed to incorporate the Client specified energy efficiency requirements, optimised through the use of green building approved refrigerant gas. The overall operation allows for maintenance to be done during a failure of single compressors to prevent the loss of air-conditioning in zones rather than the entire building. The following factors to provide the most efficient and energy saving system were taken into consideration: One outdoor unit can be connected with up to +/-50 indoor units, The use of the Heat Recovery technology to save on heat pump power requirements. The system modulates the exact amount of air-condition effect required depending on the building requirements, The electrical requirements are reduced comparative to that of the conventional system dependant on the type of design philosophy, Small and lighter units utilised, reducing dead load on buildings as per that required in UJ for the roof space, The operating noise levels have been reduced, Vast control variety from a simple hand held remote to an air-conditioning system network allowing BMS protocol, The new technology installed at UJ is directed to energy efficiency to allow a reduction in plant room space requirements and independent control of indoor units for personal comfort. Design Innovations PDNA – Civil Engineering Storm water harvesting tank at Athletics track - Due to the water intensive irrigation requirements for the FIFA spec soccer field we designed a herringbone subsoil drainage system below a good draining topsoil matrix for the soccer field. It was determined that as much as 75% of the irrigation water for this field would pass through the topsoil matrix and into the subsoil drainage and that would then discharge to the storm water system and back into the river which is wasteful. It was decided to try to capture this excess irrigation water and pump it into storage tanks at the new sports centre so that it could be re-used for further irrigation requirements. We therefore designed a storm water harvesting tank that collects the excess irrigation water as well as storm water runoff from the athletics track and pumps this up to the storage tanks at the sports centre. There is a submersible pump in the harvesting tank that switches on when the water level rises in the tank and switches off once the tank is empty. This will ensure that UJ reduces their water demand for the site thereby reducing costs to maintain these fields, Variable speed irrigation pumps - A pressure transducer sustains a constant downstream pressure, by altering the frequency (rotational speed). The RPM of the pump will increase or decrease depending on the downstream pressure, so if you have a small demand of water, the motor will turn slowly, and as the demand increase the rotation will increase to sustain the downstream pressure. The advantage of the V.S.D. (variable speed) is Greater Electrical efficiency thereby reducing electricity costs. Lessons Learnt Turner & Townsend Project Management Electronic information platform (Braidquest / PDService) against which all drawings and data were loaded and issued to the contractor was invaluable to the project. Not only does the system do away with disputes as to when information was issued, but it results in an instant and full record of all drawings and documentation relevant to the project in soft copy, One of the biggest challenges on the project was the size of the stakeholder involved, from a Client, student, City of Joburg, and local community perspective, Project Management should ideally have been brought in earlier on in the project from a briefing and stakeholder management / sign-off perspective. In this project PM only became actively involved once the initial Concept Design had already been completed by the Architect and a perception had already been created amongst the various stakeholders as to what the end-product would be, resulting in potential disappointment and ultimate designcreep once value engineering was implemented to achieve the budget constraints, The refurbishment portion of the project, particularly with regards to working in a “life environment” was underestimated by most parties, particularly the Contractor, Ultimately a spirit of “common objective” was achieved between the Client, Consultants and the Contractor. Teamwork and constant communication was key to the success of this project. Lessons Learnt PDNA - Electrical The previous practice of UJ of having one breaker per socket in the computer labs has not been used as we believed that it was overkill. We have used 3 sockets per breaker and the system works. This will save UJ money in the future, The overall project management was very good as we largely completed the works on time, however, the programming of the electrical subcontractor by the builder on occasion resulted in the electrical contractor lagging behind the builder. PDNA - Mechanical Various manufacturers were used to accommodate existing equipment already on site, timelines and budget restraints therefore not ensuring “the ideal” consistency: HVAC – Mitsubishi, Daikin, Durnham Bush, Lifts – ThyssenKrupp, Sigma/Kone. Group Five – Main Contractor What went badly? Athletics track Inclement weather impacted on the programme substantially. Refurbishment Ideally a ‘holding tank’ should have been constructed in the form of prefabricated office building to move staff into while the renovation happened. This would have helped tremendously with logistics. Failing which, more internal resources should have been seconded to help move staff or this function should have been out-sourced, Scope of builder’s work was not always clearly defined, resulting in the need for a dedicated architect from LVM for the renovation section. Too many changes were made during walkabouts which would have been prevented if there was a dedicated architect empowered to make decisions, Inkanyeli – battled to manage the refurbishment. Could have gone better of G5 had done it directly rather than Inkanyeli. Group Five – Main Contractor What went badly? Community Involvement The community was initially disorganized. Required a central point to maintain database and preferably a website, The community expectations were not correctly communicated to Group Five in the tender documents, i.e. 3 wards directly around UJ and that we were part of the Orlando Ekhaya forum, The general quality of community subcontractors very poor. We had a few success stories but they were the exception, To manage community project a dedicated site manager and QS resource is required to supplement the poor skills within the majority of community contractors. Contract No provision initially set for sectional completion in the contract, this was ultimately implemented, Structure: Should have ideally precast the Pavilion and other off-shutter concrete where possible, Group Five Team: Perhaps not strong enough on the refurbishment management, Housekeeping: Group Five housekeeping initially good but degenerated towards the end of construction. Group Five – Main Contractor What went well? General quality good, Generally the new build completed on time, Generally community expectations seem to be satisfied, Communication between client and TT and G5 good, Helping community subcontractors with their administration, Progress of de-snagging generally went well, Safety, working in live environment, no serious accident, Student and staff tolerance was excellent, Group Five fortnightly reports were good, Quick reaction time in general to post completion items, The contract ended up a success. Group Five – Main Contractor What went well? In Conclusion The Soweto Campus development and our strong link with the Soweto community is bringing back the confidence of both our campus and Soweto communities to the campus. This is one of the reasons why we are currently at 4500 students as opposed to less than 1000 in 2005. This community confidence on the campus is also reflected in what the Vice-Chancellor of UJ, Prof. Rensburg said when stating that: “If you go to the Soweto Campus now, you will see the pride and the confidence that’s returned. Not only because management created a place for us but because we are committed to making this work” (UJ Celebrates its Fifth Anniversary, 2010:03). The following is the realisation of our dream Thank You !!! Dr. J Manyaka