Space Shuttle Processing

advertisement

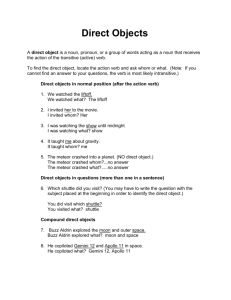

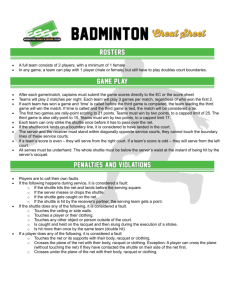

Space Shuttle Processing Space Shuttle Processing Orbiter Processing Initial Access and Safeing Payload Reconfiguration Crew Systems Structures and Mechanisms Thermal Protection System Space Shuttle Main Engines OMS/RCS Electrical Power System ECLSS APU Communications & Avionics Orbiter Modifications and Upgrades Space Shuttle Processing STS processing is a term used to describe the preparations and procedures for readying the Space Shuttle for its next mission The STS processing work cycle begins with the Orbiter’s return to KSC for its coming flight The processing cycle actually starts with the development of the flight, equipment, and operations manifest Planning begins as early as 5 years before the planned mission, or in some cases even longer Space Shuttle Processing Primary processing facilities are at KSC Supporting facilities include Other KSC sites (transportation, logistics, etc.) JSC NASA Center – Washington, D.C. NASA Centers Primary contractors – worldwide and national Federal agencies (FAA, NTSB, DoD, etc.) State agencies Local contractors Educational institutions Media service Space Shuttle Processing Facilities Space Shuttle Processing STS processing consists of four separate elements and five main facilities Orbiter Orbiter Processing Facility SRBs RSPF and Vehicle Assembly Building External Tank Vehicle Assembly Building SSME Engines SSME Processing facility Launch Launch pad Space Shuttle Processing Other KSC facilities involved in STS processing are: Hypergolic Maintenance Facility – OMS/RCS maintainance Rotation Processing and Surge Facility (RSPF) – SRB storage Shuttle Landing Facility Operations Support Building – Engineering support Logistics Facility SRB Retrieval and Disassembly Facility Space Shuttle Processing STS launch rates 1988 to 2000 Space Shuttle Processing Space Shuttle Processing Space Shuttle Processing Space Shuttle Processing Support facilities and functions The major functions of the Base Operations Contractor and Installation Operations offices in support of STS processing include: C5 Substation High voltage power and emergency power plant for the Launch Complex 39 area. A 115 kV supply includes 13.8 kV distribution lines and diesel powered emergency generators Space Shuttle Processing Support facilities and functions Utility Annex Central utility plant provides chilled water, high temperature hot water, and compressed air for HVAC systems and other equipment for: Launch Control Center Orbiter Processing Facilities Vehicle Assembly Building Operations Support Building Thermal Protection System Facility Process Control Center Logistics Facility Component Servicing Facility Space Shuttle Processing Support Functions Gaseous Nitrogen Plant (off-site vendor production facility) "Propellants North" Fluid Servicing Area and Compressor/Converter Facility (gases and cryogens) Liquid Helium Conversion Facility "Propellant South" /CCAS Fuel Storage Area #1 (fuels and chemicals) Space Shuttle Processing Support Functions (cont.) CCAS Life Support Facilities (Respiratory Protection Services) Non-Destructive Evaluation (NDE) Laboratory Sampling and Analysis Laboratory Fire & Rescue, Medical, and Security facilities Space Shuttle Processing Shuttle Landing Facility (SLF) The 15,000 ft x 300 ft concrete runway supports: Shuttle landing Shuttle Training Aircraft (STA) landing approaches General aviation uses, including: Astronaut T-38s Payload and cargo offload Military and administrative aircraft operations Facilities at the SLF include: Air traffic control tower Shuttle and aircraft navigational equipment Approach and centerline lighting systems Taxiway and parking ramp Aircraft fueling and servicing equipment Space Shuttle Processing Infrastructure facilities in support of STS processing at KSC include: 300 electrical generators, 156 substations, 60 UPS units 30,000 tons of air conditioning capacity 40 cranes, 183 hoists, 52 elevators 500,000 ft of water distribution lines Over 170 miles of fiber optic cable Over 900 fiber optic transmitters and receivers Launch Complex 39 TV system includes 166 cameras, 89 video recorders, 7770 monitors Space Shuttle Processing Management structure of STS Processing Space Flight Operations Contract Contract managed by NASA JSC Contractor is United Space Alliance Responsible for Orbiter, External Tank (ETE, Solid Rocket Booster (SRB) and Solid Rocket Motor (SRM) Responsible for facilities and GSE that supports Shuttle processing Subcontract for Space Shuttle Main Engine (SSME) Rocketdyne Space Shuttle Processing Management structure of STS Processing (cont.) Shuttle Processing Director serves as technical manager for: Launch count Landing/recovery activity Disposition of technical issues for KSC equipment Validating that contractor meets NASA processing requirements Orbiter Processing Space Shuttle Processing Orbiter processing After its return from space the Orbiter undergoes evaluation of its exterior and removal or preparation for removal of the Orbiter's previous mission equipment Within four hours after reaching KSC the Orbiter is towed into the Orbiter Processing Facility (OPF) to begin processing for its next mission Space Shuttle Processing Orbiter processing Typical processing cycles in the OPF are three months Other major processing activities include Orbiter Maintenance Down Periods (OMDP) and inspections Processing of the Orbiter consists of two major categories: Refurbishment and repair of the Orbiter after its return from an earlier mission Vehicle modification, repair, preparation and payload integration for the following mission Space Shuttle Processing Orbiter processing Actual processing of the Orbiter in the OPF is scheduled according to the critical path operation requirements and the demands on the processing teams These operations have some common scheduling from flow-to-flow (mission-to-mission) Since each mission and vehicle configuration is different, the scheduled operations often have significant differences Operations that entail hazardous or toxic materials are scheduled either first or last to provide maximum safe working conditions during the processing cycle Processing operations that are not critical to other work can be scheduled as needed to improve efficiency and reduce processing costs Space Shuttle Processing Orbiter Processing Facility - KSC Space Shuttle Processing Orbiter processing General processing operational sequence Initial access and safeing Runway - Power-down, venting, pyro disabling, hazardous gas testing, etc. OPF - Continuation of hazardous material removal, hypergolic leak detection, cryogenic removal, payload transfer (if needed) Space Shuttle Processing Orbiter processing (cont.) Post-flight troubleshooting Inspection and evaluation of reported or suspected problems Systems checkout Thermal Protection System (TPS) Operations begin with the inspection of tiles and batting early in the processing cycle because of the length of time for tile replacement and repair Space Shuttle Processing Orbiter processing (cont.) SSME removal Main engines removed for inspection and checkout, and to provide access to the aft fuselage Payload bay operations Payload removal Mission kit reconfiguration Payload installation (if horizontal installation) Space Shuttle Processing Orbiter processing (cont.) Orbiter modifications Updates and modifications to the Orbiter and/or its systems made between missions Major modifications are performed during the Orbiter Down Maintenance Period (OMDP), normally once every 7 missions SSME installation Reinstallation of prechecked SSME engines after necessary aft fuselage work is completed Power-on system reverification Powered test and checkout of electrical and hydraulic systems after processing Space Shuttle Processing Orbiter processing (cont.) Orbiter closeout Completion of the processing areas and systems before rollover to the VAB for assembly on the ET and SRBs Notes: The majority of the processing and integration workforce and time is allocated to the OPF operations Turnaround (from tow-in from the runway to the rollover to the VAB) varies with scheduling, with the average taking approximately 10 weeks Orbiter is then towed (rolled over) into the VAB on a transporter with its landing gear stowed Space Shuttle Processing Orbiter Processing Facility Three large rooms (bays) were constructed in the OPF building for simultaneous processing of three Orbiters The fourth processing bay was placed in a nearby building General Orbiter system checkout, refurbishment, and/or replacement, disassembly of the payload and crew systems is followed by installation of the new payload(s) and crew systems Space Shuttle Processing Orbiter Processing Facility Orbiter processing continues as the Orbiter, SRBs and ET are assembled in the Vehicle Assembly Building Final processing and closeout steps are made on the launch pad Orbiter Processing Facility Initial Access and Safeing Space Shuttle Processing Initial access and safeing The Orbiter is prepared for its next assignment as it enters the processing cycle that begins as the Orbiter comes to a wheel stop after landing The Orbiter contains hazardous materials and explosive devices that must be removed, stabilized or deactivated before the vehicle can be accessed by processing personnel Crew requires a safe environment while the vehicle is prepared for their exit Initial steps are accomplished by teams of safeing personnel and equipment deployed after the Orbiter's landing to maintain critical Orbiter functions, and to reduce or remove hazards while the crew are readied for exiting the Orbiter Space Shuttle Processing Initial access and safeing Safeing operations on STS-57 following a 45-minute cool-down period Attachment of Ground Service Equipment shown here provides the Orbiter with vehicle cooling Space Shuttle Processing Initial access and safeing Preliminary Orbiter safeing tasks include: Measure and evaluate the vapors on and near the Orbiter to ensure safe operational limits for the safeing teams and crew Attach ground service cooling equipment for personnel and equipment onboard Two ground support cooling units are attached to the Orbiter's right and left T-0 umbilical panel RH for mid, aft and forward fuselage equipment LH for crew compartment and avionics Space Shuttle Processing Initial access and safeing Install lock pins on landing gear Disable active pyrotechnic ordinance by installing interrupt junction boxes Remove any hazardous spent ordinance from Orbiter Space Shuttle Processing Initial access and safeing Final safeing in preparation for towing into the OPF include: Power down of the nonessential Orbiter systems The Orbiter continues to be powered by the fuel cells until ground equipment is switched over in the OPF primarily to prevent toxic OMS/RCS propellant leaks Payload removal if needed Visual inspection of SSME, exterior tiles, structure, landing gear, etc. Tow into the OPF (roll-in) Payload Reconfiguration Space Shuttle Processing Payload reconfiguration To be able to accept the new payloads for each mission, the Orbiter midbody is reconfigured with a series of mechanical adapters and attachments Longeron beams installed on the sides Keel beams installed at the bottom of the midbody These are the main structural supports for the Orbiter payloads and payload accommodations Space Shuttle Processing Payload reconfiguration (cont.) Many more specialized attachments are needed for each payload that require extensive fitting and checkout Because of their unique character, the reconfiguration procedures must be well planned and carefully coordinated to be completed in the scheduled processing cycle Space Shuttle Processing Payload reconfiguration (cont.) Active (motorized for deployable payloads) or passive (fixed payloads) latches are attached to the payload bay structural beams that are in contact with the payload trunions Another payload attachment beam, called the sidewall payload carrier beam, are used for the attachment of smaller payloads that do not span across the payload bay Space Shuttle Processing Payload reconfiguration (cont.) Several other types of brackets are used to support the electrical and fluid interfaces from the vehicle to the payloads Hardware is rearranged for each flight because each payload is unique so new procedure documents called Test Preparation Sheets (TPSs) are written and implemented for each flight Space Shuttle Processing Payload reconfiguration (cont.) Primary payloads are installed in the OPF using overhead cranes to lift them from a protective canister into the Orbiter midbody Payload is then secured in place with the payload retention latches The largest payloads are installed and processed vertically at the launch pad Eliminates the loading on the orbiter and the payload during transportation to the VAB and to the launch pad The larger payload installations are completed using a Payload Ground Handling Mechanism (PGHM) inside the Payload Changeout Room (PCR) Located at both of the Launch Complex 39 launch pads (A & B) Space Shuttle Processing Crew Systems Space Shuttle Processing Crew systems configuration and stowage (cont.) Because each Shuttle mission and flight crew is unique, different crew and safety equipment installed in the Orbiters has to be fit checked, installed and tested for each flight Space Shuttle Processing Crew systems configuration and stowage (cont.) Among the equipment installed in the crew module that changes for each flight are: Crew seats Lockers Installation of lockers with experiments, spare components, personal crew items and food Safety items Installation and testing Emergency egress devices, checkout and installation Velcro pads Prevents items from floating throughout crew module Space Shuttle Processing Crew systems configuration and stowage (cont.) Specific crew equipment for planned EVA activities must also be installed and checked. This includes: EMU adapter equipment bags Stowage of mission equipment bags The payload bay also contains crew operated equipment that must be installed, configured and/or tested for each flight. This category includes: Slidewires Tethers Safety cables inspected and tested Safety cables configured and tested Tools and toolboxes Configured Space Shuttle Processing Crew systems configuration and stowage (cont.) Specific crew equipment for planned EVA activities Foot restraints Configured Handrails, handholds and tether points Configured Instruction and reference decals Inspected Structures and Mechanisms Space Shuttle Processing Structures and Mechanisms The Orbiter structure and mechanical systems are carefully inspected and evaluated before each flight to ensure the safety and integrity of the Orbiter, and its crew and cargo Space Shuttle Processing Structures and Mechanisms (cont.) These inspections cover three general mechanical areas which include: Primary structural assemblies Fore, mid, and aft fuselage, wings, tail, body flap, etc. Secondary structures Attachments, air lock, windows, brackets, fittings, etc. Mechanisms - allow movement or access during flight operation Payload bay doors, crew hatches, gear doors, umbilical doors, etc. Space Shuttle Processing Structures and Mechanisms (cont.) Most of the structural inspections and tests for the Orbiters are done during their 1-2 year scheduled Orbiter Maintenance Down Period Orbiter upgrades and structural modifications are completed at the same time The Orbiters have been cycled through OMDP every eight flights or every three years Wide variation because of the Challenger and Columbia accidents As of 2007, only one OMDP is planned before the there Orbiters' scheduled retirement in 2010 Space Shuttle Processing Structures and Mechanisms (cont.) During these upgrades and inspections, the Orbiters are checked and inspected for corrosion, cracks, stress effects, and the general condition of the structure in much the same fashion as an airliner is inspected on a regular schedule Discrepancies and problems are evaluated and corrected by the engineering staff in coordination with the NASA engineering offices Anomalies are corrected in the same fashion, with coordination of the repairs through the engineering offices Space Shuttle Processing Structures and Mechanisms (cont.) Each of the Orbiter's window assemblies are examined carefully for scratches and pits that could interfere with the next scheduled mission, or that would create a hazard if cracking were to occur If a window assembly shows damage greater than allowed in the engineering requirements and subsequent analysis, the respective window assembly is removed and replaced Generally, two or three window sets are replaced during each flow In general, more damage occurs on longer missions, or in vertical orientation (gravity gradient) flight, or during flight into the velocity vector (forward) Space Shuttle Processing Structures and Mechanisms (cont.) The payload bay doors are examined for damage due to orbital debris, thermal stress, and operation. The payload bay radiator panels are also examined for damage Payload attach points are inspected for flight damage in preparation for installation of new hardware Space Shuttle Processing Structures and Mechanisms (cont.) The speed brake panels are checked and tested for structural degradation and washed to remove corrosion products The drag chute compartment is inspected for damage and refurbished in preparation for installation of a packaged drag chute The aft engine heat shields are removed and inspected for damage Space Shuttle Processing Mechanisms Orbiter mechanisms checkout consist mainly of testing the redundancies of the systems that are not normally operated or checked during flight Includes the functional testing per standard procedures (OMI’s) of individual redundant motors as the criticality of the system dictates Systems that are in this category include: Payload Bay door drive and latching system Radiator deployment and latching system Orbiter/External Tank umbilical door drive and latching system Orbiter docking system Payload retention latches (mission dependent) Manipulator positioning mechanism and latching system Space Shuttle Processing Mechanisms (cont.) Mechanisms that require different checkout or servicing include: Crew hatches: Forces are measured when latching/unlatching and locking/unlocking the hatches manually Hatch seal leak checks are performed by pressurizing the area between the two redundant seals Landing Gear The landing gear extension function is tested and timed New tires are installed on the main landing gear for each flight Each of the nose gear tires can be reused once after passing inspection Landing gear struts are pressurized for the expected mission landing weight Thermal Protection System Space Shuttle Processing Orbiter Thermal Protection System Orbiter requires careful evaluation of the condition of the entire Orbiter TPS after each flight, a process that begins in the earliest phase of the Orbiter’s stay in the OPF Space Shuttle Processing Orbiter Thermal Protection System (cont.) Evaluation Evaluation and processing of the TPS includes careful inspection of the complete outer surface of the Orbiter, beginning with a walkover inspection of the lower tiles on the runway after landing, cooldown and safeing Engineers examine as much of the Orbiter’s surface as possible to evaluate debris and orbital damage before it enters the OPF A complete insulation inspection takes two weeks or more because of the large number of surface tiles and the detailed inspections needed to carefully examine all aspects of the tiles, panels, and blankets TPS inspection and evaluation may take even more time if a number of the tiles and/or panels show only subtle clues of the surface damage Space Shuttle Processing Orbiter Thermal Protection System (cont.) Repair and replacement High-temperature Reusable Surface Insulation (HRSI) tile replacement operations entail exacting measurements and fitting - generally less than .005" on the edges with a 0.045" ± .020 gap between tiles Since these tiles vary between roughly 1 inch and 6 inches in depth and can take on complex shapes, each tile is individually made and fitted by hand which takes approximately two weeks from removal to completed replacement Space Shuttle Processing Orbiter Thermal Protection System (cont.) Regions of the Orbiter that require more durable insulation than the HRSI such as around surface penetrations, gear doors and the leading edge areas, are covered with Fibrous Refractory Composite Insulation (FRCI) Toughened Unipiece Fibrous Insulation (TUFI) is composed of about the same silica fiber material in the interior as the HRSI tiles Its more durable surface coating has replaced some of the HRSI tiles in high-abrasion regions such as below the nose Replacing 50 to 100 tiles from a typical flight may require from four or five weeks for a quick turnaround if there are fewer HRSI tiles to replace, to several months for an extended OPF stay Space Shuttle Processing TPS repair/replacement operations Space Shuttle Processing Orbiter Thermal Protection System (cont.) RCC panels The highest temperature insulation on the Orbiter is the Reinforced Carbon Carbon (RCC) panels that protect the leading edges of the wings and the nose cap Careful inspection of the leading wing edge panels may require removal and replacement, and includes the inner and mounting surfaces Modifications to the RCC panels because of the Columbia accident included improved inspection techniques, protective barriers for the wing front strut Because of the time needed for processing, careful examination and evaluation of each of the RCC panels takes place soon after the Orbiter arrives for processing to facilitate repairs and/or replacement Space Shuttle Processing Orbiter Thermal Protection System (cont.) Flexible insulation In addition to the replacement of HRSI, LRSI, FRCI and TUFI tiles, the Orbiter's other thermal protection coverings that include Felt Reusable Surface Insulation (FRSI) pads, and Flexible Insulation Blankets (FIBs) must be repaired, and if necessary, replaced Since the flexible blankets are much larger and are more easily removed and replaced than the tiles, the process of repair/replacement is generally much shorter Thermal barriers for the external joints (gear & umbilical doors, etc.) and gap seals must also be checked, repaired, and modified as necessary Thermal barriers and gap fillers are also inspected for compliance with often increasingly rigorous specifications Space Shuttle Processing Orbiter Thermal Protection System (cont.) VAB processing Nearly all of the TPS repair, replacement and modification is done in the OPF An exception is the final nose gear door step and gap evaluation that takes place after the Orbiter is mated with the ET Loads on the Orbiter structure can result in misalignment of the tiles, seals, and thermal barriers which must be corrected to ensure an accurate fit for a positive thermal seal Space Shuttle Processing Orbiter Thermal Protection System (cont.) Pad processing SSME work during launch pad preparation requires access to the aft compartment by engineers and technicians When completed, the base heat shield carrier panels are replaced as part of the closeout process These panels protect the engine and components in the aft compartment from the high-temperature exhaust during launch Any damage to the TPS from the integration process or transportation to the pad is repaired before launch Space Shuttle Processing Source breakdown of events requiring TPS processing Space Shuttle Main Engines Space Shuttle Processing SSME/Main Propulsion System Space Shuttle Main Engines are high performance engines which require careful inspections and checkout during Space Shuttle processing and integration These inspections and tests are performed before, during, and after the Orbiter’s stay in the OPF The arriving Orbiter has all three SSMEs removed and transported to the SSME Processing Facility (SSMEPF) for inspection and refurbishment, with some components repaired or replaced, or at times, upgraded A different engine set that has undergone inspection, refurbishment and testing is then installed in the Orbiter while in the OPF Space Shuttle Processing SSME/Main Propulsion System (cont.) Processing, testing, and inspection of the SSMEs begins on the runway after the Orbiter lands with a walkdown visual inspection The engines are checked for any visible damage and the external aft section is checked for any loose hardware At this time, throat plugs are installed, and purge lines and access ports are plugged, to protect engines from contamination Space Shuttle Processing SSME - OPF processing Once the Orbiter is towed into the Orbiter Processing Facility, the engines are readied for removal and transportation to the SSME engine shop at the Kennedy Space Center Initial processing includes: High Pressure Turbine Pump bearing drying with heated GN2 (within 48 hr of landing) Visual inspection of interior and exterior Low pressure turbopump turbine torque check Hydraulic activation of actuators to move engines into correct alignment for removal Aft heat shield removal Engine heat shield removal SSME removal Space Shuttle Processing SSME processing After the engine testing is completed in the SSMEPF, the SSMEs are prepared for installation in an Orbiter Checkout continues with Interface leak checks Gimbal nozzle clearance – hydraulic actuator check Walkdown inspection Nozzle cover installation Aft heat shield installation Space Shuttle Processing SSME processing - VAB While the Orbiter is processed in the VAB, the engines and main propulsion system are checked These steps include: Orbiter/ET interface leak test SSME leak test with GN2 Nozzle cover removal Trickle purge activation (purges humid/contaminated air from engines) Space Shuttle Processing SSME processing – Launch Pad As the Orbiter is processed for launch on the pad, the SSME/MPS is checked in preparation for operation These preparations include: Flight Readiness Testing (FRT) Helium signature test – uses aft compartment for a systems leak test similar to encapsulation leak test Electrical system checkout Ball seal leak check (5 ball valves and seals on each engine) Walkdown inspection Helium bag leak check Main combustion chamber polishing Nozzle cover removal Purging Engine heat shield installation In preparation for the propellant loading and firing and engine ignition software loads, sensor and igniter checkouts and inert purges are performed OMS/RCS Space Shuttle Processing OMS/RCS Processing OMS and RCS system, propellants, and components are hazardous, requiring careful processing and preparation steps during servicing and checkout Preparations may include removal of the OMS pods and Forward Reaction Control Section (FRCS) if internal work is required If removal is necessary, those OMS/RCS sections are taken to the Hypergolic Maintenance Facility (HMF) for servicing HMF facility is separate from all other processing buildings for safety considerations Space Shuttle Processing OMS/RCS Processing (cont.) Several procedures require evacuation of the OPF and the use of hazardous materials suits (Self Contained Atmospheric Protective Ensemble or SCAPE) Required for workers that might be exposed to the fuel (monomethyl hydrazine or MMH) or oxidizer (nitrogen tetroxide or NTO) from the OMS/RCS plumbing and/or components Space Shuttle Processing OMS/RCS Processing (cont.) Preliminary preparation of the OMS/RCS system begins as the Orbiter is powered down after landing, with the safeing crews first to reach the Orbiter Deservicing of the Orbiter is begun almost immediately in order to reduce or remove the hazardous components and toxic gas exposure to the flight crews and ground processing crews OMS/RCS systems leak detection is initiated and nozzle plugs installed Space Shuttle Processing OMS/RCS Processing (cont.) Gaseous nitrogen used to pressurize the OMS valves is vented with selectors located in the cockpit Teams deactivate and safe pyrotechnic components, and service the purge, vent and drain (PVD) system lines After the Orbiter has been towed into the OPF, the hazardous fuels, including MMH, NTO and ammonia, are again checked for leakage from the system lines, storage tanks, and interface Space Shuttle Processing OMS/RCS Processing (cont.) Fuel and oxidizer tanks are not drained since the propellants are stable Other fluids including the reactants for the fuel cells (liquid and gaseous hydrogen and oxygen) are removed and purged from the PRSD tanks and lines soon after the Orbiter arrives in the OPF Space Shuttle Processing OMS/RCS OPF processing While the Orbiter is in the OPF, checkout and functional tests are performed on the forward RCS and aft OMS pods which include: FRCS interface verification LH and RH pod interface verification RCS UTPA inspection and replacement FRCS functional checkout LH and RH pod functional checkout Oxidizer and fuel crossfeed checkout Fore and aft RCS valve, regulator, and distribution checkout LH and RH pod screen tests for fuel and oxidizer Space Shuttle Processing OMS/RCS – launch pad processing Soon after the assembled STS arrives at the launch pad, the OMS/RCS system undergoes propellant servicing that includes fuel and oxidizer tank fill and checkout Hypergolic servicing Nitrogen pressurization system servicing Normally scheduled within a week after arrival since the hypergolics are stable Normally scheduled one week or less before launch to reduce leakage losses Helium pressurization system servicing Normally scheduled one week or less before launch to reduce leakage losses Space Shuttle Processing OMS/RCS processing Thrusters OMS thrusters are not generally removed for inspection, testing, or checkout unless a problem occurs in flight or an inspection dictates removal To improve reliability the engines are removed and replaced with new or rebuilt units every other OMDP Testing is done when necessary in a vacuum chamber RCS thrusters are not generally replaced unless problems occur, which are most commonly leaks Since the thrusters are sensitive to temperature and pressure changes, a block of thrusters is replaced if one on a manifold indicates a problem Electrical Power System Space Shuttle Processing Electrical Power System After the Orbiter has landed and has been towed into the OPF, the GSE equipment is connected to supply the necessary power for operation of the Orbiter functions through the rear T-0 panels Between the landing and the GSE power connection, the three cells provide power for the Orbiter systems PRSD must have sufficient reactant reserve for critical operations, especially the OMS/RCS valve closure Fuel cells must also be drained of water and cooled during that period to prevent internal damage Space Shuttle Processing Electrical Power System (cont.) During the initial safeing of the Orbiter after its return from space, the pyrotechnic assemblies are disconnected and some removed This is generally accomplished with Load Control Assemblies (LCA) being installed to interrupt critical firing paths to the ordinance Space Shuttle Processing Electrical Power System processing - OPF During the Orbiter processing cycle in the OMS, the Electrical Power System is tested and checked during a number of operations. The major checkout operations include: Orbiter power-up: Electrical power distribution for tests and checks for other systems and components These tests include nearly all functions which requires nearly continuous power for the processing cycle Shuttle Connector Analysis Network (SCAN) tests: The myriad of connectors throughout the Shuttle must be tested and checked for proper operation during the many stages of processing and assembly Space Shuttle Processing Electrical Power System processing - OPF Orbiter lighting validation: RMS test and checkout: Checkout and testing of the Remote Manipulator System functions Wiring modifications: Checkout of the Orbiter lighting system throughout the crew cabin and the payload bay Critical testing of any modifications for the Orbiter ant its payload. Since each payload is different, these tests are conducted for each mission Ordinance wiring replacement and resistance testing: Testing and checkout of the critical wiring for the ordinance circuits Space Shuttle Processing Electrical Power System processing – OPF (cont.) Orbiter EPS modifications and payload-specific modifications Wiring repairs and troubleshooting Line Replaceable Unit (LRU) and panel installations EMU Orbiter interface test: Test and checkout of the Extravehicular Mobility Unit power and wiring interface with the Orbiter Space Shuttle Processing Electrical Power System processing – OPF (cont.) SSME aft connector inspection: Main engine wiring and connector testing Ku-band radar and communications system turnaround test Payload and payload bay verification test and checkout Space Shuttle Processing Electrical Power System processing – OPF (cont.) Instrumentation system verification Master Events Controller (MEC) verification: Pyro controller checkout Pyrotechnic Initiator Controller (PIC) verification Space Shuttle Processing Electrical Power System processing - VAB While in the VAB, the EPS checkout and testing includes the hazardous gas detection circuitry and preliminary pyrotechnic installation checks and testing ET/Orbiter electrical monoball assembly and testing: Monoball is the electrical interface panel for electrical cabling connectors between Orbiter & ET attached to the right and left umbilical panels Orbiter/ET interface test: Test and checkout of the electronic and power circuitry between the External Tank and the Orbiter Space Shuttle Processing Electrical Power System processing – VAB (cont.) SRB cabling and function tests: Check and test of SRB function wiring through the ET/Orbiter interface Installation of pyro charges: Ordinance/pyrotechnic charges are placed in position as late in the flow as possible to reduce the potential hazards during processing and integration Space Shuttle Processing Electrical Power System processing – Launch Pad While the Shuttle is on the launch pad, a number of electrical tests and checkouts are performed to ensure that the electrical systems and connections are operational. These include: SRB/ET/Orbiter/Pad interface test: Test and checkout of the Shuttle systems and pad support interface Pyro charges and wiring completed: Ordinance circuitry completed Space Shuttle Processing Electrical Power System processing – Launch Pad (cont.) Ordinance (pyro) resistance & load testing: Range Safety System (RSS) functional test: Ordinance wiring test and checkout under low current load Test and checkout of the range safety system on the Shuttle vehicle Final Pyro Initiator Controller test Space Shuttle Processing Electrical Power System processing – Launch Pad (cont.) Master Events Controller final checkout Launch pad electrical validation and test Hazardous gas detection system test and checkout: Test and checkout for the hydrogen, nitrogen and oxygen detection system for crews working on the last processing steps before launch MPS helium signature leak test: Leak check for SSMEs using pressurized helium in the engine interior and a mass spectrometer to detect helium in the aft compartment Space Shuttle Processing Fuel Cells The Orbiter fuels cells that provide electrical power for the entire vehicle require approximately 250 man-hours of processing vehicle flow to ensure operational reliability for all aspects of the Orbiter’s flight OPF processing Fuel cell load removed, then powered-down Cryogenic LH2 and LOX drained from PRSD system Space Shuttle Processing Fuel Cells – OPF (cont.) Helium inert purge of PRSD and fuel cell systems to support safe entry into payload bay Fuel cell in-depth diagnostics to evaluate system degradation Fuel cell changeout if required Space Shuttle Processing Fuel Cells – OPF (cont.) PRSD O2/H2 tank removal/installation as required to support next flight PRSD and fuel cell system pressure decay test Overboard leak checks Maintain helium pressure in the tanks to provide constant internal pad pressure to the fuel cells as well as prevent moisture induced corrosion within the tanks Space Shuttle Processing Fuel Cells VAB processing System monitoring only (if required for long term storage) Space Shuttle Processing Fuel Cells Launch pad processing LOX and LH2 servicing of PRSD tanks (loaded from mobile tanker approximately two days before launch) Fuel cell activation (approximately 15 hr before launch) High load fuel cell test Space Shuttle Processing Fuel Cells - Launch pad (cont.) System integrity (cold exposure) test O2 and H2 leak check with GN2 background in Payload Bay/midbody Payload Bay/midbody GN2 purge test for GOX and GH2 leaks Full Orbiter power switchover to fuel cells (approximately 2-3 minutes before launch) ECLSS Space Shuttle Processing Environmental Control & Life Support System Prior to landing and until shortly after wheel stop, thermal control is provided by the volume of Freon-21 in the radiators which was "cold-soaked" during the last few hours of de-orbit preparations using the Flash Evaporator System Processing begins after wheel stop The active cooling system that provides thermal conditioning for the crew and equipment is switched to the ammonia boiler system until the ground support system is manually connected to the Orbiter left side T-0 Interface Panel Within 2 ½ hours of wheel stop, the vacuum vent duct is purged with nitrogen to dilute the concentration of hydrogen gas that is captured from the fuel cell water Space Shuttle Processing ECLSS Initial OPF processing Waste Control System (WCS), which is essentially the commode and waste storage, is removed and returned to JSC for cleaning and refurbishment The waste water system is flushed to remove salt precipitates and to reduce bacterial growth Flash Evaporator System inspection and purge to reduce corrosion Purge and evacuate the ammonia boiler vent line to remove moisture Space Shuttle Processing ECLSS General OPF servicing Plug ammonia system, vacuum vent, and flash evaporator ports to avoid debris and contamination Cabin and avionics fan and filter cleaning Humidity separator testing and flush Space Shuttle Processing ECLSS Final OPF servicing Ammonia servicing and purge GN2 servicing Potable water drain and servicing Space Shuttle Processing ECLSS VAB processing Processing of the ECLSS in the VAB after integration consists of power-up testing and ground cooling loop testing with the Ground Support Equipment Space Shuttle Processing ECLSS - Pad processing ECLSS processing on the pad includes an additional Flash Evaporator purge because of its critical function while on orbit and the nature of the harsh coastal environment Gaseous oxygen for the crew compartment is provided by heated cryogenic oxygen from the onboard LOX storage and distribution system which is loaded during PRSD tanking on the pad about two days before launch Vacuum vent line purge with nitrogen prior to fuel cell start and at each 24 hour interval (in the case of launch scrubs while keeping the fuel cells on-line) Space Shuttle Processing ECLSS - Pad processing (cont.) Removal of plugs from Ammonia Boiler vent, Vacuum Vent and Flash Evaporator vent ports Perform a final 2 psid crew module pressure leak check after final crew hatch closure to ensure cabin pressurization integrity Space Shuttle Processing ECLSS Mission variations Missions beyond 16 days duration called extended duration operations employ additional PRSD LH2, LOX and GN2 tanks Provides additional electrical power, atmospheric gas, and breathing oxygen Extended Duration Operation (EDO) package also includes a Regenerative CO2 Removal System (RCRS) which is a dual amine absorption bed that replace of the heavier LiOH system and canisters Two LiOH canisters are still carried on the extended duration missions for backup APU Space Shuttle Processing APU/Hydraulic System Orbiter APU processing tasks Servicing and checkout of the APU/hydraulic systems during processing covers the mechanical system and components, and the fuel system. Those tasks include: Deservicing hydrazine fuel tanks after Orbiter arrival in the OPF Replacing APU lubricating oil Servicing APU water coolant system Hydraulic system fill, bleed, and checkout Water Spray Boiler (WSB) checkout and servicing Orbiter GN2 accumulator servicing Space Shuttle Processing APU/Hydraulic System Pad processing Before launch, the APU/hydraulic system requires: Servicing GN2 pressurization tanks Servicing hydrazine fuel tanks (Orbiter and SRB) APU confidence run (hot fire) APU leak and functional test Hydraulic system functional testing In addition, the APU system requires leak and electrical testing during the processing cycle and before launch Communications & Avionics Space Shuttle Processing Orbiter Communications Orbiter communications system undergoes little rework in the processing cycle in spite of the different mission requirements The UHF, S-band, and Ku-band communications are standard to all Orbiters and flights, and provide the necessary links from the Orbiter to ground, and for Orbiter intercommunications Because most interfaces to the Orbiter communications systems are standardized, and the communication format is exactly specified for the payloads, the checkout procedures for Orbiter communications during processing is done primarily during payload checkout Space Shuttle Processing Orbiter Communications OPF Processing Checkout and testing of the Orbiter communications system takes place either in the OPF or on the launch pad Processing and checkout of the Ku-band communications consists primarily of a powered checkout of the system and radar antenna while the Payload Bay doors are open and the antenna is deployed Further testing of UHF and S-band systems is done on the launch pad Since the Ku-band antenna is stowed in the Orbiter Payload Bay, it cannot be activated until the Orbiter is on orbit and the payload bay doors are opened Hence Ku-band processing and testing is limited to the Orbiter Processing Facility. Space Shuttle Processing Orbiter Communications Pad Processing Communications system checkout resumes on the launch pad when the T-0 umbilical line S-band communications are checked, then again when the communications are checked during the Terminal Countdown Demonstration Test (TCDT) A number of automated communications tests are performed during the countdown cycle to ensure all systems associated with the ground and Orbiter communications are functioning Space Shuttle Processing Avionics and Flight Control Systems Reliability in the flight control system is provided by a combination of the software architecture and redundant hardware Comprehensive testing of each of the Shuttle’s digital avionics systems is completed prior to each mission to ensure safe operation Hardware and software testing procedures are done in the processing (OPF), integration (VAB) and prelaunch (launch pad) stages of the vehicle's preparation for flight Testing procedures are often accomplished by utilizing the numerous digital processing systems used for following Space Shuttle processing and integration, such as the Launch Processing System (LPS) Space Shuttle Processing Avionics and Flight Control Systems Software The Shuttle’s digital system software is divided into two principal areas; flight software and ground software Majority of the ground software is written in a special language known as Ground Operations Aerospace Language (GOAL) GOAL, which was developed at the Kennedy Space Center in the 1970’s, allows for extremely fast command and control of the Orbiter systems An effort was made at KSC to replace the LPS GOAL software and hardware with C++ software and modernized computer hardware known as the Checkout, Launch, and Control System (CLCS) Space Shuttle Processing Avionics and Flight Control Systems Software Ground testing software is managed by the processing teams at Kennedy Space Center, while the flight software is managed by the Johnson Space Center Coordination between the NASA personnel and contractor teams is a continuous operation because of the complexity of the systems and the extreme reliability required for safe manned space vehicle flight Space Shuttle Processing Avionics and Flight Control Systems Processing and testing categories The various tests and evaluation operations for the avionics, digital, and flight systems are classified into several categories Turnaround testing System troubleshooting Data analysis (trend development and identification, etc.) Launch execution Metric data collection Design reviews for upgrades and new technologies Ground software review Space Shuttle Processing Avionics and Flight Control Systems Primary digital and avionics groups The primary digital and avionics groups represent the major divisions in the systems and components, but not necessarily the separate testing or operational check areas Many of the subsystems and systems overlap in many of their functions; an example being the Data Processing System (DPS) control over most of the Space Shuttle system functions The primary groups are: Data Processing Systems (DPS) Flight software (FSW) Electrical Flight Control Systems (EFC) Guidance and Navigation Systems (G&N) Space Shuttle Main Engine Avionics (SSMEA) Space Shuttle Processing Avionics and Flight Control Systems Primary processing & integration tasks The critical checks on the Shuttle digital and avionics systems take place at specified intervals The most critical tasks for each system take place in the OPF, VAB and PAD processing facilities at KSC Space Shuttle Processing Avionics and Flight Control Systems Primary processing & integration tasks Final power up and checkout of many Space Shuttle systems occurs at the launch pad during launch countdown The following list is representative of some of the critical tests required on each of the STS vehicles during processing Data Processing System (DPS) DPS Computer Complex Checkout Dedicated display/HUD checkout Multifunction CRT Display System (MCDS) checkout Flight Software Load Dump and Compare Space Shuttle Processing Avionics and Flight Control Systems Electrical Flight Control System (EFC) Aero/Ascent Thrust Vector Control (ATVC) checkout Space Shuttle interface test (Orbiter, SRB, ET) Power Redundancy Testing Manned Maneuvering Unit (MMU) operations Nose Wheel Steering (NWS) checkout Brake/Antiskid system checkout Space Shuttle Processing Avionics and Flight Control Systems Guidance & Navigation System (G&N) Inertial Measuring Unit (IMU) functional checkout Star Tracker inspection and self test Air Data Transducer Assembly (ADTA) checkout SSME Control Pad Flight Readiness Test (FRT) SSME engine avionics checkout (sensors, pneumatics, igniter, actuator, power supply, command controller, skin temp, flight readiness, controller load) Space Shuttle Processing Avionics and Flight Control Systems Additional tests are made on the Space Shuttle’s digital, flight and avionics systems based on conditions or events that might require retesting (contingency due to hardware failure), or upon return from modification and upgrades from the OMDP Approximately fifty percent of the testing done at KSC is unplanned and is due to system anomalies Space Shuttle Processing Avionics and Flight Control Systems Examples of tests run for contingency events are: Flight control aerosurface checkout Flight control frequency and step response OMS/RCS checkout in the Hypergolic Maintenance Facility DPS/EFC/FSW/G&N/SSMEC retesting for Orbiter lightning strike Examples of testing after OMDP return include: HUD checkout Star tracker installation and checkout NWS interval testing Space Shuttle Processing Processing emphasis Processing and checkout by each of the various Space Shuttle teams requires vastly different procedures and emphasis because of the widely varied system functions The digital, flight control, and avionics teams handle extensive testing routines. EFC engineers are also involved in all hydraulic operations DPS engineers are also involved in the tests of most of the other systems since most functions are under GPC control Space Shuttle Processing Processing emphasis To enhance safety, reduce errors, and optimize the man-hours for each flow, the emphasis of the digital and avionics teams is on measuring, improving testing and launch execution efforts This continual improvement is accomplished by examining the underlying principles and philosophies of the vehicle testing and its effectiveness Emphasis is also placed on the lessons learned from previous STS missions, and from testing and evaluation experience Orbiter Modifications and Upgrades Space Shuttle Processing Orbiter Modifications Each Orbiter undergoes repairs, upgrades, improvements, payload kit installations, and other modifications during their processing and integration cycles These modifications can be for payload installations, or to increase performance, or to improve operating costs, repair worn or damaged equipment or materials, or to correct potential or existing problems The entire collection of changes to the Orbiter, and the ET and SRBs, could be simply called modifications, since the same principle of work authorization, work completion, and documentation is used to accomplish each Space Shuttle Processing Orbiter Modifications Separate projects and programs direct these changes through different channels to be completed during the processing and integration flow Modifications to the Orbiter, ET, and SRBs have different origins but are completed by the same processing teams The most extensive of these modifications is performed during the Orbiter Maintenance Down Period Space Shuttle Processing OMDP OMDPs were completed previously at the Rockwell Palmdale, California plant OMDP inspections and modifications now take place in the Kennedy Space Center within the OPF OMDP maintenance and upgrade program is scheduled every seven to eight flights for each Orbiter, or approximately once every three years Space Shuttle Processing OMDP OMDP provides the most efficient means of comprehensive inspection and major modification for the Orbiter because of the ample time available, and because of the scheduling conflicts that can arise during the normal vehicle flow OMDP period is approximately 14 months in length, with some variation due to arrival, departure and scheduling differences Space Shuttle Processing Upgrades Orbiter modification approval is generally a different procedure from the upgrade approvals, even though both may include large-scale or small-scale alterations and come from the same engineering office at JSC, and may even be done at the same time or at the same site Generally, upgrades cover longer-term planning and approval, and may include larger-scale alterations than most modifications The Shuttle upgrade program is an ongoing improvement program for extending the operational capability and safety of the Shuttle that was to extend through the year 2012 Space Shuttle Processing Upgrades The overall program has been altered to bring the Orbiters to a fleet standard before the retirement of the Orbiters, currently scheduled for 2010, or at the completion of the International Space Station Priorities for NASA's STS upgrade program include: Safety Supportability Reliability Maintainability Cost reduction Space Shuttle Processing Upgrades NASA's emphasis on STS improvements and upgrades in the post-Columbia era are focused on the safety and reliability of the flight and ground operations Many of the more visible upgrade projects are on the External Tank and the attachment to the Orbiter in compliance with the Columbia Accident Investigation Board recommendations. Some of those improvements/upgrades are: Bipod attachments between the ET and Orbiter have had foam replaced with electric heaters because of the susceptibility of the insulation foam on the ET to shed during ascent Space Shuttle Processing Upgrades Improved foam application procedures to reduce the incidence of foam shedding from the ET Removal of the Portrubance Air Load Ramp foam to reduce the incidence of foam shedding from the ET Improvements in the thermal insulation for the LOX bellows on the ET Addition of leading-edge temperature sensors on the Orbiters wings to measure thermal distribution Space Shuttle Processing Upgrades – post-Columbia Addition of sensitive accelerometers to the Orbiter wing's leading edges to help identify possible damage during ascent or descent Improved bolt catchers on the pyrotechnic devices used to separate the SRBs from the ET Improved booster separation motors to reduce potential damage to the Orbiter Space Shuttle Processing Upgrades – post-Columbia Addition of inspection cameras to the forward section of the SRBs to view the Orbiter and ET during ascent Addition of an inspection boom to the Orbiter's Remote Manipulator System to provide detailed inspection of the Orbiter after arrival on orbit, and again to check for possible micrometeoroid damage before deorbit Development of tools, materials, and procedures for repairing damage to thermal tiles and RCC panels on orbit Fish-eye view of the Orbiter's new Multifunction Electronic Display Subsystem (MEDS) glass cockpit shown here in the Johnson Space Center's Shuttle Mission Simulator The End