An Introduction to Lean Six Sigma in Higher Education

advertisement

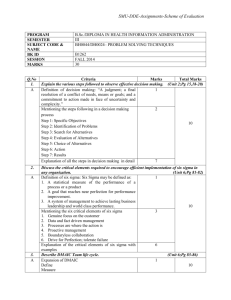

An Introduction to Lean Six Sigma (6σ) in Higher Education Dr. Andrew Luna Director Institutional Research and Planning University of West Georgia Stan DeHoff University Project Portfolio Manager Office of Decision Support Medical College of Georgia Six Sigma - As Easy to Understand As Parking Your Car 2 Agenda • • • • • • History of Quality in Higher Education The World We Live In Six Sigma Defined DMAIC Lean Defined Example: Using Statistical Measures for Quality Control in higher education • Example: Using Lean Six Sigma at MCG 3 History of Quality in Higher Education • In 1980, NBC aired “If Japan can…Why can’t we?” and the Quality movement took off in the U.S. • In 1991, IBM offered $1 million ($3 million in IBM equipment) to those colleges and universities that could adapt quality management initiatives • In 1992 all of higher education went TQM “crazy” 4 History of Quality in Higher Education, cont. • TQM failed in higher education because of lack of knowledge. • TQM lost its appeal to many business because of increased labor and documentation costs and decreased reliance on Statistical Process Control • Six Sigma was an effort by Motorola and GE to bring back statistical measurement to quality • Six Sigma is now slowly entering the halls of academe 5 The World We Live In Sonny Perdue • Governor, State of Georgia – Changing the culture of state government • Principle-centered, people-focused, customer-friendly – Commission for a New Georgia • Best managed, growing, educated, healthy, safe “Our government needed new thinking from a fresh perspective to see better ways to manage our assets and services and map our future.” 6 The World We Live In Erroll B. Davis, Jr. • Chancellor, University System of Georgia – Ongoing series of changes to improve System communication and institutional engagement • Reorganization, new System Strategic Plan, more unified System – Focus on accountability and quality and “Six Sigma” “I want our actions and decisions to be based upon knowledge. So that is an initial expectation; that we will focus on data-driven decision-making.” 7 What is Six Sigma (6σ)? • Sigma (σ) is a statistical concept that represents how much variation there is in a process relative to customer specifications. • Sigma Value is based on “defects per million opportunities” (DPMO). • Six Sigma (6σ) is equivalent to 3.4 DPMO. The variation in the process is so small that the resulting products and services are 99.99966% defect free. Amount of Variation Effect Sigma Value Too much Hard to produce output within customer specifications Low (0 – 2) Moderate Most output meets customer specifications Middle (3 – 5) Very little Virtually all output meets customer specifications High (6) 8 Six Sigma Concept Every Human Activity Has Variability... Customer Specification Customer Specification defects Target Reducing Variability is the Key to Understanding Six Sigma 9 Six Sigma Concept Parking Your Car in the Garage Has Variability... Customer Specification defects Target Customer Specification defects 10 Six Sigma Concept Before 3s A 3 s process because 3 standard deviations fit between target and spec Target Customer Specification 1s 2s 3s After Target By reducing the variability, we improve the process 6s ! 1s Customer Specification No Defects! 3s 6s 11 What’s Wrong With 99% Quality? 3.8 Sigma 99% Good Six Sigma 99.99966% Good 20,000 articles of mail lost per hour 7 articles of mail lost per hour Unsafe drinking water for almost 15 minutes each day Unsafe drinking water for 1 minute every 7 months 5,000 incorrect surgical operations per week 1.7 incorrect surgical operations per week 2 short or long landings at most major airports each day 1 short or long landing at most major airports every 5 years 200,000 wrong drug prescriptions dispensed each year 68 wrong drug prescriptions dispensed each year 12 Why Use Sigma as a Metric? Focuses on defects • Even one defect reflects a failure in your customer’s eye Establishes a common comparisons easier metric to make Is a more sensitive indicator than percentage or average-based metrics … 13 Limitations of Average-Based Metrics FOXTROT BY BILL AMEND 14 Where Did 6σ Come From? • Started at Motorola Corporation in the mid-1980’s, when the company discovered that products with a high first-pass yield (i.e., those that made it through the production process defect-free) rarely failed in actual use, resulting in higher customer satisfaction. • Popularized by former General Electric CEO Jack Welch’s commitment to achieving Six Sigma capability (realized $12 Billion savings over 5 years). "Six Sigma is a quality program that improves your customers' experience, lowers your costs and builds better leaders." 15 Isn’t 6σ Just For Manufacturing? • No, Six Sigma is good for ANY business. – Has been successful in industries such as banking, retail, software, and medical – Has been successful in improving processes throughout operations, sales, marketing, information technology, finance, customer services, and human resources • Why? – Because every business suffers from the two key problems that Six Sigma can solve: defects and delay 16 Six Sigma (6σ) in Academia Institutions which have implemented some form of Six Sigma methodology within their operations: Health Sciences: Other: Medical College of Pennsylvania Medical College of Virginia Medical College of Wisconsin Medical U of South Carolina St. Louis U Health Sciences Center U of Michigan Health System U of Tennessee Health Science Center U of Texas Health Science Center U of Texas Medical Branch University System of Georgia: University of Georgia University of West Georgia Valdosta State University Alabama Boston University Cal Poly State California Carnegie Mellon Central Florida Central Michigan Clemson Coastal Carolina Colorado Connecticut Florida Tech Illinois Central Jackson State Johns Hopkins Kettering Michigan Mississippi Mississippi State NC State Ohio Penn State Purdue Rockhurst Rutgers San Diego South Carolina South Dakota State Tennessee Texas Texas A&M Tulane UNC Chapel Hill Vanderbilt Vermont Villanova Washington Western Illinois Western Kentucky USG Institutions Teaching Six Sigma Abraham Baldwin Armstrong Atlantic State Bainbridge College Clayton State Columbus State Darton College Georgia State Georgia Inst of Tech Kennesaw State Southern Polytechnic State University of Georgia Valdosta State 17 Six Sigma (6σ) Methodologies Control Define Improve Measure Analyze Verify Design Define Measure Analyze DMAIC: This method is used to improve the current capabilities of an existing process. This is by far the most commonly used methodology of sigma improvement teams. DMADV: This method is used when you need to create or completely redesign a process, product, or service to meet customer requirements. DMADV teams are usually staffed by senior managers and Six Sigma experts. 18 DMAIC Methodology DEFINE Identify, prioritize, and select the right project(s) MEASURE Identify key product characteristics & process parameters, understand processes, and measure performance ANALYZE Identify the key (causative) process determinants IMPROVE Establish prediction model and optimize performance CONTROL Hold the gains 19 Six Sigma Toolbox Analysis of Variance (ANOVA) Box Plots Brainstorming Cause-effect Diagrams Correlation & Regression Design Of Experiments Graphs and Charts Histograms Hypothesis Testing Pareto Analysis Process Capability Studies Process Control Plans Process Flow Diagrams Quality Function Deployment Response Surface Methods Scatter Diagrams Standard Operating Procedures (SOPs) Statistical Process Control 20 Project Focus Process Characterization Define The right project(s), the right team(s) Measure Y Analyze Process Optimization Improve X’s Control Process Problems and Symptoms Process outputs Response variable, Y Independent variables, Xi Process inputs The Vital Few determinants Causes Mathematical relationship Goal: Y = f ( x ) 21 Different Views of the Organization 30,000 Ft. – View of Entire Organization 5,000 Ft. – View of One Process 22 So, What is Lean? • The methodology of increasing the speed of production by eliminating process steps which do not add value – those which delay the product or service – those which deal with the waste and rework of defects along the way 23 Where Did Lean Come From? • Lean thinking originated at Toyota with the Toyota Production System (TPS). The original ideas were formulated by Sakichi Toyoda in the 1920s and 1930s, but only made the leap to full implementation in the 1950s. • Many of the principles of lean came from a surprising source: American supermarkets where small quantities of a vast selection of inventory is replenished as customers "pull" them off the shelf. 24 Core Ideas of Lean • Determine and create value – What does the customer want? • Use “pull” instead of “push” systems to avoid overproduction – Inventories hide problems and efficiencies. • One piece flow – Make the work “flow,” so that there are no interruptions and no wasted time or material • Eliminate the seven speed bumps (non-value adds) caused by waste • Use the “five whys?” and Six Sigma problem solving to eliminate defects 25 The Seven Speed Bumps of Lean Non-value added waste – is any activity which absorbs money, time, and people but creates no value. 1. 2. 3. 4. 5. Over production which creates inventories that take up space and capital Excess inventory caused by over production Waiting for the next value-added process to start Unnecessary movement of work products Unnecessary movement of employees 6. 7. Unnecessary or incorrect processing Defects leading to repair, rework, or scrap. 26 The Antidote to Waste: The 5 S’s 1. Sort – Keep only what is needed 2. Straighten – A place for everything and everything in its place 3. Shine – Clean systems and work area to expose problems 4. Standardize – Develop systems and procedures to monitor conformance to the first three rules. (Six Sigma’s Define and Measure phases) 5. Sustain – Maintain a stable workflow. (Six Sigma’s Analyze, Improve, and Control phases) 27 Synergy of Lean and Six Sigma Lean reduces non-value-add steps # of Steps ±3s 1 93.32% 99.379% 99.976% 99.999% 7 61.63% 95.733% 98.839% 99.997% 10 50.08% 93.96% 99.768% 99.996% 20 25.08% 88.29% 99.536% 99.993% 40 6.29% 77.94% 99.074% 99.986% ±4s ±5s ±6s Six Sigma improves quality of value-add steps Source: Motorola Six Sigma Institute 28 The Birth of “Lean Six Sigma” • Six Sigma improves effectiveness by eliminating defects (improves Quality) • Lean improves efficiency by eliminating delay and waste (improves Speed) • Most Six Sigma efforts are incorporating the principles of Lean. Therefore, Six Sigma is often called Lean Six Sigma. 29 Pareto Chart in Residence Halls Residential Life Incident Reports – 2 Years 250 100.00% 90.00% 200 70.00% 150 Count 60.00% 50.00% 100 40.00% 30.00% 50 20.00% Cumlative Percentage 80.00% 10.00% 0 0.00% M . isc ise o N n ol ty h e it o ism f l o a a c a S d sit Al re an Vi i V F t ef h T l l t ca ca en i i n m ed ha ss M c a e rr a M H 30 Using Pareto and Trend Analysis Trend Analysis 31 Control Chart for Hot Water in Residence Hall Problem • Survey found that most residents in a female hall were unhappy with the bathrooms • Subsequent focus groups found that residents were upset over the quantity and quality of hot water • Define – Hot water variability in high-rise residence hall • Measure – Record temp. of hot water on high, med., and low floors for two weeks, three times a day • Analyze – Plot hot water on X-Bar/R Control Chart 32 Control Chart for Hot Water in Residence Hall, Cont. X - Bar Hugging of the Mean Periodicity Means 140 130 120 110 100 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 2 21 2 2 2 2 2 2 2 2 3 31 3 3 3 3 3 R 3 3 4 41 Exceeding Control Limit 45 40 Trend 35 Ranges 3 30 Run 25 20 15 10 5 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 2 21 2 2 2 2 2 2 2 2 3 31 3 3 3 3 3 3 3 3 4 41 33 Control Chart for Hot Water in Residence Hall, Cont. • Improve – After understanding the process and the control chart, the team offered suggestions to control variability • Control – A new control chart was run after changes to the system and the process was found to be in control • Money – The changes decreased utility costs and increased student retention in the hall 34 Regression Analysis • Multiple Regression was used to explain variability in academic departmental budget allocations • Credit hours, professors, degrees, market of the discipline, and majors were used to predict budget allocation • Predicted allocations were compared to actual allocations and significant discrepancies were addressed. 35 Reference Our Master Improvement Story a.k.a., Balanced Scorecard A Master Improvement Story links key measures to improvement efforts. This linkage helps leaders and employees focus on the customer / stakeholder and align all of their actions to achieve desired outcomes. Vision The Medical College of Georgia will become one of the nation's premier health sciences universities. Long-Term Objectives I - Enhance Educational Environment and Update Educational Programs Annual Objectives Improve Program Effectiveness Improve Student Performance II - Enhance the Research Enterprise Improve Research Productivity Improve Research Outcomes III - X Measures Number of applications Enrollment Number of Degrees conferred Passage rate Targets * * * * * * * * * * * Grade point averages Standard examination scores Fulfilled requirements % retained % promoted % graduated % certified/licensed ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ * Amount of external funding * NIH funding * Comparative ranking ___ ___ ___ * * * * * ___ ___ ___ ___ ___ Number of new grants Dollar amount of new grants Number of research studies Number of publications Presentations per Faculty 36 DMAIC: Define the Project Define the project’s purpose and scope. Collect background information on the process and your customers’ needs and requirements. As an example project, let’s focus on the Full-Time Instructional Faculty (FTI) Turnover Rate metric … IV - Continuously Enhance the Quality of Faculty and Staff Improve Recruitment * Incentive packages * Time to fill open reqs ___ ___ Improve Retention * Competitive salaries * Tenure status * Turnover rate ___ ___ ___ Definition: Number of full-time instructional faculty (FTI) who left during a fiscal year (July 1 - June 30) divided by the total number of FTI faculty present as of June 30 of the prior fiscal year. Source: 37 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. MCG Faculty Turnover Rate 20 15 % Turnover Most problems can be easily expressed as a line graph showing the current trend. 10 5 0 91 9 1 92 9 1 93 9 1 94 9 1 95 9 1 96 9 1 97 9 1 98 9 1 99 9 1 MCG Turnover 00 0 2 01 0 2 02 0 2 03 0 2 04 0 2 05 0 2 Trendline 38 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. A Control Chart is used to detect and monitor variation over time. This chart tells us that the process is unstable. 39 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. Stop! Wait a minute! We had an early retirement program in 2001 and 2002, where we planned to have a high faculty turnover rate. What if we were to flag those years as “special causes” and remove them from our measurement? Okay, let’s see … 40 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. (excluding early retirement years 2001-2002) 20 15 10 5 MCG Turnover 20 05 20 04 20 03 20 00 19 99 19 98 19 97 19 96 19 95 19 94 19 93 19 92 0 19 91 But is the process stable? 1991-2005 Faculty Turnover Rate % Turnover If we remove the “special cause” early retirement program years of 2001 2002, our trend is actually downward. Trendline 41 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. The Control Chart still indicates an unstable process with points too close to the Upper and Lower Control Limits. But is the process capable of meeting specifications? 42 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. A Histogram measures the process’s capability of meeting the customer’s specifications. Our process is not capable, as there is too much variation. The Target and Customer Specification values are examples based on peer reports. 43 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. Now that we have seen that our Faculty Turnover process is both unstable and incapable of meeting specifications, let’s take a closer look at the year 2005… 44 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. Calculating Sigma Value Worksheet Determine the number of defect opportunities per unit Determine the number of units 2. processed Determine the total number of 3. defects made 1. 4. Calculate Defects per Opportunity 5. Calculate Defects per Million Opportunities 6. Calculate Yield 7. Lookup Sigma in the Sigma Table [=NORMSINV(Yield)+1.5] O = 1 N = 647 = Fiscal Year End 2004 Faculty D = 64 = Faculty Terminations during 2005 DPO = D N*O= = 0.098918 DPMO = DPO X 1M = 98,918 Yield = (1 - DPO) x 100 = Sigma Value = 90.108% 2.79 = 2005 Faculty Turnover (9.89%) = % of Units (Faculty) which went through the process (Fiscal Year) without a defect (Termination) = 2005 Faculty Turnover Sigma In Good To Great, author Jim Collins mentions the need for a BHAG or Big Hairy Audacious Goal. Using Six Sigma as a guide, you can measure your current performance and set a BHAG of reaching the next level sigma. 45 DMAIC: Measure the Current Situation Gather information on the current situation to provide a clearer focus for your improvement effort. A Pareto Chart helps you break down a big problem into its parts and identify which are the most important. Terminations 64 56 48 40 32 24 16 8 0 86% 80% 70% 98% 95% 91% 100% 80% 52% 60% 30% 19 40% 14 20% 12 6 4 3 3 2 1 0% Co lle gi at e Em In pl vo oy lu m nt en ar t y El N se on .. Vo R . ea lu p nt po ar in y tm Tr Vo en an lu t sf n er ta re ry d O to th Cl er in ic al Vo St lu at nt us ar y Vo Te m lu nt po ar ra y ry Re si Vo gn lu at nt io ar ns y Re In tir vo em lu en nt ts Vo ar y lu D nt ec ar ea y se Pr d iv at e Pr ac tic e lu nt ar y Vo “Voluntary Collegiate Employment Elsewhere” caused 30% of the Faculty turnover, and “Involuntary NonReappointment” caused 22%. 2005 MCG Faculty Turnover Reasons Pareto Principle: 80% of the problems are caused by 20% of the contributors. 46 DMAIC: Analyze to Identify Causes Identify the root cause of defects. Confirm them with data. An Ishikawa (Fishbone) Cause-and-Effect diagram is used to identify potential causes of the problem. Resources Process/Methods Why? Why? Why? Why? Why? Why? Problem Statement Why? Why? Why? Why? Why? Why? Why? Why? People During 2005, "Voluntary Collegiate Employment Elsewhere" accounted for 30% of Faculty Turnover. Why? Why? Technology 47 DMAIC: Improve Develop, try out, and implement solutions that address the root causes. Use data to evaluate results for the solutions and the plans used to carry them out. A Countermeasures chart is used to identify potential solutions and rank them for implementation. Feasibility: 1-low, 5-high 1-Expensive & Difficult to implement 5-Inexpensive and easy to implement Value ($/period) Action (Who?) Specific Actions Overall Countermeasure/ Proposed Solutions Effectiveness Root Cause Feasibility Problem Statement: During 2005, "Voluntary Collegiate Employment Elsewhere" accounted for 30% of Faculty Turnover. 0 0 0 0 0 0 0 0 0 0 Effectiveness: 1-low, 5-high 1-Not very effective 5-Very Effective 48 DMAIC: Control Maintain gains that you have achieved by standardizing your work methods or processes. Anticipate future improvements and make plans to preserve the lessons learned from this improvement effort. After Before Before } A1 A2 A3 A4 A2 A1 Improvement A3 4. Calculate Defects per Opportunity 5. Calculate Defects per Million Opportunities 6. Calculate Yield 7. Lookup Sigma in the Sigma Table [=NORMSINV(Yield)+1.5] }Remaining Gap A4 Countermeasures implemented = 1 1 N = 647 647 D = 64 7 DPO = D N*O= = 0.098918 0.010819 DPMO = DPO X 1M = 98,918 10,819 90.108% 98.918% 2.79 3.80 Yield = (1 - DPO) x 100 = = Target After O Sigma Value Good }Improvement Calculating Sigma Value Worksheet Before Determine the number of defect 1. opportunities per unit Determine the number of units 2. processed Determine the total number of 3. defects made After 49 To Recapitulate Six Sigma • Define – Choose a significant process • Measure – Track the output of that process • Analyze – Determine the causes of variability within the process • Improve – Minimize the variability • Control – Stabilize the process Remember: Minimize variability, increase quality. Increase quality, decrease costs! 50 QUESTIONS? 51