Design Report for Formula SAE Drivetrain

advertisement

Design Report for Formula SAE

Drivetrain

F11-77-FSAE

4/19/2012

SIUC

FORMULA

Racing

2012

Prepared by Saluki Engineering Team #77

Eric Schackmann (Project Manager)

Skyler Johnson

Dustin Kull

Danny Grohmann

Aaron Zscheck

Kathy Grimes

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Design Report for Formula SAE

Drivetrain

From:

Saluki Engineering Company

Engineering Resource Center

College of Engineering

Carbondale, IL 62901

(618)-553-0396

Formula SAE Team #77

Project: F11-77-FSAE

Prepared by:

Eric Schackmann (Project Manager)

Skyler Johnson

Dustin Kull

Danny Grohmann

Aaron Zscheck

Kathy Grimes

4/19/201

Transmittal Letter

Saluki Engineering Company

Southern Illinois University Carbondale

College of Engineering - Mailcode 6603

Carbondale, IL 62901-6604

eschack@siu.edu

Department of Mechanical Engineering

Southern Illinois University Carbondale

Carbondale, IL 62901-6603

(618)-453-7031

Dear Dr. A. Weston:

On behalf of our team, I would like to thank you for giving us the opportunity to design and

build this project. We believe that we have met all of you criteria and you will be satisfied with

our work.

The racecar built for the 2012 Formula SAE competition includes an optimized intake system

made from carbon fiber to reduce weight, an exhaust that has been re-routed to the side of the car

and satisfies the noise level requirement, a traction control system, and a digital dashboard

display.

Items that have also been designed are an oil pan that allows the engine to be mounted lower and

a pneumatic shifting apparatus.

Thank you again for selecting our team for this project. It was a pleasure working with you.

Sincerely,

Eric Schackmann

Project Manager, Formula SAE

Saluki Engineering Company

1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Acknowledgments

The Saluki Engineering Company Team 77 would like to sincerely thank the individuals and

groups that have helped us on our design of the quarter scale formula one racecar.

Dr. Kanchan Mondal from the ME Department for his guidance, expertise, and

funding.

Dr. Glafkos Galanos, ECE Department Chair, for providing funding that allowed

us to complete our project.

Tim Attig in the ME Machine Shop for assistance in machining components and

use of shop.

Center for Advanced Friction Studies for our recognition of our project and

funding.

Dr. Rasit Koc, ME Department Chair, for his enthusiasm and funding of our

project.

Dr. Lizette Chevalier, Acting Associate Dean, for her enthusiasm and funding of

our project.

Dr. Haibo Wang from the ECE Department for assistance in grounding issues of

the Arduino.

Dr. Alan Weston, Dr. Kay Purcell, and Frances Harackiewicz for their guidance

us on a proper senior design project.

2

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Table of Contents

Transmittal Letter (SJ)

1

Acknowledgements (DG)

2

Executive Summary (AZ)

4

Project Description (ES)

5

Cost Estimates (ES) (SJ)

7

Schedule of Construction (ES)

8

Conclusion and Recommendations (AZ)

9

Appendices

Arduino ADK Technical Specifications

1.1

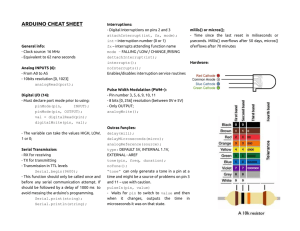

Programming code: Dashboard and traction control (KG)

2.1

Programming code: Shifting (KG)

3.1

FSAE Rules and Regulations

4.1

References

4.5

Subsystem Descriptions

Intake Manifold (AZ)

A1

Exhaust (ES)

B1

Oil Pan (DK)

C1

Axles (DK)

D1

Shifting Apparatus (DG)

E1

Dashboard (KG)

F1

Traction Control (SJ)

G1

3

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Executive Summary

The design outlined in this report pertains to the FSAE drivetrain. The prototype drivetrain was

completed in April of 2012. The subsystems included in this project are the intake manifold,

exhaust, oil pan, axles, digital dashboard, traction control system, and a pneumatic shifting

system. The goal was to increase the airflow through the engine by improving the intake and

exhaust efficiency, thus increasing power. We will also be reducing the weight of the axles,

lowering the overall weight of the vehicle and the rotating mass that the engine needs to turn.

The oil pan design will allow the engine to be placed lower giving a much more ideal center of

gravity, allowing for better handling. The traction control system will allow for maximum power

transfer to the wheels, and reducing wheel slip giving the driver better control of the vehicle. The

pneumatic shifting system is also meant to give the driver better control of the vehicle, with

faster shift times and allowing the driver to keep both hands on the wheel at all times.

The total cost of the drivetrain system as a prototype is $3,174.92 and there is a breakdown of

each of the subsystems in the cost report.

The report contains a detailed description of the overall system, a breakdown of each subsystem

and its functionality, and a financial report detailing what each subsystem cost.

4

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Project Description

The proposed project was to build an improved drivetrain for the SIU Formula SAE Racing

racecar. The car is to be entered in the 2012 competition that will be held in May at Michigan

Motor Speedway. At last year’s competition, SIUC placed 60th overall. It is the 2012 team’s goal

to improve on the design of the racecar to propel us to a Top 25 finish.

The racecar built for the 2012 Formula SAE competition includes an optimized intake system, an

exhaust that has been re-routed to the side of the car, a traction control system, and a digital

dashboard display. Items that have also been designed are an oil pan that allows the engine to be

mounted lower and a pneumatic shifting apparatus

The intake manifold has been constructed from carbon fiber which is very lightweight and

reduces the overall weight of the car. The rerouted exhaust and redesigned oil pan allows the

engine to be mounted lower, thus reducing the racecar’s center of gravity. The traction control

system reduces power lost due to wheel slip. The digital display gives the driver crucial

information about the car’s performance. Lastly, the pneumatic shifting apparatus provides fast,

accurate shifts while allowing the driver to keep both hands on the wheel.

Upon completion of this project, a fully functional FSAE racecar was built using the drivetrain

designed. Our goals, which were to increase the power output of the engine and to improve the

overall performance and ergonomics of the vehicle, have been satisfied.

5

6

Cost Estimates

The total material costs for the final product are estimated at $3,174.92. Various manufacturing

techniques were used to create these products.

Cost of Prototype

Subsystem

Amount

Intake

$ 266.34

Exhaust

$ 575.39

Oil Pan

$ 153.92

Axles

$ 797.00

Shifting Apparatus $ 656.16

Dashboard

$ 366.47

Traction Control

$ 359.64

Total

$ 3,174.92

Cost to Implement

Subsystem

Amount

Intake

$ 266.34

Exhaust

$ 583.39

Oil Pan

$ 153.92

Axles

$ 797.00

Shifting Apparatus $ 663.26

Dashboard

$ 75.46

Traction Control

$ 359.64

Total

$ 2,899.01

7

Schedule of Construction

Description

Order intake Parts

Order Exhaust Parts

Order Shifter Parts

Order Digital Display Parts

Orders Traction Control Parts

Machine Aluminum For Intake

Cut Pipe and Mandrel Bends to Specification (Exhaust)

Machine Components for Shifting Apparatus

Assembling Components for Shifting Apparatus

Adhere Aluminum Parts Together (Intake)

Tack Pipes into place (Exhaust)

Lay Carbon Fiber (Intake)

Weld Pipes (Exhaust)

Attach Slip on Muffler (Exhaust)

Tack Pipes into place (Exhaust)

Machine Timing Wheels (Traction Control)

Write Code (Digital Display)

Soldering, Write Code, and mount circuit board (Traction Control)

Mount Circuit Board (Digital Display)

Adhere Aluminum to Carbon Fiber (Intake)

Final Completion

Start

Stop

Date

Date

4-Jun

8-Jun

4-Jun

8-Jun

4-Jun

8-Jun

4-Jun

15-Jun

4-Jun

15-Jun

11-Jun

12-Jun

11-Jun

12-Jun

8-Jun

11-Jun

11-Jun

12-Jun

12-Jun

13-Jun

12-Jun

13-Jun

13-Jun

22-Jun

13-Jun

14-Jun

14-Jun

14-Jun

15-Jun

18-Jun

15-Jun

18-Jun

18-Jun

19-Jun

18-Jun

19-Jun

19-Jun

19-Jun

22-Jun

23-Jun

23-Jun

Time and Dates are based on a 40 hour work week. Any system that is not accounted for did not

present sufficient data for schedule

7

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Conclusion and Recommendations

Many of the engineering problems encountered were due to fitting components within the frame.

The frame was not completely designed when work began on this project, nor did we have a

complete rendering of the engine to accompany the model of the frame. This caused a problem

because the frame fits so tightly around the engine and the driver, and not all the systems had

enough room to fit in the confined space. The pneumatic shifting system was unable to fit on the

car because the cylinders could not fit on the engine. The initial intake manifold and the

dashboard display had to be modified to fit within the space allowed by the frame.

For the electrical systems on the traction control, shifting system and the dash board display we

would have used printed circuit boards if we had more time. The printed circuit boards are easier

to solder and look much more professional. In addition, given more time on the Arduino board,

we would have developed a better filtering circuit to eliminate noise issues as the board inputs

are extremely sensitive. We could use the opto-isolators to protect the board from spikes in

voltage that could destroy the board. Another problem with the Arduino board is that it is

currently powered by a small 9V battery that is not secured very well. We see now that it would

be better to have wired it to the vehicle battery.

We did run into some problems with designing the axles. This problem came from the fact we

were reusing the hubs from last year, which limited what we could do as far as the diameter of

the axles. This and our inability to hollow the axles were due to limited funding.

9

Appendices

Arduino ADK[1]

Arduino ADK R3 Front

Arduino ADK R3 Back

Arduino ADK Front

Arduino ADK Back

Overview

The Arduino ADK is a microcontroller board based on the ATmega2560 (datasheet). It has a

USB host interface to connect with Android based phones, based on the MAX3421e IC. It has 54

digital input/output pins (of which 14 can be used as PWM outputs), 16 analog inputs, 4 UARTs

(hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, an ICSP

header, and a reset button.

The ADK is based on the Mega 2560.

1.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Similar to the Mega 2560 and Uno, it features an ATmega8U2 programmed as a USB-to-serial

converter.

Revision 2 of the MegaADK board has a resistor pulling the 8U2 HWB line to ground, making it

easier to put into DFU mode.

Revision 3 of the board has the following new features:

1.0 pinout: added SDA and SCL pins that are near to the AREF pin and two other new

pins placed near to the RESET pin, the IOREF that allow the shields to adapt to the

voltage provided from the board. In future, shields will be compatible both with the board

that use the AVR, which operate with 5V and with the Arduino Due that operate with

3.3V. The second one is a not connected pin that is reserved for future purposes.

Stronger RESET circuit.

For information on using the board with the Android OS, see Google's ADK documentation.

Schematic, Reference Design & Pin Mapping

EAGLE files: Arduino_ADK-Mega_2560-Rev3-reference-design.zip

Schematic: Arduino ADK_Mega_2560-schematic.pdf

Pin Mapping: PinMap2560 page

Summary

Microcontroller

ATmega2560

Operating Voltage

5V

Input Voltage (recommended) 7-12V

Input Voltage (limits)

6-20V

Digital I/O Pins

54 (of which 14 provide PWM output)

Analog Input Pins

16

DC Current per I/O Pin

40 mA

DC Current for 3.3V Pin

50 mA

Flash Memory

256 KB of which 8 KB used by bootloader

SRAM

8 KB

EEPROM

4 KB

Clock Speed

16 MHz

1.2

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Power

The Arduino ADK can be powered via the USB connection or with an external power supply.

The power source is selected automatically.

External (non-USB) power can come either from an AC-to-DC adapter (wall-wart) or battery.

The adapter can be connected by plugging a 2.1mm center-positive plug into the board's power

jack. Leads from a battery can be inserted in the Gnd and Vin pin headers of the POWER

connector.

NB: Because the ADK is a USB Host, the phone will attempt to draw power from it when it needs

to charge. When the ADK is powered over USB, 500mA total is available for the phone and

board.The external power regulator can supply up to 1500mA. 750mA is available for the phone

and ADK board. An additional 750mA is allocated for any actuators and sensors attached to the

board. A power supply must be capable of providing 1.5A to use this much current.

The board can operate on an external supply of 5.5 to 16 volts. If supplied with less than 7V,

however, the 5V pin may supply less than five volts and the board may be unstable. If using

more than 12V, the voltage regulator may overheat and damage the board. The recommended

range is 7 to 12 volts.

The power pins are as follows:

VIN. The input voltage to the Arduino board when it's using an external power source (as

opposed to 5 volts from the USB connection or other regulated power source). You can

supply voltage through this pin, or, if supplying voltage via the power jack, access it

through this pin.

5V. This pin outputs a regulated 5V from the regulator on the board. The board can be

supplied with power either from the DC power jack (7 - 12V), the USB connector (5V),

or the VIN pin of the board (7-12V). Supplying voltage via the 5V or 3.3V pins bypasses

the regulator, and can damage your board. We don't advise it.

3V3. A 3.3 volt supply generated by the on-board regulator. Maximum current draw is 50

mA.

GND. Ground pins.

Memory

The ADK has 256 KB of flash memory for storing code (of which 8 KB is used for the

bootloader), 8 KB of SRAM and 4 KB of EEPROM (which can be read and written with the

EEPROM library).

Input and Output

Each of the 50 digital pins on the ADK can be used as an input or output, using pinMode(),

digitalWrite(), and digitalRead() functions. They operate at 5 volts. Each pin can provide or

receive a maximum of 40 mA and has an internal pull-up resistor (disconnected by default) of

20-50 kOhms. In addition, some pins have specialized functions:

1.3

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Serial: 0 (RX) and 1 (TX); Serial 1: 19 (RX) and 18 (TX); Serial 2: 17 (RX) and 16

(TX); Serial 3: 15 (RX) and 14 (TX). Used to receive (RX) and transmit (TX) TTL

serial data. Pins 0 and 1 are also connected to the corresponding pins of the ATmega8U2

USB-to-TTL Serial chip.

External Interrupts: 2 (interrupt 0), 3 (interrupt 1), 18 (interrupt 5), 19 (interrupt

4), 20 (interrupt 3), and 21 (interrupt 2). These pins can be configured to trigger an

interrupt on a low value, a rising or falling edge, or a change in value. See the

attachInterrupt() function for details.

PWM: 0 to 13. Provide 8-bit PWM output with the analogWrite() function.

SPI: 50 (MISO), 51 (MOSI), 52 (SCK), 53 (SS). These pins support SPI

communication using the SPI library. The SPI pins are also broken out on the ICSP

header, which is physically compatible with the Uno, Duemilanove and Diecimila.

USB Host: MAX3421E. The MAX3421E communicate with Arduino with the SPI bus.

So it uses the following pins:

o Digital: 7 (RST), 50 (MISO), 51 (MOSI), 52 (SCK).

NB:Please do not use Digital pin 7 as input or output because is used in the

communication with MAX3421E

o Non broken out on headers: PJ3 (GP_MAX), PJ6 (INT_MAX), PH7 (SS).

LED: 13. There is a built-in LED connected to digital pin 13. When the pin is HIGH

value, the LED is on, when the pin is LOW, it's off.

TWI: 20 (SDA) and 21 (SCL). Support TWI communication using the Wire library.

Note that these pins are not in the same location as the TWI pins on the Duemilanove or

Diecimila.

The ADK has 16 analog inputs, each of which provide 10 bits of resolution (i.e. 1024 different

values). By default they measure from ground to 5 volts, though is it possible to change the

upper end of their range using the AREF pin and analogReference() function.

There are a couple of other pins on the board:

AREF. Reference voltage for the analog inputs. Used with analogReference().

Reset. Bring this line LOW to reset the microcontroller. Typically used to add a reset

button to shields which block the one on the board.

Communication

The Arduino ADK has a number of facilities for communicating with a computer, another

Arduino, or other microcontrollers. The ATmega2560 provides four hardware UARTs for TTL

(5V) serial communication. An ATmega8U2 on the board channels one of these over USB and

provides a virtual com port to software on the computer (Windows machines will need a .inf file,

but OSX and Linux machines will recognize the board as a COM port automatically. The

Arduino software includes a serial monitor which allows simple textual data to be sent to and

from the board. The RX and TX LEDs on the board will flash when data is being transmitted via

the ATmega8U2/16U2 chip and USB connection to the computer (but not for serial

communication on pins 0 and 1).

A SoftwareSerial library allows for serial communication on any of the ADK's digital pins.

1.4

The ATmega2560 also supports TWI and SPI communication. The Arduino software includes a

Wire library to simplify use of the TWI bus; see the Wire library for details. For SPI

communication, use the SPI library.

The USB host interface given by MAX3421E IC allows the ADK Arduino to connect and

interact to any type of device that have a USB port. For example, allows you to interact with

many types of phones, controlling Canon cameras, interfacing with keyboard, mouse and games

controllers as Wiimote and PS3.

Programming

The Arduino ADK can be programmed with the Arduino software (download). For details, see

the reference and tutorials.

The ATmega2560 on the Arduino ADK comes preburned with a bootloader (the same on Mega

2560) that allows you to upload new code to it without the use of an external hardware

programmer. It communicates using the original STK500v2 protocol (reference, C header files).

You can also bypass the bootloader and program the microcontroller through the ICSP (InCircuit Serial Programming) header; see these instructions for details.

The ATmega8U2 firmware source code is available in the Arduino repository. The ATmega8U2

is loaded with a DFU bootloader, which can be activated by:

On Rev1 boards: connecting the solder jumper on the back of the board (near the map of

Italy) and then resetting the 8U2.

On Rev2 or later boards: there is a resistor that pulling the 8U2/16U2 HWB line to

ground, making it easier to put into DFU mode. You can then use Atmel's FLIP software

(Windows) or the DFU programmer (Mac OS X and Linux) to load a new firmware. Or

you can use the ISP header with an external programmer (overwriting the DFU

bootloader). See this user-contributed tutorial for more information.

Automatic (Software) Reset

Rather than requiring a physical press of the reset button before an upload, the Arduino ADK is

designed in a way that allows it to be reset by software running on a connected computer. One of

the hardware flow control lines (DTR) of the ATmega8U2 is connected to the reset line of the

ATmega2560 via a 100 nanofarad capacitor. When this line is asserted (taken low), the reset line

drops long enough to reset the chip. The Arduino software uses this capability to allow you to

upload code by simply pressing the upload button in the Arduino environment. This means that

the bootloader can have a shorter timeout, as the lowering of DTR can be well-coordinated with

the start of the upload.

This setup has other implications. When the ADK is connected to either a computer running Mac

OS X or Linux, it resets each time a connection is made to it from software (via USB). For the

following half-second or so, the bootloader is running on the ADK. While it is programmed to

ignore malformed data (i.e. anything besides an upload of new code), it will intercept the first

few bytes of data sent to the board after a connection is opened. If a sketch running on the board

receives one-time configuration or other data when it first starts, make sure that the software with

which it communicates waits a second after opening the connection and before sending this data.

10

The ADK contains a trace that can be cut to disable the auto-reset. The pads on either side of the

trace can be soldered together to re-enable it. It's labeled "RESET-EN". You may also be able to

disable the auto-reset by connecting a 110 ohm resistor from 5V to the reset line; see this forum

thread for details.

USB Overcurrent Protection

The Arduino ADK has a resettable polyfuse that protects your computer's USB ports from shorts

and overcurrent. Although most computers provide their own internal protection, the fuse

provides an extra layer of protection. If more than 500 mA is applied to the USB port, the fuse

will automatically break the connection until the short or overload is removed.

Physical Characteristics and Shield Compatibility

The maximum length and width of the ADK PCB are 4 and 2.1 inches respectively, with the

USB connector and power jack extending beyond the former dimension. Three screw holes allow

the board to be attached to a surface or case. Note that the distance between digital pins 7 and 8

is 160 mil (0.16"), not an even multiple of the 100 mil spacing of the other pins.

The ADK is designed to be compatible with most shields designed for the Uno, Diecimila or

Duemilanove. Digital pins 0 to 13 (and the adjacent AREF and GND pins), analog inputs 0 to 5,

the power header, and ICSP header are all in equivalent locations. Further the main UART

(serial port) is located on the same pins (0 and 1), as are external interrupts 0 and 1 (pins 2 and 3

respectively). SPI is available through the ICSP header on both the ADK and Duemilanove /

Diecimila. Please note that I2C is not located on the same pins on the ADK (20 and 21) as the

Duemilanove / Diecimila (analog inputs 4 and 5).

10

Programming Code: Dashboard display and traction control

#include <stdio.h>

//constant pin input and outputs

const double Analog_Tachometer = 14; // inputs voltage level which tells the RPM

const int pin_T0 = 15; // output Aqua LEDs - 10000 - 10999 rpm

const int pin_T1 = 16; // output Green LEDs - 11000 - 11999 rpm

const int pin_T2 = 17; // output Orange LEDs - 12000 - infinity rpm

const int pin_S0 = 19; // output A - Bit 0 of 16 seg display 1 of ticksRev

const int pin_S1 = 20; // output B - Bit 1 of 16 seg display 1 of ticksRev

const int pin_S2 = 21; // output C - Bit 2 of 16 seg display 1 of ticksRev

const int pin_S3 = 22; // output D - Bit 3 of 16 seg display 1 of ticksRev

const int pin_S4 = 23; // output A - Bit 0 of 16 seg display 2 of ticksRev

const int pin_S5 = 24; // output B - Bit 1 of 16 seg display 2 of ticksRev

const int pin_S6 = 25; // output C - Bit 2 of 16 seg display 2 of ticksRev

const int pin_S7 = 26; // output D - Bit 3 of 16 seg display 2 of ticksRev

const int ticksRev1 = 27; // inputs a high if hits a tick on front wheel left

const int ticksRev2 = 28; // inputs a high if hits a tick on front wheel right

const int ticksRev3 = 39; // inputs a high if hits a tick on rear wheel left

const int ticksRev4 = 40; // inputs a high if hits a tick on rear wheel right

const double Analog_Gear1 = 29; //inputs which gear it is in

const int pin_G0 = 30; // output A - Bit 0 of 16 seg display Gear

const int pin_G1 = 31; // output B - Bit 1 of 16 seg display Gear

const int pin_G2 = 32; // output C - Bit 2 of 16 seg display Gear

const int pin_G3 = 33; // output D - Bit 3 of 16 seg display Gear

const int pin_G4 = 34; // output wire to High for Neutral (the \ part of the N) of the 16 seg

display Gear

const int Warn1 = 35; // input of oil warning

const int Warn2 = 36; //input of coolant warning

const int pin_Warn1 = 37; //output flashing heat warning

const int pin_Warn2 = 38; //output flashing Pressure cool warning

//variables for things that are not input or outputs

double anTach = 0.0;

int digTicksRev = 0;

double anGear1 = 0.0;

int warnOil = 0;

int warnCoolant = 0;

int MPH = 0;

int t1 = 0; //Sensing period

int t2 = 0;

int t3 = 0;

int t4 = 0;

double N_t1 = 0.0; //ticks per period

double N_t2 = 0.0;

2.1

double N_t3 = 0.0;

double N_t4 = 0.0;

int P = 20; // number of teeth per rotation = 20

double B = 0.0; //Wheel rotation in one period

double n = 0.0; //rotations per second

double w = 0.0; //radians per second

double r = 9.75; //radius of wheel = 9.75 inches

double v = 0.0; // velocity of wheel feet per second

double v_rr = 0.0; //rear right wheel

double v_rl = 0.0; //rear left wheel

double v_fr = 0.0; //front right

double v_fl = 0.0; // front left

void setup() {

pinMode(pin_T0, OUTPUT);

pinMode(pin_T1, OUTPUT);

pinMode(pin_T2, OUTPUT);

pinMode(pin_S0, OUTPUT);

pinMode(pin_S1, OUTPUT);

pinMode(pin_S2, OUTPUT);

pinMode(pin_S3, OUTPUT);

pinMode(pin_S4, OUTPUT);

pinMode(pin_S5, OUTPUT);

pinMode(pin_S6, OUTPUT);

pinMode(pin_S7, OUTPUT);

pinMode(pin_G0, OUTPUT);

pinMode(pin_G1, OUTPUT);

pinMode(pin_G2, OUTPUT);

pinMode(pin_G3, OUTPUT);

pinMode(pin_G4, OUTPUT);

pinMode(pin_Warn1, OUTPUT);

pinMode(pin_Warn2, OUTPUT);

pinMode(Analog_Tachometer, INPUT);

pinMode(ticksRev1, INPUT);

pinMode(ticksRev2, INPUT);

pinMode(Analog_Gear1, INPUT);

pinMode(Warn1, INPUT);

pinMode(Warn2, INPUT);

Serial.begin(115200); //baud rate set to max

}

//All Functions-----------------------------------------------------//ticks and time to speed

double v_ftsec(double N_t, int T_o) {

2.2

int P = 20;

double pi = 3.14159265359;

double r = 9.75;

B = N_t/P;

n = B/T_o;

w = n*2*pi;

v = w*r; //for each wheel

return v;

}

//function to change the analog voltage to a number

//Depend on input voltage and what the total voltage it could

int ana_to_dig(double ana, int anaVoltTotal, double mult) {

int digi = 0;

//formula to change to a digital number is (mult)*ana/anaVoltTotal

digi = (mult)*ana/anaVoltTotal;

return digi;

}

//dec to binary

char *dectoBinary(int dec) {

int c, d, count;

char *pointer;

count = 0;

pointer = (char*)malloc(4+1);

if( pointer == NULL ) {

exit(1);

}

for(c= 3; c>= 0; c--) {

d = dec>>c;

if( d & 1) {

*(pointer + count) = 1 + '0';

} else {

*(pointer + count) = '\0';

}

count++;

}

*(pointer+count) = '\0';

return pointer;

2.3

}

//Warning lights (when to turn on)

void flash_warn(int whichWarn) {

if(whichWarn==0) {

digitalWrite(pin_Warn1, HIGH);

delay(150);

digitalWrite(pin_Warn1, LOW);

} else if(whichWarn == 1) {

digitalWrite(pin_Warn2, HIGH);

delay(150);

digitalWrite(pin_Warn2, LOW);

} else if(whichWarn == 2) {

digitalWrite(pin_Warn1, HIGH);

digitalWrite(pin_Warn2, HIGH);

delay(150);

digitalWrite(pin_Warn1, LOW);

digitalWrite(pin_Warn2, LOW);

} else {

digitalWrite(pin_Warn1, LOW);

digitalWrite(pin_Warn2, LOW);

}

}

//End Function Group-------------------------------------------------void loop() {

N_t1 = analogRead(ticksRev1);

N_t2 = analogRead(ticksRev2);

N_t3 = analogRead(ticksRev3);

N_t4 = analogRead(ticksRev4);

double ticksRev = (N_t1 + N_t2) / 2;

anTach = analogRead(Analog_Tachometer);

digTicksRev = digitalRead(ticksRev);

anGear1 = analogRead(Analog_Gear1);

warnOil = digitalRead(Warn1);

warnCoolant = digitalRead(Warn2);

//SKYLER INFO

//digtickscount = number of ticks in 1 second

int millisTickstart = millis();

int digtickscount = 0;

2.4

while ((millis() - millisTickstart) < 1000) {

if (digTicksRev == HIGH) {

digtickscount++;

}

}

//Traction Control System

/*P = 20; // number of teeth per rotation = 20

B //Wheel rotation in one period

n //rotations per second

w //radians per second

r //radius of wheel = 9.75 inches

v // velocity of wheel feet per second

*/

// actual speed of car

v_av = (v_fr + v_fl)/2

// choose fastest rear wheel v_r

if (v_rr > v_rl){

vr = v_rr

} else {

vr = v_rl;

}

// calculating slip

s = vr - v_av;

// if v_av < 10 & s > 3

// output 1

// if v_av >10 & s > 3

// output 2

//Digital Speed Portion

double MPH_with20 = v_av*.6818181818;

MPH = round(MPH_with20);

//Serial.write("the output is %d", MPH);

2.5

char *pointer1;

char *pointer10;

int place_1 = MPH % 10;

int place_10 = MPH/10;

pointer10 = dectoBinary(place_10);

pointer1 = dectoBinary(place_1);

digitalWrite(pin_S0,(int)pointer1[3]);

digitalWrite(pin_S1,(int)pointer1[2]);

digitalWrite(pin_S2,(int)pointer1[1]);

digitalWrite(pin_S3,(int)pointer1[0]);

digitalWrite(pin_S4,(int)pointer10[3]);

digitalWrite(pin_S5,(int)pointer10[2]);

digitalWrite(pin_S6,(int)pointer10[1]);

digitalWrite(pin_S7,(int)pointer10[0]);

//End Digital Speed Portion

//Begin Gear Portion

char * pointerGear;

int Gear = ana_to_dig(Analog_Gear1, 5, 2);

switch(Gear) {

case 2:

digitalWrite(pin_G0,LOW);

digitalWrite(pin_G1,LOW);

digitalWrite(pin_G2,LOW);

digitalWrite(pin_G3,LOW);

digitalWrite(pin_G4, HIGH);

break;

default :

pointerGear = dectoBinary(Gear);

digitalWrite(pin_G0,(int)pointerGear[3]);

digitalWrite(pin_G1,(int)pointerGear[2]);

digitalWrite(pin_G2,(int)pointerGear[1]);

digitalWrite(pin_G3,(int)pointerGear[0]);

digitalWrite(pin_G4, LOW);

}

//End Gear Portion

//Warning/Dummy Lights

int warn = 3;

if ((warnOil == HIGH) && (warnCoolant == HIGH)) {

warn = 2;

} else if((warnOil == HIGH) && (warnCoolant == LOW)) {

2.6

warn = 1;

} else if((warnOil == LOW) && (warnCoolant == HIGH)) {

warn = 0;

} else {

warn = 3;

}

flash_warn(warn);

//End Warning/Dummy Lights

//Begin RPM

long Tach = ana_to_dig(Analog_Tachometer, 5, 3000);

if (Tach<10000) {

digitalWrite(pin_T0, LOW);

digitalWrite(pin_T1, LOW);

digitalWrite(pin_T2, LOW);

} else if((Tach>=10000) &&(Tach<11000)) {

digitalWrite(pin_T0, HIGH);

digitalWrite(pin_T1, LOW);

digitalWrite(pin_T2, LOW);

}else if((Tach>=11000) &&(Tach<12000)) {

digitalWrite(pin_T0, HIGH);

digitalWrite(pin_T1, HIGH);

digitalWrite(pin_T2, LOW);

}else if(Tach>=12000) {

digitalWrite(pin_T0, HIGH);

digitalWrite(pin_T1, HIGH);

digitalWrite(pin_T2, HIGH);

}

//End RPM

}

//EOF keep to run file properly

2.7

Programming Code: Shifting

const int button_ShiftDown1 = 23; // the pin that the pushbutton is attached to

const int pin_SDS = 22; // SDS

const int button_SlowClutch1 = 35;

const int button_Clutch1 = 31;

const int pin_Cex = 30;

const int pin_Cin = 34;

const int button_Upshift1 = 27;

const int pin_sigIgnCut = 24;

const int pin_Upshift = 26;

//const int button_Neutral1 = 13;

// Variables

int button_ShiftDown = 0;

int button_SlowClutch = 0;

int button_Clutch = 0;

int button_Upshift = 0;

//int button_Neutral = 0;

int prevbutton_ShiftDown = 0; // previous state of the button

int prevbutton_Upshift = 0;

//int prevbutton_Neutral = 0;

int prevbutton_Clutch = 0;

int prevbutton_SlowClutch = 0;

boolean ShD = 'FALSE';

boolean NeT = 'FALSE';

boolean ClT = 'FALSE';

boolean SlC = 'FALSE';

boolean UpS = 'FALSE';

//NEEDED FOR DEBOUNCING BUTTONS DUE TO NOISE/EXCESS VIBRATION

long time_start_ShiftDown = 0; // the last time the output pin was toggled

long time_start_SlowClutch = 0; // the last time the output pin was toggled

long time_start_Clutch = 0; // the last time the output pin was toggled

long time_start_Neutral = 0; // the last time the output pin was toggled

long time_start_Upshift = 0; // the last time the output pin was toggled

long on_time_req = 60; // the debounce time; increase if the output flickers

void setup() {

pinMode(button_ShiftDown1, INPUT);

pinMode(button_SlowClutch1, INPUT);

pinMode(button_Upshift1, INPUT);

//pinMode(button_Neutral1, INPUT);

pinMode(button_Clutch1, INPUT);

pinMode(pin_SDS, OUTPUT);

3.1

pinMode(pin_Cex, OUTPUT);

pinMode(pin_Cin, OUTPUT);

pinMode(pin_sigIgnCut, OUTPUT);

pinMode(pin_Upshift, OUTPUT);

//pinMode(pin_Downshift, OUTPUT); //ONLY NON PNEUMATIC

Serial.begin(115200); //baud rate set to max

}

void clutch() {

digitalWrite(pin_Cin, HIGH);

digitalWrite(pin_Cex, HIGH);

Serial.write("Clutch");

}

void slowClutch() {

for(int i = 0; i<1075; i+=60) {

digitalWrite(pin_Cin, LOW);

digitalWrite(pin_Cex, HIGH);

delay(30);

digitalWrite(pin_Cex, LOW);

delay(30);

}

Serial.write("\nslow clutch");

clutch();

}

void shiftDown() {

digitalWrite(pin_Cin, HIGH);

digitalWrite(pin_Cex, HIGH);

delay(170);

digitalWrite(pin_SDS, HIGH);

delay(30);

digitalWrite(pin_SDS, LOW);

delay(50);

digitalWrite(pin_Cin, LOW);

digitalWrite(pin_Cex, LOW);

Serial.write("\nshift down");

}

void upShift() {

digitalWrite(pin_sigIgnCut, HIGH);

Serial.write("ECU = 1");

delay(60);

digitalWrite(pin_sigIgnCut, LOW);

3.1

Serial.write("ECU = 0");

digitalWrite(pin_Upshift, HIGH);

delay(30);

digitalWrite(pin_Upshift, LOW);

Serial.write("\nupshift");

}

/*

void neutral() {

digitalWrite(pin_sigIgnCut, HIGH);

delay(2000);

digitalWrite(pin_Upshift, HIGH);

digitalWrite(pin_sigIgnCut, LOW);

delay(10);

digitalWrite(pin_Upshift, LOW);

Serial.write("\nneutral");

}

*/

void loop() {

int reading_ShiftDown = digitalRead(button_ShiftDown1);

int reading_Clutch = digitalRead(button_Clutch1);

int reading_SlowClutch = digitalRead(button_SlowClutch1);

int reading_Upshift = digitalRead(button_Upshift1);

//int reading_Neutral = digitalRead(button_Neutral1);

//Clutch debounce

if (reading_Clutch != prevbutton_Clutch) {

Serial.write("\nClutch activated");

int readClutch[30] = {};

readClutch[0] = reading_Clutch;

int output = 1;

for (int i = 1; i <on_time_req; i++) {

readClutch[i] = digitalRead(button_Clutch1);

delay(2);

if ((output == readClutch[i]) && (output == 1)) {

output = 1;

} else {

output = 0;

}

}

if (output == 1) {

digitalWrite(button_Clutch, HIGH);

}

button_Clutch = output;

Serial.write("\nbutton_Clutch = ");

Serial.println(button_Clutch, 2);

3.1

}

//SlowClutch debounce

if (reading_SlowClutch != prevbutton_SlowClutch) {

Serial.write("\nSlowClutch activated");

int readSlowClutch[30] = {};

readSlowClutch[0] = reading_SlowClutch;

int output = 1;

for (int i = 1; i <on_time_req; i++) {

readSlowClutch[i] = digitalRead(button_SlowClutch1);

delay(2);

if ((output == readSlowClutch[i]) && (output == 1)) {

output = 1;

} else {

output = 0;

}

}

if (output == 1) {

digitalWrite(button_SlowClutch, HIGH);

}

button_SlowClutch = output;

Serial.write("\nbutton_SlowClutch = ");

Serial.println(button_SlowClutch, 2);

}

//Upshift debounce

if (reading_Upshift != prevbutton_Upshift) {

Serial.write("\nUpshift activated");

int readUpshift[30] = {};

readUpshift[0] = reading_Upshift;

int output = 1;

for (int i = 1; i <on_time_req; i++) {

readUpshift[i] = digitalRead(button_Upshift1);

delay(2);

if ((output == readUpshift[i]) && (output == 1)) {

output = 1;

} else {

output = 0;

}

}

if (output == 1) {

digitalWrite(button_Upshift, HIGH);

}

button_Upshift = output;

Serial.write("\nbutton_Upshift = ");

3.1

Serial.println(button_Upshift, 2);

}

//ShiftDown debounce

if (reading_ShiftDown != prevbutton_ShiftDown) {

Serial.write("\nShiftDown activated");

int readShiftDown[30] = {};

readShiftDown[0] = reading_ShiftDown;

int output = 1;

for (int i = 1; i <on_time_req; i++) {

readShiftDown[i] = digitalRead(button_ShiftDown1);

delay(2);

if ((output == readShiftDown[i]) && (output == 1)) {

output = 1;

} else {

output = 0;

}

}

if (output == 1) {

digitalWrite(button_ShiftDown, HIGH);

}

button_ShiftDown = output;

Serial.write("\nbutton_ShiftDown = ");

Serial.println(button_ShiftDown, 2);

}

UpS = (prevbutton_Upshift != button_Upshift);

ClT = (prevbutton_Clutch != button_Clutch);

//NeT = (prevbutton_Neutral != button_Neutral);

SlC = (prevbutton_SlowClutch != button_SlowClutch);

ShD = (prevbutton_ShiftDown != button_ShiftDown);

if(button_Clutch == HIGH) {

clutch();

button_ShiftDown = digitalRead(button_ShiftDown1);

if (button_ShiftDown == HIGH) {

digitalWrite(pin_SDS, HIGH);

delay(50);

digitalWrite(pin_SDS, LOW);

}

}else if((button_Clutch == LOW)&&(button_SlowClutch == HIGH)) {

slowClutch();

3.1

digitalWrite(pin_SDS, LOW);

while(true){

digitalWrite(pin_Cex, HIGH);

digitalWrite(pin_Cin, LOW);

button_Clutch = digitalRead(button_Clutch1);

if (button_Clutch == HIGH) {

break;

}

}

}else if((button_Clutch == LOW)&&(button_SlowClutch == LOW) && (button_ShiftDown

== HIGH) && ShD) {

shiftDown();

}else {

digitalWrite(pin_Cin, LOW);

digitalWrite(pin_Cex, LOW);

digitalWrite(pin_SDS, LOW);

}

if((button_Upshift == HIGH) && UpS) {

upShift();

}

/*

if((button_Upshift == HIGH) && (button_Neutral == HIGH) && NeT) {

neutral();

}else if((button_Upshift == HIGH) && (button_Neutral == LOW) && UpS) {

upShift();

}else if((button_Upshift == LOW) && (button_Neutral == HIGH) && NeT) {

neutral();

}else if((button_Upshift == LOW) && (button_Neutral == LOW)) {

}*/

prevbutton_ShiftDown = button_ShiftDown;

prevbutton_Upshift = button_Upshift;

//prevbutton_Neutral = reading_Neutral;

prevbutton_Clutch = button_Clutch;

prevbutton_SlowClutch = button_SlowClutch;

}

//EOF ALWAYS LEAVE THIS SPACE

3.1

FSAE Rules and Regulations[2]

Rules and Regulations For Intake [FS]

B8.4 Air Intake System

B8.4.1 Air Intake System Location

All parts of the engine air and fuel control systems (including the throttle or carburetor, and the

complete air intake system, including the air cleaner and any air boxes) must lie within the

surface defined by the top of the roll bar and the outside edge of the four tires. (See Figure

below).

B8.4.2 Any portion of the air intake system that is less than 350 mm (13.8 in) above the ground

must be shielded from side or rear impact collisions by structure built to Rule B3.24 or B.3.31 as

applicable.

Surface Envelope

B8.4.3 Intake Manifold – The intake manifold must be securely attached to the engine block or

cylinder head with brackets and mechanical fasteners. This precludes the use of hose clamps,

plastic ties, or safety wires. The use of rubber bushings or hose is acceptable for creating and

sealing air passages, but is not considered a structural attachment.

B8.4.4 Intake systems with significant mass or cantilever from the cylinder head must be

supported to prevent stress to the intake system. Supports to the engine must be rigid. Supports

to the frame or chassis must incorporate some isolation to allow for engine movement and

chassis flex.

4.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

B8.5 Throttle and Throttle Actuation

B8.5.1 Carburetor/Throttle Body

The car must be equipped with a carburetor or throttle body. The carburetor or throttle body may

be of any size or design.

B8.5.2 Throttle Actuation

The throttle must be actuated mechanically, i.e., via a cable or a rod system. The use of

electronic throttle control (ETC) or “drive-by-wire” is prohibited.

B8.5.3 The throttle cable or rod must have smooth operation, and must not have the possibility of

binding or sticking.

B8.5.4 The throttle actuation system must use at least two (2) return springs located at the

throttle body, so that the failure of any component of the throttle system will not prevent the

throttle returning to the closed position.

Note: Throttle Position Sensors (TPS) are NOT acceptable as return springs.

B8.5.5 Throttle cables must be at least 50.8 mm (2 in) from any exhaust system component and

out of the exhaust stream.

B8.5.6 A positive pedal stop must be incorporated on the throttle pedal to prevent over stressing

the throttle cable or actuation system.

B8.6 Intake System Restrictor

B8.6.1 In order to limit the power capability from the engine, a single circular restrictor must be

placed in the intake system between the throttle and the engine and all engine airflow must pass

through the restrictor.

B8.6.2 Any device that has the ability to throttle the engine downstream of the restrictor is

prohibited.

B8.6.3 The maximum restrictor diameters are:

- Gasoline fueled cars – 20.0 mm (0.7874 in)

- E-85 fueled cars – 19.0 mm (0.7480 in)

B8.6.4 The restrictor must be located to facilitate measurement during the inspection process.

B8.6.5 The circular restricting cross section may NOT be movable or flexible in any way, e.g.

the restrictor may not be part of the movable portion of a barrel throttle body.

B8.6.6 If more than one engine is used, the intake air for all engines must pass through the one

restrictor

Rules and Regulations-Drivetrain [FS]

B8.12 Transmission and Drive

Any transmission and drivetrain may be used.

B8.13 Drive Train Shields and Guards

B8.13.1 Exposed high-speed final drivetrain equipment such as Continuously Variable

Transmissions (CVTs), sprockets, gears, pulleys, torque converters, clutches, belt drives and

clutch drives, must be fitted with scatter shields in case of failure. The final drivetrain shield

must cover the chain or belt from the drive sprocket to the driven sprocket/chain wheel/belt or

pulley. The final drivetrain shield must end parallel to the lowest point of the chain

wheel/belt/pulley. (See figure below) Body panels or other existing covers are not acceptable

unless constructed from approved materials per B8.13.3 or B8.13.4.

Comment: Scatter shields are intended to contain drivetrain parts which might separate from the

car.

4.2

Percent Male with Helmet

B8.13.2 Perforated material may not be used for the construction of scatter shields.

B8.13.3 Chain Drive - Scatter shields for chains must be made of at least 2.66 mm (0.105 in)

steel (no alternatives are allowed), and have a minimum width equal to three (3) times the width

of the chain. The guard must be centered on the centerline of the chain and remain aligned with

the chain under all conditions.

B8.13.4 Non-metallic Belt Drive - Scatter shields for belts must be made from at least 3.0 mm

(0.120 in) Aluminum Alloy 6061-T6, and have a minimum width that is equal to 1.7 times the

width of the belt.

The guard must be centered on the centerline of the belt and remain aligned with the belt under

all conditions.

B8.13.5 Attachment Fasteners - All fasteners attaching scatter shields and guards must be a

minimum 6 mm Metric Grade 8.8 (1/4 in SAE Grade 5) or stronger.

B8.13.6 Finger Guards – Finger guards are required to cover any drivetrain parts that spin while

the car is stationary with the engine running. Finger guards may be made of lighter material,

sufficient to resist finger forces. Mesh or perforated material may be used but must prevent the

passage of a 12 mm (1/2 in) diameter object through the guard.

Comment: Finger guards are intended to prevent finger intrusion into rotating equipment while

the vehicle is at rest.

Rules and Regulations for Exhaust [FS]

ARTICLE 10: EXHAUST SYSTEM AND NOISE CONTROL

B10.1 Exhaust System General

B10.1.1 Exhaust Outlet

The exhaust must be routed so that the driver is not subjected to fumes at any speed considering

the draft of the car.

B10.1.2 The exhaust outlet(s) must not extend more than 45 cm (17.7 in) behind the centerline of

the rear axle, and shall be no more than 60 cm (23.6 in) above the ground.

4.3

B10.1.3 Any exhaust components (headers, mufflers, etc.) that protrude from the side of the

body in front of the main roll hoop must be shielded to prevent contact by persons approaching

the car or a driver exiting the car.

B10.2 Noise Measuring Procedure

B10.2.1 The sound level will be measured during a static test. Measurements will be made with a

free-field microphone placed free from obstructions at the exhaust outlet level, 0.5 m (19.68 in)

from the end of the exhaust outlet, at an angle of forty-five degrees (45°) with the outlet in the

horizontal plane. The test will be run with the gearbox in neutral at the engine speed defined

below. Where more than one exhaust outlet is present, the test will be repeated for each exhaust

and the highest reading will be used.

B10.2.2 The car must be compliant at all engine speeds up to the test speed defined below.

B10.2.3 If the exhaust has any form of movable tuning or throttling device or system, it must be

compliant with the device or system in all positions. The position of the device must be visible to

the officials for the noise test and must be manually operable by the officials during the noise

test.

B10.2.4 Test Speeds

The test speed for a given engine will be the engine speed that corresponds to an average piston

speed of 914.4 m/min (3,000 ft/min) for automotive or motorcycle engines, and 731.5 m/min

(2,400 ft/min) for “industrial engines”. The calculated speed will be rounded to the nearest 500

rpm. The test speeds for typical engines will be published by the organizers. An “industrial

engine” is defined as an engine which, according to the manufacturers’ specifications and

without the required restrictor, is not capable of producing more than 5 hp per 100cc. To have an

engine classified as “an industrial engine”, approval must be obtained from organizers prior to

the Competition.

B10.3 Maximum Sound Level

The maximum permitted sound level is 110 dBA, fast weighting.

B10.4 Noise Level Re-testing

At the option of the officials, noise can be measured at any time during the competition. If a car

fails the noise test, it will be withheld from the competition until it has been modified and repasses the noise test.

Rules and Regulations for Shifting Apparatus

ARTICLE 13: COMPRESSED GAS SYSTEMS AND HIGH PRESSURE HYDRAULICS

B13.1 Compressed Gas Cylinders and Lines

Any system on the vehicle that uses a compressed gas as an actuating medium must comply with

the following requirements:

a. Working Gas-The working gas must be nonflammable, e.g. air, nitrogen, carbon dioxide.

b. Cylinder Certification- The gas cylinder/tank must be of proprietary manufacture,

designed and built for the pressure being used, certified by an accredited testing laboratory

in the country of its origin, and labeled or stamped appropriately.

c. Pressure Regulation-The pressure regulator must be mounted directly onto the gas

cylinder/tank.

d. Protection – The gas cylinder/tank and lines must be protected from rollover, collision

from any direction, or damage resulting from the failure of rotating equipment.

4.4

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

e. Cylinder Location- The gas cylinder/tank and the pressure regulator must be located either

rearward of the Main Roll Hoop and within the envelope defined by the Main Roll Hoop

and the Frame (see B3.2), or in a structural side-pod. In either case it must be protected by

structure that meets the requirements of B3.24 or B3.31. It must not be located in the

cockpit.

f. Cylinder Mounting- The gas cylinder/tank must be securely mounted to the Frame, engine

or transmission.

g. Cylinder Axis- The axis of the gas cylinder/tank must not point at the driver.

h. Insulation- The gas cylinder/tank must be insulated from any heat sources,

e.g. the exhaust system.

i. Lines and Fittings- The gas lines and fittings must be appropriate for the maximum possible

operating pressure of the system

References

[1] http://arduino.cc/en/Main/ArduinoBoardADK

[2] 2012 Formula SAE Rules: SAE International 2012

4.5

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Subsystem: Intake Manifold

Table of Contents

Functional Description

A1

Parts List

A1

Prototype Cost List

A2

Implementation Cost List

A2

Time to Build

A3

Fault Analysis

A3

Appendix

Drawing A1 Injector holder

A1.1

Drawing A2 Manifold

A1.2

Drawing A3 Runner base

A1.3

Table A1 Pre-design table

A2.1

Table A2 Pre-design

A2.1

Table A3 Pressure drop table

A2.2

References

A3.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Functional Description

The intake manifold allows the engine to breathe. It needs to flow air efficiently through a 20mm

restrictor. Tuning this and the exhaust manifold together will help overall power produced by the

engine. I have calculated the runner lengths, length and diameter of the inlet, and volume of the

manifold using the equations in table A1, A2, and A3. The equations used are [1]:

4 ∗ tan(

𝜔𝐿1

)

𝑎

𝐴2

𝜔𝐿2

𝜔𝑉

∗ cot(

)−

𝐴1

𝑎

𝑎𝐴1

Setting theses equations equal to each other gives the rest of the dimensions needed to complete

the intake. Using these dimensions and working around the frame, an intake model was made.

This is in drawing A2 below. The runner bases were designed to fit in the rubber grommets

already on the engine while allowing the injector spay to atomize; the runner bases and the

injector seat is shown in drawings A1 and A3. The manifold design was then verified in ANSYS

Fluent using pressure drops that occur at the valve when they open (see table A1).

Parts List

SIU Formula SAE Drivetrain Team

A Division of Saluki Engineering Company

Parts List- Intake

#

1

2

3

4

5

6

Item

Runner Base

Injector Seat

Aluminum Epoxy

Manifold Top

Manifold Bottom

Aluminum to Carbon Epoxy

Company

Speedy Metals

Speedy Metals

Aremco

US Composits

US Composits

MSC

Part #

805

FG-CFT5750

FG-CFT5750

611905

Qty

4

1

1

1

1

1

Speedy Metals [2] Aremco[3] US Composits [4]

A1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Prototype Cost table

SIU Formula SAE Drivetrain Team

A Division of Saluki Engineering Company

Prototype Cost List- Intake

#

1

2

3

4

5

6

Item

Runner Base

Injector Seat

Aluminum Epoxy

Manifold Top

Manifold Bottom

Aluminum to Carbon Epoxy

Company

Speedy Metals

Speedy Metals

Aremco

US Composits

US Composits

MSC

Part #

805

FG-CFT5750

FG-CFT5750

611905

Unit Cost

$18.63

$5.86

$95.00

$41.50

$41.50

$63.85

Qty

1

1

1

1

1

1

Total Cost

Total Cost

$18.63

$5.86

$95.00

$41.50

$41.50

$63.85

$266.34

Unit Cost

$18.63

$5.86

$95.00

$41.50

$41.50

$63.85

Qty

1

1

1

1

1

1

Total Cost

Total Cost

$18.63

$5.86

$95.00

$41.50

$41.50

$63.85

$266.34

Implementation Cost Table

SIU Formula SAE Drivetrain Team

A Division of Saluki Engineering Company

Implementation Cost List-Intake

#

1

2

3

4

5

6

Item

Runner Base

Injector Seat

Aluminum Epoxy

Manifold Top

Manifold Bottom

Aluminum to Carbon Epoxy

Company

Speedy Metals

Speedy Metals

Aremco

US Composits

US Composits

MSC

Part #

805

FG-CFT5750

FG-CFT5750

611905

Time to Build

Item

Order Parts

Machine Aluminum

Adhere Aluminum Parts Together

Lay Carbon fiber

Adhere Aluminum to Carbon fiber

Time

1 week

17 hrs

2 hrs

1.5 weeks

2 hrs

A2

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Fault Analysis

One of the main concerns using the carbon fiber is that it may not be strong enough on the flat

surfaces to deal with the sudden pressure changes within the manifold. Last year’s intake was

made of aluminum and there was noticeable flexing when the throttle was rapidly opened. The

current intake will be reinforced to ensure that it will not have any problems with strength. The

other areas of concern are where the epoxies are being used; both types of epoxies have been

researched and should be strong enough. Extra care will be taken when dealing with the

application of the epoxies also.

A3

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Appendix

Drawing A1 Injector holder

A1.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

A1.1

Drawing A2 Manifold

A1.2

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

A1.2

Drawing A3 Runner base

A1.3

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

A1.3

Table A1. Pre-design model for intake manifolds in internal combustion engines

RPM RPS Q(24) f system

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

16.7

33.3

50

66.7

83.3

100

117

133

150

167

183

200

217

233

250

267

283

300

317

333

350

367

383

400

417

433

450

467

483

ω

3

50

314.2

3.3

110 691.2

3.6

180 1131

3.9

260 1633.7

4.2

350 2199.2

4.5

450 2827.5

4.8

560 3518.7

5.1

680 4272.8

5.4

810 5089.6

5.7 950.1 5969.3

6

1100 6911.9

6.3 1260 7917.3

6.6 1430 8985.5

6.9 1610 10117

7.2 1800 11310

7.5 2000 12567

7.8 2210 13887

8.1 2430 15269

8.4 2660 16714

8.7 2900 18223

9

3150 19793

9.3 3410 21427

9.6 3680 23124

9.9 3960 24883

10.2 4250 26706

10.5 4550 28591

10.8 4860 30539

11.1 5180 32549

11.4 5510 34623

L1

(m)

1.7

0.77

0.47

0.33

0.24

0.19

0.15

0.13

0.11

0.09

0.08

0.07

0.06

0.05

0.05

0.04

0.04

0.04

0.03

0.03

0.03

0.03

0.02

0.02

0.02

0.02

0.02

0.02

0.02

4L1

(m)

6.806

3.094

1.891

1.309

0.972

0.756

0.608

0.5

0.42

0.358

0.309

0.27

0.238

0.211

0.189

0.17

0.154

0.14

0.128

0.117

0.108

0.1

0.093

0.086

0.08

0.075

0.07

0.066

0.062

8L1 (m) 12L1 (m) Overlap

13.6115

6.187

3.7809

2.6175

1.9444

1.5123

1.2153

1.0008

0.8402

0.7164

0.6187

0.5401

0.4759

0.4227

0.3781

0.3403

0.3079

0.2801

0.2558

0.2347

0.216

0.1996

0.1849

0.1719

0.1601

0.1496

0.14

0.1314

0.1235

20.4172

9.2805

5.6714

3.9263

2.9167

2.2685

1.8229

1.5012

1.2603

1.0745

0.928

0.8102

0.7139

0.634

0.5671

0.5104

0.4619

0.4201

0.3838

0.352

0.3241

0.2994

0.2774

0.2578

0.2402

0.2244

0.21

0.1971

0.1853

226.86

206.23

189.05

174.5

162.04

151.23

141.78

133.44

126.03

119.39

113.42

108.02

103.11

98.63

94.52

90.74

87.25

84.02

81.02

78.22

75.61

73.18

70.89

68.74

66.72

64.81

63.01

61.31

59.7

#18.1

#18.2

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

1.13E-14

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-1.72E-14

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

-2.94E-15

3.894

-1.834

-5.778

-9.593

-13.609

-17.939

-22.634

-27.727

-33.252

-39.275

-46.029

-56.294

-55.606

-64.711

-72.983

-81.485

-90.437

-100.27

-94.302

-117.11

-128.02

-139.07

-150.78

0

-172.23

-185.19

-198.39

-213.96

-223.25

Table A2. Pre-design

A2.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Speed

of

Volume

Sound D1 (m) A1 (m2)

D2 (m) A2 (m2)

Lsecondary

(m3 )

(m/min)

a

5.6715 0.038 0.001134 0.031995 0.000804 0.128948498 0.0025

Table A3. Pressure drops at the valve

A2.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

degree

cam

Sec.

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

275

280

290

300

310

320

330

340

350

360

0

3.47E-05

6.94E-05

0.000104

0.000139

0.000174

0.000208

0.000243

0.000278

0.000313

0.000347

0.000382

0.000417

0.000451

0.000486

0.000521

0.000556

0.00059

0.000625

0.00066

0.000694

0.000729

0.000764

0.000799

0.000833

0.000868

0.000903

0.000938

0.000955

0.000972

0.001007

0.001042

0.001076

0.001111

0.001146

0.001181

0.001215

0.00125

Pressure Pressure Pressure Pressure

Cyl 1

Cyl 2

Cyl 3

Cyl 4

101

101

96.252

101

92.224

101

88.916

101

86.328

101

84.46

101

83.312

101

82.884

101

83.176

101

84.188

101

85.92

96.252

88.372 92.224

91.544 88.916

95.436 86.328

100.048 84.46

101

83.312

101

82.884

101

83.176

101

84.188

101

85.92

101

88.372

101

91.544

101

95.436

101

100.048

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

84.964

87.056

89.868

93.4

97.652

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

98.536

96.252

92.224

88.916

86.328

84.46

83.312

82.884

83.176

84.188

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

101

96.252

92.224

88.916

86.328

84.46

83.312

82.884

83.176

84.188

84.964

85.92

88.372

91.544

95.436

100.048

101

101

101

101

References

A2.2

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

[1] J. Benajes, “Predesign Model for Intake Manifolds in Internal Combustion Engines,” SAE

Technical Paper Series, pp.1-11, February 24, 1997

[2]http://www.speedymetals.com

[3]http://www.aremco.com

[4]http://www.uscomposites.com

A1.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Subsystem: Exhaust

Table of Contents

Functional Description

B1

Parts List

B2

Prototype Cost List

B2

Implementation Cost List

B3

Time to Build

B3

Fault Analysis

B3

Appendix

Drawing B1 Side view of exhaust

B1.1

Drawing B2 Front view of exhaust

B1.2

References

B2.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Functional Description

The main goal of the exhaust is to exhaust gases from an internal combustion engine to the

environment while keeping these gasses out of the driver’s obstruction. Along with this, the

exhaust limits the noise from the engine. The goal for our competition is to limit the noise levels

to 110 decibels.

The 2012 racecar operates using the Kawasaki Ninja ZX-6R 4-cylinder engine. Each cylinder

will exhaust gasses from the engine. This year the team will be using a 4-2-1 system. This means

there are four header pipes in which two each flow into one collector pipe, Y-pipe. These two

collectors will then flow into the final Y-pipe which connects to the muffler.

Mild steel was selected as the material of pipe to be used. This was chosen because of its high

resistance to heat along with its availability. It also allows for a much easier machinability than

with other materials such as stainless steel and titanium while being much less expensive.

One of the main tasks in designing the layout of the exhaust was to keep the collector pipes as

close to the motor as possible. By keeping it tight to the engine, it allows the exhaust to exit out

the port just in front of the motor and wrap around allowing the exhaust to exit toward the rear as

shown in the appendix B1. By allowing the exhaust to exit through the rear, it avoids all contact

with the driver while reducing backpressure caused by the air force in. Without the access to a

mandrel bender, a bender that will not crimp the pipe, pre-bent sections of pipe were purchased

with the smallest radius available, two inches. With all this, we were able to keep the exhaust

wrapped relatively tight.

The muffler used for the 2012 racecar is a Muzzy Carbon Fiber Slip on Exhaust muffler. This

muffler provides us with a very light weight solution, only weighing 3.5 lbs. Along with the light

weight it gives a low decibel allowance. In the event that the noise level exceeds 110 dB,

additional fiberglass can be packed into the muffler.

B1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Parts List

SIU Formula SAE Drivetrain Team

A Division of Saluki Engineering Company

Parts List- Exhuast

#

1

2

3

4

5

6

7

Item

Mild Steel J Bend 1-3/8" 2" Radius

Mild Steel J Bend 1-3/4" 2" Radius

Mild Steel J Bend 2" 3" Radius

2 into 1 Collector 1.375" to 1.75"

2 into 1 Collector 1.75" to 2"

Exhaust Flange

Muzzy Carbon Fiber Slip on Exhaust

Company

Part #

Qty

JEGS

555-319200

4

JEGS

555-319215

1

JEGS

555-319222

1

Cone Engineering, Inc CL2-138175-MS 2

Cone Engineering, Inc CL2-17520-MS 1

Klistom 1 Warehouse

3510

4

Indysuperbikes

5739

1

JEGS [1] Cone Engineering Inc [2] Klistom 1 Warehouse [3] Indysuperbikes [4]

]

Cost of Prototype

SIU Formula SAE Drivetrain Team

A Division of Saluki Engineering Company

Prototype Cost-Exhaust

#

1

2

3

4

5

6

7

Item

Mild Steel J Bend 1-3/8" 2" Radius

Mild Steel J Bend 1-3/4" 2" Radius

Mild Steel J Bend 2" 3" Radius

2 into 1 Collector 1.375" to 1.75"

2 into 1 Collector 1.75" to 2"

Exhaust Flange (on hand)

Muzzy Carbon Fiber Slip on Exhaust

Company

Part #

Unit Cost

JEGS

555-319200

$14.99

JEGS

555-319215

$14.99

JEGS

555-319222

$19.99

Cone Engineering, Inc CL2-138175-MS $21.50

Cone Engineering, Inc CL2-17520-MS $21.50

Klistom 1 Warehouse

3510

$

Indysuperbikes

5739

$415.95

Qty

4

1

1

2

1

4

1

TotalCost

Total Cost

$59.96

$14.99

$19.99

$43.00

$21.50

$

$415.95

$575.39

B2

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Cost of Implementation

SIU Formula SAE Drivetrain Team

A Division of Saluki Engineering Company

Implementation Cost List- Exhaust

#

1

2

3

4

5

6

6

Item

Mild Steel J Bend 1-3/8" 2" Radius

Mild Steel J Bend 1-3/4" 2" Radius

Mild Steel J Bend 2" 3" Radius

2 into 1 Collector 1.375" to 1.75"

2 into 1 Collector 1.75" to 2"

Muzzy Carbon Fiber Slip on Exhaust

Exhaust Flange

Company

Part #

Unit Cost

JEGS

555-319200

$14.99

JEGS

555-319215

$14.99

JEGS

555-319222

$19.99

Cone Engineering, Inc CL2-138175-MS $21.50

Cone Engineering, Inc CL2-17520-MS $21.50

Indysuperbikes

5739

$415.95

Klistom 1 Warehouse

3510

$2.00

Qty

4

1

1

2

1

1

4

Total Cost

Total Cost

$59.96

$14.99

$19.99

$43.00

$21.50

$415.95

$8.00

$583.39

Schedule of time to build

Item

Time in Hours

Order All Components

7 Days for Arrival

Cut Pipe and Mandrel Bends to Specification

2

Tack Pipes into place

4

Weld in pipes

2

Attach Slip on Muffler

0.5

Fault Analysis

When the exhaust exits the engine, harmful CO2 emissions are emitted. With the exhaust running

out the side of the car, emissions are closer to the vehicle than that of a normal vehicle. To

remove these emissions, side pods are used in the car and the exhaust is looped around toward

the rear. Therefore, the exhaust is emitted behind the driver and is contained inside the pod.

Along with this the muffler does not guarantee the car to emit a decibel rating below 110 dB. By

choosing the Muzzy Carbon Fiber Oval muffler, the outside can be removed and more fiberglass

can be packed allowing for more muffling of the exhaust.

B3

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Appendix

Drawing B1

B1.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

B1.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Drawing B2

B1.2

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

B1.2

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

References

[1] http://www.jegs.com

[2] http://www.coneeng.com

[3] http://www.kustom1warehouse.net

[4] http://www.indysuperbike.com

B2.1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Subsystem: Oil Pan

Table of Contents

Functional Description

C1

Parts List

C1

Fault Analysis

C1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Functional Description

The oil system of the 2012 racecar is primarily made of the oil pan, oil pickup, and oil pump.

The oil pan and oil pickup tube with be reused from stock so the only redesign on the system will

be of the oil pan itself. There was one main reason for the redesign of the oil pan, to lower the

engine. For the 2012 racecar, as much was taken into consideration during the design of the

entire car to lower the center of gravity to make the car handle better. By lowering the center of

gravity of the car, this creates a lower roll center on the vehicle and creates less body roll under

lateral accelerations. Since the engine, which is mounted directly behind the driver, is

approximately 25% of the overall weight of the car, affects the center of gravity of the entire car

greatly due to its positioning. Being that the oil pan is at the lowest point on the entire car, it is

crucial to make the oil pan more “shallow” while still keeping the same amount of oil capacity

for proper cooling of the oil before it is recycled through the engine. Since the pan will be almost

1.5” lower than the stock pan, baffles have been designed to slow down the flow of oil during

increased lateral accelerations due to the lowered center of gravity.

The material chosen to construct the oil pan was 6061 aluminum due to its high strength and

thermal diffusivity. The outer ring that provides the bolting flange to the bottom of the engine

block will be cut from 0.25” material using a CNC waterjet machine. This will ensure that the

holes are all accurate and everything will fit properly so that there will not be any oil leaks. The

sides and bottom of the oil pan will be cut from 0.070” aluminum sheet and welded together.

This makes the construction of the pan actually very easy where all of the pieces are fitted

together like a puzzle and just welded together.

#

1

2

Item

6061 Aluminum 0.25" plate

6061 Aluminum 0.070" sheet

Company

speedy metals

speedy metals

Part #

Unit Cost

$ 25.22

$ 42.90

Qty

Total Cost

1

$ 25.22

3

$ 128.70

Total Cost $ 153.92

Fault Analysis

Failure of this oil pan could be something as simple as low oil pressure during high lateral

accelerations. This would be caused to oil not surrounding the oil pickup tube because of

improperly placed baffles or an incorrectly shaped oil pan. Due to its placement within the

frame, this part should never fail mechanically because it should not come in contact with the

ground at any point in time. However, if the oil pressure happens to drop under lateral

accelerations it should be only for a very short period of time and we will be able to monitor this

through the ECU by data logging the oil pressure sensor output. If the oil pan does fail,

additional baffling could be added to try to reduce the movement of the oil inside the pan.

C1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Subsystem: Axles

Table of Contents

Functional Description

D1

Parts List

D1

Fault Analysis

D1

Formula SAE Drivetrain

F11-77-FSAE

4/19/12

Functional Description

The axles of a racecar are one of the most important parts of a racecar’s drivetrain system. The

axles are the part of the car that transmits torque from the output of the transmission to the

wheels, through the tires, and into the pavement. The design of these parts becomes difficult

because in order to maximize performance of the overall vehicle, weight must be removed from

every designed part going onto the car. Since the axles have to transmit such a high amount of

torque, it becomes a delicate balance between strength, stiffness and weight.

At the beginning of the design process, various constraints were taken into consideration because

of other design decisions made for the car.

1. Length

2. Material

3. Splined ends

The length of the axles was decided by the geometry of the suspension and chosen CV (constant