File - Maruti Welcomes U all.

advertisement

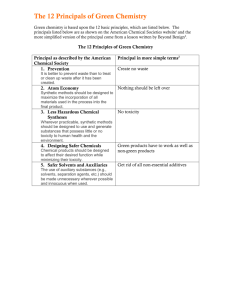

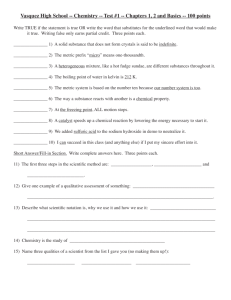

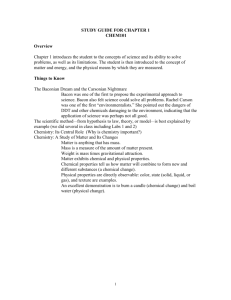

8. GREEN CHEMISTRY Necessity to introduce Green Chemistry: The beginning of green chemistry is frequently considered as a response to the need to reduce the damage of the environment by man-made materials and the processes used to produce them. A quick view of green chemistry issues in the past decade demonstrates many methodologies that protect human health and the environment in an economically beneficial manner. To meet the demands of modern civilization, variety of chemical products and industries have evolved which lead to the formation of hazardous substances. In order to prevent or minimize the formation and use of such hazardous substances, the chemists are required to develop the novel technologies which has inspired the generation of new branch of chemistry called Green Chemistry. Thus, wherever the term “Green” involve, it refers to the environment friendly objects. Green Chemistry may be defined as environment friendly chemical synthesis or the alternate synthetic pathways through which it reduces or eliminates the generation of hazardous substances. The four R’s of Integrated waste management are reduce, recycling, reuse and recover where all 4 R’s refer to different “Green items” such as: Source reduction Green chemistry Recycling Green building Reuse Green product Recover Green energy The term green chemistry was first used in 1991 by P.T. Anastas in a special program launched by the U.S. Environmental Protection Agency (EPA) to implement sustainable development in chemistry and chemical technology by industry, academia and government and Technology and the Journal of Chemical Education, have devoted sections to green chemistry. DEFINITION: “The invention, design and application of chemical products and processes to reduce or to eliminate the use and generation of hazardous substances”. Throughout history there have been many cases of environmental disasters like Bhopal disaster, India; Love Canal (Carcinogenic contaminants); Times Beach (Dioxin Contamination); Cuyahoga River (Burning / Firing river). Green chemistry is commonly presented as a set of twelve principles proposed by Anastas and Warner. The principles comprise instructions for professional chemists to implement new chemical compounds, new synthesis and new technological processes. The first principle describes the basic idea of green chemistry – protecting the environment from pollution. The remaining principles are focused on such issues as atom economy, toxicity, solvent and other media using consumption of energy, application of raw materials from renewable sources and degradation of chemical products to simple, nontoxic substances that are friendly for the environment. TWELVE PRINCIPLES OF GREEN CHEMISTRY: Paul T. Anastas and John C. Warner in 1998 introduced the 12 principles of green chemistry for practicing them to save the environment. 1) PREVENTION: “It is better to prevent waste than to treat or clean up waste after it is formed”. (or) “An ounce of prevention is worth of a pound of cure”. The first principle aims to develop the Zero Waste Technology (ZWT). In terms of ZWT, in a chemical synthesis, waste product should be zero or minimum. It also aims to use the waste product of one system as the raw material for other systems. For example, bottom ash of thermal power station can be used as a raw material for cement and brick industry. In the same way, water used for cleaning machinery parts, the effluents coming out and they may be used as coolant water in thermal plants. 2) ATOM ECONOMY and E-FACTOR: “Synthetic methods should be designed to maximise the incorporation of all materials used in the process into the final product.” “It is a simple measure of the amount of waste in a process”. 𝐹𝑜𝑟𝑚𝑢𝑙𝑎 𝑤𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑑𝑒𝑠𝑖𝑟𝑒𝑑 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 % 𝐴𝑡𝑜𝑚 𝑒𝑐𝑜𝑛𝑜𝑚𝑦 = 𝑋 100 𝑆𝑢𝑚 𝑜𝑓 𝐹𝑜𝑟𝑚𝑢𝑙𝑎 𝑊𝑡. 𝑜𝑓 𝑎𝑙𝑙 𝑡ℎ𝑒 𝑟𝑒𝑎𝑐𝑡𝑎𝑛𝑡𝑠 𝑢𝑠𝑒𝑑 𝑖𝑛 𝑟𝑒𝑎𝑐𝑡𝑖𝑜𝑛 Example: 𝐶𝐻3 − 𝐶𝐻2 − 𝐶𝐻2 − 𝐶𝐻2 − 𝑂𝐻 + 𝑁𝑎𝐵𝑟 + 𝐻2 𝑆𝑂4 ⟶ 𝐶𝐻3 − 𝐶𝐻2 − 𝐶𝐻2 − 𝐶𝐻2 − 𝐵𝑟 + 𝑁𝑎𝐻𝑆𝑂4 + 𝐻2 𝑂 % 𝐴𝑡𝑜𝑚 𝑒𝑐𝑜𝑛𝑜𝑚𝑦 = 𝑀𝑎𝑠𝑠 𝑜𝑓 (4𝐶 + 9𝐻 + 1𝐵𝑟) 𝑋 100 𝑀𝑎𝑠𝑠 𝑜𝑓 (4𝐶 + 12𝐻 + 5𝑂 + 1𝐵𝑟 + 1𝑁𝑎 + 1𝑆) 137 = 𝑋 100 = 50% 275 But in the following equation: 𝐶𝐻3 − 𝐶𝐻 = 𝐶𝐻2 + 𝐻2 ⟶ 𝐶𝐻3 − 𝐶𝐻2 − 𝐶𝐻3 , % Atom economy = 100% E-factor (Environmental factor): The mass efficiency of such process can be judged by the E-factor. 𝐸 − 𝑓𝑎𝑐𝑡𝑜𝑟 = 3) 𝑀𝑎𝑠𝑠 𝑜𝑓 𝑤𝑎𝑠𝑡𝑒𝑠 𝑀𝑎𝑠𝑠 𝑜𝑓 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 ⇒ 𝐸 − 𝑓𝑎𝑐𝑡𝑜𝑟 = 𝑀𝑎𝑠𝑠 𝑜𝑓 𝑟𝑎𝑤𝑚𝑎𝑡𝑒𝑟𝑖𝑎𝑙𝑠 − 𝑀𝑎𝑠𝑠 𝑜𝑓 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑀𝑎𝑠𝑠 𝑜𝑓 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 LESS HAZARDOUS CHEMICAL SYNTHESIS: “Wherever practicable, synthetic methodologies should be designed to use and generate substances that possess little or no toxicity to human health and the environment.” By changing pathways of the chemical reaction (or) reactants can reduce the toxic nature. 4) DESIGNING SAFE CHEMICALS: “Chemical products should be designed to produce efficacy of the function while reducing toxicity”. In many chemical industries not only the waste product but the starting materials are also quite hazardous to the workers and environment. For example: Adipic acid is widely used in polymer industries in manufacture of nylon, polyurethane, lubricants etc., Benzene is the starting material for the synthesis of adipic acid but Benzene is Carcinogenic substance. In green technology (or) green synthesis, adipic acid can be prepared by enzymatically synthesized from D-Glucose. Here, D-Glucose can be readily obtained from the corn, starch and many other agricultural wastes and waste paper. 5) SAFER SOLVENTS AND AUXILLIARIES: “The use of auxiliary substances (solvents, separating agents etc.,) should be made unnecessary whenever possible and when used, innocuous (harmless). This principle aims to use green solvents (Eg. Water, Supercritical CO2 etc.,) in place of volatile halogenated organic solvents like CH2Cl2, CHCl3, CCl4 etc., for chemical synthesis and other purposes. If possible solvent free synthesis is preferred. For example, Claisen Rearrangement can be carried out in solid phase. 2) The solvents traditionally used in Nail polish have potential toxicity and are certainly not pleasant to smell. A water-based alternative polish would avoid the exposure that goes along with the nail products and reduce the hazards associated with traditional products. 6) DESIGN FOR ENERGY EFFICIENCY: “Energy requirements should be recognized for their environmental and economic impacts and should be minimized. Syntheti methods should be conducted at ambient temperature and pressure.” In the synthesis of a chemical product the energy consumption should be minimized to make the process more and more economic .It needs suitable catalyst that will accelerate the reaction rate even at lower temperature. The biocatalyst can work at the ambient conditions. Another way of increasing efficiency of the heating system is by using the burner rather than other heating systems. In this process methane and air will produce flame and it is exothermic. 𝐶𝐻4 + 2𝑂2 ⟶ 𝐶𝑂2 + 2𝐻2 𝑂 + 𝐻𝑒𝑎𝑡 7) USE OF RENEWABLE FEEDSTOCKS: “A raw material or feedstock should be renewable rather than depleting whenever technically and economically practical”. In fact, continuous use of non-renewable feedstock will deplete the resource, on the other hand, use of renewable resources ensures the sharing of resources by future generation. For example: 1) Furfural is syntehsised from Biomass. 2) Alternative fuel Biodiesel is syntehsised from Vegetable Oils. 3) One of the important Plastics – Poly Lactic Acid is synthesized from Corn, Potato Waste. These Biomass, Vegetable Oils, Corn, Potato Waste etc., are all renewable feedstocks. 8) REDUCE DERIVATIVES: (Minimisation of Steps): “Unnecessary derivatization (blocking group, protection / deprotection, temporary modification of physical / chemical processes) should be avoided whenever possible”. Thus, there should be a minimum number of steps to synthesise a reaction. In such cases atom economy is also less. 9) CATALYSIS: “Catalytic reagents (as selective as possible) are superior to stoichiometric reagents.” The use of catalysts is performed because of the following advantages. 1) In a chemical process catalysts are used in order to reduce energy requirements 2) to make reactions happen more efficiently. 3) many times quicker. 4) generally small amounts are required to have an effect. 5) 100% atom economy because the true catalyst are fully recovered without any change in their chemical and physical properties. 6) Reactions yields are better. Enzymes are wonderful examples of catalysts that have been proven to perform amazing chemistry. Many times enzymes will have reduced toxicity, increased specificity and efficiency. 10) DESIGN FOR DEGRADATION: (Life time of a Chemical product): “Chemical products should be designed, so that at the end of their function, they do not persist in the environment and breakdown into innocuous (harmless) degradation products.” For example, DDT is effective chemical pesticide but its stability in the natural environment causes several environmental hazards. According to this principle, waste product should degrade automatically to clean the environment. Hence, the bio-degradable polymers and bio-degradable pesticides should preferred and then degraded products should not be toxic. Biodegradable Juvenile Harmones are better than the chemical pesticides. 11) REAL-TIME ANALYSIS FOR POLLUTION PREVENTION: (Monitoring the generation of hazardous substances): “Analytical methods need to be further developed to allow for real-time in-process monitoring and control prior to the formation of hazardous substances.” The aim of this principle is to stop the chemical process instantly and necessary modifications can be made for the process to control hazardous substances by doing in-process monitoring in real-time. 12) INHERENTLY SAFER CHEMISTRY FOR ACCIDENT PREVENTION: (Use of Chemically Safer substances) : “Substance – and the form of substance – used in a chemical process should be chosen to minimize the potential for chemical accidents including releases, explosions and fires”. For example, the solid substances in chemical process has minimum risk compare with liquid (either volatile / non-volatile) and gaseous substances because of their releasing, exploding and firing. THE SHORTCUT FORM TO REMEMBER THESE 12 PRINCIPLES IS: “P R O D U C T I V E L Y” Prevent wastes Renewable Resources Omit derivatization steps Design for Degradation Use safe synthetic methods Catalytic reagents Temperature, pressure ambient In-process monitoring Very few auxiliary substances E-factor / atom economy Low toxicity of chemical products Yes, it is safe from accidents. - 1st principle - 7th principle - 8th principle - 10th principle - 3rd principle - 9th principle - 6th principle - 11th principle - 5th principle - 2nd principle - 4th principle - 12th principle SOME GREEN CHEMICAL REACTIONS (OR) GREEN SYNTHESIS: PREPARATION OF ACETANILIDE FROM ANILINE: CONVENTIONAL METHOD: 1) Pyridine is not eco-friendly. 2) Use of Chlorinated solvent like CH2Cl2 3) Acetic anhydride leaves one molecule of Acetic acid not used (not atom-economic) ALTERNATIVE METHOD: BROMINATION OF STILBENE CONVENTIONAL METHOD: 1) 2) Using Liquid Molecular Bromine. Use of chlorinated organic solvents. ALTERNATIVE METHOD: BENZOIN CONDENSATION CONVENTIONAL METHOD: 1) Involves the use of highly poisonous Compound NaCN. ALTERNATIVE METHOD: NITRATION OF PHENOL CONVENTIONAL METHOD: 1) Involves use of Con. Sulphuric Acid. ALTERNATIVE METHOD: BROMINATIN OF ACETANILIDE CONVENTIONAL METHOD: 1) Liquid Molecular Bromine is not eco-friendly. ALTERNATIVE METHOD: PREPARATION OF URETHANE CONVENTIONAL METHOD: (𝑹′ 𝑶𝑯) 𝑹 − 𝑵𝑯𝟐 + 𝑪𝑶𝑪𝒍𝟐 ⟶ 𝑹𝑵𝑪𝑶 + 𝟐𝑯𝑪𝒍 → 𝑹𝑵𝑯𝑪𝑶𝑶𝑹′ 1) Using of Phosgene (CoCl2) is a poisonous substance. ALTERNATIVE METHOD: (𝑹′ 𝑶𝑯) 𝑹 − 𝑵𝑯𝟐 + 𝑪𝑶𝟐 ⟶ 𝑹𝑵𝑪𝑶 + 𝑯𝟐 𝑶 → APPLICATIONS OF GREEN CHEMISTRY: 1) 𝑹𝑵𝑯𝑪𝑶𝑶𝑹′ Replacement of CFC and Hydrocarbon blowing agents with CO2 for the production of Polystyrene. The commonly used blowing agents are CFC’s and aliphatic hydrocarbons which are cause environmental hazards. Use of CO2 is more ecofriendly and economic. The reason for use of CO2 as alternate is: 1) It does not deplete ozone layer. 2) It does not contribute in smog formation 3) It is more economic as it is readily available from different sources. 2) Replacement of Organic Solvents used in industry with liquid or supercritical CO2: Precision cleaning of Microelectronics, optics and electroplating, medical device fabrication, dry cleaning etc., can be done by using a large amount of Organic solvents like Chloro Fluoro Carbons (CFC) and other volatile organic Organic Compounds. In the place of these hazardous organic compounds, Use of Liquid (or) Supercritical CO2 in presence of suitable surfactants is far better to reduce environmental hazardness. 3) Use of activated Hydrogen Peroxide as bleaching agent in paper industry in the place of Free chlorine (or) chlorine related bleaching agents: In paper industry the final process is: removal of residual lignin compound. For this, industries are using Chlorine (or) chlorine related bleaching agents to remove lignin. When free Chlorine is used for bleaching the pulp, the possibility of formation of several environmental hazards like organo chlorine waste products including the highly toxic chemicals like dioxins and furans. In the place of chlorine, if chlorine diamide is used can obtain chlorine free paper, but this process cannot completely eliminate the risk. And hence, this can be avoided by taking totally chlorine free bleaching agents like H 2O2, O3, O2 etc., They donot produce any hazardous waste. But their oxidation capacity is somewhat less that Chlorine or chlorine diamide and also it requires long time and high temperature causes decrease the strength of paper. Hence, Fe-complex with the ligand which can act as a catalyst to H2O2 and increases its oxidation capacity. In the presence of this catalyst, H2O2 can bleach faster and do not produce any hazardous substances. 4) Replacement of Yttrium Oxide in the place of red lead (Pb3O4) as a corrosive inhibitor: Electrodeposition of red lead on the steel surfaces provides a strong corrosion resistance. But because of the toxicity of lead, this practice causes health hazards and environmental problems. Yttrium oxide has several benefits like: 1) It is twice as effective in resisting the corrosion as done by red lead. 2) Its toxicity is also very less compared to that of red lead. In fact, red lead is about 120 times more toxic than Yttrium oxide. 3) In the pretreatment process, Ni and Cr like metals are produced as waste in the case of Red lead. But in the case of Yttrium oxide, no such rigorous treatment is required and hence protects the environment from Ph, Ni and Cr. 5) Use of microwaves for heating: Use of microwaves for heating and chemical reactions as the heating is more uniform and a range of temperatures can be obtained without any byproducts like in burning of fossil fuels. 6) By using bio-technology processes: By using bio-technology processes, the biomass is converted to fermentable sugars in presence of enzymes from crop residues such as corn stalks, sugarcane bagasse, wheat straw. For example, Furfural can be prepared from Bio-mass and Poly Lactic Acid can be prepared from Corn, Potato waste. Biodiesel can be prepared from Vegetable Oils etc., 7) Production of Biodiesel from a renewable sources (vegetable oils): Fossil fuels are rapidly getting depleted and burning of petroleum based fuels like diesel puts a pressure on environment by releasing the pollutants like SO2. “Biodiesel” (mono alkyl esters of vegetable oil and animal fats) is a renewable sources prepared from the vegetable oils and animal fats and can be used as a fuel. It can be prepared as follows: CH2 – O – COR | CH – O – COR | CH2 – O- COR + 3 R’OH KOH -------------------> CH2OH | CHOH | CH2OH The properties of bio-diesel depend on the nature of the carbon chain R. O || + 3 R – C – OR’