UG Foods - Orient Water Technologies

advertisement

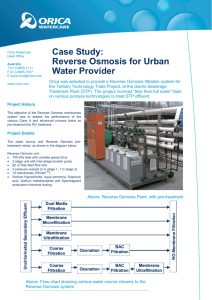

Orient Water Technologies CASE STUDY REVERSE OSMOSIS PLANT Fo r UG FOODS COMPANY PVT. LTD. Capacity: (5 m3/hr) 1 Introduction: 2 Scope of Work: Ülker, whose history goes back to 1944, is 4 Technical Characteristics: The Plant’s average capacity is 5 m3/hr. one of the best loved brand names in The scope of work includes the The treatment process is capable of Turkey. Founded and built in the 20th followings: producing product of following century, the Ülker brand, riding on its characteristics: phenomenal momentum, was carried into - Process design and engineering the 21st century, seemingly unlimited by - Manufacture and supply of time and space. With its roots in tradition equipment. but reaching toward the future, Ülker is a - Delivery at your Site, Karachi. name that continues to focus on the - Provide warranty sociological and economic wellbeing of the community, but in parallel with that side of its existence, the organization is 3 General Information: gaining new meaning. For the timeless The engineered reverse osmosis Ülker brand, there seems to be no end in treatment plant consisted of the following: sight. Today, Ülker has hundreds of sub-brands that serving the consumers and holding a strong presence in the marketplace. The brands all share the same principles and values of Ülker manufacturing a wide span of products such as biscuits, chocolate, candy, chewing gum, liquid oil, - dairy products, carbonated beverages, ice cream, coffee and baby food. - . Pre- chlorination dosing set. Filter feed / backwash pumps. Sand filter. De-chlorination dosing set. Reverse Osmosis Unit comprising: Acid dosing set. Antiscalant dosing set. 5 Micron cartridge filtration. High pressure pump set Booster pump Lot of reverse osmosis membranes. Lot of instrumentations. Control Panel. Post chlorination dosing set. pH Adjustment dosing set. PLC. Flushing system. Lot of interconnecting pipe work. Lot of interconnecting electrical cabling. Lot of drawings. Operating and maintenance manuals. Reverse Osmosis The feed water is filtered through Cartridge Filtration The water is pressurized by a high pressure Multimedia filter and then RO cartridge Cartridge filtration units generally pump to the Reverse Osmosis membranes filters. It is further pumped online to RO operate most effectively and to produce permeate/reject as designed. units and the permeate water is taken for economically on applications having storage / use (by others). contamination levels of less than 100 ppm. Multi Media filter Filtered water is feed to Multimedia For heavier contamination applications, cartridges are normally used as final polishing filters. filters. Multimedia filter is also provided designed to cater the rated flow of 100,000.00 GPD. Filter backwash is manual process and shall be carried out manually every 24 hrs The pre filtered water is passed through a cartridge filtration system, where particles greater than 5 micron are retained to product membrane etc. or earlier. The filter cartridges are periodically replaced when the differential pressure across the cartridge filter exceed the designed limits. The permeate water quality is monitored at the outlet of the RO permeate where water is dumped through the dump line in case the water quality is below the set standards, with respect to conductivity. Permeate is stored in permeate tank provided by other Control Philosophy Antiscalant Dosing Suitable antiscalant is added to inhibit the The plant provided herewith is controlled formation of scales in the reject brine through Electric Control Panel .However the operation of Filter is manual based on 24 hrs backwash cycle stream Orient Water Technologies 5 Conclusion: As a result the Reverse Osmosis plant by Orient Water Technologies managed to improve the performance of UG FOODS (Pvt.) Ltd. , whilst meeting the local environmental regulation . Raw Water Multimedia Filter Antiscalant Dosing Cartridge Filtration Reverse Osmosis system Storage Tanks Schematic Flow Diagram