BENIFICIATION PLANT - 12 SEPTEMBER 2013

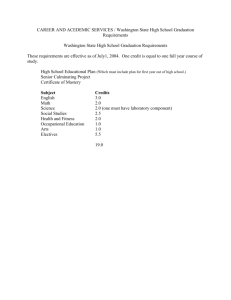

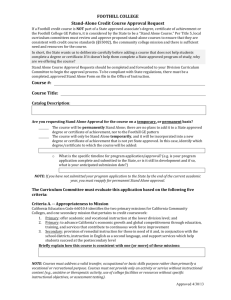

advertisement

313912 - Mineral Beneficiation Process Controller AGENDA/DELIVERABLES 1. Deal with overall questions and issues 2. Agree the overall structure of the qualifications (Number of occupations involved) 3. Develop the basic Occupational Profiles for the agreed qualifications 4. Agree the work groups required 5. Agree time lines and work schedules OCCUPATIONAL QUALIFICATIONS FRAMEWORK NQF Doctoral Degree Level 10 Masters Degree Level 9 HEQF Master Postgraduate Diploma Professional Qualifications s Degree Level 8 Level 7 Diploma Advanced Certificate Level 6 Adult National Senior Certificate Units of learning to be accumulated General Education & Training Certificate (Grade 9) Adult National Senior Certificate National Certificate (Vocational) 4 National Certificate (Vocational) 3 National Certificate (Vocational) 2 Level 5 GFETQF National Senior Certificate (Grade 12) Incl. subject / unit certificates AdvancedNational National Advanced Certificate Certificate (Vocational) 5 (Vocational) Higher Certificate OQF Bachelor Degree Advanced Diploma Level 4 Level 3 Level 2 Level 1 Version: 2007-12-17 National Occupational Certificate OFO – Organising Framework of Occupations DQP – Development Quality Partner AQP – Assessment Quality Partner QCTO – Quality Council for Trades and Occupations QDF – Qualification Development Facilitator STEPS Submit Develop Assessment Specifications Manage Verification Process RESPONSIBLE QUALIFICATIONS DEVELOPMENT PROCESS 8 DQP & QDF 7 QDF with Expert Practitioners, AQP & Educationalists 6 DQP with Constituency Group Develop Module and Subject 5 Specifications QDF with Expert Practitioners, AQP & Educationalists Manage Verification Process 4 DQP with Expert Practitioners and AQP Develop Occupational Profile 3 DQP with Expert Practitioners (incl Assesors Oversee Scoping Meeting with Constituency 2 QCTO Staff Receive and Process Application 1 QCTO Staff RESULTS Service Level Agreement Occupational Profile (DQP & AQP) A B QCTO Learning Component Specifications (& Internal Assessment) C Occupational Curriculum (B+C) Qualification Assessment Specifications (External) D Occupational Qualification (C+D) E THE CURRICULUM PROCESS 1. Occupational Profile • • • • • Occupational descriptor Occupational Tasks Knowledge Focus Areas Practical skills Work Experience 3. Learning Curriculum • Learning sequence • Formative Assessment Criteria • Learning processes • Learning methods • Planning Spreadsheet 2. Planned Curriculum • Subject Specifications • Practical Skills Module Specifications • Work Experience Module Specifications • Work Experience Record • External Assessment Specification 4. Learning Material • Facilitator guides • Learning resources • Learning tools • Presentation material • Lesson Plans • Assessment tools Occupational Profile 1 Products/ 4 Occupational Task Services 2 Occupational Responsibility 3 Occupational Context Occupational Conceptual Knowledge 5 Practical Skills and Applied Knowledge 6 Work Experience Workplace Knowledge 8 Purpose Products/Se rvices Knowledge Practical Skills Occupational Task Occupational Responsibility Occupational Context Work Experience Workplace Knowledge 7 8 49049 Further Education and Training Certificate: Lump Ore Beneficiation 57692 64209 Further Education and Training Certificate: Carbonate Materials Manufacturing Processes Further Education and Training Certificate: Metals Production 64889 Further Education and Training Certificate: Mineral Processing PROGRESSION PROGRESSIONAL OCCUPATIONS THIS CURRICULUM 312201 - Manufacturing Supervisors (Shift Supervisor/Plant Foreman/Processing Foreman) (NQF 5) 313912- Mineral Beneficiation Process Controller (NQF 4) Plant Controller (NQF 3) Pyro Metallurgy Chemical Metallurgy Lump Ore 711201 - Mineral Processing Machine Operator (NQF 2) FEEDER OCCUPATIONS 831101 - Mineral Beneficiation Plant Support Worker (NQF1) New entrants to the industry 10 CORE PROCESSES AND THE COMMODITIES BEING PROCESSED 1. PYRO METALLURGY 2. CHEMICAL/Extraction METALLURGY Chrome Gold Manganese Platinum Cement and Lime Copper Nickel Cobalt Sodium Vanadium Char 3. LUMP ORE BENEFICIATION Aggregates Coal, Diamonds, Iron Ore, Industrial Minerals) Pyro - Outputs Raw materials available for processing Final product ready for dispatch Final Products prepared Raw materials blended/prepared for processing Blended materials dried or pre heated Waste product disposed of Raw materials processed for processing Products extracted form the hot process Material hot processed Raw material fed into the hot process Refinery ? 12 Chemical - Outputs Raw materials available for processing Final product and waste ready for dispatch Final products and waste prepared Raw materials prepared (Crushing, screening and milling . Prepared Raw materials processed for processing (Thickening, Leaching, etc.) Products and waste separated Precious metals recovered Products extracted form the hot process Material hot processed Raw material fed into the hot process Refinery ? 13 Lump Ore - Outputs Raw materials available for processing Size Reduction (Pre screening and crushing Final products and waste handling Separation, dewatering and classification processes Product Handling, Storage and preparation 14 Assessment Quality Partner bbbb CEP WORK TEAMS Employers • Professional Bodies Unions Educationalists/Training Service Providers