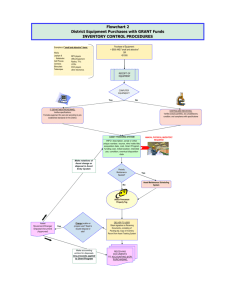

Fleet Asset Management Plan

advertisement