Manufacturing Advisory Service (MAS)

advertisement

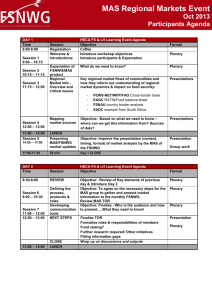

Manufacturing Advisory Service (MAS) Lean in the process Industry – “It’s not just about cars!!” Nick Brandwood @NickB_MAS Manufacturing Advisor 1 >Manufacturing Advisory Service (MAS) Dealing with Complexity Definition of complexity • High Volume • High Number of Finished Variants • High Variability in demand Cereals, Biscuits, Crisps, Additives, Fertilisers, Lubricants, Adhesives, Toothpaste, Paints, Cable, Carpet, Paper, Glass, Petroleum, Pharmaceutical, Plastic 2 >Manufacturing Advisory Service (MAS) 3 Search AlCereals /wEPDwU l brands >Manufacturing Advisory Service (MAS) 4 Manufacturing Advisory Service (MAS) Characteristics of Process Plants that differentiate them from discrete / assembly plants: • Diverging “V” type processes versus Converging “A” type processes • Capital intensive versus labour intensive • Throughput limited by equipment not labour • Equipment is large and difficult to relocate • Processes are difficult to stop and restart • Product changeovers are complex • Raw Materials and Finished Product Inventory versus WIP 5 Manufacturing Advisory Service (MAS) However….. The Lean goals are still appropriate and aspirational business goals in process industries: Quality, Cost and Delivery • Reduce Inventory • Reduce Lead Times • Eliminate bottlenecks, make what the customer wants at the rate the customer wants it • Improve Employee Engagement • Improve Quality and Process Capability 6 Manufacturing Advisory Service (MAS) Achieved through the 5 lean principles • Value • Value Stream • Flow • Pull • Perfection 7 Manufacturing Advisory Service (MAS) The first key to living the lean principles and achieving the lean goals is Waste elimination: 7 Wastes: • Transportation • Inventory • Movement • Waiting • Overproduction • Overprocessing • Defects 8 Manufacturing Advisory Service (MAS) Wastes relevant to the Process Industries • • • • Inventory /Overproduction Waiting Overprocessing Defects 9 Manufacturing Advisory Service (MAS) • All Operations are compromised by the effect of waste • Universal Lean Goal – Satisfy your customers requirements on time in full whilst holding less and less inventory • Inventory is the big evil, the big buffer, the big cost – what Quality, Performance and Delivery Issues are you hiding behind inventory Leads to two questions: 10 Manufacturing Advisory Service (MAS) • If you identify waste in your process –what inventory is it generating and what are you doing about it? • If you identify excess inventory in your process what wastes are you buffering yourself against and what are you doing about it? 11 Manufacturing Advisory Service (MAS) The second key to living the Lean Principles– Reduce variabilty and do the same thing every day – Lean Foundations • • • • Standard Work 5S Visual Management Data Data Data 12 Manufacturing Advisory Service (MAS) The rigorous pursuit of the Lean philospophy – essential tools applied every day. • • • • The visual factory – 5S and Visual Management Standard Operations Level Scheduling Shopfloor performance data and review –good day/bad day • Kaizen 13 Manufacturing Advisory Service (MAS) Conclusion: Complexity = Volume x Variety x Variability = STOCK Continuous improvement is about people doing small things every day to eliminate waste Continuous improvement is about people doing small things every day to eliminate variability What are you doing about it? 14 Manufacturing Advisory Service (MAS) Recommended Reading: • Lean for the process industries - Peter L. King • The Goal - Eliyahu M. Goldratt / Jeff Cox • Learning to see – Mike Rother, John Shook 15