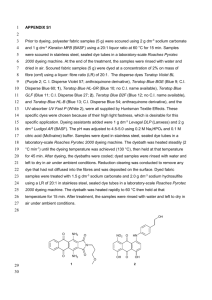

The project is on “Techniques of Producing Denim Fabrics”.

advertisement