physiological measures to determine the recommended weight limit

advertisement

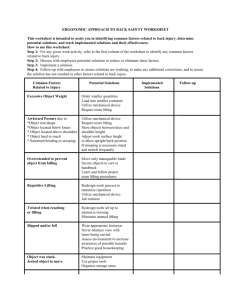

PHYSIOLOGICAL MEASURES TO DETERMINE THE RECOMMENDED WEIGHT LIMIT USING NIOSH LIFTING EQUATION 1 GARIMA MISRA M.Tech( ME) IFTM University Moradabad, India 2 garimamisra17@gmail.com Dr.VISHAL SAXENA HOD of ME IFTM University Moradabad, India 3 hodme@iftmuniversity.ac.in ahmad.nadeem61@gmail.com ABSTRACT In industrial workplaces, many workers perform processes jobs in standing position for a long period of time. Working in standing position can be linked to versatility because the mobility of legs position and having large degree of freedom.Measurement of energy expenditure of the worker during manual material handling (MMH) task depends upon various parameters that can be used to assign the task to particular worker.[1] The present study follows a approach to evaluate physical work capacity during manual material handling (MMH) tasks on Indian male workers. This study involves six independent variables such as lifting frequency, lifting load, vertical height, horizontal distance. The selected two responses variables were heart rate and blood pressure. The National Institute for Occupational Safety and Health (NIOSH) recognize the growing problem of work related back NADEEM AHMED Assistant Professor in ME IFTM University Moradabad, India injuries and published a summary of lifting related literature. The components of the original and revised lifting equation were defined by using three criteria (Biomechanical, Physiological and Psychophysical). The NIOSH lifting equation consists of two primary products, the recommended weight limit (RWL) and lifting index (LI). The RWL is defined for a specific set of task condition as the weight of the load that nearly all healthy workers could perform over a substantial period of time( e.g. up to 8 hours) without an increased risk of developing lifting related low back pain by healthy workers. Physiological measures including heart rate and blood pressure have also been considered reliable tool to identify a safe workload, especially concerning manual works. Heart rate is usually used as a primary indicator of physical and mental stress reflecting a marked linear connection with effort experienced by a healthy worker. KeywordsRevised NIOSH Lifting Equation, Lifting Index, Manual Lifting, Low Back Pain, Energy Expenditure. 1.INTRODUCTION Manual Material Handling (MMH) is a general process in all types of manufacturing industries under which the workers are working in different type of manufacturing task like lifting or lowering, carrying and holding etc. Basically industrial activities involve lifting/ lowering of objects or moving material from one place to another is termed as Manual Material Handling (MMH). In developing and under developed countries, MMH is associated with nearly all types of industries as manual labor is cheap in these countries and is available in plenty. During the manual material handling task the risk factors leading to musculoskeletal disorders (MSDs) are always present. Physiological measures for assessing physicalstresses are necessary for measuring the expenditure of workers energy during the task. MMH is an expensive public health problem. The governments and industries of many industrialized nations, including USA, UK, Germany pay not only for workman’s compensation, but also spend billions on their treatment, employee insurance claims etc. due to loading workers suffer from cardiovascular and musculoskeletal disorders. Various short and long term health effects can be attributed to MMH.[2] Manual material handling (MMH) tasks play a vital role in a various manufacturing industries. Many jobs and activities in industries require manual material handling. This includes a wide variety of activities such as loading and unloading boxes and carbons, removing materials from a conveyor belt, stocking items in a warehouse, etc. as a result, and workers may suffer from cardiovascular and musculoskeletal disorders (MSDs). Various short term and long term health effects can be attributed to MMH. Some of these are (National Institute for Occupational Safety and Health) fractures, cardiovascular strain, such as increased heart rate and oxygen intake, musculoskeletal injury, especially to the spine and back pain. [2] The National Institute for Occupational Safety and Health (NIOSH) developed a lifting equation in 1981 to indicate safe occupational lifting limits. This equation was revised in 1991.In 1981, National Institute for Occupational Safety and Health (NIOSH) recognize the growing problem of work related back injuries and published a summary of lifting of lifting related literature. It also provides a lifting equation for calculating a recommended weight for specific two handed, symmetrical lifting task, an approach foe controlling the hazard associated with low back injury from manual lifting. The components of the original and revised lifting equation were defined by using three criteria (Bio mechanical, Physiological and Psychophysical).Threecriteria biomechanical, physiological and psychophysical were used to define the components of the original and revised lifting equation. The present document describes the rationale for selecting these criteria and demonstrates how they were used to determine the equation values. The document also discusses the limitations of the lifting equation and the use of a lifting index for identifying hazardous jobs. [6] The NIOSH guidelines for Psychophysical criteria were based on the maximum acceptable weight of load that can accommodate 75% of the women and 99% of the men. In the workforce for the RWL criteria. The guidelines for physiological criteria were based on an assumed aerobic capacity of 15 Kcal/ min for men and 10.5 Kcal/min for women. These aerobic capacities are average values for males and females. The biomechanical criteria of NIOSH lifting equation were based on the maximum amount of compression that can be tolerated by the lumbar spine, estimated from a axial loading compression tests. Heart rate and oxygen intake are used to assess the state of health, identify status of general health. Physiological measures, including heart rate and blood pressure have also been considered as reliable tool to identify a safe workload, especially concerning manual works. [ 5] Heart rate is usually used as a primary indicator of physical and mental stress reflecting a marked linear connection with effort experienced by a healthy person. Physiological reactions of a person to different lifting techniques, frequency and distances was investigated and it was determined that changes is consumed metabolic energy are in line with characteristics of different lifting methods and help in identifying changes in ability to lift weights..[7] 2.RELATED WORK It can be observed that there are two fundamentals rules to be observed while lifting, keep the load as close as to the body and avoid twisting. [3] Another type of lifting job is defined as a sequential lifting job where a worker may rotate between different specific workstations for a fixed period of time (either single or multi task), and then transfer or rotate another workstation to perform a different series of specified lifting tasks.[4] The 1981 equation could only be applied to a limited number of lifting tasks, the 1981 equation was revised and expanded in 1991 to apply to a larger percentage of lifting tasks. [5] 3.PROPOSED WORK The main components related to the study were as follows: (i) Selection of manual lifting job (ii) Measurement of data needed to calculate the RWL and LI for the selected job. Weight of the load lifted Horizontal and vertical location of hand with respect to midpoint between ankles. Angle of symmetry Frequency of lift Lifting duration. Coupling type. (iii) Measurement of physiological response. The revised lifting equation for calculating the recommended weight limit (RWL) was based on multiplicative model that provided a weighing for each of six task variables. The weights were expressed as coefficient that serve to decrease the load constant, which represent the maximum recommended load weight to be lifted under ideal conditions. The NIOSH lifting equation is a method to assess risk of low back disorders in jobs with repeated lifting. It consists of two primary products, the recommended weight limit (RWL) and the lifting index (LI). The RWL is defined for a specific set of task conditions as the weight of the load that nearly all healthy workers could perform over a substantial period of time (up to 8 hours) without an increased risk of developing lifting related low back pain. It is calculated as a product of the weight that is considered safe for an ideal lift( load constant equal to 23 kg) and six weighted task variables, which include the (1) horizontal distance of the load from the worker( H), (2) vertical height of the lift(V), (3) vertical displacement during the lift( D), (4) angle of asymmetry (A), (5) Frequency(F) and duration of lifting and (6) quality of the hand to object coupling ( C) RWL= H * V* D* A*F*C......(i) The LI is defined by the following equation: LI = Load Weight/ RWL = L/ RWL.......(ii) 4.EXPERIMENTS & RESULTS This study explored the workers performances as subjects lifted from a sagitally symmetric lift origin and three asymmetric origins to a sagitally symmetric lifting destination. Subjects were asked to perform all lifts using a two handed lifting technique. The experiment involved the lifting of rectangular box from the ground level to a platform of height of 100 cm from the ground for 10 minute duration symmetrically as well as asymmetrically. Then various parameters as defined by revised NIOSH lifting equation were measured. The heart rate and the oxygen intake were measured using cosmed pulmonary function equipment. It measured the responses simultaneously. It produces two curves one for heart rate and other uptake vs. time span. Two kinds of face masks were provided with the instrument. Face oxygen mask was put on the subjects with the help of belt to ensure that no leakage of oxygen take place. The mask was connected through a wire to the main instrument. A belt provided with the instrument was put around the chest of the subject. A heart rate probe was clamped to the belt, the other end of the probe was connected to the main unit to measure the variation in heart rate vs time. Time of experiment was noted on the stop watch. The effects of five lifting parameters (lifting frequency, load weight, horizontal distance from object, angle of asymmetry and the vertical distance of lifting) and the operator with their interactions were evaluated. It has been found that when the participants performed lifting tasks, there was increase in oxygen intake. The effects of five lifting parameters (lifting frequency, load weight, horizontal distance from object, angle of asymmetry and the vertical distance of lifting) and operator with their interactions were evaluated. It has been found that when the participants performed lifting tasks, there was increase in heart rate. 5. CONCLUSION The results of the experiment showed that lifting loads and higher lifting frequencies increases the physiological workloads. The tasks become more stressful when the vertical distance of the lift is above the shoulder level. The effect of the load weight and frequency of lift was found to be most significant factors leading to the increased oxygen intake and heart rate. 6. FUTURE WORK In future a detailed work guide should be created fixing the higher levels of lifting parameters to lower the cardiovascular risks of the workers. Further investigations are also necessary to identify the strenuous levels of lifting parameters which stresses the cardiovascular system of the workers. We have focused in this work on male population which could be analyzed further for the female population. Also we can extend this work for larger age groups. Proper training such as proper handling, proper posture etc, should be instructed while lifting tasks. 7. REFERENCES [1] ZenijaRoja., 2005.Mrasures to overcome health problems of Latvian road builders created by ergonomical risks. [2] Isa Halim, Abdul Rahman Omar., 2012. A review on health effects associated with prolonged standing in the industrial workplaces. IJEAT .Vol 2 [3] ICMR Bulletin, 2000. Ergonomics in manual materials handling tasks.Vol .30, No. 8, ISSN 0377-4910 [4] CHUNG, M.K., Kee,D.,2000. Evaluation of lifting tasks frequently performed during fire brick manufacturing processes using NIOSH lifting equation. International journal of Industrial Ergonomics. Vol. 25, 423-433 [5] Astrand, P., Rodahl,K., 1977. Textbook of work physiology, McGraw Hill, New York. [6] Putz-Anderson, v., and Waters, T.R., 1991. Revisions in NIOSH guide to manual lifting. Paper presented as national conference entitled” A national strategy for occupational musculoskeletal injury prevention. [7] Jaswinder ,Singh., P.Kalra., R.S.Walia. 2012. Study of manual material handling tasks using Taguchi technique. [8] Maiti,R.,Ray, G.G., 2004. Manual lifting load limit equation for abult Indian women workers based on physiological criteria. Ergonomics, Vol.47, No, 1, 59-74. [9] Batish, A., Bhattacharya,A.,Singh,B., 2011. Multi response optimization and empirical modeling of cardiopulmonary responses during manual lifting tasks. Human factors and Ergonomics in manufacturing and service industries. Vol. 21, No.1, 29-43. [10] Balderrama, C., Ibarra, G.,Riva, J., Lopez,S., 2010. Evaluation of three methodologies to estimate the VO2 max in people of different ages. Applied Ergonomics. Vol.42, 162-168. [11] Ceriello, V.M.,2007. The effects of container size, frequency and extended horizontal reach on maximum acceptable weights of lifting for female industrial workers. Applied Ergonomics. Vol. 38, 1-5. [12] Singh,S.,Kumar,S.,2010. The effect of mechanical lifting aid in single task lifting using revised NIOSH lifting equation. International journal of Advanced Engineering Technology, Vol.1, Issue II, 165-172.