Transportation Cost

advertisement

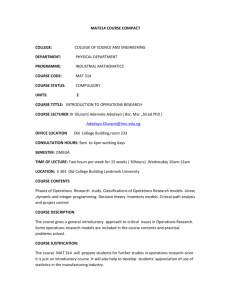

Basic Optimization Training LLamasoft, Inc October 2008 Optimization Course Overview • Course Goal: Understand the basics of supply chain optimization through lecture, computer exercises, and coaching • Course Objective: Students will be able to use the software, with minimal assistance, to correctly build a supply chain model; add the basic components of optimization to the model; perform an optimization; interpret the results through outputs; and perform an infeasibility analysis. Agenda • • Overview of Model Components Optimization Basic Components – Structure – Cost – Constraints • • • Infeasibility Analysis Optimization Results Review Model and Optimization Overview Model Elements Understanding Optimization What is the optimal network structure? • Evaluate millions of alternatives, find the global optimal structure: lowest cost structure that meets the constraints • Determine the optimal supply chain network structure using MIP/LP programming Thousands of possibilities… …One Optimal Answer! Optimization Basic Component 1 Structure Learning Objective- Structure • Explain the basic components to modeling in the software • Use the components to create a supply chain network • Perform a network optimization Goal: Successfully design a new optimal supply chain network using the software Example Network Design- Sites FW1 CZ1 P1 FW2 CZ2 PW1 S1 P2 FW3 PW2 S2 FW4 P3 PW3 FW5 CZ3 CZ4 CZ5 CZ6 Structure • 6 Essential Elements in Models – – – – – – Sites Products Demand Sourcing Policies Transportation Policies Inventory Policies Exercise 1: Network Optimization Model Folder • Go to Computer and Create Folder: C://Llamasoft/Training/Optimization Open Supply Chain Guru • Start Add a New Model • Go to File Add A New Model Saving Models and Projects • Save Model in Training Folder: C://Llamasoft/Training/Optimization • Save Model As: Opt_Training_Basic • Save Project As: Guru_Training Site Types • Customer Site – Only customer sites can have demand – Customer sites have sourcing policies but NO inventory policies – They do not ship to other sites or produce any products – Flow into customer sites = $$$ (revenue!) • Existing Facility – Indicates this site presently exists in the supply chain • Potential Facility – Indicates this site presently does not exist in the supply chain • Type, and Choice combine to determine which costs to apply – Open Potential Facility = Add Startup Cost – – Closing Existing Facility = Add Closing Cost Always incur Fixed Operating Costs if flow exists Creating the Opt_Training_Basic Model 4 Sites IP IP SP CZ DC 1 TP SP IP TP SP SP TP TP DC 2 Product A 2 Products Product B MFG Opt_Training_Basic Model: Sites MFG DC 1 DC 2 CZ • Name • Location (Address, City, State, Country, Postal Code, Latitude, Longitude) • Capacity Period, Capacity Basis • Fixed Startup Cost/Cap, Fixed Operating Cost/Cap • Closing Cost Opt_Training_Basic Model: Add Customer Site • Open the Sites Table • Add Customer Site – Name: CZ – City: New York – State: New York – Type: Customer – Graphic: Circle – Graphic Color: Green – Leave all other fields default Opt_Training_Basic Model: Add DCs • Add Distribution Center 1: – Name: DC_1 – – – – – City: Omaha State: Nebraska Type: Existing Facility Graphic: Triangle Graphic Color: Yellow • Add Distribution Center 2: – Name: DC_2 – – – – – City: Austin State: Texas Type: Existing Facility Graphic: Triangle Graphic Color: Yellow Opt_Training_Basic Model: Add Manufacturer • Add Manufacturer: – Name: MFG – City: Los Angeles – State: California – Type: Existing Facility – Graphic: Square – Graphic Color: Red Opt_Training_Basic Model: Column Update • Place cursor in the Graphic Size Field • Right Click or Select the Column Update Button on the toolbar • Select 10 from the drop down menu and apply the update Opt_Training_Basic Model: Layout Map • Display the Sites on the Layout Map Opt_Training_Basic Model: Products Product A • • • • • Name/ SKU Inventory Valuation Price Weight, Cubic Status Product B Opt_Training_Basic Model: Add Products • Open the Products Table • Add (2) Product Records • Product_A – – – – – Value: 5 Price: 10 Weight: 5 Cubic: 5 Status: Include • Product_B – – – – – Value: 10 Price: 20 Weight: 10 Cubic: 10 Status: Include Opt_Training_Basic Model: Demand Demand In • • • • Customer Site Product Quantity Occurrences CZ • Time Between Orders • Due Date • Price Opt_Training_Basic Model: Add Demand • Open the Demand Table • Add (2) Demand Records • Record 1 – Customer Site: CZ – Product Name: Product_A – Quantity: 100 – Order Time: 0 • Record 2 – Customer Site: CZ – Product Name: Product_B – Quantity: 100 – Order Time: 0 Shipments Vs. Demand • Shipments are typically modeled through the Transportation Policies table • Shipments table allows you to model shipments outside of the Transportation Policies table • There are no cost fields in the Shipments data table- the costs in the Transportation Policies table are used to calculate the transportation costs • Allows for accurate modeling of a “Push” system, instead of a demand driven supply chain Opt_Training_Basic Model: Sourcing Policy DC 1 CZ Product_A, Product_B Product_A, Product_B MFG DC 2 • Identifies which sites to send replenishment and customer orders, and whether product is ordered from an outside source or made at that site Types of Sourcing Policies • • • • • • Single Source Single Source (Select Closest) Multiple Sources (Most Inventory) Multiple Sources (Order of Preference) Multiple Sources (Probability) Source by Transfer • • • • • Make Make by Schedule Make (Single Process) Make (Order of Preference) Make (Probability) Hint: Use the Quick Reference Card for descriptions of these policies! Opt_Training_Basic Model: Adding Sourcing Policies • Open the Sourcing Policies Table • Add a total of (10) Sourcing Policies – 4 Multiple Sources (Most Inventory) • CZ can source Product_A from DC_1 and DC_2 • CZ can source Product_B from DC_1 and DC_2 – 4 Single Source • Each DC can only source from the MFG for Both Products – 2 Make • 1 for each product at the Manufacturer Opt_Training_Basic Model: Layout Map • Display the Sourcing Policies on the Map Opt_Training_Basic Model: Transportation Policy DC 1 CZ MFG DC 2 • • There must be at least one Transportation Policy that applies to source and destination which is not “Make” Each Transportation Policy defines a “Flow” – – – – Source Site Destination Site Product (all applicable products if not explicitly entered) Mode (1 if not explicitly entered) Types of Transportation Policies • • • • • Parcel LTL (Less than Truckload) Full TL (Full Truckload) Air, Rail and Ship Daily or Weekly Shipment • • • • • • • Periodic Shipment Pooled Outbound/ Pooled Inbound Pooled Periodic Outbound/ Pooled Periodic Inbound Flow (Optimization Only) Link To Lane Aggregate Container Disaggregate Container Opt_Training_Basic Model: Add Transportation Policies • Open the Transportation Policies Table • Add (4) Transportation Policies • One for each Source-Destination combination defined in the Sourcing Policies - Source Sites: MFG, DC_1, DC_2 - Destination Sites: DC_1, DC_2, CZ - Leave all other fields at default value Opt_Training_Basic Model: Inventory Policy Product_A Product_B MFG Product_A Product_B DC 1 Product_A Product_B DC 2 • Defines – Initial Inventory Levels – Safety/ Cycle Stock Levels – Associated Costs • One Inventory Policy is optional for each product at the facility sites Opt_Training_Basic Model: Add Inventory Policies • Open the Inventory Policies Table • Add (6) Inventory Policies – One for each Facility (non-Customer Site) and Product combination • Sites: MFG, DC_1, DC_2 • Product Name: Product_A, Product_B • Leave all other fields at default value Opt_Training_Basic Model: Add Costs • • Open the Sourcing Policies Table Add a sourcing cost to one lane (2 policies) – Use the filter bar – Update the Average Unit Cost to 1 and clear the filter to view only DC_1 How do you think this will affect the optimization results? Opt_Training_Basic Model: Model Options • Go to Tools Model Options (F3) • Review Optimization Period – Start Date / Time – End Date / Time Opt_Training_Basic Model: Run the Optimization • Optimize the Supply Chain • Save the Project and the Model Opt_Training_Basic Model: Optimization Solver • View Optimization Results – Optimization Output Tables – Metrics – Graphs – Auto Implement Optimized Network Check on Learning- Structure • You should be able to: – – – – – – – – – – – Open Supply Chain GuruTM Add a new model Save a project Save a model Open a table Understand differences between sites and customers Use the filter bar Move from field to field Open the layout map Change settings on the layout map View sites and policies on the layout map – Understand the types of Sourcing policies – Understand the types of Transportation Policies – Understand when to use shipments vs demand – Understand the types of Inventory Policies – Enter data into tables – Access the help system – Set Optimization Options – Run a simple optimization – Run the error check on a model – Access Optimization Outputs Optimization Basic Component 2 Costs Learning Objective- Cost • Distinguish between the different costs used in Supply Chain Optimization with the software • Apply costs to the network built in Exercise 1 Goal: Successfully optimize the network with the new costs included Three Basic Components of Optimization • Structure • Costs • Constraints Basic Costs for Optimization • Site Costs – Fixed operating – Fixed startup – Closing • Transportation Costs – – – – – Average Cost Duty Rate Discount Rate Return Trip Cost Transportation Asset Costs • Unit Fixed Cost • Inventory Costs – Site inventory – In-transit inventory – Inbound and Outbound Warehousing • Production Costs – Work Center Costs • Fixed Operating • Fixed Startup • Closing – Work Resource Cost Basic Costs Site Costs Site Costs • • • Fixed Operating Fixed Startup Closing Site Costs: Fixed Operating • Costs associated with the day to day operations of the facility • Enable use of a step- function to associate the operating cost based upon operating capacity Site Costs: Fixed Operating • Facility is closed/not used if the throughput is zero. • Facility is open at Level 1 if the throughput is between 0 and 5,000 pounds. • Facility is open at level 2 if throughput greater than 5,000 pounds Site Costs: Fixed Start-Up • • • • Costs to open and begin operating a new facility Only applies to Potential Facilities No thoughput constraints Ability to use step- function to associate start up cost with operating capacity Site Costs: Closing • Cost to end operations at an Existing Facility • Does not apply to Potential Facilities or Customers Exercise 2a: Add Site Costs Exercise 2a: Create New Cost Model • From the Project Explorer, right click on the Opt_Training_Basic Model • Select Copy Model • Right Click on the copied model • Select Save Model As • Save model as: Opt_Training_Cost Exercise 2a: Add Fixed Operating Costs • Open the Sites Table • Open the Field Guru • Enter the following Fixed Costs: DC_1 Capacity Cost 0 500 100 500 DC_2 Capacity 0 500 Cost 50 250 Exercise 2a: Complete Fixed Operating Costs • Now run the optimization and view the results! Basic Costs Transportation Costs Transportation Costs: The Concept of “Flow” • In Optimization, there are no individual shipments • Instead it is the total amount shipped, as determined by the optimizer • This total amount is the “Flow”. 10,000 Units Site A Site B Transportation Cost • “Average Unit Transportation Cost” – – – – Average Cost Cost Basis Shipment Weight Distance Transportation Cost: Average Cost • Related to Cost Basis • Transportation Cost per Cost Basis Unit • Associated Field Guru Transportation Cost: Cost Basis • • • • • • • • Weight = Avg Cost * Weight of Flow Qty = Avg Cost * Number of Units of Flow Cubic = Avg Cost * Volume of Flow Distance = Cost per Mile Fixed = Fixed Cost per Shipment Weight-Distance = Cost per Pound per Mile Qty-Distance = Cost per Unit per Mile Cubic-Distance = Cost per Volume per Mile Transportation Cost: Distance and Fixed Cost Basis • In order to cost these correctly the optimizer needs to approximate the number of shipments made 10,000 Units Site A Site B Total Flow Transportation Cost: Shipment Weight • Since the optimizer only knows the flow (sum of all shipments), the only way to cost at the “shipment” level is to approximate the shipment size. • If the flow is 10,000 pounds, and the average shipment weight is 1000 pounds that corresponds to 10 shipments. Transportation Cost: Distance • Calculate using Straight Line – Based on latitude and longitude of source and destination sites – Adds a circuity factor (17%- in Model Options) • Calculate Using Mappoint Routing – Interfaces with Microsoft Mappoint to determine actual road distance – Must have Map Point installed on the same computer Transportation Cost: Transportation Assets • Total cost of owning or using each unit of this asset • This is a fixed cost, not used to calculate profits or expenses in the network operation • Included on the summary report, can be used to compare various scenarios Transportation Cost: Other Costs • Duty • Discount Rate • Return Trip Cost Exercise 2b: Add Transportation Costs to Cost Model Exercise 2b: Add Transportation Costs • Copy Opt_Training_Cost Model • Save as Opt_Training_Cost_Transpo • Add the following costs: – MFG facility always costs 2.00 per unit shipped to any location – DC_1 costs 10.00 per unit, per mile to ship to the customer – DC_2 costs 20.00 per unit, per mile to ship to the customer Exercise 2b: Results • Now run the optimization and view results! Basic Costs Inventory Costs Inventory Costs • • • • Facility Inventory Holding In-transit Inventory Holding Inbound Warehousing Outbound Warehousing Inventory Costs: Facility Inventory Holding Inv Holding Cost = Avg Inv * Product Value * (i/365) * T • Avg Inv = Average Inventory • Product Value = Value in Products Table • i = Annual inventory carrying cost % • T = Optimization period in days Inventory Costs: Average Inventory Calculation • Method of Calculation – Inventory Turns OR – Constituent Parts • • • Safety Stock Inventory Cycle Stock Inventory Pre-Build Inventory Facility Inventory Level Determination • Total Facility Inventory Factors which affect inventory levels – Volume/ Qty of product throughput (Tput) – Number of facilities in the network Avg Inv Tput (Qty) • As the number of facilities decreases, the average inventory in the remaining facilities increases due to increased throughput, but at a decreasing rate. Average Inventory Calculation 1: Inventory Turns • • • • Ratio of inventory throughput to average inventory Increasing Inventory Turns reduces Facility Holding Costs Must balance turnover with safety stock to avoid stockout Also called Stock turns, turns, stock turnover Inventory Turns: Linear Approximation Avg Inv Inv Turns = 8 Slope=1/8 Tput (Qty) Avg Inv = m * Tput • m = Inverse of Inventory Turns • Tput = Volume of Product Throughput Inventory Turns: Pooling Effect • Piecewise linear approximation • Used in locations with considerable amounts of product, typically called a distribution center • Average Inventory can defined over multiple ranges of throughput. • Format for the relationship is a series of pairs <lower range value, turns value> Inv Turns = <0,5><1000,8><3000,15> Avg Inv 1/15 1/8 1/5 1000 3000 Tput (Qty) Up to 1000, Avg Inv = (1/5) * Tput. Between 1000 and 3000, Avg Inv = (1/8) * Tput + 75. After 3000, Avg Inv = (1/15) * Tput + 250. Average Inventory Calculation 2: Constituent Parts • Pre-build • Safety Stock • Cycle Stock Constituent Parts: Pre-Build Inventory • Results from demand exceeding production capability in one period, but excess production completed in the previous period • Example – – – – • In a 2 period model MFG has a production capacity of 50 units The demand is 20 and 80 units in Periods 1 and 2 respectively The MFG site produces 50 units each period In the first period the 30 excess units produced are stored as Pre-Build Inventory Viewed in the Optimization Output- Inventory Table Constituent Parts: Safety Stock • Held excess product • Also called a buffer • The model may tap into the safety stock when necessary Constituent Parts: Cycle Stock 2.5 2 Cycle Inventory • Portion of inventory allocated to meet anticipated demand • In a simple model where demand is constant, cycle stock equals half the order size 1.5 1 0.5 0 0 0.5 • • • 1 1.5 2 2.5 3 3.5 4 Time The blue line refers to actual cycle inventory The red line refers to the average cycle stock The order size is 2 units and occurs once per unit time 4.5 Average Inventory Calculation: Constituent Parts • Sum of pre-build inventory, safety stock and the cycle stock Inventory Costs: Facility Inventory Holding Why determine Average Inventory? Avg Inv is used to calculate Facility Inventory Holding Costs in the Optimization Inv Holding Cost = Avg Inv * Product Value * (i/365) * T Avg Inv = Average Inventory Product Value = The Product’s Value in the Products Table i = Annual inventory holding cost % T = Optimization period in days Inventory Costs: In-transit Inventory Total Cost due to value of products being transported and transport time T days Site A Site C Quantity Q In-transit Inventory Cost = Q * Product Value * (i/365) * T • • • • Q = Quantity of Products in-transit Product Value = Value in Products Table i = Capacity Cost % in Model Options T = Transport Time in Days In-transit Inventory Costs: Example Product Value = $500 DC_A_Local 10 days DC_B_Overseas Customer Demand = 1000 units In-transit Inventory Cost = Q * Product Value * (i/365) * T A to C 1000 * $500 * (15%/365) * 10 = $2,055 B to C 1000 * $500 * (15%/365) * 90 = $18,493 Inventory Costs: Inbound and Outbound Warehousing • Inbound Warehousing Cost: activity cost of handling and moving one unit of product from receiving dock to inventory • Outbound Warehousing Cost: activity cost of removing one unit of this product from inventory to the shipping dock • Includes such costs as paper tracking procedures, handling equipment, and personnel • Does not include Transportation Costs Exercise 2c: Add Inventory Costs Exercise 2c: Add Inventory Costs • Copy Opt_Training_Costs_Transpo • Save as Opt_Training_Costs_Inventory • DC_1 – 5 Inventory Turns – 15% Annual Inventory Holding Cost – Inbound Warehousing= .5 – Outbound Warehousing = .6 • DC_2 – 7 Inventory Turns – 15% Annual Inventory Holding Cost – Inbound Warehousing = .7 – Outbound Warehousing = .8 Exercise 2c: Results • Run the Optimization and View the Results! Basic Costs Production Costs Production Costs • Simple Costing • Work Center Costs (Sub Models) – Fixed Operating – Fixed Startup – Closing • Work Resource Costs Production Costs: Simple Unit Production • Avg Unit Cost field for a “Make” sourcing policy • Source Name field is left blank. • Field Guru enables costing from a Step Graph for Economies of Scale Optimization Basic Component 3 Constraints Learning Objective- Constraints • The learner will be able to explain the different constraints involved in the software, identify potential constraints to a supply chain model, apply constraints to a practice model, and successfully perform an optimization on the model Constraints in Optimization • Basics of Constraints • Aggregate Constraints – – – – Flow Inventory Production Site • Service Constraints – – – – Max Sourcing Distance Due Date End to End Bundled Demand The Basics of Constraints: Definition • Restrictions placed upon the model • Aggregate Constraints: restriction defined for a sum over multiple objects, with at least one object having two or more values – – – – Flow Inventory Production Site • Service Constraints: restriction placed on the service to a customer The Basics of Constraints: Use in the Software • Types of Constraints – – – – Minimum Maximum Fixed Conditional Minimum • Constraint Variable Inputs – Specific: Refers to one site/ product/ time period/ mode – Set: Refers to a group of sites/ products/time periods/ modes – All: Refers to all sites/ products/ time periods/ modes Aggregate Constraints • • • • • Throughput Flow Inventory Production Site Aggregate Constraints: Throughput • Site is restricted by the amount of flow (basis)in the model during the specified period • Step function depicts capacity limit with INF Aggregate Constraints: Flow Flow requirement, flow requirement type, flow requirement basis, and time period that the restriction occurs DC 1 CZ 1 Restricted by 5 elements: Site, Destination, Mode, Product , or Time Period Aggregate Constraints: Flow • Places a restriction on the product flow over a set of time periods, between source and destination sites, for products or when using a specified mode Aggregate Constraints: Flow Count • Sets up intricate constraints in the model linking the following 5 variables; Source, Destination, Product, Mode and Period • By aggregating the Destination Sites, Products and Modes it disregards the various possible flows that are due to these variables Aggregate Constraints: Inventory • Restricted by 3 Elements – Site – Product – Time Period Aggregate Constraints: Inventory • Allows the specification of additional rules regarding inventory • Defines aggregated quantities over sites, products, and time periods Aggregate Constraints: Inventory Count • Similar to aggregate flow count • Can utilize the “Set” feature of the Groups Table Aggregate Constraints: Production • Restricted by 4 elements – – – – Site Process Product Time Period Aggregate Constraints: Production • Defines aggregated productions that need to be restricted by a plant, or set of plants and by products, or set of products Aggregate Constraints: Production Count • Similar to Aggregate Flow Count, but pertains to Productions Aggregate Constraints: Site • Defines the minimum and maximum number of open sites allowed in a set of periods Aggregate Constraints at Sites • Allows the user to customize the number of sites that can be used in a specific time period Service Constraints • • • • Maximum Sourcing Distance Due Date End to End Bundled Demand Service Constraints: Maximum Sourcing Distance Consider a network with manufacturing, warehousing, and customer echelons. All flows between two successive echelons are permitted. DISTANCES M1 WH1 CZ_1 CZ_2 M2 WH1 WH2 WH3 M1 500 800 120 M2 600 1000 200 M3 300 500 750 CZ_1 CZ_2 CZ_3 CZ_4 WH1 180 720 340 600 WH2 700 150 280 100 WH3 150 200 70 640 WH2 CZ_3 M3 WH3 CZ_4 Maximum Sourcing Distance If the maximum sourcing distance is 200 miles for customers and 500 for the warehouses, the network is reduced to the following flow alternatives. DISTANCES M1 WH1 CZ_2 M2 WH1 WH2 WH3 M1 500 800 120 M2 600 1000 200 M3 300 500 750 CZ_1 CZ_2 CZ_3 CZ_4 WH1 180 720 340 600 WH2 700 150 280 100 WH3 150 200 70 640 CZ_1 WH2 CZ_3 M3 WH3 CZ_4 Maximum Sourcing Distance • Between the end site and the source node • Distance Based • Can be set in either the Sourcing Policy Table or the Service Requirements Table Service Constraints: Customer Due Date Customer due date-driven service constraints force the demand to be classified by customer lead times. Suppose P1 demand at each customer is 100 units. Classified demand CZ_1 2 P1 in 7 days=75 P1 in 3 days=25 1 WH1 3 1 4 3 Air Truck Rail CZ_2 7 3 6 5 2 4 WH2 1 P1 in 5 days=50 P1 in 1 days=50 5 CZ_3 P1 in 6 days=40 P1 in 5 days=60 Customer Due Date All supply alternatives are feasible for the first demand classification, but only the following alternatives are feasible for the second classification CZ_1 P1 in 3 days 2 1 WH1 4 Air Truck Rail 1 3 CZ_2 3 P1 in 1 days 5 5 4 WH2 1 CZ_3 P1 in 5 days Customer Due Date • Only from the last echelon site to the customer • Time- based • Set in the Demand Table Service Constraints: End-to-End End-to-end service requirements are given from a make-node to a customer node. WH1 CZ_1 M1 WH2 CZ_2 M2 WH3 Time from M1 to CZ_1 for Product1 <= 5 days Time from M2 to CZ_1 for all products <= 7 days Distance from M1 to CZ_2 for Product2 <= 250 miles End to End Constraints • Source Site does not have to directly deliver to the customer; there may be other facilities in the network where the order will pass through • Specified by maximum time for an order to leave the facility and reach the customer OR by maximum allowable distance between the facility and the customer • Set in Service Requirements Table Service Constraints: Bundle Demand When choosing to bundle demand, demand for all products at one customer site will be sourced from one or multiple facilities at the same ratio WH1 450 75 CZ_1 150 WH2 25 Demand CZ_1(P1) = 600 Demand CZ_1(P2) = 100 Bundled Demand • Check this box to aggregate all the demand by customers • When a customer demands multiple products, these are sourced in equal ratios from one or multiple sites (proportional to the demand quantities for these products) Exercise 3a: Constraining the Optimization Model Unconstrained Model • Al Five DCs in Use • Houston Processing Plant supplies only DC_KC With Aggregate Flow Constraints • Max Flow Reqt Type means at most 500 units of flow can go through DC_Albany. • Cond Min Flow Reqt Type means we either have at least 1000 units flow through DC_Portland or none at all. • How does this change our optimized results? With Aggregate Flow Constraints • DC_Portland not used, customers now served by DC_Phoenix • Fewer CZs in Northeast are served by DC_Albany, more by DC_Atlanta With Aggregate Production Constraints • Max Flow Requirement Type means that at most 1000 units can be produced at Norfolk. • Min Flow Requirement Type means at least 850 units must be produced at Reno. • How does this change our optimized results? With Aggregate Production Constraints • Fewer CZs in Midwest served by DC_Atlanta, more by DC_KC. With Aggregate Site Constraints • Create Group that contains all five DCs. • Constrain Optimizer to select between one and three sites from within that group. • How does this change our optimized results? With Aggregate Site Constraints • Portland and Phoenix DCs are unused, KC picks up the slack. With Aggregate Inventory Constraints • Open the Optimization Output Inventory table and note the inventory costs at DC_KC. • Set Minimum Inventory at DC_KC to 100 units. • Optimize the model. • How does this change inventory costs at DC_KC? Exercise 3b: Add Constraints Exercise 3b: Add Constraints • Copy the Final Cost Model • Save as Opt_Training_Constraints • Add the following Constraint: – DC_1 can only ship a maximum of 50 units of Product_A to CZ_1 for the entire model period (Horizon) • Now run the model and view the results! How this affect the network design? Check on Learning- Constraints • You should be able to: – Define aggregate constraints – Define service constraints – Open the service requirements table – Open the aggregate constraint tables – Create service constraints – Create aggregate constraints – Define and distinguish between serve and aggregate constraints – Explain the constraint requirement types – Apply aggregate constraints to a model – Apply service constraints to a model – Understand aggregate constraints sum and objects Infeasibility Analysis Guru Infeasibility Analysis • • • Sometimes the optimization solver returns with a “Problem Infeasible” error message Infeasibility refers to a problem with input datathere is no solution that fulfills all the constraints Guru provides the following tools to help the user identify the source of infeasibility – – – Check for supply-demand imbalance Check for logic errors in defining the network structure Remove all or some hard constraints and solve again Infeasibility Analysis Select the hard constraints to impose Optimization Results Optimization Results • • • • • Output Tables Graphs Metrics Layout Map Comparing Models Optimization Results: Output Tables • Summary – – – – – – Network Customer Facility Work Center Transportation Asset Work Resource • Flows – Customer – InterFacility – Production Process • Details – Productions – Inventory – Aggregated Demand Optimization Results: Graphs • Click of button to display results • Numerous choices for data display Optimization Results: Metrics • Quick access to outputs • Tables can be exported to Excel Exercise 4: View Optimization Outputs Viewing Optimization Outputs • Compare optimization outputs from the Basic Model and the final Model – Graphically depict – Compare Tables Review Review • • • • • • Model Components Structure Cost Constraints Infeasibility Analysis Optimization Results LLamasoft Support • Email: Support@llamasoft.com • Phone: (734)-418-3133 • Website: www.llamasoft.com