Process Monitoring - Process Control Education

advertisement

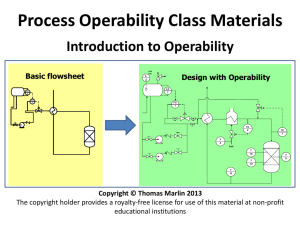

Process Operability Class Materials Process Monitoring Basic flowsheet LAH LAL Design with Operability L 2 LC 1 LC 1 FC 1 FC 1 TC 2 TC 1 F 4 fuel T 10 T 12 T 13 Copyright © Thomas Marlin 2013 The copyright holder provides a royalty-free license for use of this material at non-profit educational institutions T 11 Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS To perform monitoring and diagnosis, people need information. Sensor Issues (a little review) 3. Reliability Real-time Decisions* 4. Safety & equipment protection • Trouble shoot incidents using proven method Real-time sensors • Information to support decisions required quickly Fast lab analyses 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Process Performance Improvement • • Longer term performance indicators based on data and calculations Usually identifying slow trends * See trouble shooting lesson for more on strategy and examples Sensors for calculations Lab analysis Data for statistical analysis Sensors Key Operability issues MONITORING AND DIAGNOSIS Sensors 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection Selecting sensor technology • Achieve required accuracy and reproducibility • Achieve required reliability - Functions well for range of process environments - Protect from damage (e.g., thermowell) or sample from process and measure in less harsh conditions - Redundancy, if required - Redundancy with diversity, if required 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance • Provide means for calibration and maintenance • Balance cost (capital,maintenance and operating) with benefit to achieve economic return 8. Monitoring & diagnosis http://www.pc-education.mcmaster.ca/instrumentation/go_inst.htm (Select 2.0 Sensors) Sensors Key Operability issues 1. Operating window MONITORING AND DIAGNOSIS Sensors 2. Flexibility/ controllability analysis all other level 3. Reliability 4. Safety & equipment protection Sensors used for plant control flow temperature pressure 5. Efficiency & profitability all other flow analysis 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Sensors used for plant display and monitoring level pressure temperature Higham, E.H., A Route to Better Process Measurements, I.Chem.E. Hazards X - Process Safety in Fine Chemical and Specialty Plants, 1989. (Current practice might include more on-stream analysis.) Sensors Key Operability issues 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection MONITORING AND DIAGNOSIS Sensors Class exercise on sensors You have been asked to evaluate the performance of a process. You will use all forms of data, from trend to historical reports. What are some of the questions that you might to ensure that you interpret the sensor data correctly? 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Why should I ask questions? Every data value is exact, at least to the number of significant figures on the plot or in the numerical display! Sensors Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window 2. Flexibility/ controllability Class exercise: a. Sensor range 3. Reliability 1. Most sensor accuracies depend on the range (or span). A sensor with a range of 1000 K has a poorer accuracy than one with a range of 100 K. 2. Some sensor accuracies depend on the position in the range. For example, an orifice meter has a very poor accuracy at 10% of maximum range. 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Also, a flow meter can report a very small value when the flow is actually zero. 3. If the measured value equals the maximum (minimum) of the range, the plant value could be much higher (lower) than the reported value. Sensors Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window 2. Flexibility/ controllability Class exercise: b. Sensor Technology 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis 1. Different sensors for the same process variable (P, T, F, L, etc) can have very different accuracies. For example, a RTD is much more accurate that a thermocouple. 2. Different sensor technologies are robust (sensitive) to changes in process conditions,such as suspended solids in a flowing fluid. This knowledge helps in anticipating potential sensor problems, sensor loss of accuracy and in trouble shooting process operation. Sensors Key Operability issues 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis MONITORING AND DIAGNOSIS Process Performance Improvements Class exercise: c. Measurement compensation. Several measurements can be used to provide a more accurate value for a single process variable. Orifice flow meters relate the pressure change across the orifice to the flow rate. The relationship depends on the fluid density. Either the density or gas pressure and temperature can be used to correct for changes for an assumed (design) value. You need to know whether or not this correction has been performed. Is this measured and used in the calculation, or is the value assumed constant (at the design value?) Real-time Key Operability issues MONITORING AND DIAGNOSIS Real-time Decisions 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection We have learned the importance of measurements in trouble shooting. • During process design, we need to brainstorm a list of likely faults that will require trouble shooting • Faults in sensors are expected and can easily mislead personnel. Select reliable sensors that match process environment and add redundancy where appropriate. • For each, the diagnosis procedure can be documented (and used for training and manual writing). Fishbone diagrams aid the thought process and documentation. • We need to ensure that the required measurements (sensors and laboratory) are provided to support successful trouble shooting! 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Real-time Key Operability issues MONITORING AND DIAGNOSIS Real-time Decisions 1. Operating window 2. Flexibility/ controllability We select measurements based on an analysis of design goals and possible incidents 3. Reliability Significant Incident # 3 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis • Safety • Equipment damage Root cause 1 Root cause 2 • • • Environmental impact • • Product quality • • Production rate • • Profitability Root cause n Select measurements that enable operations personnel to uniquely determine the most likely root causes of every significant incident. Real-time Key Operability issues MONITORING AND DIAGNOSIS Real-time Decisions 1. Operating window Balancing Function and Cost – Location of sensors 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection Control room Displayed & Automatic Control 7. Dynamic Performance 8. Monitoring & diagnosis 1 • The variable is required to achieve one of the control objectives for the process. • Necessary information for the controller can be measured. Variable should be monitored reliably and rapidly. • Rapid and reliable feedback is required. • Automated action may be discrete or continuous. • Manipulated variable can be adjusted automatically • Stored in computer history and available on trend plot • All of above applies to safety shutdown as well as modulating control. 5. Efficiency & profitability 6. Operation during transitions TC Real-time Key Operability issues MONITORING AND DIAGNOSIS Real-time Decisions 1. Operating window 2. Flexibility/ controllability Balancing Function and Cost – Locations of sensors 3. Reliability Control room Displayed T 2 4. Safety & equipment protection • Variable need not be controlled automatically; can be used to monitor process/equipment performance 5. Efficiency & profitability • If controlled, slowly by operator action is acceptable 6. Operation during transitions • If controlled, manipulated variable adjusted from control room (“manual” station to change valve % open or motor on/off) • Stored in computer history and available on trend plot 7. Dynamic Performance 8. Monitoring & diagnosis Real-time Key Operability issues MONITORING AND DIAGNOSIS Real-time Decisions 1. Operating window Balancing Function and Cost – Location of sensors 2. Flexibility/ controllability Locally Displayed 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 3 • Variable need not be controlled; can be used to monitor process/equipment performance • Operator must travel to unit to observe the display • Used to monitor slowly changing process/equipment performance, for example, heat exchanger fouling and pressure drops in packed beds • Can be used for trouble shooting when rapid response is not required • Not stored in computer history - can be recorded on written log very infrequently (1/shift or day) 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis T Real-time Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS Real-time Decisions Real-time data is used to determine the “health” of the process. Use your process knowledge! 3. Reliability For a chemical reaction with a significant heat of reaction (endo- or exothermic), the temperature change across the reactor provides an inference of the extent of reaction. 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Hydrocracker reactions are highly exothermic Runaway is possible. Very useful, especially when on-stream analysis is not practical Real-time Key Operability issues MONITORING AND DIAGNOSIS Real-time Decisions 1. Operating window 2. Flexibility/ controllability Real-time data is used to determine the “health” of the process. Use your process knowledge! 3. Reliability 4. Safety & equipment protection For semi-batch (batch-fed) bio-reactor, the off-gas flow rate and composition can be used to monitor the “health” of the reaction system – should the batch continue to completion or be aborted? PC 5. Efficiency & profitability TC FC 6. Operation during transitions fo fc Gas produced by the biological process L fo 7. Dynamic Performance 8. Monitoring & diagnosis CW fo Real-time Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS Real-time Decisions Real-time data is used to determine the “health” of process equipment. Use your knowledge of equipment. 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis • Used for monitoring, display, and alarms to personnel • Used for SIS for safety and equipment protection Monitoring rotating equipment can include • Vibration • Temperature • Flow • Lubrication pressure • Power consumption • Equipment manufacturers often provide monitoring Turbine T. Reeves, EPTQ, Q3, 2005 (www.eptq.com) Compressor Real-time Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS Real-time Decisions Real-time data is used to determine the “health” of process equipment. Use your knowledge of equipment. 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis In a chemical reactor, poor flow distribution can lead to “hot spots” that can damage catalyst or even the reactor vessel. Locating many temperature sensors at various locations in the bed provides monitoring for poor flow distribution. Used for monitoring, alarms and control. Real-time Key Operability issues 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis MONITORING AND DIAGNOSIS Real-time Decisions We need information for process troubleshooting. Remember that people are the ultimate backup protection; they have to correct for equipment malfunctions. Class Workshop: Add the sensors required to monitor this distillation tower in real time. Hints: • What limits must not be violated? • What incidents must we diagnose? • What equipment can fail? • What redundancy is needed? • Where should display be located? FR FV Real-time Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS Real-time Decisions Class Workshop: Add the sensors required to monitor this distillation tower in real time. 3. Reliability Some thoughts: 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis • pressure of closed vessel is very important • levels in the accumulators are unstable • trays can leak liquid to lower trays • trays can become blocked • internal flows can exceed hydraulic limits • utility streams are important (e.g., steam) • the composition of trays should have an expected profile • pumps can malfunction • cooling water temperature should be below maximum limit Real-time Key Operability issues MONITORING AND DIAGNOSIS Real-time Decisions 1. Operating window To flare T 29 PAH 2. Flexibility/ controllability T 30 PC-1 PV-3 Do we need to increase the capital costs with all theses sensors? L4 P3 T5 3. Reliability P 12 P 20 4. Safety & equipment protection LAH LAL LC-1 17 FC 7 16 Plus maintenance! dP-1 F 30 15 T6 5. Efficiency & profitability AC 1 P 21 T10 3 TC 7 6. Operation during transitions T20 FC 4 2 dP-2 1 P 11 7. Dynamic Performance T 44 T 22 LC 3 LAH LAL F9 FC 8 8. Monitoring & diagnosis YES !! T 45 P 23 Longer term Key Operability issues 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis MONITORING AND DIAGNOSIS Process Performance Improvements • Many features of a process change slowly, over days, weeks or months • The performance of complex systems is often not obvious from direct observation of the data • Engineers can identify key process performance measures that can be calculated automatically and stored in history • Actions are based on careful analysis of the data and might require either minor changes or extensive plant changes, during shutdowns Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions Often, several measurements are used to calculate a key process variable from a complex process. Examples of performance measures are: • • • • • 7. Dynamic Performance • 8. Monitoring & diagnosis Yields from a reactor Electricity consumption per kg feed Total effluent (of water, sulfur, etc.) Efficiency of equipment (turbine, compressor, fired heater, etc.) Operating conditions for successful and unsuccessful batches Inventory in plant (work in progress, feed, and finished products) Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection Engineers must understand the sensors used and the methods for data storage before deciding how to use the measurement data. • Each sensor has a physical principle affecting its accuracy and reproducibility • Data is stored in a history data base, but some information is lost • Some actions by people are also recorded • Sometimes, measurement and computing equipment fail 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window 2. Flexibility/ controllability History data base 3. Reliability Display Exercise: What questions would we like to answer using the history data base? 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis The historical data base typically contains 1. 2. 3. 4. 5. Sensor measured values Events: Alarms, set point changes, controller mode and tuning changes, SIS activation Calculated variables (defined and build by engineer) Cause of SIS activation Laboratory analysis Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window History data base 2. Flexibility/ controllability Display 3. Reliability 4. Safety & equipment protection Some typical questions answered using the historical data base 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis • • • • • • How much feed did we process last week? What was the yield of vinyl chloride monomer? How much energy was consumed per 1000 kg of product? What was the total release of sulfur from the plant last month? What was the distribution of product quality, displayed as a histogram? How much valuable hydrogen was diverted to fuel gas last week? Longer term Key Operability issues 1. Operating window MONITORING AND DIAGNOSIS Process Performance Improvements 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection Storing ½ second data for 1000 measurements for 30 years is a lot of data! 1000 x 120 x 60 x 24 x 365 x 30 2 x 1012 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Therefore, the data base has several layers with data aggregated to reduce storage. While storage capacity and computer speeds will continue to increase, the basic design will likely persist for a long time because we don’t need every data point for many analyses. MONITORING AND DIAGNOSIS Process Performance Improvements Sampling periods and storage duration tailored to need. For example, SIS period is very fast (milliseconds) to diagnose fault. Special purpose systems Aggregation: Large amounts of data stored for long times. Data is taken periodically with long sampling periods, e.g., 5 minutes. Historian Data is stored with decreasing resolution, e.g., 3 days of 1/min, 7 days of 1/hr, 30 days 1/day Trend plots are updated 1/sec for new data, but this high-frequency data is not stored for later recall. DCS control system Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions Some typical ways to aggregate a variable • Average (shift, daily, weekly, monthly) • Integration, e.g., total flow per day (for material or energy) • Maximum and minimum over a period • Standard deviation (or histogram) • Analysis can have multiple values To aggregate several variables, use process insight 7. Dynamic Performance 8. Monitoring & diagnosis • Calculate key process performance measures (efficiencies, yields, etc.) Longer term Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS Process Performance Improvements History data base 3. Reliability Display 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Class Exercise: Occasionally, a sensor fails or the history storage fails for a period of time. How does the aggregation method handle these situations? Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window History data base 2. Flexibility/ controllability Display 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Class exercise: Periods when a reliable value is not available is marked questionable. 1. Reports should provide information on whether any data within the aggregation period was questionable. (Best if % of data that is questionable reported) 2. You need to determine how the algorithm deals with missing data (ignore, interpolate, use last good before, use first good after, etc.) when calculating results, such as average or total. Longer term Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS Process Performance Improvements History data base 3. Reliability Display 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Plant personnel also check local sensors periodically (per shift or day) and record values. This data can be stored on paper, or the values can be entered into a hand-held computer and transferred to the history data base. Longer term Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS Process Performance Improvements History data base 3. Reliability Display 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Plant personnel extract samples of material for laboratory analysis. This data can be stored on paper, or the values can be entered into the history data base. The time the sample was taken is essential information. Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection Class Exercise: The data changes from sample to sample. How do we determine when a “significant” change has occurred? 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Key process variable, e.g., Product quality 5. Efficiency & profitability Time Desired value Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection We can use principles of statistical process control (SPC) to monitor and decide when a significant change has occurred. Process personnel trouble shoot, diagnose and eliminate the cause 5. Efficiency & profitability 7. Dynamic Performance 8. Monitoring & diagnosis Key process variable, e.g., Product quality 6. Operation during transitions “Shewhart Chart” Action limit Action limit Time Desired value Longer term Key Operability issues MONITORING AND DIAGNOSIS Process Performance Improvements 1. Operating window Class Workshop: In your first job, you are responsible for the heat exchangers and fired heater in this process. Design a monitoring procedure (with sensors and lab analyses). 2. Flexibility/ controllability 3. Reliability Heat exchange with process streams that must be cooled. 4. Safety & equipment protection feed tank 5. Efficiency & profitability 6. Operation during transitions fuel Hints: 7. Dynamic Performance 8. Monitoring & diagnosis • What can change? • Is it important for plant performance? • How does it affect measurements? • Define measurements and calculations. product Longer term Key Operability issues 1. Operating window MONITORING AND DIAGNOSIS Process Performance Improvements 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Class Workshop: In your first job, you are responsible for the reactor (and catalyst regenerator) in the process shown on the next slide. Design a monitoring procedure (with sensors and lab analyses). Hints: • What can change? • Is it important for plant performance? • How does it affect measurements? Include laboratory samples for variables that might not be measured on-stream. • Define measurements and calculations. Longer term COMPRESSOR OVERHEAD CONDENSER/ACCUMULATOR HIGH PRESSURE CONDENSER/ SEPARATER Hints: • What can change? • Is it important for plant performance? • • ABSORBER TAIL GAS How does it affect measurements? SPONGE OIL ABSORBER TOP P.A. DEETHANIZER LCGO P.A. Define measurements and calculations. HCGO P/A LCGO STRIPPER BPA P/A RAW GASOLINE ABSORBER MAIN FRACTIONATOR REACTOR PRODUCTS C4'S DEPROPANIZER HCGO P.A. C3'S LCGO REACTOR EFFLUENT FLUE GAS STEAM BOTTOM P.A. DEBUTANIZER LCPA P/A BPA P/A HCGO STEAM AIR STEAM FRESH FEED FULL RANGE CAT NAPHTHA Longer term Key Operability issues 1. Operating window 2. Flexibility/ controllability 3. Reliability 4. Safety & equipment protection 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis MONITORING AND DIAGNOSIS Real-Time & Process Performance Improvements INDUSTRIAL PRACTICE • Standard measurement choices have been developed for most unit operations. • Some issues require advanced analysis, for example, pipeline leak detection, rotating machinery vibration, pump alignment/lubrication, compressor surge, etc. • Process performance monitoring has not been comprehensively studied. Opportunity exists for innovation, especially using statistical correlation to distinguish good/bad. Key Operability issues 1. Operating window 2. Flexibility/ controllability MONITORING AND DIAGNOSIS To perform monitoring and diagnosis, people need information. Sensor Issues (a little review) 3. Reliability Real-time Decisions* 4. Safety & equipment protection • Trouble shoot incidents using proven method Real-time sensors • Information to support decisions required quickly Fast lab analyses 5. Efficiency & profitability 6. Operation during transitions 7. Dynamic Performance 8. Monitoring & diagnosis Process Performance Improvement • • Longer term performance indicators based on data and calculations Usually identifying slow trends * See trouble shooting lesson for more on strategy and examples Sensors for calculations Lab analysis Data for statistical analysis