PRODUCTIONS/OPERATIONS MANAGEMENT

advertisement

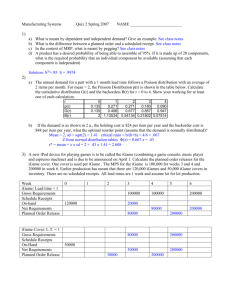

Materials Requirements Planning Collins Industries Largest manufacturer of ambulances in the world International competitor 12 major ambulance designs 18,000 different inventory items 6,000 manufactured parts 12,000 purchased parts MRP seems to be a good way to manage inventories: IBM’s MAPICS system is used Independent and Dependent Demand Independent Demand Dependent Demand A C(2) B(4) D(2) E(1) D(3) F(2) Independent demand is uncertain. Dependent demand is certain. Dependent Demand Dependent demand: Demand for items that are subassemblies or component parts to be used in production of finished goods. Once the independent demand is known, the dependent demand can be determined. Demand Characteristics Independent demand Dependent demand 100 x 1 = 100 tabletops 100 x 4 = 400 table legs 100 tables Continuous demand Discrete demand 400 – 300 – No. of tables No. of tables 400 – 200 – 100 – 1 2 3 Week 4 300 – 200 – 100 – 5 M T W Th F M T W Th F Stable demand Demand Demand Dependent vs Independent Demand Time Amount on hand Amount on hand Time “Lumpy” demand Safety stock Time Time Material Requirements Planning Defined Materials requirements planning (MRP) is a computerized inventory planning and control system for determining when (no earlier and no later) and how many of each of the parts, components, and materials should be ordered or produced. It translates master schedule requirements fr end items into time-phased requirements for subassemblies, components and raw materials. Dependent demand drives MRP MRP is a software system When to Use MRP Dependent and discrete items Complex products Job shop production Assemble-to-order environments Material Requirements Planning System Based on a master production schedule, a material requirements planning system: Creates schedules identifying the specific parts and materials required to produce end items Determines exact unit numbers needed Determines the dates when orders for those materials should be released, based on lead times 10 Aggregate production plan Firm orders from known customers Engineering design changes Master production Schedule (MPS) Bill of material file Material planning (MRP computer program) Forecasts of demand from random customers Inventory transactions Inventory record file Secondary reports Primary reports Planned order schedule for inventory and production control (work orders, purchase orders), rescheduling notices Exception reports Planning reports Reports for performance control ©The McGraw-Hill Companies, Inc., 2004 MRP System MRP Inputs MRP Processing MRP Outputs Changes Order releases Master schedule Planned-order schedules Primary reports Bill of materials Inventory records MRP computer programs Exception reports Planning reports Secondary reports Performancecontrol reports Inventory transaction MRP Inputs 1: Master Production Schedule Drives MRP process with a schedule of finished products; states which end items are to be produced, when these are needed, and in what quantities Quantities may consist of a combination of customer orders & demand forecasts Quantities represent what needs to be produced, not what can be produced Master Production Schedule (MPS) Time-phased plan specifying how many and when the firm plans to build each end item Aggregate Plan (Product Groups) MPS (Specific End Items) Master Production Schedule Shows items to be produced Derived from aggregate plan Example: Item / Week Clipboard Lapdesk Lapboard Pencil Case Oct 3 Oct. 10 Oct. 17 Oct.24 Oct. 31 85 95 120 100 100 0 50 0 50 0 75 120 47 20 17 125 125 125 125 125 MRP Inputs 2: Bill-of-Materials Bill of materials (BOM): One of the three primary inputs of MRP; a listing of all of the raw materials, parts, subassemblies, and assemblies needed to produce one unit of a product. Product structure tree: Visual depiction of the requirements in a bill of materials, where all components are listed by levels. Product Structure Tree: Example 1 Level 0 1 Chair Leg Assembly 2 Legs (2) 3 Cross bar Seat Back Assembly Side Cross Back Rails (2) bar Supports (3) Product Structure Tree: Example 2 Bicycle(1) P/N 1000 Handle Bars (1) P/N 1001 Frame Assembly (1) P/N 1002 Wheels (2) P/N 1003 Frame (1) P/N 1004 Product Drawing: Example 3 Clipboard Top clip (1) Pivot (1) Bottom clip (1) Spring (1) Rivets (2) Finished clipboard Pressboard (1) Product Structure Tree ( Example 3) Clipboard Pressboard (1) Top Clip (1) Level 0 Clip Ass’y (1) Bottom Clip (1) Rivets (2) Pivot (1) Level 1 Spring (1) Level 2 MRP Inputs 3: Inventory Records File One of the three primary inputs of MRP Includes information on the inventory status of each item by time period Gross requirements Scheduled receipts Amount on hand Lead times Lot sizes And more.... MRP Terminology (1 of 3) Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Planned-order releases MPR Terminology (2 of 3) Gross requirements Total expected demand Scheduled receipts Open orders scheduled to arrive Projected on hand Expected inventory on hand at the beginning of each time period MRP Processing Terminology (3 of 3) Net requirements Actual amount needed in each time period Gross requirements – available inventory Planned-order receipts Quantity expected to be received at the beginning of the period Offset by lead time Planned-order releases Planned amount to be ordered in each time period MRP Processing Logic: Assembly Time Chart Procurement of raw material D Fabrication of part E Subassembly A Procurement of raw material F Procurement of part C Final assembly and inspection Procurement of part H Fabrication of part G Procurement of raw material I 1 2 3 Subassembly B 4 5 6 7 8 9 10 11 Weeks Calculation of Gross Requirements A S C B 10 11 15 8 B Lead time = 4 for A Master schedule for A Periods 5 6 7 40 Periods Gross requirements: B 8 50 9 1 2 10 40+10 = 50 C Lead time = 6 for S Master schedule for S 3 4 5 40 50 20 9 10 11 12 13 40 20 30 6 7 15+30 = 45 8 Master schedule for S sold directly 1 2 10 10 3 Therefore, these are the gross requirements for B Basic MRP Processes 1. 2. 3. 4. Exploding the bill of material Netting out inventory Lot sizing Time-phasing requirements The MRP Matrix ITEM NAME OR NO. LLC - LOW LEVEL CODE LOT SIZE QTY MADE IN LY - LEAD TIME Gross Requirements Scheduled Receipts Projected on Hand Net Requirements Planned Order Receipts Planned Order Releases Beg Inv 1 PERIOD 2 3 4 5 Derived from MPS or planned order releases of the parent On order and scheduled to be received Anticipated quantity on hand at the end of the period Gross requirements net of inventory and scheduled receipts When orders need to be received When orders need to be placed to be received on time MRP Processing: Example 1-School Mate Products Master Production Schedule Clipboard Lapdesk 1 2 3 85 0 95 60 120 0 4 5 100 60 100 0 Item Master File (ınventory record file On hand On order (sch receipt) LLC Lot size Lead time CLIPBOARD 25 175 (Period 1) LAPDESK 20 0 PRESSBOARD 150 0 0 L4L 1 0 Mult 50 1 1 Min 100 1 School Mate Products Product Structure Record Clipboard Level 0 Clip Ass’y (1) Pressboard (1) Rivets (2) Level 1 Lapdesk Pressboard (2) Trim (3’) Level 0 Beanbag (1) Glue (4 oz) Level 1 School Mate Products ITEM: CLIPBOARD LLC: 0 LOT SIZE: L4L 1 2 3 4 5 Gross Requirements 85 95 120 100 100 Scheduled Receipts 175 Projected on Hand Net Requirements Planned Order Receipts Planned Order Releases LT: 1 PERIOD 25 School Mate Products ITEM: CLIPBOARD LLC: 0 LOT SIZE: L4L 1 2 3 4 5 Gross Requirements 85 95 120 100 100 Scheduled Receipts 175 Projected on Hand Net Requirements LT: 1 PERIOD 25 115 0 Planned Order Receipts Planned Order Releases (25 + 175) = 200 units available (200 - 85) = 115 on hand at the end of Period 1 School Mate Products ITEM: CLIPBOARD LLC: 0 LOT SIZE: L4L 1 2 3 4 5 Gross Requirements 85 95 120 100 100 Scheduled Receipts 175 Projected on Hand Net Requirements LT: 1 PERIOD 25 115 20 0 0 Planned Order Receipts Planned Order Releases 115 units available (115 - 85) = 20 on hand at the end of Period 2 School Mate Products ITEM: CLIPBOARD LLC: 0 LOT SIZE: L4L 1 2 3 4 5 Gross Requirements 85 95 120 100 100 Scheduled Receipts 175 115 20 0 0 0 100 Projected on Hand Net Requirements LT: 1 PERIOD 25 Planned Order Receipts Planned Order Releases 100 100 20 units available (20 - 120) = -100 — 100 additional Clipboards are required Order must be placed in Period 2 to be received in Period 3 School Mate Products ITEM: CLIPBOARD LLC: 0 LOT SIZE: L4L 1 2 3 4 5 Gross Requirements 85 95 120 100 100 Scheduled Receipts 175 115 20 0 0 0 0 0 100 100 100 100 100 100 100 100 Projected on Hand Net Requirements LT: 1 PERIOD 25 Planned Order Receipts Planned Order Releases 100 Following the same logic Gross Requirements in Periods 4 and 5 develop Net Requirements, Planned Order Receipts, and Planned Order Releases School Mate Products ITEM: LAPDESK LLC: 0 LOT SIZE: MULT 50 LT: 1 Gross Requirements Net Requirements Planned Order Receipts Planned Order Releases 1 2 0 Scheduled Receipts Projected on Hand PERIOD 20 60 3 4 0 60 5 0 School Mate Products ITEM: LAPDESK LLC: 0 LOT SIZE: MULT 50 LT: 1 Gross Requirements PERIOD 1 2 3 4 5 0 60 0 60 0 20 10 10 0 0 0 40 50 50 50 Scheduled Receipts Projected on Hand Net Requirements 20 Planned Order Receipts Planned Order Releases 50 50 Following the same logic, the Lapdesk MRP matrix is completed as shown School Mate Products ITEM: CLIPBOARD LOT SIZE: L4L LLC: 0 LT: 1 1 Planned Order Releases ITEM: LAPDESK LOT SIZE: MULT 50 LLC: 0 LT: 1 Planned Order Releases ITEM: PRESSBOARD LLC: 0 LOT SIZE: MIN 100 LT: 1 Gross Requirements Scheduled Receipts Projected on Hand 150 Net Requirements Planned Order Receipts Planned Order Releases 1 2 PERIOD 3 4 100 100 100 2 PERIOD 3 4 5 4 5 50 50 1 PERIOD 3 2 5 School Mate Products ITEM: CLIPBOARD LOT SIZE: L4L LLC: 0 LT: 1 1 Planned Order Releases ITEM: LAPDESK LOT SIZE: MULT 50 LLC: 0 LT: 1 Planned Order Releases ITEM: PRESSBOARD LLC: 0 LOT SIZE: MIN 100 LT: 1 Gross Requirements Scheduled Receipts Projected on Hand 150 Net Requirements Planned Order Receipts Planned Order Releases 2 PERIOD 3 4 100 100 100 x1 x1 2 PERIOD 3 4 5 x1 1 50 x2 1 100 5 50 x2 PERIOD 2 3 4 100 200 100 5 0 School Mate Products ITEM: CLIPBOARD LOT SIZE: L4L LLC: 0 LT: 1 1 Planned Order Releases ITEM: LAPDESK LOT SIZE: MULT 50 LLC: 0 LT: 1 Planned Order Releases ITEM: PRESSBOARD LLC: 0 LOT SIZE: MIN 100 LT: 1 Gross Requirements Scheduled Receipts Projected on Hand 150 Net Requirements Planned Order Receipts Planned Order Releases 1 2 PERIOD 3 4 100 100 100 2 PERIOD 3 4 50 50 1 100 PERIOD 2 3 4 100 200 100 50 100 50 50 100 150 0 150 150 100 0 100 100 5 5 5 0 0 School Mate Products Planned Order Report PERIOD ITEM Clipboard Lapdesk Pressboard 1 50 100 2 3 4 100 100 50 100 100 150 5 MRP Processing: Example 2 Item X A B C D X A(2) C(3) B(1) C(2) On-Hand Lead Time (Weeks) 50 2 75 3 25 1 10 2 20 2 D(5) Requirements include 95 units (80 firm orders and 15 forecast) of X in week 10 X A(2) It takes 2 A’s for each X X LT=2 Onhand 50 A LT=3 Onhand 75 B LT=1 Onhand 25 C LT=2 Onhand 10 D LT=2 Onhand 20 Day: Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release 1 2 3 4 5 6 7 8 9 10 95 50 50 50 50 50 50 50 50 50 50 45 45 45 90 75 75 75 75 75 75 75 75 15 15 15 45 25 25 25 25 25 25 20 40 45 10 10 10 10 35 25 10 35 35 40 40 40 100 20 20 20 20 20 80 20 20 80 80 25 20 20 X LT=2 X A(2) B(1) It takes 1 B for each X Onhand 50 A LT=3 Onhand 75 B LT=1 Onhand 25 C LT=2 Onhand 10 D LT=2 Onhand 20 Day: Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release 1 2 3 4 5 6 7 8 9 10 95 50 50 50 50 50 50 50 50 50 50 45 45 45 90 75 75 75 75 75 75 75 75 15 15 15 45 25 25 25 25 25 25 20 40 45 10 10 10 10 35 25 10 35 35 40 40 40 100 20 20 20 20 20 80 20 20 80 80 25 20 20 X LT=2 X A(2) C(3) It takes 3 C’s for each A B(1) Onhand 50 A LT=3 Onhand 75 B LT=1 Onhand 25 C LT=2 Onhand 10 D LT=2 Onhand 20 Day: Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release 1 2 3 4 5 6 7 8 9 10 95 50 50 50 50 50 50 50 50 50 50 45 45 45 90 75 75 75 75 75 75 75 75 15 15 15 45 25 25 25 25 25 25 20 40 45 10 10 10 10 35 25 10 35 35 40 40 40 100 20 20 20 20 20 80 20 20 80 80 25 20 20 X LT=2 X A(2) C(3) B(1) C(2) It takes 2 C’s for each B Onhand 50 A LT=3 Onhand 75 B LT=1 Onhand 25 C LT=2 Onhand 10 D LT=2 Onhand 20 Day: Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release 1 2 3 4 5 6 7 8 9 10 95 50 50 50 50 50 50 50 50 50 50 45 45 45 90 75 75 75 75 75 75 75 75 15 15 15 45 25 25 25 25 25 25 20 40 45 10 10 10 10 35 25 10 35 35 40 40 40 100 20 20 20 20 20 80 20 20 80 80 25 20 20 X LT=2 X A(2) C(3) B(1) C(2) D(5) It takes 5 D’s for each B Onhand 50 A LT=3 Onhand 75 B LT=1 Onhand 25 C LT=2 Onhand 10 D LT=2 Onhand 20 Day: Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planner order release 1 2 3 4 5 6 7 8 9 10 95 50 50 50 50 50 50 50 50 50 50 45 45 45 90 75 75 75 75 75 75 75 75 15 15 15 45 25 25 25 25 25 25 20 40 45 10 10 10 10 35 25 10 35 35 40 40 40 100 20 20 20 20 20 80 20 20 80 80 25 20 20 MRP Outputs Planned orders (schedule indicating the amount and timing of orders) Work orders Purchase orders Order releases (authorization for the execution of planned orders) Changes to previous plans or existing schedules (revision of due dates or order quantities, or cancellations of orders) Action notices Rescheduling notices Updating the MRP System Regenerative system Updates MRP records periodically Net-change system Updates MPR records continuously MRP Secondary Reports Performance-control reports Planning reports Exception reports MRP Dynamics Supports “replanning” “Time fence” - allows a segment of the master schedule to be designated as “not to be rescheduled” “Pegging” - tracing upward in the bill-of-materials from the component to the parent item That a manager can react to changes, doesn’t mean he/ he should Other Considerations Safety Stock Lot sizing Lot-for-lot ordering (L4L) Economic order quantity Part Period Balancing Wagner-Whitin algorithm & others Which one to use? The one that is least costly! MRP in Services Can be used when demand for service or service items is directly related to or derived from demand for other services Food catering service End item => catered food Dependent demand => ingredients for each recipe, i.e. bill of materials Hotel renovation Activities and materials “exploded” into component parts for cost estimation and scheduling Benefits of MRP Reduced inventories without reduced customer service Ability to track material requirements Ability to evaluate capacity requirements Means of allocating production time Increased customer satisfaction due to meeting delivery schedules Faster response to market changes Improved labor and equipment utilization. Better inventory planning and scheduling Requirements of MRP Computer system and necessary software Mainly discrete products Stable lead times Accurate and up-to-date Master schedules Bills of materials Inventory status records Integrity of data Extensions of MRP Extensions of MRP Closed loop MRP Capacity planning - load reports MRP II - Manufacturing Resources Planning Enterprise Resources Planning MRP and The Production Planning Process Forecast & Firm Orders Aggregate Production Planning Material Requirements Planning Master Production Scheduling Resource Availability No, modify MPS Capacity Requirements Planning Realistic? Yes Shop Floor Schedules Closed Loop MRP Capacity Planning Capacity requirements planning: The process of determining short-range capacity requirements. Load reports: Department or work center reports that compare known and expected future capacity requirements with projected capacity availability. Time fences: Series of time intervals during which order changes are allowed or restricted. Capacity Requirements Planning (CRP) Computerized system that projects load from material plan Creates load profile Identifies underloads and overloads Capacity Usually expressed as standard machine hours or labor hours Capacity = (no. machines or workers) x (no. shifts) x (utilization) x (efficiency) Capacity Terms Load reports Department or work center reports that compare known and expected future capacity requirements with projected capacity availability. Load profile Compares released and planned orders with work center capacity Capacity Productive capability; includes utilization and efficiency Utilization % of available working time spent working More Capacity Terms Efficiency Refers to how well a machine or worker porforms compared to a standard output level Load The standard hours of work assigned to a facility Load percent The ratio of load to capacity Load % = (load/capacity)x100% Capacity Requirements Planning MRP planned order releases Routing file Capacity requirements planning Load profile for each machine center Open orders file Capacity Planning Develop a tentative master production schedule Use MRP to simulate material requirements Convert material requirements to resource requirements Revise tentative master production schedule No Is shop capacity adequate? Yes Firm up a portion of the MPS No Can capacity be changed to meet requirements Yes Change capacity Determining Loads and Capacities 2 copiers, 2 operators 5 days/wk, 8 hr/day 1/2 hr meals, 1/2 hr maintenance per day The machines are new, so efficiency is estimated at 100% Utilization = 7/8 = 87.5% Daily capacity = 2 machines x 2 shifts x 8 hours/shift x 100% efficiency x 87.5% utilization = 28 hours or 1,680 minutes Determining Loads and Capacities JOB NO. NO. OF COPIES SETUP TIME (MIN) RUN TIME (MIN/UNIT) TOTAL TIME 10 20 30 40 50 500 1,000 5,000 10,000 2,000 5.2 10.6 3.4 11.2 15.3 0.08 0.10 0.12 0.14 0.10 5.2 + (500 x 0.08) = 45.2 10.6 + (1,000 x 0.10) = 110.6 3.4 + (5,000 x 0.12) = 603.4 11.2 + (10,000 x 0.14) = 1,411.2 15.3 + (2,000 x 0.10) = 215.3 2385.7 min Load percent = 2,385.7 / 1,680 = 1.42 x 100% = 142% Add another shift: Daily capacity = 2 machines x 3 shifts x 8 hours/shift x 100% efficiency x 87.5% utilization = 42 hours or 2,520 minutes Revised load percent = 2,385.7 / 2,520 = 0.9467 x 100% = 94.67% Hours of capacity Initial Load Profile 120 – 110 – 100 – 90 – 80 – 70 – 60 – 50 – 40 – 30 – 20 – 10 – 0– Normal capacity 1 2 3 4 Time (weeks) 5 6 Remedies for Underloads 1. Acquire more work 2. Pull work ahead that is scheduled for later time periods 3. Reduce normal capacity Remedies for Overloads Eliminate unnecessary requirements Reroute jobs to alternative machines or work centers Change lot-sizing or safety stock requirements Split lots between two or more machines Send pieces to the second operation before the entire lot has completed the first operation Increase normal capacity Subcontract Increase the efficiency of the operation Push work back to later time periods Revise master schedule Hours of capacity Adjusted Load Profile 120 – 110 – 100 – 90 – 80 – 70 – 60 – 50 – 40 – 30 – 20 – 10 – 0– Pull ahead Overtime 1 2 Work an extra shift 3 Push back Push back 4 Time (weeks) Normal capacity 5 6 Relaxing MRP Assumptions Material is not always the constraining resource Lead times can vary Not every transaction needs to be recorded JIT can be used with MRP The shop floor may require a more sophisticated scheduling system Manufacturing Resources Planning- MRP II Expanded MRP with emphasis placed on integration of: Financial planning Marketing Engineering Purchasing Manufacturing Human resources Manufacturing Resources Planning (MRP II) Goal: Plan and monitor all resources of a manufacturing firm (closed loop): manufacturing marketing finance engineering Simulate the manufacturing system MRP II Manufacturing Master production schedule Marketing Production plan MRP Rough-cut capacity planning Capacity req. planning Adjust production plan Yes Problems? No Requirements schedules No Problems? Adjust master schedule Market Demand Finance Yes MRP II Manufacturing Resource Planning (MRP II) Customer orders Aggregate production plan Forecast No Feasible? Yes Master production schedule Material requirements planning Capacity requirements planning No Feasible? Feedback Yes Purchase orders Work orders Inventory Shop floor control Manufacture Manufacturing Resource Planning (MRP II) Aggregate production plan Forecast Customer orders Aggregate production plan Forecast No Feasible? Customer orders Yes Master production schedule Material requirements planning No Capacity requirements planning Feasible? No Feasible? Feedback Yes Master production schedule Yes Purchase orders Work orders Inventory Shop floor control Manufacture Manufacturing Resource Planning (MRP II) Master production schedule Customer orders Aggregate production plan Forecast No Feasible? Yes Master production schedule Material requirements planning Material requirements planning Capacity requirements planning Capacity requirements planning No Feasible? Feedback Yes No Feasible? Yes Purchase orders Work orders Inventory Shop floor control Manufacture Manufacturing Resource Planning (MRP II) Purchase Work orders Customer orders Aggregate production plan Forecast No Feasible? Yes Master production schedule orders Material requirements planning Capacity requirements planning Shop floor control Inventory No Feasible? Feedback Yes Purchase orders Work orders Inventory Shop floor control Manufacture Manufacture Manufacturing Resource Planning (MRP II) Customer orders Aggregate production plan Forecast No Feasible? Yes Master production schedule Material requirements planning Capacity requirements planning No Feasible? Feedback Yes Purchase orders Work orders Inventory Shop floor control Manufacture Enterprise Resource Planning (ERP) The next step in the evolution that began with MRP and evolved into MRP II ERP system is a computer system that integrates application programs in accounting, sales, manufacturing, human resources and other functions in the firm. ERP provides a system to capture and make data available in real time do decision makers and other users in the organization ERP MRP II with ties to customers and suppliers (connects with supply-chain and customer management applications) Integrates financial, manufacturing and human resources on a single computer system. Provides tools for planning and monitoring various business processes Enterprise Resource Planning (ERP) Attempts to integrate all departments and functions across a company onto a single computer system that can serve all those different departments’ particular needs Organizes and manages a company’s business processes by sharing information across functional areas Standardized record-keeping permit information sharing and communication throughout the organization Enterprise Resource Planning - ERP Such an integration is accomplished through a database shared by all the application programs ERP ERP allows companies to: 1. Automate and integrate many of their business processes 2. Share a common database and business practices throughout the enterprise 3. Produce information in real time ERP systems also include: 1. Supply Chain Management software and 2. Customer Relationship Management software ERP Modules ERP’s Central Database Finance & Accounting Sales & Marketing ERP Data Repository Human Resources Production & Materials Management ERP Strategy Considerations High initial cost High cost to maintain Future upgrades Training