AUTOMOBILE ENGINEERING

advertisement

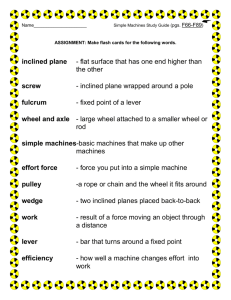

AUTOMOBILE ENGINEERING 2013-14 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA DEPARTMENT OF MECHANICAL ENGINEERING ACADEMIC YEAR 2013-14 NOTES OF AUTOMOBILE ENGINEERING [12159] 1 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 CHAPTER NO - 1 [Introduction of Automobile] I] To improve the stability a stream lining is done to automobile body which is called as aerodynamic shapes. This is done to minimize air resistance when the automobile is in motion. Features area) Air drag force is reduced. b) Aerodynamic lift acting in vertical upward direction is reduced. c) Air eddies are not formed. d) Cross wind force acting in lateral direction is minimized. e) Speed of the automobile is maintained. f) Obtained best fuel economy. ( Any four should be written. One mark for each feature) OR I] AERODYNAMIC SHAPE OF CAR The body of automobile is designed to protect the engine and accessories ,as well as passengers from resistance of air, Therefore it is shaped to reduce the resistance of air as it moves forword. Shaping of car to reduce the resistance of air is called as streamlining. The streamlining of the car is done by introducing aerodynamic shape. Few streamlining shapes are given below: 2 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Note:- Alternate justification with analytical method may also be considered. ( 04 marks for appropriate answer) 3 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 II] TYPES OF VEHICLE LAYOUT :- ( 02 marks for types & 02 marks for explanation) a)Front Engine rear wheel drive b)Front engine front wheel drive c)Front engine four wheel drive d) rear engine rear wheel drive *Front Engine rear wheel drive 4 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 In this case Engine is mounted at font as shown in figure and advantages and advantages of above are as follows :It gives good balanced weight distribution. Steering location is easy. Various components like engine gear box etc can be easily mounted. Radiator can be fitted at front, which is easy for cooling. Better traction while driving. III] Vehicle Body Construction Sketch Any Appropriate sketch depicting all parts of body-------- 04 Marks 5 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 IV] Listing major vehicle manufactures. Writing two models per manufacturer per class of vehicle 4 marks i) Two wheeler :a) Bajaj auto :– Pulsor 150 DTS, Avenger, Discover, wave etc. b) Hero Honda :– Splendor Plus, Passion Plus, Glamair, CBZ, Karizma, Pleasure. c) Honda Motor cycle :– Dio, Activa, Elino, Aviator. d) Royal enfielt :– Bullet standard, bullet 500, Electra etc. e) TVS motor :– Scooty pep, star city, centra, fiero etc. ii) Four wheeler :a) Tata motors :- Ace, Indica, Winger, Manza, Safari, Sumo,Nano,Indigo e-cs etc. b) Maruti Suzuki :- Ertiga, Wagen R, Swift, Dezire, AltoK10 etc. c) Honda :- Jazz, Honda CT (1.3 & 1.5), Accord,Amaze,Brio etc. d) Mahindra & Mahindra :- Duster, Commander 750 DP, Scorpio, Xylo. e) Skoda :- Superb, Laura, Octavia, fabia ,Rapid etc. f) Mercedes-Benz :- ‘C’ class –C200K, C280 petrol, ‘CLS’ Class CLS 500, ‘S’ class – S350L. g) Ford: Ikon,Classic,Figo,Fiesta.Endeaveur h) Cheverlet: Spark,Sail,Land Cruzer iii) Heavy commercial vehicles :a) Tata motors Buses :- Starbus, Globus, SFC 407 Turbo Mini-bus, LP 407 Turbo Mini-bus, LP 709 E Turbo Bus, LPO 1510 CGS bus (CNG bus), LP /LPO 1510, LP/LPO 1512 TC Turbo Bus, LPO 1610 TC RE semi low floor Bharat stage-II Bus, LPO 1616 TC Luxury Bharat Stage – II Bus, LP 1109 Bharat Stage II. b) The major Heavy vehicles manufactured by Ashok Leyland are:- Cargo 1512, Cargo 1614, Hippo Tipper, Hippo Haulage, Coal Carrier, Taurus Tipper, Titan Double Decker, Cruiser Luxury Coach, Viking/Cheetah and Viking Super (CNG). c) Eicher Motors Trucks :- Eicher 10.50, Eicher 10.59, Eicher 10.75, Eicher 10.90, Eicher 11.10, Eicher Jumbo 20.16, Eicher Galaxy 30.25. d) Eicher Motors Buses :- Eicher Skyline Bus, Eicher School Bus, Eicher Cruiser, Eicher Skyline CNG. e) Swaraj Mazda Ambulance :- T3500/WT48D, WV26 Model High Roof, WV26 6 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Model Low Roof, f) Swaraj Mazda Buses :- WT-48, WR50, WT-50LWB, WV-26. Swaraj Mazda Truck :- WV26-SNG, WT49NG SHD, ZT54ESNG A, ZT54ESaNG SHD, ZT54 NG ALWB. ( 04 marks for approprioate answer) V] a) full forward chassis: In this type of chassis the engine is fitted in front of driver seat or in driver cabin. It provides safety to the driver. b) Semi forward cassis: In this chassis engine is mounted half in driver compartment and remaining half out of driver compartment. The extra passengers or luggage can be placed in the driver’s cabin. c) Bus chassis: Engine is completely mounted inside driver cabin. Provides clear view of the road, extra space for passengers. d) Engine at front chassis: Engine mounted at front and drive may be given to front axle or rear axle. Extra floor area, extra space for luggage and passengers. e) Engine fitted at rear: Engine mounted at rear side of automobile. Provides clear view of the road at the front, eliminates long length propellers shafts and provides lot of space at front. f) Engine mounted at center: Uniform distribution of weight. Weight is concentrated at C.G. of automobile which improves stability of automobile when it is in motion. ( Any four should be written. One mark for each type) 7 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 VI] Automobile market in India:Followings are the leading automobile vehicles manufacturers in India and their market share is as follows:- Car manufacturers :- Mauti udyog ltd Fiat india ltd Ford india ltd General motors ltd Hundai motors ltd Toyoto motors Skoda auto India Tata motors Hindustan motors Mahindra and Mahindra Two wheelers:Bajaj auto ltd Hero Honda motors ltd Royal Enfield ltd Yamaha Motors Suzuki motors Kinetic engg. Ltd Commercial motors Tata motors Ashok layland ltd Force motors Eicher motors Mahindra and Mahindra ltd Swaraj mazda ltd 8 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Escort india ltd Domestic market share for year 2009-10 is about Passenger car -15.86% Commercial vehicles-4.32% Two wheelers-76.23% three wheelers-3.58% In early pre independence days all the automobiles were directly imported from Europe,America. After independence with formation of TELCO,Hindustan Motors, Premier Auto limited four wheelers were manufactured in India. With starting of Escorts, Lamberetta, Enfields,Vespa etc two wheelers were also manufactured. Jeeps were manufactured by Mahindra Ltd and Trucks were manufactured by TATA and Leyland In india. Till 1980’s Automobile sector was restricted as licenses were required for manufacturing. Fast impetus to automobile market occurred with entry of Maruti Suzuki for four wheelers in 1984. Thereafter with enhancement in technology ,effect of globalization and Liberalization, Relaxation in tax structure as on today virtually all the leading automobile manufacturers of the globe are present in India producing automobiles of varied types with phenomenal quantities. ( 02 marks for market & 02 marks for growth ,appropriate answer should be given marks ) OR The Indian automobile industry is the fastest growing industry in the world. A millions of vehicles are produced annually in this country. India has emerged as the third largest market in Asia Pacific regions, with various car manufacturing companies setting up their units, in different parts of the country. Taking intoconsideration needs of the vehicle owners, that is range of the vehicle model, capacity and performance of the vehicles, automobile manufacturing companies are introducing new models and new features. The increased competition has forced companies to focus on reducing their product cost, use of improved technology and stylish new designs. (01 mark) Following are the major vehicle running on road. a) Maruti Suzuki India – alto. 800, eco, swift, wagon –R, Zen estilo, ritz 9 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 b) Hundai Motor India – accent, i10,i20, santro, sonata, transformer, verna c) Skoda Auto India – fabia, laura, superb d) Chevrolet – forester, optra, corsa, spark e) Ford India – figo, fiesta, endevour f) Tata Motors – indica, indigo, safari, sumo, nano g) Mahinda and Mahindra – bolero, logan, scorpio, Xylo h) Toyota – camry, corolla, altis, innova, etios i) Fiat India – palio, petra, punto j) Mitsubhishi – pajero, cedia, lancer. ( 02 marks) The category wise share of these vehicles in market a) passenger cars – about 15.86% b) Commercial Vehicle – about 4.32% c) Three wheelers – about 3.58% d) Two wheelers – about 76.23% (01 marks) VII ] Major components in automobiles (Below Listed Typical Components with its functions ---ANY FOUR ---Each point 1 mark) 1) Engine :- It is source of power ,which drives the vehicle. 2) Clutch:- Main function of clutch is to disconnect the drive from the engine to driving wheels while changing gear and to engage the drive from engine to the driving wheels gradually while vehicle is moving from rest. 3) Gear Box:- The main function of gear box is to provide the necessary variation to driving torque according to operating conditions. 4) Propeller Shaft:- Its function is to transmit the power from gear box to the differential. 5) Differential:-While running straight both wheels have to run with equal speed,but while taking turn inner wheel covers less distance with respect to outer wheel ,therefore wheel must run with different speed ,this is done by differential. 6) Rear axle and Front axle:-Weight of vehicle and chassis is bared by axle on which wheels are mounted is known as rear and front axle . 10 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 7) Chassis:- A framed structure on which vehicle accessories are mounted. 8) Acessories and systems:-Cooling system,System,Braking system, Suspention system.etc VIII ] Detail Classification of Automobiles Automobiles are classified on various basis as under, 1. According to Fuel used: a. Petrol Vehicles such as Cars, Jeeps, Mopeds, Scooters, Motorcycles. b. Diesel Vehicles such as Jeeps, Buses, Pick ups, Cars etc. 2. According to No. of wheels: a. Two wheeler vehicles such as Mopeds, Scooters, Motorcycles. b. Three wheeler vehicles as Rickshaws c. For wheeler vehicles such as Trucks, Buses. 3. According to Load carrying capacity: a. Light Vehicles such as Mopeds, Scooters, Motor cycles b. Heavy Vehicles such as Trucks, Buses, Articulated trailers 4. According to type and use: a. Passenger vehicles such as Car,Jeep, and Bus. b. Load carrying vehicles such as Trucks, Jeeps, Vans, Matador. c. Tractors, racing cars 5. According to wheel drive: a. Front wheel drive Vehilces b. Rear wheel drive vehicles c. Four Wheel drive vehicles. 6. According to Total piston displacement Volume: a. 50cc Moped b. 100cc Motor Cycle c. 1400cc Car 7. According to Type of control: a. Forward Control vehicle b. Semi Forward control vehicle 11 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 8. According to Drive: a. Right hand drive Vehicles b. Left hand drive vehicles 9. According to type of Body: a. Hatchback (Two box) b. Sedan (Three box) c. Limousine d. Convertible e. Van f. SUV (Any Four Relevant Classifications - 4 Marks) 12 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 CHAPTER NO. - 2 [Automobile Transmission] I ] Diaphragm type clutch ( 01 mark for necessity & 03 marks for working) Clutch is a device which is used in automobile to connect or disconnect engine flywheel with the primary shaft of the gear box, so that power can be transmitted from flywheel to gearbox or can be stopped as per the need or requirement. Diaphragm clutch uses a diaphragm instead of helical coil springs hence called as diaphragm clutch. The clutch plate is pressed in between the flywheel and pressure plate by the diaphragm force. This is a engaged position of the clutch during which power or torque is transmitted from engine flywheel to the gear box. To disengage the clutch, effort is applied on thrust bearing. Thrust bearing moves axially towards diaphragm forcing central portion of diaphragm moving towards flywheel. This phenomenon causes the peripheral portion of the diaphragm to move in opposite direction thereby causing backward movement of pressure plate, thus freeing the clutch plate. And the clutch is disengaged. 13 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 II] Differential ( 02 marks for sketch & 02 marks for working) The constructional detail of the differential is as shown in figure. The crown wheel is fixed to asing. The inner ends of the half shaft passes through the bosses of differential case in which are free to rotate. The ends of the half shafts inside the differential casing carries two sun gears. A pin fixed in to the casing carry planet pinions which are in mesh with sun gears. These planet pinions are free to rotate on the pin. When vehicle is going straight the cage and the inner gears rotates as a single unit and the two half shafts revolves at the same speed of ‘N’ r.p.m.. In this situation there is no relative movement among the various differential gears. But when vehicle is taking a turn towards left at that time there will be more resistance to the motion of the left wheel than right wheel. This will cause reduction in the speed of left wheel by ‘n’ r.p.m. and increase in speed of right wheel by ‘n’ r.p.m. this will give the resultant speed of left wheel as ‘N-n’ and that of right wheel as ‘N+n’ This variation in the speed of left and right wheel will force the vehicle to turn in left direction without skidding. 14 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 III] Working Of Coil Spring Type Clutch A Coil spring type clutch is used to engage and disengage the engine shaft with gear box input shaft to facilitate the gear changing operation. A typical clutch contains number of helical coil springs to apply pressure on pressure plates and for operation. A typical coil Spring type clutch is shown in Fig. Figure shows the clutch in the engaged position. The clutch or driven plate is kept clamped between the flywheel and pressure plate with the help of pressure or thrust coil springs. When the clutch plate is depressed by the driver, the pressure plate is pushed away by the clutch fork acting on the clutch sleeve. Now the spring pressure due to thrust springs is removed from the clutch plate. The plate gets unlocked and is free. No power can now be transmitted through the clutch or primary shaft. The Engine is now disengaged from transmission system. ( Correct Figure – 02Marks, Appropriate short Description- 02 Marks) IV ] Tractive Effort and Tractive Resistance a. Tractive Effort:The driving force produced parallel to road between tyre and road due to the wheel torque is known as tractive effort.It depends on coefficient of friction between tyre and road. It varies with engine speed. – 02 Marks 15 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 b. Tractive Resistance: It is the total resistance encountered to vehicle motion.Vehicle will move in forward direction only when the tractive effort produced by vehicle will be greater than tractive resistance.The tractive resistsnace is given by, Tractive Resistance= Air resistance + Gradient resistance + Miscellaneous Resistance Miscellaneous resistance depends on Road characteristics,Tyre characteristics,Vehicle weight and Vehicle speed. --- 02 Marks V] Constant Mesh Gear Box A Constant mesh gear box employs helical gears and it is silent in operation. It contains constant mesh gears mounted on two shafts. Three speed Constant mesh gear box is shown in the Figure 5a.The main shaft is splined and carries gears 7 and 8 mounted on bushes.These gears are in constant mesh with Layshaft gears 3 and 2 respectively. Gears on layshaft are fixed on it permanently. Gears on main shaft are free to rotate on bushes. There are two Dogs with external teeth on their outer surfaces as shown by Dog A and Dog B. These dogs have splined holes which fit on splined main shaft. So Dogs can freely slide on Main shaft by gear shifters as shown in figure. 16 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 First Gear: Here Dog B moves left and engages with Gear No.7 i.e. First gear. Here motion transfer from Driving shaft to Lay shaft to Gear3 to gear 7 to Dog B to Main shaft. Second Gear: Here Dog A moves right and engages with Gear No.8 i.e. Second gear. Here motion transfer from Driving shaft to Lay shaft to Gear2 to gear 8 to Dog A to Main shaft. Third Gear: Here Dog A moves left and engages with Gear No.9 i.e. Clutch gear. Here motion transfer from Driving shaft to to Gear9 to Dog A to Main shaft. Reverse Gear:The Dog B is slid to the right to engage with the reverse gear on the main shaft. The idler gear 5 makes the main shaft rotate in a direction opposite to driving or clutch shaft. ( Correct Equivalent Figure – 04 Marks, Appropriate short Description04 Marks) VI ] Types of rear axles ---------------- Enlist -----------2 marks a) Semi floating axle b) full floating axle c) Three quarter floating axle Explanation of any one with figure---------------------2marks 17 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING iii) Semi floating axle;-The semifloating axle is simplest 2013-14 and cheapest arrangement,which is widely used in cars,in which inner end of axle is splined and supported in differential and on outer end of axle shaft,wheel hub is fixed with taper key.the wheel is mounted on wheel hub. Single bearing is provided between axle shaft and axle casing. Therefore, it has to support all the loads. b) full floating axle:-The axle shaft is provided with flange at outer end, which is fastened to the wheel hub by means of bolts,and thus rotary motion of the hub is transmitted to the wheel,There are two taper roller bearing supporting the axle casing in the hub,which takes side load. Therefore, inthis way,the axle is relieved from all strains caused by weight of the vehicle and end thrust.The weight of vehicle is taken by axle casing and wheels. The function of axle shaft is to transmit the driving torque to the wheel through hub.This type of arrangement is robust which is used in heavy vehicles. 18 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 c) Three quarter floating axle:-The three quarter floating axle ,the bearing is located between the axle casing and the wheel hub instead of between the axle casing and the axle shaft as in case of semi floating axle . The axle shaft does not carry shearing and bending stress due to weight of vehicle but they are taken by axle casing through the hub and bearing. Axle shaft is keyed rigidly to provide the driving torque to the wheel. This type is used in some trucks. Applications:- -------------------------2 marks Semi floating axle ------ Passenger cars Full floating ------ Heavy Duty Vehicle Three quarter floating axle---- Light Duty Vehicle 19 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 VII] Epicyclic gear train ( 02 marks for sketch & 02 marks for application) Applications of epicyclic gear train iii) Cars having automatic transmission ii) Army Tanks iii) Wrist watches / wall clocks Fig. may be different appropriate fig. may be given full marks VIII] CENTRIFUGAL CLUTCH ( 04 marks for appropriate answer) 20 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Working of centrifugal clutch:The centrifugal clutch uses centrifugal forces instead of spring force for keeping it in engaged condition,It does not required clutch pedal for operating a clutch. clutch is operated automatically depends up on engine speed. As accelerator pedal is pressed the engine speed is increases .weight “A” is attached to one end of crank lever flies upword exerting a pressure on the pressure plate”C”through spring ‘E’. The friction plate ‘D’ pressed against flywheel ‘F’,That engages the clutch. IX] SYNCHROMESH GEAR BOX:- 21 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Advantages of Synchromesh gear box :Noise less gear changing Double declutching is not required Smooth gear changing Less vibration. Disadvantages of Synchromesh gear box:Initial cost is high More space is required Prescise operation is required ( 02 marks for sketch & 01 mark each for adv. & disadv.) X] Torque Converter Appropriate Figure ---- 03 Marks In torque converters, a fluid drive is used in conjunction with automatic transmissions. The figure shows a three member torque converter. It has a i. pump or impeller ii. Startor iii turbine and iv.a free wheel mechanism. This allows the stator to run free when the pump and turbine run at the same speed. The turbine shaft goes to the gear box and crank shaft is connected to the impeller.The only difference between fluid flywheel and torque converter is that the latter has a stator. 22 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Working: Working of torque converter is as under, Idling speed:The centrifugal force is insufficient to move the turbine or the vehicle.The creep would be maximum. High starting Torque: Greater is the change in the fluid direction, greater shall be the force or the torque acting on the turbine. The oil leaves the turbine vanes and hits the stationary stator vanes. The oil is redirected to the impeller or pump vanes. Once again, the oil is thrown on the turbine vanes by the pump. This action gives extra power to the turbine blades increasing the starting torque considerably. High Speed: As the turbine increase its speed, the stator starts revolving. When the turbine, pump and startor revolve at the same speed, the oil flow is not appreciably deflected and hence torque decreases. Appropriate Description ----------- 03 Marks XI ] Overdrive: - ( 04marks for one appropriate sketch & 04 marks for explanation) Overdrive is a device interposed between transmission and propeller shaft to permit the propeller shaft to turn faster than main shaft. Generally overdrive is fitted on top gears. Construction : It consists of set of planetary gears. Solenoid or pawl arrangement for locking the sun gear. 23 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Free wheel assembly. Working: - If driver wants to overdrive, when car in running above cut in speed momentarily release the accelerator pedal. 1) Free wheel unit :It is called as over running clutch. Transmit power only in one direction i.e. transmission main shaft to output shaft when sun gear is unlocked. Fly wheel consists of hub and outer race. Hub has internal splines to connect it to transmission main shaft. 24 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 When hub is driven in clock wise direction the rollers side up the cams, and by wedging action they force outer race of follow the hub. Thus outer race moves in same direction and at speed as the hub. Free wheel unit transmits lover only from main shaft to output shaft. 2) Planetary gear system :There are three types of gears. Outer ring gear, three planet pinions held on pinion shaft & sun gear at the centre The ring gear is attached to output shaft. The three planet pinions are assembled into a cage that is splined to transmission main shaft. The sun gear is permitted to either turn or lock. When it is locked, the ring gear i.e. output shaft turned faster than main shaft. The various combinations of planetary gear system are. i) Speed increase :a) Sun gear stationary, turn planet pinion cage, now ring gear rotate faster than planet pinion cage. b) Hold ring gear stationary, turn planet pinion cage. The sun gear will turn faster than the case. ii) Speed Reduction :a) Hold sun gear stationary, turn the ring gear, planet gear will run slow than ring gear. b) Hold ring gear stationary, turn sun gear. Planet pinion will rotate slower than sun gear. 25 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 iii) Reverse :- a) Hold planet cage stationary, turn ring gear, planet pinion will acts as a idler causing sun gear to turn in reverse direction. XII ] Comparison rear axle: - Difference any four 04 marks (Explaining semi floating 4 M.) 26 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 CHAPTER NO. 3 [Control Systems] I] sketch of recirculation ball type steering gear box II] POWER STEERING:Working principle:In order to reduce the steering wheel turning effort ,turn sharp corner easily, power steering is used. It consist a solid cylinder on which two grooves are cut to form valve spool slide in housing. The system is filled with housing. The reservoir keeps sufficient oil in the system. The pump is driven by engine power. When vehicle takes turn return oil line is closed and pressure is created in the cylinder to 27 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 have steering action. Advantages:It gives comfort It gives vehicle stability Less effort required Power steering gives better straight road recovery. Disadvantages:Hydraulic power steering required oil ,high maintenance cost. Initial cost is high More space is required ( 04 marks for explanation, 02 marks for adv. & disadv.) OR II] Power steering ( 03 marks for figure & 03 marks for explanation) When load of the vehicle increases, the steering effort required to turn the vehicle also increases. In case of heavy duty vehicles the steering force may be beyond the limit of driver or to follow 28 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 the sharp turns of road quick steering effect is required. In all such a circumstances the power steering becomes more useful. Power steering takes the assistance of hydraulic power to reduce steering efforts. The small movement of steering wheel actuates a valve so that the fluid under pressure from the reservoir enters in to the hydraulic cylinder whose piston operates steering linkage to steer vehicle in desired direction. [DIGRAM] There are two types of hydraulic steering system i) integral type – in this power operating assembly is a part of steering gear ii) linkage type – in this power operating assembly is a part of steering linkage. Integral type power steering system – Integral type power steering consists of a solid cylinder in which two grooves are cut to form valve spool. Valve spool slides in housing. The system is filled with oil. The reservoir always keeps the system filled with oil. The pump which is driven by engine power delivers oil under pressure in the central part of the cylinder. When vehicle is pitching in straight direction the oil going to the central portion of cylinder is sent back to reserviour as shown in fig. when vehicle is taking a turn the return lines to reservoir are closed and the pressurised oil is sent to the steering actuating cylinder to have turning of vehicle. (*** different appropriate fig. and linkage type power steering may be given full marks.) III] Differentiation between Disk Brakes and Drum Brakes Disk Brakes 1. Consists of Disk and flat shoes Drum Brakes 1. Consists of Drum and internal expanding Curved shoes 2. Brake pads on shoes are flat shaped 2. Brake pads on shoes are curved in shape 3. Pad wear adjustment is automatic 3. Pad wear adjustment is not automatic 4. Uniform pressure on the disk surface 4.Non uniform pressure on curved drum 5. Better stability 5. Less stability 6. Better cooling of brakes. 6.Less cooling of brakes due to closed design 29 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 7. Less braking effort by driver required 7.More braking effort required. 8. Uniform wear on brake pad 8. Non uniform wear on brake pad 9. Maintenance & repair easy 9.Miantenance & repair difficult 10. More costlier 10.Less costlier 11. Wear rate of pad is faster 11. Wear rate of pad is slower 12. No protection from dirt,dust 12. Protected from dirt and dust. 13. No self energizing effect so survo 13. Self energizing effect so no survo mechanism Mechanism required required. 14. Difficulty in installation of 14. No Difficulty in installation of hand brake Hand brake mechanism Mechanism. Any four relevant points -------- 04 Marks OR III] Comparison of disk brake with drum brake ( 01 marks each for any correct point) 30 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 IV] Compare hydraulic brake with pneumatic brake----(Each point --1marks) V] Steering System Need Of Steering System: Steering system in an automobile vehicle is needed due to following, 1. To turn the vehicle at the will of driver 2. To control direction of automobile vehicle. 3. To provide directional stability and rolling action of the wheels on the road. 4. To achieve the self –rightening effect. 5. To control wear and tear of tyres. --- 03 Marks Types Of Steering System: Types of steering systems available in the market are as under, A. Mechanical Steering Systems: Here Mechanical effort applied by driver is utilized for steering the vehicle. These steering system includes, Worm and sector gear steering system Rack and pinion steering system Recirculating ball type steering system. Cam and lever type steering system Screw and Nut type steering system. 31 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 B. Power Steering Systems: Here the basic effort is applied by driver supplemented by the additional effort generated by Hydraulic power system assisted by electrical /electronic control. --- 03 Marks Effect on driver if Steering System is not good: Following effects are observed by the driver if the steering system is not good, Play in the steering gear Hard steering Side to side wandering of vehicle Shimmy front wheels Abnormal tyre wears Tyre squeals on turning Poor recovery on turns VI] Rack and pinion type steering gear box Appropriate Figure ------------ 02 Marks This steering gear is widely used in cars with independent front suspension. It consists of a rack, pinion, tie rods, ball joints, universal joint , rubber boot and spring pad as shown in figure. Hardened pinion is attached at the end of steering shaft. A universal joint is provided at the bottom of steering shaft to mount the steering box centrally and to provide more leg space. The 32 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 pinion engages with a rack which moves sideways to give lateral movement to front wheels. The tie rods are attached to this rack by ball joints enclosed in bellow type rubber boots. The ball joints allow for rise and fall of the wheels. Spring pads on the underside of rack tend to reduce the backlash between gears to a minimum. Drivers effort is transmitted to the front wheel through the steering wheel ,steering shaft,rack,tie rod and then lastly to steering knuckle. The gearing ratio obtained are 17.5:1 to 19:1 in general. Appropriate Short explanation ------------- 02 Marks VII] 1. Toe-in The toe in is the turning in of the front wheels from straight ahead position. The wheels are viewed from the top, the distance between the front wheels is less at top than at bottom wheels. ---------------------------------------01 Mark 2.Camber Camber is the tilt of the front wheels from the vertical plane. When the tilt is outward at the top, then the camber is positive and when the tilt is inward at top then the camber is negative. ------------- 01 Mark 33 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 3.Caster 34 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 The kingpin or the steering axis is tilted forwards or backwards from the vertical as shown in figure.The backward tilt from vertical is known as positive castor and forward tilt is known as negative castor. ------------- 01 Mark 4.King Pin Inclination The angle between the central line of king pin and vertical line is called as king pin inclination. ------------- 01 Mark VIII] Hydraulic Brakes : Principle: Pascal’s principle, “The confined liquid transmits pressure without loss equally in all direction”. 35 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 The hydraulic braking system consists of master cylinder and wheel cylinder. Master cylinder is connected by tubing to wheel cylinder at each of the four wheels. Each wheel brake consists of a cylinder brake drum which is mounted on inner side of the wheels. Two brake shoes are mounted in side brake drum. Shoes are filled with brake lining on their faces. Master cylinder: Heart of hydraulic system. It consists of fluid reservoir and compression chamber. Rubber seals on both sides of piston to avoid leakage. Fluid check value with rubber cup retains residual pressure in brake lines even when brakes are released. Two types of holes are provided. Smaller are is called by pass or compensation port. Second is called intake or recuperation port. Reservoir is vented to atmosphere. When brake pedal is pressed master cylinder piston moves forward to force liquid into the system. Liquid pressure is conducted to wheel cylinder. The wheel cylinder piston forces out ward. Brake shoes force out against brake drums. On release of pedal return spring quickly forces master cylinder piston back. Wheel cylinder: It consists of two pistons mores in opposite direction by the fluid pressure. 36 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Bleeder valves are provided in cylinder to permit air and liquid to be pumped out of system during bleeding operation. Spring serves to hold the cups against the piston when pressure is decreased. When brakes are applied the brake fluid enters the cylinder from brake line connections. It causes to force out of the two pistons in opposite direction. This motion is transmitted to brake shoes directly force them against brake drum. Thus applying the brake. Advantages : Simple construction Equal braking effort for all wheels Increased braking effort Self compensating system. Low wear etc. Disadvantages : System fails on leakage. Brake shoes are liable to get ruined if brake fluid leakage out.( 03 marks for suitable sketch, 03 marks for explanation ,02 marks for adv. & disadv.) 37 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 CHAPTER NO. – 4 [Suspension systems, wheels & Tyres] I] Write a short note on suspension system Necessity of suspension system (02 marks) i. To provide the comfort and safeguard to the occupants from road shocks. ii. To prevent the road shocks being transmitted to the vehicle components. iii. To give the stability to the vehicle in case of rolling, pitching etc. when the vehicle is in motion. iv. To provide particular height to the vehicle body structure and to bear driving and braking torque reactions. Classification of suspension systems (02 marks) i) Conventional suspension system ii) Independent suspension system a. Independent front end suspension system i. Wishbone type suspension system ii. Macpherson strut type suspension system iii. Vertical guide suspension system iv. Trailing link type suspension system b Independent rear suspension system. iii) Air suspension system a Bellow type air spring b Piston type air spring iv) Hydrostatic suspension system II] Classification of suspension system a) Conventional suspension system in which rigid springs are attached to rigid beam axle. b) Independent suspension system in which there is no rigid axle beam each wheel is free to 38 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 move vertically without any reaction on other wheel. c) Air suspension system in which air bags are mounted on each axle . d) Hydraulic suspension system in which hydraulic fluids are filled with cylinders known as shock absorbers are used for resist the damped vibrations. Air suspension system:- Air suspension systems are of two types 1. Bellow type air springs 2.piston type air springs, in which Air compressor is mounted on the vehicle frame supplies high air pressure into the reservoir. The compressor sucks the air from atmosphere . The pressure is about 20 kg/cm2 The compressed air is admitted into the four air bags through circuits & pressure regulator. This pressure is kept in air bags through leveling valve & it is adjusted accordingly. The leveling valve operates as per increased or decreased in vehicle load. Air suspension system is costly but more comfortable. Advantages of Air suspension system:Improve comfort Less noise Maintain constant height from road surface ( 02 marks for classification & 02 marks for explanation of air suspension) 39 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 III] Necessity of wheel balance and Wheel Alignment: A.Wheel Balance: Wheel balancing means balancing the wheels for static and dynamic balance. During the course of running of vehicle the tyres gets worn out and wheel rim gets bend or damaged. There may be lateral run out of wheels, Radial run out may be created due to tyre out or rim out conditions. In some cases this leads to uneven distribution of weight around axis of rotation of wheel assembly. Due to this there is an unbalance created in the wheel assembly. If this unbalance is not removed , then this may lead to wobbling of front wheels,vibrations,tyre wear, and may adversely affect steering system assembly parts. This can be avoided by balancing the wheels properly for static and dynamic balance. ( One Mark for correct representation of above concept covering points) B.Wheel Alignment: Wheel alignment means positioning or aligning of front wheels relative to each other and steering mechanism. The Wheel alignment depends upon wheel geometry i.e. Castor,Camber,King pin inclination,Toe-in and Toe-out parameters. So wheel alignment involves setting of these parameters to a correct value. Due to running of vehicle over a period of time on various road conditions leads to change in the setting of all the above mentioned parameters. In wheel alignment all these parameters are set to their design values. Otherwise directional stability of vehicle gets hampered.Uneven tyre wear , damage to various links of steering system may result. ( One Mark for correct representation of above concept covering points) C. Static Wheel Balancing Procedure : Following is the summary procedure Remove wheel from vehicle & place on static balancer If wheel is in unbalanced condition the bubble in balancer will move off from centre Balance the wheel by adding wheel weights to the rim until the bubble is centred. D. Dynamic Wheel Balancing Procedure : Dynamic balancing is equal distribution of weight on each side of tyre centre line. Summary Procedure is as under, Fill tyre with recommended tyre pressure.Check for tyre /Wheel damage.Dont use damaged rim for balancing. Mount wheel on balancing machine and lock it.Remove old balance weights. Set balance for size of tyre and start the machine. Balancer will stop automatically after some time. Read values of imbalance on right and left side of wheel on display. 40 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Put respective weights on both sides on marks. Start balancer again and check that reading is zero on both sides then wheel is balanced. If reading on both sides is not zero then repeat the procedure. ( Two Marks for correct representation of above concepts covering points) IV] Working Of Macpherson Suspension This is a single wishbone with a telescopic strut type front suspension This is shown in the Figure 6d. The strut is fixed to the body structure at the upper end through a flexible mounting and the lower part of strut is connected to bottom by a joint to the lower arm.The lower part of the strut also carries a stub axle, which in turn carries a wheel. The steering motion is supplied to lower part of strut and it turns the whole strut. A coil spring and hydraulic damper surrounds the upper part of the strut which takes care of road irregularities , shocks and vibrations. This suspention is mainly provided to modern cars. This suspension is simple in construction and strong. It contains light moving parts. It is very useful for vehicles with transverse mounted engines like cars where there is little space for upper links to fit. Maintenance of this suspention is very easy. 41 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 ( Correct Figure – 02Marks, Appropriate short Description- 02 Marks) OR IV] McPherson strut suspension system:- ( 04 marks for approprioate answer) In this type of suspension only lower wish bones are used. A strut containing shock absorber and the spring carries also stub axle on which wheel is mounted. The wish bone is hinged to the cross member and positions the wheel as well as resists accelerating, braking and side forces. This is lighter, keeps unsparing weight lower. Camber also does not change when wheel mores up and down. This gives maximum room in engine comportment commonly used on front wheel drive vehicle. Examples: Maruti 800. Volkswagen Passat, Antiroll bar is used along with McPherson strut suspension. Increased road safety, improved ride comfort, light & self stabilizing steering. V] Factors affecting tyre life ------------------------ 3marks Main factors affecting tyre life 1) Inflation pressure --2) Wheel alignment---3) Driving manners, this includes sudden acceleration, high speed, sudden braking. Driving on bad roads. etc 42 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 4) Tyre maintenance ,this includes tyre rotation at fixed interval and checking of wheel balancing . Remedial measures ------------------------- 3marks 1) Use of correct tyre pressure recommended by manufacturers. 2) Get it corrected with ref. to steering geometry 3 Avoid rash driving, Avoid sudden acceleration, avoid sudden braking. Avoid Driving on bad roads. 4) Proper wheel balancing, wheel alignment & removal of lateral run-out, Radial runout, uneven load distribution etc. VI] Comparison of radial tyre with tubeless tyre ( tubeless and tubed tyre ) *** Marks should also be given to the comparison of tubed tyre with tubeless tyre OR 43 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 VI] Differentiation between Tube and Tubeless tyre VII] Necessity of suspension system 02 marks i. To provide the comfort and safeguard to the occupants from road shocks. ii. To prevent the road shocks being transmitted to the vehicle components. iii. To give the stability to the vehicle in case of rolling, pitching etc. when the vehicle is in motion. iv. To provide particular height to the vehicle body structure and to bear driving and braking torque reactions. Classification of suspension systems 02 marks i) Conventional suspension system ii) Independent suspension system a). Independent front end suspension system i. Wishbone type suspension system ii. Macpherson strut type suspension system iii. Vertical guide suspension system iv. Trailing link type suspension system 44 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 b) Independent rear suspension system. iii) Air suspension system a) Bellow type air spring b) Piston type air spring iv) Hydrostatic suspension system VIII] Tyre Specification A tyre is specified by following method, 1. Width (Measured at the widest point when tyre is inflated to the correct pressure) in mm 2. A code number giving speed rating, a. In case of radial tyres, the speed rating code becomes SR , HR or VR i. SR speeds upto 170 Km/hr ii. HR speeds upto 210 Km/hr iii. VR speeds more than 210 Km/hr. b. For cross –ply tyres the speed ratings are coded as S or H 3. Diameter (Same as Rim Diameter) usually in inches. 4. PR represents the number of plies in the tyre. For example a tyre is specified as 145 SR 13 Means, Width of tyre is 145 mm Speed rating is SR means tyre is used upto 170 Km/hr speed. The diameter of tyre is 13 inches. Sometimes tyre is also designated with ply rating as under i.e. 9-20-12 Ply Rating Means, Tyre having width =9 inches,Rim Diameter= 20 Inches and 12 Ply rating. Appropriate Description/Example ----------- 03 Marks 45 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 IX] Types of tyre wears 1. Shoulder Wear: Wear takes place at the shoulders of the tyre as shown in the figure.This may be due to under inflation, Lack of rotation or high speed cornering.This can be corrected by aintaining correct pressure, Tyre rotation, Care during cornering by going at a slow speed. 2. Centre Wear: Wear takes place at centre of the tyre as shown in the figure.This may be due to Over inflation, Excessive Camber, Lack of rotation. This can be corrected by proper tyre pressure, Correct Camber Angle, Rotation of tyre . 3. One side wear: Excessive Wear takes place at one side of the tyre as shown in the figure.This may be due to Excessive Camber. This can be corrected by maintaining Correct Camber Angle. 46 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 4.Saw Tooth Wear: Saw toothed shape wear takes place on the tyre outer surface. This may be due to Incorrect toe In. This can be corrected by adjusting To-In to theThis may be due to Incorrect toe In. This can be corrected by adjusting To-In to the correct value. 5.Random Bald Spots: Wear is observed on the outer surface of the tread in the form of the random bald spots as shown in the figure. This may be due to Unbalanced wheel and tyre assembly, Defective tyre. This can be corrected by balancing tyre and wheels, replacing tyre. 6.Cupped Wear: Wear is observed on the outer surface of the tread in the form of the cup shaped spots on one side as shown in the figure, This may be due to Lack of rotation, Improper Alignment, Worn steering. This can be corrected by rotating tyres , Proper Wheel Alignment, Replacement of worn steering parts. 7.Cracked Treads: Wear is observed on the outer surface of the tread in the form of the cracks as shown in the figure, This may be due to Alternating Over Inflation and Under Inflation, Over Loading, High speed driving. This can be corrected by Maintaining proper tyre pressure pressures, Proper loading, Slow speed driving. 47 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 Any Three wear types with proper explanation & figure -------- 03 Marks 48 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 CHAPTER NO. – 5 [Automobile Electrical Systems & Body] I] Bendix Drive Bendix drive is the starting mechanism for the I.C.engine which starts the engine by engaging a pinion driven by starting motor with the ring gear on crankshaft. Once engine gets started the pinion gets automatically disengaged from ring gear. Figure 5c shows a typical assembly of bendix drive and action of bendix drive while engaging in starting of engine. Bendix drive consists of a pinion mounted on hollow sleeve having external square threads.The pinion has internal square threads and it is loose fit on sleeve.The anti drift spring prevents the pinion from striking the flywheel. 49 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 As the motor is switched on,the drive head rotates with armature shaft. The drive spring transmits this speed to the sleeve. The pinion due to its inertia effect does not pick up speed instantly but rotates along with the sleeve and travels to come in mesh with the flywheel ring gear.The engine is thus started and its speed increases, it forces back the pinion to its original position.This disengagement is due to inertia effect. ( Correct Figure – 04 Marks, Appropriate Description- 04 Marks) OR I] Bendix drive :- ( 02 marks for sketch , 02 marks for explanation) Construction :Bendix drive is fastened in armature shaft of the starting motor. The driver head is keyed to the end of the armature shaft. The pinion gears have internal threads mounted on threaded sleeve. Spring is attached to the drive head and also to the sleeve. Working :When starting motor is at rest the pinion gear is not engaged with fly wheel. When starting motor is put on, the armature starts rotating. This causes sleeve to rotate. The pinion due to its inertia of rest and its unbalanced weight, turns very slowly, but moves forward on revolving on it until it engages the teeth of fly wheel. The slight turning of pinion gear helps to engage it properly with fly wheel to run with it. When fly wheel turns the crank shaft also turn and engine starts. As engine has started the pinion is turned by engine much faster than when started by starting motor. This caused pinion gear to turn back on thread sleeve making it disengaged with the fly wheel. 50 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 II] Neat Sketch of Alternator . Neat sketch ------------2 marks Operating Principle -----------2 marks Operating Principle :- Alternator converts mechanical energy from engine to electrical energy .Alternator is usually mounted on the side of engine .Engine crank shaft pulley drives the alternator by belts at two to three times the cranks speed. A Regulator prevents excessive generation of voltage. Alternator has stationary shaft known as stator and armature as rotary part. The armature has windings of coil having its end connected to slip rings .The current thus generated fed to slip ring through carbon brush. The out put is alternating current. ( Suitable block diagram may also be considered) 51 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 III] State the construction and working of CDI ignition system Construction ----------------2 marks Working principle ------------2 marks 52 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 IV] Draw circuit diagram of lighting system ------------------------4 marks IV] Use of microprocessor in automobiles --------------------4Marks Following are the areas where microprocessor is recommended in modern car technology for efficient working of various controls. 1)Fuel feed system 2) Automatic transmission system 3)Braking system 4)To control oil pressure 5) Cooling water temp. 6)Pollution control 7) Safety Devices etc 53 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 V] Enlist various colour codes used in wiring system. --------------3 marks ( At least three of following and significance is expected ) Necessity :-It is necessary to identify the wires in automobile by colour coding Because of Identification and Insulation purpose .---------------------01 mark 54 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 VII] OIL PRESSURE GAUGE Construction and working principle of oil pressure gauge:Oil pressure gauge consist of diaphragm type oil pressure plug in which pressure of oil is acting on diaphragm ,Resistance on sliding contact varies according to position. This variable resistance is recorded on indicator armature pointer.This variation of resistance is proportional to the pressure exerted at diaphragm. ( 03 marks for sketch & 03 marks for explanation) VIII] Use of microprocessor in automobiles -------------------following are the area where microprocessor is recommended in modern car technology for efficient working of various controls. 1)Fuel feed system 2) Automatic transmission system 3)Braking system 4)To control oil pressure 5) Cooling water temp. 6)Pollution control 7) Safety Devices etc 55 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 ( 04 marks for appropriate answer) IX] Balancing Coil Type fuel Guage Appropriate Figure ------------ 02 Marks Figure shows a wiring diagram of gauge. The dash and tank units are connected in series by a wire to the battery through the ignition swich. When the switch is turned on, the current flows through both the units. A hinged arm in the tank unit has a float mounted at one end and a sliding contact at the other. The sliding contact moves along the resistance. The float lever moves up and down with the fuel level in the tank. As the fuel level goes down, the sliding contact moves to left. Consequently more current flows through the left hand coil while less current flows through right hand coil. The left hand coil becomes magnetically stronger than the right hand coil.The armature and the pointer move towards left and hence a low fuel level is seen in the tank. When fuel level rises, the float moves up and allows more resistance to be inserted into the circuit.Most of the current flows through the left hand coil and also in the right hand coil. The right hand coil becomes stronger and causes the armature and pointer to swing to the right, showing the amount of fuel in the tank. Appropriate Short explanation ------------- 02 Marks 56 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 X] Electronic Ignition system In Capacitive discharge system a battery of 6 volt is used. Battery is connected to trasisterized DC to DC converter,which gives a high voltage of 250 Volts to 350 Volts. From the battery.The condenser of the circuit is charged by this voltage through charging resistance.The charging resistance is designed to control current in silicon controlled rectifier(SCR).The condenser is discharged when SCR triggering device sends a pulse and high voltage spark is produced at spark plug. OR In transistorized Ignition system,The contact points are connected to base of the transistor,which is further connected to primary winding of ignition coil through ballast resistor.The collector of 57 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 transistor is connected to battery.When contact breaker opens,The base circuit is disturbed and current in primary delays causing normal induction,which produces spark in spark plug. Any one system with figure and appropriate description ------ 04 Marks XI] Battery Description of any one of the component Container: Container is a single piece construction made up of a hard rubber, plastic or bituminous composition.It is divided into compartments by partitions for different cells.Bridges are formed at the bottom of each compartment on wich plates rest.Places between bridges ribs can be used to collect sediments.This minimizes danger of short circuit due to sediments. Appropriate Description ----------- 02 Marks 58 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA AUTOMOBILE ENGINEERING 2013-14 XII] Magneto Ignition system: ( 04 marks for approprioate answer) Construction :It consists of magneto which produces and supplies current in the primary winding. Magneto consists of fixed armature having primary and secondary windings and rotating magnetic assembly which is driven by the engine. Working :When magnet rotates current flows in primary winding. The secondary winding gives high voltage current to the distributor, which distributes it to respective spark plug. The magneto may be either rotating or armature type or rotating magnet type. Application: - Used in motor cycles, scooters, racing cars. 59 K B P COLLEGE OF ENGINEERING & POLYTECHNIC , SATARA