Chapter 16 Product Liability

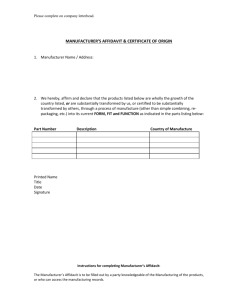

advertisement

Brad Curry Mark Medlyn Number of product accidents estimated to be 50 million per year Cost of 50 billion dollars Lawsuits filed as a result of faulty design (Ford Pinto gas tank–a 10.00 repair was turned down for cost ) http://www.youtube.com/watch?v=VS8hWQIm D9w Three area’s for product injuries 1. Behavior or knowledge of product user 2. The environment where it is used 3. Factory design using safety analysis and safety controls Human behavior hard to control Best recourse is to design products that are idiot proof Examples: Lawn mowers with guard chutes Redesigning car interiors to reduce sharp edges Safety glass on vehicles that does not shatter into sharp edges Lawsuits filed as a result of Faulty design ( Ford Pinto gas tank)– (a 10.00 repair was turned down for cost ) Manufacturing process- a defect in a part Firestone 500 tire which failed History Ancient times: sample of grain shipments tested for quality By 14th century, textiles were sampled If they passed, then they received a seal Middle of 18th Century two concepts Caveat emptor (let the buyer beware) Followed Adam Smith “invisible hand” theory Purchaser was to take care of his or her own interest Under this doctrine, the consumer could not sue the manufacturer Could only sue the retailer Who then could sue the wholesaler Who then sues the manufacturer Under this doctrine, the consumer could not sue the manufacturer Could only sue the retailer Who then could sue the wholesaler Who then sues the manufacturer This began to change in 1916 Macpherson vs. Buick Motor car Court held that Buick ( rather than the component manufacturer) was responsible for injuries to plaintiff due to defective wheel Buick failed to inspect a defective wheel before it was put in the car Product Safety law Consumer Product Safety Commission Established 1972 Designed to protect public From unreasonable risks and injuries Assist in evaluating safety of products Promote research and investigation into Causes and prevention of accidents, illnesses and injuries Factors juries use to determine product design is defective and unreasonably dangerous Utility of the product Feasibility of cost of improvements Frequency and severity of injuries Adequacy of warnings Environment in which product is used Consumers reasonable care in using product Defenses Defendant must prove that product not responsible for injury Bad judgment (using a chair as a stepstool) Plaintiff's failure to maintain the equipment Improper use of the product by owner Accident caused by alterations of product i.e. removing safety features Legal theories Comparative negligence: the user did something wrong.. As a result, the verdict is split….80% fault of consumer 20% on the product Assumed risk of injuries i.e. bungee jumping or parachuting Misuse of product by consumer i.e. flying Cessna 182 into a thunderstorm Expert Witnesses Used by both sides Must be technically competent in area of testimony Personal character must be above reproach Most important is that they must be able To communicate with the jurors and Judge Statutes of repose Product does not injure person within a period of time Then there is no liability for the producer http://www.youtube.com/watch?v=QkfVrqas 6qI&feature=related Consumer Product Safety Improvement Act (2008) CERTIFICATION OF COMPLIANCE 1. Identification of the product covered by this certificate: 2. Citation to each CPSC product safety regulation to which this product is being certified: 3. Identification of the U.S. importer or domestic manufacturer certifying compliance of the product: 4. Contact information for the individual maintaining records of test results: 5. Date and place where this product was manufactured: 6. Date and place where this product was tested for compliance with the regulation(s) cited above: 7. Identification of any third-party laboratory on whose testing the certificate depends: 1. 2. 3. 4. 5. 600 ppm within 180 days 100 ppm with in 3 years if able Exemptions for lead that cannot be accessed by consumer by coverings ( not paint) 300 ppm one year after enactment Limit now down to 90 ppm for paint down from 600 ppm. Lead paint and total Lead content Full and non full cribs: and pacifiers Small parts Children’s metal jewelry Baby bouncers Products subject to all other children product rules One year after law goes into effect Manufactures must place Permanent distinguishing marks/labels that allows the consumer to know where/when and by whom the product was manufactured Requires that consumers have cards or electronic means To register their purchase Manufacturer must then keep that registration and notify consumer of any recalls Requires that there be safety standards enacted Including flammability Uses existing standards Products that contain Pthalates and lead 1. In toys 2. Child care article (sleepwear) 3. Clothing 4. Bedding 5. Every product intended for children under the age of 12 Stipulates type of language to be used Must be used at point of sale and in advertising Financial loss Award compensates plaintiff for current And future medical expenses For pain and suffering Loss of earning Used by both sides to bolster their argument Requires that the person who testifies Be technically competent in the area Either through training or education Should be able to communicate well with the Judge or Jury Actual vs. Punitive Actual loss is what the Plaintiff ( or his family) Is out of money for. Can be for wages lost Loss of limbs Death Property that is damaged or lost Goes beyond what the actual loss is Very rare and usually only when the Defendant knew the product that is being Manufactured has a high potential for failure Pinto gas tanks Simple 10.00 brace wasn’t used despite Engineers saying needed Result was rear impacts caused tank to split Potential for fire and death Increased insurance Cost of recall, replacement or repair of product Cost of damage to reputation to company Cost of holding back production Cost of increased quality efforts for prevention or appraisal Program is part of organization structure Product safety committee Members should be from legal, design, manufacturing, marketing and quality areas Safety engineer should be chair person Chair person’s responsibility Liaison between insurance and government regulators Participates in injury cases Maintains education programs Conducts audits Acts as consultant Keeps informed of trends Needs a thorough understanding of products Background in manufacturing Professional and diplomatic Direct access to senior management Respect of everyone in organization Be able to take charge of a project Team player Education New-Product Review Initial Production Review Periodic Production Audits Control of Warranties, ads, agreements Warning Labels and Instructions Complaints and Claims Records ISO 9000 Documents Product-Recall Plan Subrogation Risk Criteria Standards Audit Customer Service Redress Employees need to be aware of product safety both internally and externally Train employees on how to handle productrelated incidents Inform employees of laws and lawsuits that may have an impact on the company Product safety is a design parameter Must be considered first Adopt product safety design techniques Document, Document, Document Have a product review team List all the possible hazards Design control is required for ISO 9000 Start with a limited production run Control the distribution The more people involved in evaluating the product the better Process control is required for ISO 9000 Perform regular audits on all products This documentation is legally binding for organizations Reviews must be performed regularly to protect the company interest All of these documents can and will be used in court Evaluate the cost problems of these documents Largest cause of manufacturer’s negligence is inadequate warnings Consider the knowledge level of the average user A product is not defective if it has an adequate warning that when followed makes the product safe to use ANSI has established guidelines to follow Product safety signs Type of hazard Degree of hazard Consequence of involvement with hazard How to avoid the hazard Warning labels and instructions are not the same Care should be taken to develop both Overuse of warning will dilute the message Alerts the organization that a change is needed Complaint or claim should trigger a review for: ◦ ◦ ◦ ◦ ◦ Cause Nature and seriousness of injury Failure mode causing situation Was defect present when product was sold Any negligence by the parties involved Maintain records on all of the following 1. Product development and testing 2. Audits 3. Verbal and written communications 4. Original design data and revisions 5. Service life 6. Outside organization acceptance and approvals 7. Raw material acceptance records Records provide traceability Records must be protected from loss Records must be maintained over time Record retention procedure is required for ISO 9000 Can be used to show that a company is diligent in design validation and corrective procedures Can also be used to show that a company is negligent if the company is not following it’s own quality manual 1. 2. 3. Minimizes costs and potential liability The decision to recall is based on 3 things Exposure to personal injury or property damage Form of communication used to notify users of recall Will the product be repaired, replaced or reimbursed Traceability is important to find affected products Suppliers are just as important to the product liability prevention program Buyers and suppliers should work together to visit and audit prevention programs Buyer needs to make supplier aware of all relevant documentation. Determine what the risk is for each product Involve employees in developing standards Continuously audit for improvement First line defense against a potential lawsuit Better to make friends than enemies Provide customers with a policy that addresses their needs in a timely manner Provide repairs quickly and fairly