Introduction to Chemistry 2001

advertisement

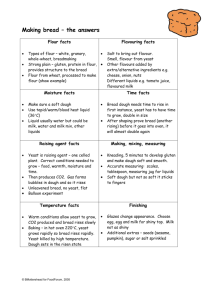

BREAD Cereals provide Bread Cereals are the World’s staple Provide the majority of carbohydrates as starch for the world’s population Members of the grass family Wheat Rice Maize Oat, Rye Barley, Sorghum How are they used? Direct consumption Rice, Maize, Oats Milled for flour Wheat, Rice, Maize, Rye Milled for starch Maize, wheat, rice Fermentation substrate Barley, Wheat, Rye, Rice, Maize Milling Grains crushed by a series of rollers Remove hull and bran Remove germ (embryo) Pulverise endosperm Wholemeal flour Contains bran & embryo Higher lipid content, rancidity problem Mills 8,000 BC first grain crops, hand crushing 1,500 BC Millstones 1,000 BC animal powered mills 400 BC watermills 1,000 windmills 1780 steam power 1870 use of steel rollers Flour Carbohydrate Bulk of endosperm, in intact starch granules Protein Endosperm storage proteins Wheat 13% protein Glutenin & Gliadin Lipid Mostly removed with embryo Types of Flour Strong flour From hard wheat High protein content For bread Soft flour From soft wheats Lower protein content For cakes & biscuits Bread Dough formation Mixture of flour & water Water uptake depends on protein content Kneading Developing gluten Leavening Generation of gas to expand dough Baking Straight Dough Flour & water mixture Yeast, leavening agent Sugar for yeast growth Salt for yeast metabolism Fat to soften texture, reduce staling. • Saturated fats better • 5% in bread 30-50% in cakes Milk to improve crumb texture Kneading to mix thoroughly Develop elastic gluten network Proofing Incubate 30°C 1 to 2h Yeast fermentation Production of ethanol & CO2 Gas expands dough Elastic dough will stretch Punching, allows some CO2 to escape Moulding & shaping Cake All-purpose Strong bread Alternative leavening agents Baking powder Acid + alkali mix Cream of tartar & baking soda Produces CO2 when heated Mechanical Beating or creaming to whip in air Steam generation Whipped egg white Baking 250 – 300°C, 30 – 60 min Further gas generation Dough rises to final shape Yeast killed off Starch gelatinises Gluten coagulates Bread becomes hard Crust develops and browns Sponge Dough Moderately stiff dough Only 50 % of the flour + yeast & sugar Fermented 3 –4 hours Remaining flour, fats & water added Finer texture, smaller gas holes Batter whipped process Chorleywood Process Continuous production Liquid fermentation with little flour Remaining flour added Agitated to incorporate air Extruded into baking pans Fine uniform texture Starch Starch, main polysaccharide in flour Present in starch granules Contains 2 polysaccarides Amylose & amylopectin As heat increases Starch granules absorb water & swell Release amylose from granule On cooling Amylose molecules combine to form gel 5 0 0 9 c 8 0 h 0 7 0 6 0 5 0 0 0 2 5 0 0 0 u r 1 0 0 n g 0 3 2 i M a i z e s t a 0 r 1 5 0 0 4 0 1 0 0 0 3 0 2 0 1 0 5 0 0 0 2 5 0 0 5 1 0 T i 1 m 5 e 2 ( 0 m i n ) 0 p e r a t 3 p a s t T e m V i s c o s i t y S t a r c h Starch Retrogradation Realignment of amylose chains Stick to each other more strongly Forms more rigid crystalline structure Slow process so takes time Inhibited by fats that can interact with amylose Starch becomes harder Staling Stale bread = old bread Harder texture Crumb more brittle Dryer, poor release of flavour Promoted by low temperature Regeneration possible by wet heat Bread deterioration Prone to fungal contamination Fungal growth normally prevented in foods by low humidity and temperature Dry storage at low temp. promotes staling Added mould inhibitors common Eg. Calcium propionate