Bread

advertisement

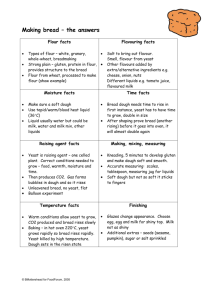

Bread •Bread is a staple food prepared by baking a dough of flour and water and often additional ingredients, such as butter or salt to improve the taste. 1 Bread Ingredients Flour Yeast Water Salt Optional Ingredients in Bread: Bread Sweeteners Dough Conditioners Egg 2 Flour Flour is the primary ingredient of any bread recipe. Flour contains gluten, a protein that provides elasticity and the basic structure of bread. Bread made from flour that does not have the germ or bran has lesser nutrients and fiber. 3 Yeast In presence of water, yeast makes use of the sugar present in the flour and releases carbon dioxide. Carbon dioxide is a gas that rises within the dough. The gluten present in flour makes the dough elastic. So, as the carbon dioxide bubbles are formed in the dough, instead of making holes and escaping, the gas bubbles make the dough rise. 4 Water Water helps to combine all the ingredients together. It also aids in activating yeast that releases carbon dioxide. 5 Salt Salt allows the baker a control over the rising of bread by strengthening gluten in flour. As it slows down the rising process of bread, salt allows the dough to develop flavor. 6 Egg When lots of eggs are used, they add a distinct flavor to bread. They also act as a leavening agent. Fat in the yolk increases the tenderness and light texture of bread. It also gives a smooth texture to the finished product. 7 Bread Sweeteners If included in bread recipe, the major role of sugar is to provide food for yeast. However, this does not necessitate addition of sugar to the dough as flour itself has enough sugar for the yeast to produce carbon dioxide. Hence sugar is primarily used to add a sweet flavor to the bread. It also contributes to browning of the bread. 8 Dough Conditioners Dough conditioners like calcium dioxide, potassium iodated, ascorbic acid, etc. are used by bakers for greater control over the baking process. 9 SAFETY REGULATIONS Bakers must be vigilant when they are sourcing ingredients. They also need to have means of screening new employees. Good cleaning and sanitation practices to remove allergen residues from equipment and the food production environment is always important. 10 Bakers have to identify best practices for cleaning tasks; train the sanitation staff to adhere to the best practice; inspect all areas of the bakery on at least a monthly frequency to effectively identify issues and to take corrective actions; establish and keep an effective and up-to-date master sanitation schedule that tracks cleaning tasks and established frequency. 11 SAFETY REGULATIONS IN PACKAGING Bakers must take special care during the ingredient packaging materials and conveyors. Plant operators must be careful when cutting ingredient bags so as not to create loose pieces, and conveyors must often be inspected to observe for wear and cracks. Care must be taken with wooden pallets to make sure that neither the pallet nor the product packaging on the pallet is damaged during transport. 12 13 Production of Bread Scaling Mixing Bulk Fermentation Folding/Degassing Dividing Pre-shaping Benching Shaping Proofing Baking Cooling Storing 14 Scaling Scaling is weighing/massing out the ingredients. 15 Mixing Mixing the ingredients together sounds simple enough, but there are many finer points that come into play with different breads and make a huge impact on the final results in the bread - points like when the fat is to be added, or when to allow an autolyse, or mixing speeds and lengths for different doughs. 16 Bulk Fermentation During bulk fermentation the dough gets its motor running as the yeast starts to feast upon the sugars present. It's the baker's job to make sure they don't either eat themselves to death or starve, and that control can be achieved through manipulation of time and temperature. 17 Folding/Degassing For many if not most doughs , a long, slow fermentation will yield the best results and when taking this route it is often advisable to fold/ degass the dough. After a length of time the yeast can end up more or less sitting in pools of its own waste, unable to reach enough food or oxygen. 18 Dividing In most cases, a batch of dough will be divided into several pieces to be made into individual loaves. 19 Pre-shaping It's a stop-off point on the way to the final shape, after which you can let the gluten relax for a few minutes to allow for an easier time in your final shaping. 20 Benching The pre-shaped loaf generally could use a moment to let the gluten relax so that the final loaf is more easily shaped. 21 Shaping Shaping determines what the loaf will actually look like. 22 Proofing This is the final rise the bread will have before it goes into the oven, though the baker should keep in mind that "oven spring" will produce a final quick lift, especially when using a baking stone. 23 Baking The moment of truth. Cook the bread! 24 Cooling Breads are at their best completely cooled. 25 Nutrtional value Bread is not only a source of carbohydrates and fibre but also provides us with essential vitamins and minerals. Bread contains vitamin B1 or thiamine, vitamin B2 or riboflavin, vitamin B3 or niacin, vitamin B6 or pyridoxine and vitamin B9 or folic acid. With respect to minerals, it contains large amounts of phosphorus, magnesium, calcium and potassium, and in lesser quantities others such as sodium, iron, or iodine. For this reason, we have to ensure their intake through our daily diet in order to cover our body’s needs. Both vitamins and minerals are concentrated in the bran and in the germ, parts that are removed during the milling. In consequence, white bread has a much lower content of vitamins and minerals than whole grain bread. 26 Nutrtional value A daily bread intake of about 250g is recommended which corresponds to 4-8 slices. Taking into account its nutritional value, bread should constitute a vital part of the diet, being present in all meals from breakfast to dinner. 27 28