Chem Feed Powerpoint Presentation

advertisement

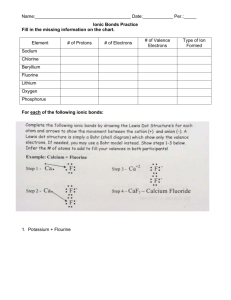

STATE OF WISCONSIN DEPARTMENT OF SAFETY & PROFESSIONAL SERVICES (DSPS) AN INTRODUCTION TO POTABLE WATER TREATMENT CHEMICALS, FEEDERS AND PUMPS 1 THANK YOU! I would like to thank the Wisconsin Association of Dairy Plant Field Representatives, President Eric Helms, Chris Theder of DATCP, UW-Madison Dept. of Food Service, UW Extension and DSPS management for the opportunity to speak with you here today. 2 CONTACT INFORMATION Glen Schlueter Wisconsin Department of Safety & Professional Services (DSPS) Phone: 608-267-1401 Email: glen.schlueter@wisconsin.gov I have been working for the State of Wisconsin for 23 years. Prior to this, I was the Laboratory Supervisor for the Water Quality Association in Lisle, Il. Prior to that, I was a Technical Data Analyst/chemist for a number of petroleum based laboratories. 3 CONTACT INFORMATION I am the primary contact for water treatment installed in/on: one- and two-family dwellings; Transient Non-Community Water Supplies [TNC's (e.g. bars, restaurants, quick-marts; ≥ 25 different people)]; and Non-Transient Non-Community Water Supplies in Wisconsin [NTNC's (e.g. schools, daycares, factories; ≥ 25 same people)]. I also work on healthcare plumbing appliances, water reuse systems, alternate plumbing products and materials, and act as a general technical resource to the DSPS. 4 OVERVIEW Chemical feed systems are comprised of three main components: a. a pump or feeder b. a chemical (solid, liquid or gas); and c. a reservoir/solution tank (I'll not discuss these much, it at all, this evening) We shall now discuss the basics of each with a special emphasis on what you're most likely to experience in the field and effective techniques for common contaminants. 5 FEEDERS AND PUMPS Not all methods are created equal. Each method has pros and cons and is well suited for specific end uses. EROSION FEEDERS use a solid chemical [e.g. calcium hypochlorite (Ca(ClO)2] and can be prone to highly variable chemical concentrations in the treated water when undersized or misapplied. This is because erosion feeders may initially release highly concentrated chemical dosages after sitting idle or under low flow conditions for an extended time and contrarily release low dosages during sustained periods of high flow. Erosion feeders are well suited to the pool and spa applications. I place well-mounted pellet chlorinators in this category. 6 A FLOATING SOLID CHLORINE [Ca(ClO) ] FEEDER 2 7 A WELL SOLID [Ca(ClO)2]PELLET CHLORINATOR 8 PELLET CHLORINATOR CUTAWAY 9 COMMERCIAL-INDUSTRIAL SOLID [Ca(ClO)2] CHLORINE FEEDER 10 VENTURI FEEDERS VENTURI FEEDERS use the suction created via the venturi effect to draw a liquid or gas into a flowing water stream. A given venturi requires a specific range of pressure differential/flow rate to function correctly. Venturi feeders are well suited to irrigation applications in which the flow rates are relatively constant and predictable. 11 A VENTURI INJECTOR/ASPIRATOR 12 A PROPER VENTURI INSTALLATION 13 A PROPER VENTURI INSTALLATION 14 DIAPHRAGM PUMPS DIAPHRAGM PUMPS rely on the positive displacement of a flexible diaphragm to operate a series of check valves. 15 BASIC DIAPHRAGM PUMP PRINCIPLE OF OPERATION 16 DIAPHRAGM PUMP CUTAWAY 17 DIAPHRAGM PUMP PRIMARY CONSIDERATIONS Dosage is altered by increasing the length of the stroke and/or rate of the stroke of the plunger/piston. Water system pressure directly affects pump output. Prone to fouling because the check valves become may become fouled/fail; check valves should be replaced every 6-12 months, more frequently if service conditions demand it. If checks, and other components, continually show signs of premature wear, that may be indicative of a chemical compatibility problem. Difficult to prime/loses prime (out gassing). Many serviceable parts relative to the other methods discussed. Well suited to high pressure applications. With proper service and maintenance, a very reliable, accurate and widely used variety of positive displacement pump. High shearing forces may damage some molecules. 18 PERISTALTIC PUMPS PERISTALTIC PUMPS rely on the positive displacement of a flexible tube via a series of external pinch rollers. 19 PERISTALTIC PUMP CUTAWAY 20 PERISTALTIC PUMPS PRIMARY CONSIDERATIONS Peristaltic pumps have relatively few serviceable parts, and do not use small valves subject to fouling. In most cases, the primary maintenance consideration is to replace the tube on a regular basis. Dosage is altered by increasing the rate of pinch roller rotation. Water system pressure does not affect pump output. Low shear forces do not damage delicate molecules. 21 DIAPHRAGM VS. PERISTALTIC The diagram below depicts the differences in the uniformity of chemical dosages delivered. 22 A HANDY COMPARATIVE CHART 23 COMMON WATER TREATMENT CHEMICALS The chemicals. The first step is a comprehensive water analysis by a reputable, certified, lab to determine what, if any, water treatment is indicated and if so, what type. The best and primary option is always a naturally occurring safe source of water with acceptable aesthetic quality; only when that option is exhausted does treatment become an attractive secondary option. The second step, and most important step in using, handling and storing chemicals is SAFETY. Insists on Safety Data Sheets [SDS’s (formerly known as MSDS sheets)], proper container labeling and in the case of potable water treatment, a NSF/ANSI Standard 60 listing label. Also, all disinfectant chemicals must be registered with the EPA as required under FIFRA. 24 NSF/ANSI STANDARD 60 LABEL 25 ANSI/NSF STANDARD 60 LISTINGS Any bulk container displaying the NSF/ANSI Standard 60 seal should be directly traceable to a listing. We start here: http://info.nsf.org/Certified/pwsChemicals/ http://info.nsf.org/Certified/PwsChemicals/ Let's use the example of a container labeled with a mfg. of “Better Water Industries”, a brand name of “Well Safe”, a calcium hypochlorite product. 26 NSF/ANSI STANDARD 60 SEARCH PAGE 27 ACTUAL SEARCH RESULT 28 RAPID HAZARD RECOGNITION Also be familiar with the NFPA 704 Material Hazard Identification System and HazCom 2012 labeling requirements. 29 NFPA 704 LABELING SYSTEM 30 HAZCOM 2012 LABELING SYSTEM 31 THE OXIDANTS: CHLORINE Chlorine. Chlorine exists in a variety of forms. Listed in order of increasing hazard, we have: 1. Liquid = sodium hypochlorite (NaClO) 32 THE OXIDANTS: CHLORINE (CONTD.) Solid = calcium hypochlorite [Ca(ClO2)] 33 THE OXIDANTS: CHLORINE (CONTD.) Gaseous = chlorine gas (Cl2) 34 THE OXIDANTS: CHLORINE (CONTD.) Chlorine is used for a variety of water treatment applications; principle uses include disinfection and aesthetic water treatment (e.g. iron, manganese and hydrogen sulfide). 35 THE OXIDANTS: CHLORINE (CONTD.) In the context of disinfection, chlorine kills pathogens such as bacteria and viruses by breaking the chemical bonds in their molecules. The toxicity of chlorine is thought to be derived not from the chlorinen itself or its release of nascent oxygen, but rather from the reaction of the HOCl with the enzyme system of the cell. The superiority of HOCl over OCl may be due to the small molecular size and electrical neutrality of HOCl which allow it to pass through the cell membrane. For example, when enzymes come in contact with chlorine, one or more of the hydrogen atoms in the molecule are replaced by chlorine. This causes the entire molecule to change shape or fall apart. When enzymes do not function properly, a microorganism will die. 36 THE OXIDANTS: CHLORINE (CONTD.) A crucial consideration for disinfecting water with free chlorine, and other disinfectant chemicals, is “CT” value. “CT” stands for Concentration x Time; concentration is typically expressed in parts per million (ppm) or milligrams per liter (mg/l), time is measured in minutes. The lower the “CT” value, the more effective a given disinfectant is. As you might surmise, there are two options to get the same resultant “CT.” If the concentration (C) of disinfectant increases, then the amount of time (T) required decreases. Conversely, if the concentration (C) of disinfectant decreases, then the amount of time (T) increases. 37 THE OXIDANTS: CHLORINE (CONTD.) Chlorine gas rapidly hydrolyzes to hypochlorous acid : Cl2 + H2O → HOCl + H+ + Cl– Aqueous solutions of sodium or calcium hypochlorite hydrolyze : Ca(OCl)2 + 2H2O → Ca2+ + 2HOCl + 2OH– NaOCl + H2O → Na+ + HOCl + OH– Notice, the same equilibria are established whether elemental chlorine or hypochlorite is used for chlorination. The two chemical species formed by chlorine in water, hypochlorous acid (HOCl) and hypochlorite ion (OCl– ) are commonly referred to as “free” or “available” Hypochlorous acid is a weak acid and will disassociate: HOCl ↔ H+ + OCl – In waters with pH between 6.5-8.5, the reaction is incomplete and both species (HOCl and OCl– ) will be present. Hypochlorous acid (HOCl) is the more (20x) germicidal form. 38 THE OXIDANTS: CHLORINE (CONTD.) Temperature, and pH in particular, affect the efficacy of free chlorine. In short, warm water temperatures and low (i.e. acidic) to neutral pH are favorable. 39 THE OXIDANTS: CHLORINE (CONTD.) pH EFFECT ON HOCl CONCETRATION 40 AVAILABLE CHLORINE OF CHLORINATION CHEMICALS Chemical % available Cl2 Chlorine gas (Cl2) 100 Chlorine dioxide (ClO2) 263 Hypochlorites (OCl) Calcium [Ca(OCl)2] Sodium (NaOCl) 70 - Industrial grade 12 - 15 Domestic grade 3-5 41 THE OXIDANTS: CHLORINE (CONTD.) In the context of aesthetic contaminants, chlorine is used as an oxidizing agent that induces precipitation, meaning that dissolved substances are converted to solid particles that can be subsequently removed via mechanical filtration. The oxidation/filtration strategy is often used to remove iron, manganese and hydrogen sulfide: 2 Fe2+(aq) + HOCl + 5H2O → 2 Fe(OH)3 (solid) + 5H+ + Cl- H2S(aq) + HOCl → H+ + Cl- + S (solid) + H2O Mn2+(aq) + HOCl + H2O → MnO2 (solid) + Cl- + 3H+ THE IRONY OF IRON. SPECIATE. 42 THE OXIDANTS: CHLORINE (CONTD.) UNDESIRABLE BYPRODUCTS OF CHLORINATION If a chlorination process is applied to water containing organics such as Total organic carbon (TOC) or natural organic material (NOM), then the formation of disinfection by-products (DBPs) is possible and monitoring for DBP’s must be performed on a regular basis. 43 THE OXIDANTS: HYDROGEN PEROXIDE (H2O2) Hydrogen peroxide (H2O2). Hydrogen peroxide (H2O2) is rarely used in drinking water treatment as a stand-alone treatment process. A significant obstacle to widespread use as a disinfectant is related to the unstable nature of H2O2 as it pertains to the calculation of the aforementioned “CT.” Consequently, it is not approved by regulatory agencies as a stand-alone disinfection treatment process. 44 THE OXIDANTS: HYDROGEN PEROXIDE (CONTD.) 45 THE OXIDNATS: HYDROGEN PEROXIDE (CONTD.) H2S + 4H2O2 → SO4 2- + 4H2O + 2H+ (for pH > 8) 2Fe2+ + H2O2 + 2H+ → 2Fe+3 + H2O 46 THE OXIDANTS: HYDROGEN PEROXIDE (CONTD.) However, there are a number of technologies where H2O2 is used as part of the treatment program. The advanced oxidation process (AOP) uses H2O2 in conjunction of O3 and/or UV light to produce hydroxyl radicals (OH-). The powerful hydroxyl radicals are more effective than ozone or UV alone. 47 THE OXIDANTS: HYDROGEN PEROXIDE (CONTD.) In the H2O2/UV AOP, H2O2 is fed ahead of the UV unit such that the water containing H2O2 is irradiated by the UV. The oxidation potential of a hydroxyl radical (2.8V) is much greater than other oxidizing agents such as ozone (2.07V) and chlorine (1.39V) and thus has the capability of oxidizing a variety of organic and inorganic contaminants. The UV/ H2O2 process is accomplished through two stages of oxidation. In the first step, UV light catalyzes the dissociation of hydrogen peroxide into hydroxyl radicals through chain reactions. These oxidants then react with the contaminants of interest in the water: H2O2 + hv = 2OH- 48 THE OXIDANTS: HYDROGEN PEROXIDE (CONTD.) In the H2O2/ozone (O3) AOP, H2O2 is added either before or after the point of ozone injection. Addition of hydrogen peroxide following ozone is the best way to operate. Oxidation efficiency is increased via the conversion of ozone molecules to hydroxyl radicals. Such systems are sometimes referred to as “peroxzone” systems. 49 THE OXIDANTS: HYDROGEN PEROXIDE (CONTD.) Hydrogen Peroxide is one of the most powerful oxidizers known; stronger than chlorine, chlorine dioxide, and potassium permanganate. Through catalysis using UV and/or ozone, H2O2 can be converted into hydroxyl radicals (OH-) with reactivity second only to fluorine. Oxidant Oxidation Potential, V Fluorine 3.0 Hydroxyl radical Ozone Hydrogen peroxide 2.8 2.1 1.8 Potassium permanganate 1.7 Chlorine dioxide 1.5 Chlorine 1.4 50 THE OXIDANTS: OZONE (O3) A complete of discussion of ozone (O3) would be substantially similar previous discussion of hydrogen peroxide and would therefore be wasteful of our allotted time. However, there is some information worth mentioning: Ozone is highly unstable and must therefore be generated on-site Ozone has a short half-life that depends on temperature, pH, pressure and velocity of the water. Under standard conditions (21°C, 1 bar) the half-life of ozone gas is 20 minutes. Dissolved ozone half-life is 20 minutes at pH 6, 15 minutes at pH 7 and 5 minutes at pH 8. Ozone is generated using air/O2 feed via two primary methods: Corona discharge (dessicants) UV exposure (λ = 185 nm) 51 THE OXIDANTS: OZONE (CONTD.) 52 THE OXIDANTS: HONORABLE MENTIONS Potassium permanganate (KMnO4): Chlorine dioxide (ClO2): Air (ambient ≈ 78% N2, 21% O2): 53 THE OXIDANTS: A COMPARISON Oxidant Oxidation Potential, V Fluorine 3.0 Hydroxyl radical 2.8 Ozone 2.1 Hydrogen peroxide 1.8 Potassium permanganate 1.7 Chlorine dioxide Chlorine 1.5 1.4 54 BY NOW YOU'VE PROBABLY HEARD SO MUCH ABOUT OXIDANTS... That you're blue in the face! So let's move on to... 55 THE PHOSPHATES The phosphate “family” is comprised of two primary groups: Orthophosphates (PO4 3-) are used to halt corrosion of metallic pipes (e.g. Pb/Cu), commonly on low alkalinity/low pH waters, by forming an artificial passivating layer on wetted surfaces. Polyphosphates (variable and many) are used for “sequestration”, chemical combination of a chelating agent and metal ions in which soluble complexes form. 56 THE PHOSPHATES (CONTD.) Hardness ions (i.e. Ca+2, Mg+2) and dissolved iron (Fe+2) are metal ions commonly found in water and include calcium and magnesium. Sequestration is dependent upon pH; a given sequestrant works best in a particular pH range: Sodium hexametaphosphate [(NaPO3)6] (SHMP) performs very well at neutral pH ranges and is a good place to start. 57 THE NEUTRALIZERS In the context of our discussion, there are two primary chemicals to speak of: 1. Sodium carbonate [Na2CO3 (aka “soda ash”)]; and 58 THE NEUTRALIZERS (CONTD.) 2. sodium hydroxide [NaOH (aka “lye”, “caustic soda”)]. Both chemicals are used to increase and/or buffer low pH. Low pH is typically a problem because the water is corrosive to metallic piping materials resulting in contamination and water leaks. 59 THE NEUTRALIZERS (CONTD.) (AND PHOSPHATES) 60 THE NEUTRALIZERS (CONTD.) (AND PHOSPHATES) 61 THE NEUTRALIZERS (CONTD.) (AND PHOSPHATES) 62 THE NEUTRTALIZERS (CONTD.) (AND PHOSPHATES) 63 THE NEUTRALIZERS (CONTD.) (AND PHOSPHATES) 64 THE NEUTRALIZERS (CONTD.) (AND PHOSPHATES) 65 THE END That concludes this evening's presentation. Any questions? If you have an opinion about tonight's presentation, then please let DSPS supervisory staff know: Thom Braun Thomas.Braun@Wisconsin.gov 608-266-8981 Paula Veltum Paula.Veltum2@Wisconsin.gov 66 WHAT DOES THE CODE SAY? NR 812.37 Water treatment. (1) Scope. This section applies to treatment of water for potable use in a private or noncommunity water system except for the disinfection treatment, batch chlorination, and acidification prescribed in ss. NR 812.22 and 812.41. (2) General standards. (a) Water treatment devices installed in a water system shall have a plumbing product approval in accordance with chs. SPS 382 and 384. NR 812.37(2)(b) (b) A water supply to be treated for health related contaminants or requiring approval under sub. (3) shall produce bacteriologically safe water prior to treatment, unless the department determines that a bacteriologically safe water supply is not available. The water system owner or operator shall assure that the water supply remains bacteriologically safe after installation of a water treatment device. Health related contaminants are those contaminants for which: primary drinking water standards are established in ch. NR 809, public health groundwater quality standards are established in ch. NR 140, and health advisories are established on a contaminant specific basis by the department. Note: The department recommends that a bacteriologically safe water supply be used when any water treatment device is installed for removal of any contaminant for any purpose. (c) Water treatment devices shall be installed in accordance with the manufacturer's printed instructions, chs. SPS 382 and 384, and, if specified, department written installation approval conditions. If there is a conflict between the manufacturer's instructions and the code requirements or approval conditions, the code requirements and approval conditions shall take precedence . 67 WHAT DOES THE CODE SAY (CONTD.) (d) Water treatment devices shall be installed by a: 1. DSPS licensed plumber if installed following the pressure tank; 2. Licensed pump installer if installed before the pressure tank; or 3. Property owner in a one family building owned and occupied by the owner as their home or farm building, except where a DSPS licensed plumber is required by local ordinance. (c) Water treatment devices shall be installed in accordance with the manufacturer's printed instructions, chs. SPS 382 and 384, and, if specified, department written installation approval conditions. If there is a conflict between the manufacturer's instructions and the code requirements or approval conditions, the code requirements and approval conditions shall take precedence. (d) Water treatment devices shall be installed by a: 1. DSPS licensed plumber if installed following the pressure tank; 2. Licensed pump installer if installed before the pressure tank; or 3. Property owner in a one family building owned and occupied by the owner as their home or farm building, except where a DSPS licensed plumber is required by local ordinance. 68 WHAT DOES THE CODE SAY? (CONTD.) SPS 384.20(5)(r) Water treatment devices. 1. Water softeners shall conform to NSF-44. Note: See s. SPS 382.40 for limitations as to the types of water treatment devices which may discharge to a POWTS. 2. a. Except as provided in subd. 2. b., water treatment devices shall function and perform in accordance with the assertions submitted to the department under s. SPS 384.10, relating to rendering inactive or removing contaminants. b. A water treatment device which injects a water treatment compound into a water supply system shall maintain the compound concentration in the system over the working flow rate range and pressure range of the device. 3. Except as specified in subd. 4., water treatment compounds introduced into the water supply system by a water treatment device shall be listed as an acceptable drinking water additive by a listing agency approved by the department. Listing agencies approved by the department shall include: a. United States environmental protection agency; b. United States food and drug administration; and c. National sanitation foundation. 69 WHAT DOES THE CODE SAY? (CONTD.) 4. A water supply system shall be protected from backflow when unlisted water treatment compounds, which may affect the potability of the water, are introduced into the system. The department shall determine the method of backflow protection. Water supply outlets for human use or consumption may not be installed downstream of the introduction of an unlisted water treatment compound. 5. Water treatment devices designed for contaminated water supplies shall be labeled to identify the following information: a. The name of the manufacturer of the device; b. The device's trade name; and c. The device's model number. 70 WHAT DOES THE CODE SAY? (CONTD.) EmR1423 Rule Text Department of Safety and Professional Services (SPS) Administrative Code Chapter Group Affected: Chs. SPS 380-387; Plumbing Administrative Code Chapter Affected: Ch. SPS 384 (Revised) Related to: Water-treatment devices Finding of Emergency: The Department of Safety and Professional Services finds that an emergency exists and that this rule is necessary for the immediate preservation of the public peace, health, safety, or welfare. A statement of facts constituting the emergency is as follows. Under current rules, water treatment devices – including water softeners – may need two separate approvals before being used in Wisconsin. The first approval is typically from a third party, such as NSF International, and is based on an industry standard. The second approval is under SPS chapter 384, which addresses situations where a plumbing product must receive approval from the Department. Due to prolonged extreme weather conditions this past winter, spring, and summer, more private well owners than usual have chosen to upgrade their water supply systems this year. The Department has reason to believe that its secondary review is delaying some of these well owners from accessing plumbing products which would improve the safety of their drinking water. These products have been approved under industry standards and are available to consumers in other states but have not yet received approval from the Department. Promulgating revisions through the emergency rule process is needed to avoid further delays in using these products. Date Rule Filed with LRB: September 25, 2014 Date Rule Published in State Newspaper: September 27, 2014 Effective Start Date: September 27, 2014 Expiration Date: February 23, 2015 Related documents: EmR1423 Fiscal Estimate 71 CROSS CONNECTION CONTROL 72 CROSS CONNECTION CONTROL (CONTD.) 73 CROSS CONNECTION CONTROL (CONTD.) 74 PLUMBING CONSULTANTS 75 WHAT KIND OF SALESMAN… 76 WHAT KIND OF PLUMBER… 77 WHAT KIND OF PLUMBER… 78