What we have learnt and what we haven*t

advertisement

Green Rating

of

Coal-based Power Sector

Priyavrat Bhati

Centre for Science and Environment

CSE’s Green Rating Project - what and why?

Started in 1997; Rated 6 sectors:

1.

2.

3.

4.

5.

6.

Pulp and Paper 1999, revisited 2004, 2013

Automobile, 2001

Chlor-alkali, 2002

Cement, 2005

Iron and steel, 2012

Thermal power, 2014

Centre for Science and Environment

Coal : central to energy mix

Centre for Science and Environment

3

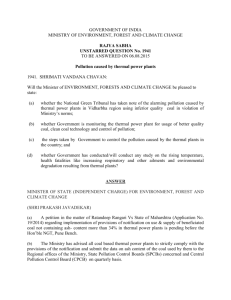

The dilemma : coal’s env. costs

Water: 70 per cent of the total freshwater withdrawal by

industrial sector

Coal: Over 70 per cent of the total coal consumed in India

GHG Emission: over 50 per cent of India’s total CO2 from

fuel combustion is by coal-based power plants

Pollution: Of the total industrial sector

• 60 per cent of PM emissions (includes mining)

• 45-50 per cent of SO2 emissions

• 30 per cent of NOx emissions

• More than 80 per cent of mercury emissions

Centre for Science and Environment

4

Resource needs – coal, water & land

Coal needs to more than double in 10 years (from ~600 mt

in 2012)

Increase in evacuation infrastructure

2-3 times increase in coal beneficiation capacity to use very

poor quality coal

Ash generation around 160mt; will increase to ~300mt by

2022

Water – withdrawal from 22 BCM to 24 BCM; consumption

from 2.9 BCM to 5.3 BCM over 10 years

Land requirement (based on EC granted till Feb, 2015):

2.85 lakh ha (0.75 lakh ha for plants + 2.1 lakh ha for coal

mines, including 46,719 ha forest land)

Centre for Science and Environment

5

Pollution Load (in

million tonnes)

Pollution load, if unchecked

14.0

12.0

10.0

8.0

6.0

4.0

2.0

0.0

13.1

7.8

5.5

2011-12

3.3

0.7

Sox

Nox

1.5

2021-22

PM

Massive increase in clusters

ALL THESE FACTORS DROVE DECISION TO RATE

Centre for Science and Environment

6

Sample selection

Sample size: 47 plants, 54 GW; Over half of the capacity

when study began in 2012

wide range representing sector profile

• Geographically diversified

• Varying unit sizes – 30% were 210 MW units; 25% were

500 MW units

• Varying age – quarter each exceeded mid-life and fulllife

Centre for Science and Environment

7

Sample selection

Diversified by ownership (state, centre and private)

Good participation by state-owned; Only 2 of 10 central ones

non-participating also rated based on survey of plant location

and stakeholders, secondary information

Centre for Science and Environment

8

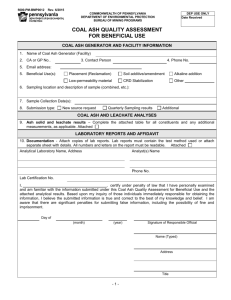

Parameters studied and weights

Over 60 parameters analysed

Weights: pollution – 42%; energy – 29%; water/ land

use – 19%; others – 10%

Centre for Science and Environment

9

Poor energy efficiency

Efficiency (%)

38

36

34

32.8

33.3

India (study

average)

Australia

35.7

35.8

China

United States

32

30

Indian fleet one of the most inefficient – 3 percentage points

below China’s

Indian plants emit 15% more CO2 than Chinese plants

14 plants < 32% EE, almost all state-owned; JSEB-Patratu

21%

Only 12 plants’ efficiency in excess of 36%, around Chinese

avg.

Centre for Science and Environment

10

Reasons for poor efficiency

Supercritical capacity

• India 15% currently; China was around 30%; US was 27%

Capacity over 300MW and under 10 years old:

• India 18%; China 58%.

Efficiency 10% lower than design considered poor O&M

• more than half the plants in the study

• 6 plants were 15% lower than design

• Age is a factor, but huge variations in study; Newer plants

such MPPGCL Birsinghpur – 20%+

• State-owned old plants were the worst performers

• Efficiency and deviation from design vs. PLF (Adani

Mundra)

Centre for Science and Environment

11

Air Pollution : stack emissions

Over half of the plants were clearly violating PM norms, of

which 85 per cent were state plants; another 10% were

likely non-compliant

Data reported to regulators was frequently unreliable

Ambient Air Quality – only 7 monitor continuously

Centre for Science and Environment

12

Water Guzzlers

12

9.8

10

m 3 / MWh

8

6

4

4

2

2.5

2

2

0

USA

China

Indian Average

Study best

Study worst (JSEB

(JSWEL, GIPCL)

Patratu)

Inefficient water users (both in cooling and ash handling);

Annual water draw (22 BCM) is over half of India’s domestic

water needs; significant OTC capacity

Two thirds of the plants located in water stress areas

Low tariff: as low as 20 paisa/m3; Rajasthan 70 paisa/m3

Centre for Science and Environment

13

90

80

70

60

50

40

30

20

10

0

100

80

50

53

57

60

40

20

Percentage Utilisation

Ash Generation in mt

Solid waste - Ash

0

2010-11

Ash Generation in mt

2011-12

Ash Utilization in mt

2012-13

Percentage Utilisation

Second largest solid waste stream of the country.

Average utilisation during 2010-13 was only 53 per cent for

plants in study.

Three-fourths not meeting 2013 ash-use target

Unused ash dumped in poorly maintained ponds (around 80%

non compliance – lining, leakage, piezometers)

Centre for Science and Environment

14

CSE Recommendations : Technology

Old inefficient , polluting plants should be retired or

modernized at an accelerated pace; Environmental

clearance process should incentivize this

• Estimated12,000 MW capacity below 30% efficiency

• Around 20,000 MW is older than 30 years

New capacities should be only SC/USC

Efficient stock should be optimally utilised;

• Inclusion of environmental costs/ compliance in Merit Order

Dispatch – cheaper but polluting plants shouldn’t be called

first.

Centre for Science and Environment

15

CSE Recommendations : pollution &

resource efficiency

Set strict standards for PM, SOx, NOx and Hg

Water use to be cut; incorporate norms for water use in

clearances.

Increase water tariff to promote recycling and reuse

Promotion, standards for utilisation of policies on ash use

in infrastructure, bricks, cement industry etc.

Loopholes that allow ash dumping, yet consider it utilization

(for eg. in low lying areas) need to be closed;

Centre for Science and Environment

16

CSE Recommendations : Improved

assessment and regulatory tool

Capacity concentration in few areas

• Regional carrying capacity assessment and tighter norms

for critically polluted areas

55 GW of coastal capacity expected to come up

• Potential impacts on marine biodiversity need to be

investigated

Pollution monitoring and control by regulators are weak;

need capacity and tools

• Protocol and infrastructure for CEMS

• Economic tools (incentives)

Centre for Science and Environment

17

JSW Energy

Vs

Top Performers

Topper- No comparison with average performers

Topper- Higher benchmarks, higher expectations

Proven ability- Move to GLOBAL BEST

Sanjeev K Kanchan

Centre for Science and Environment

Score Comparisons

Energy

Total

Weight

JSW

Torangallu

(% score)

JSW

Ratnagiri

(% score)

Best in Category JPL

Raigarh

Best in parameter

Plant Gross Heat Rate

and Trends

7.0

36.8

26.2

34.0

37.6

Tata, Mundra

Design Gross Heat Rate,

and Tech

5.0

47.8

49.9

43.8

64.0

Tata, Mundra

Avg. Auxiliary

2.0

45.1

21.0

33.5

80.0

Tata, Trombay

Deviation from Design

Heat rate

3.0

57.1

0.0

80.0

80.0

JPL, Raigarh

Availability

3.0

0.0

0.0

56.56

75.00

Dahanu

24.0

9.6

6.2

11.7

Total Weight

Note- Other parameters: Sec. fuel, avg size, GHG

•Among top performers: < 92% PAF

•Ratnagiri- Deviation in GHR >12% , Aux ~9%

Centre for Science and Environment

19

Score Comparisons

Water

Total

Weight

Torangallu

(% score)

Ratnagiri

(% score)

Best in Category

Ratnagiri

Water Sources

4

50

75

75

75.0

Sp. Water consumption

5

62

50

50

64.0

Water Stress

3

10

100

100

100

Total Weight

16 or 12

8.39 / 16

8.5 / 12

8.5

Best in parameter

GIPCL

Note- Other parameters: water use in ash handling, COC

• Toranagallu- uses 13% COREX (Bellary – water stressed)

Can consumption be further reduced?

•Ratnagiri- Sea water based

Centre for Science and Environment

20

Score Comparisons

Air Pollution

Total

Weight

Torangallu

(% score)

Ratnagiri

(% score)

Best in Category

Ratnagiri

Best in parameter

(% score)

PM

4

53

56

56

69

Budge Budge

SO2

2

0.0

0.0

0.0

61

Trombay

Pollution Control Tech

2

41

50

50

100

NTPC Singrauli

Coal Storage &

Handling

6

25

88

88

88

JSW Ratnagiri

Total Weight

19

5.3

8.5

8.5

Note- Other parameters: AAQ index

•Estimated SO2 (FGD plant- given value); compared against

Chinese norm.

Centre for Science and Environment 21

Score Comparisons

Water Pollution

Total Weight

Torangallu

(% score)

Ratnagiri

(% score)

Best in Category

NLC Barsingsar

Score for ETP, STP

1

50

100

100

Water Pollution Index

4

100

20

100

Total Weight

7

5/7

3/7

6/7

Best in parameter

(% score)

100

100

Note- Other parameters: coal run-off treatment, CSE lab test

• Ratnagiri- Water pollution related complaints

Centre for Science and Environment 22

Score Comparisons

Solid Waste

Total Weight

Toranagallu

(% score)

Ratnagiri

(% score)

Best in Category

GIPCL Surat

Best in parameter

(% score)

Type of Ash handling

2

100

100

100

100 Many

Ash Utilization

1

0

0

100

>100 Mettur, Torrent

Gainful Ash Utilization

5

8

69

89

>100 Mettur / RRVUNL Kota

Ash Pond Maint.

4

80

40

60

Total Weight

15

7.59

8.27

11.03

80

Torangullu /

NLC - Barsingsar

Note- Other parameters: stakeholders observation ash pollution

• Imported coal – at-least 80% ash use criteria

(domestic coal at-least- >58%)

• Gainful- Imported at-least- 33% (Domestic at-least- 48%)

•Ash pond maintenance- Ratnagiri- bund, pipeline

Centre for Science and Environment

23

JSW- Toranagallu

Energy

• SBU-I (2x130 MW)- in 2000, SBU-II (2x300 MW)- 2009

• Avg. GHR - 2,261kCal/kWh (38 %), design GHR 2,162 kCal/kWh,

(BAT- <1,800kCal/kWh, Nordjylland-Denmark)

• Deviation - 4.6% (Hissar, Mundra etc.- <1%)

• Auxiliary -7.6 % (Maithon/Hissar etc.- ~6%)

• PAF- 90.9%; PLF- 94% (PAF- 99%, PLF- >100%)

• Sp. Coal consumption at 0.46 kg/KWh (13% energy from COREX)

Water

• Water stress area

• ZLD, Sp. Water- ~2m3/MWh {Best- 1.6 ; Dry- 0.11(m3/MWh)}

• COC of 5-7 (Jojobera- 8, achievable 10)

Centre for Science and Environment

24

Issues to Deal

• Community complaints- Red dust emission (steel), vehicular movement

through village (steel, power, mines)

• CSR (< 2% of profit)- demand for more access to heath facility

•Study of impact (of complex) on Daroji bear sanctuary

Centre for Science and Environment

25

JSW- Toranagallu

Solid Waste

• Dry ash handling; Bottom as- Dry/Semi-wet

• Ash use-79%; (Budge Budge, Torrent, Mettur, Kota etc.- >100%)

• Gainful use- 51 % (Mettur, Kota- >100%)

Air Pollution

• No visible emission

• PM- 60-62 mg/Nm3 (norm 100 mg/Nm3)

• SO2- 665-934 mg/Nm3

• NOx- 366-429 mg/Nm3

• No mercury emission monitoring

(Implication of new pollution norms) ? CEMS ?

Centre for Science and Environment

26

JSW- Ratnagiri

Energy

• 300 MW x 4 - in 2010/11

• Avg. GHR - 2,418kCal/kWh (35.5 %), design GHR- 2,151

kCal/kWh (39.9%), (BAT- <1,800kCal/kWh, NordjyllandDenmark)

• Deviation - 12% (Hissar, Mundra etc.- <1%)

• Auxiliary ~9 % (Maithon/Hissar etc.- ~6%)

• PAF- 89%; PLF- 81% (PAF- 99%, PLF- >100%)

• Sp. Coal consumption at 0.49 kg/KWh (Imported)

• Covered coal storage- only one in India

Water

• Sea water with CT- Sea water requirement- 9.7m3/MWh

• Issues to deal- Ground water contamination, CT saline mist

Centre for Science and Environment

27

Issues to Deal

• Community complaints- Saline mist & leakage from CT, coal dust emission, hot

CW discharge -Impact on orchards, fishes

•How to convey your work/improvement?

Centre for Science and Environment

28

JSW- Ratnagiri

Solid Waste

•

•

•

•

Dry ash handling

Ash use-77.6%; (Budge Budge, Torrent, Mettur, Kota etc.- >100%)

Gainful use- 83.8 % (Mettur, Kota- >100%)

Issues to deal- ash pond maintenance, ash transport pipeline,

complaints on ash emissions

Air Pollution

• No visible emission

• PM- 9-24 mg/Nm3 (norm 50 mg/Nm3)

• SO2- 373-405 mg/Nm3

• NOx- not monitored

• No mercury emission monitoring

(Implication of new pollution norms) ? CEMS ?

Centre for Science and Environment

29

Implication of new pollution norms

Pollutan

Unit size

ts

Installed before

Dec 31st, 2003

(shall meet within 2

yrs)

Installed after Dec

31st, 2006

(shall meet within 2

yrs)

Installed Jan 1, 2017

onwards

(Includes accorded EC,

under construction)

PM

All

100mg/Nm3

50 mg/Nm3

30 mg/Nm3

<500MW

600 mg/Nm3

--

--

>=500MW

200 mg/Nm3

200 mg/Nm3

100 mg/Nm3

All

>=500MW

600 mg/Nm3

0.03 mg/Nm3

300 mg/Nm3

0.03 mg/Nm3

100 mg/Nm3

0.03 mg/Nm3

SO2

NOx

Hg

Centre for Science and Environment

30

Implication of CEMS ?

CEMS- Selection, installation, certification, calibration/re-calibration, daily

check, data recording, record keeping, compliance check, publish

• Device health check- daily 10.00 a.m.; zero drift

• calibration verification- 3 months

• Zero and span drift – every week

• >85% data capture

• Data verification/ calibration- 6 monthly by empanelled Lab

• Compliance

Any exceedance- violation

Data spikes (< 1 min)- not for avg

Continuous exceedance upto 10% of norms,

o >30 mins- preventive action by industry

o >60 mins- to inform SPCB/PCCs about preventive action

o Second time- closure

Frequent exceedance- > 5% of data/day- action by SPCBs/PCCs

Industry fails to control emissions- closure as per SOP

Start-up/shut down ( batch process for 30 mins)- not for avg

Centre for Science and Environment

31