Version 2012 Updated on 022412 Copyright © All rights reserved

Dong-Sun Lee, Prof., Ph.D. Chemistry, Seoul Women’s University

Chapter 2

Chemicals and Apparatus

Classification of commercial chemicals

1) Technical or commercial grade

Not use in analytical work, but cleaning solution.

2) USP grade : United States Pharmacopoeia

The specifications are designed to limit impurities that are physiological

hazards

3) Reagent grade

Minimum specifications of the Reagent Chemical Committee of

the American Chemical Society

4) Primary standard grade / Reference standards

5) Special purpose reagents

Spectroscopic, chromatographic etc.

Primary standard

★★★

- Definition by the IUPAC(1978) :

a substance of high purity which, by stoichiometric reaction, is used to establish

the reacting strength of a titrant, or which itself can be used to prepare a titrant

solution of accurately known concentration.

- Requirements for a primary standard :

1) High purity (99.9% or better) 4) Ready availability

2) Stability in air

5) Reasonable solubility

3) Absence of hydrate water

6) Reasonable large formula weight

- Types of primary standards :

1) Reference material(RM) ; used mainly for the calibration

2) High purity substance = chemical standard

3) Certified reference material (CRM) ; by NIST, etc.

- Working or secondary standards

Inorganic

Reference materials

Organic

Nonferrous

Ferrous

Primary

standard

materials

Quality

of life

Certified reference

materials

Physical &

technical

properties

Biologicalclinical labs

Industry

RMs, CRMs, primary standard materials and their main application fields

Physical standards (kg)

International Prototype Kilogram: IPK:

Kilogram Standard: Le Gran K: 1 kg

Chemical

standards(12C,

Analytical standards

Reference

materials

N)

Primary

standards

Chemical standards

Secondary

standards

CRM

(pure substance)

Types of analytical standards, and relationships between them and traceability of

physical, chemical and analytical standards.

Table Selected pure chemical standards used in titrimetric analysis

(at least 99.9% purity) ★★★

Type of titration

Standard

Acid-base

Potassium hydrogen phthalate

Sulfanilic acid, Benzoic acid

Sodium carbonate, Borax

Complexometric

Calcium carbonate,

Magnesium,

Zinc,

EDTA

Precipitation

Silver, Silver nitrate, Sodium chloride

Redox

Potassium iodate, Potassium dichromate,

Sodium oxalate, Arsenic oxide

Rules for Handling Reagents and Solutions

1. Select the best grade of chemical / pick the smallest bottle

2. Replace the top of every container immediately after removal of the reagent

3. Hold the stoppers of reagent bottles between your fingers;

never set a stopper on a desk

4. Never return any excess reagent to a bottle.

5. Never insert spatulas, spoons, or knives into a bottle that contains a solid

chemical. Pour out the desired quantity.

6. Keep the reagent shelf and the lab balance clean and neat.

7. Observe local regulations concerning the disposal of surplus reagents and

solutions

Safe handling of chemicals and waste

- Material Safety Data Sheet (MSDS) : http://family.swu.ac.kr/~cat/links-1.html/

- Primary safety rule is not to do something that you consider to be dangerous.

- Goggles or safety glasses with side shields are necessary at all times in every

laboratory to protect you from flying liquids and glass.

- Food is never eaten in the lab.

- Organic solvents and conc. acids that produce harmful fumes should be handled only

in a fume hood. The purpose of a fume hood is to reduce levels of pollutants.

- Solid or liquid spills should be cleaned up immediately to prevent accidental contact

by the next person who comes along.

- Chemical spills on your skin usually are treated first with water. Rubber gloves are

recommended to protect your hands.

- Proper chemical storage minimizes fire and explosion hazards and human contact

with vapors.

- Preservation of a habitable environment on our planet demands that we minimize

waste production and responsibly dispose of the waste.

Goggle

All vessels should have labels that indicate what they contain.

Safety equipment and hazardous operations are prominently labeled.

(D.C. Harris, Quantitative Chemical Analysis, 4th ed., Freeman, 1995, p. 20)

Bumping is sudden, often violent boiling

that tends to spatter solution out of its

container.

Wet ashing is the oxidation of the organic

constituents of a sample with oxidizing

reagents such as nitric acid, sulfuric acid,

hydrogen peroxide, aqueous bromine, or a

combination of these reagents in a fumehood.

Arrangement for the

evaporation of a liquid

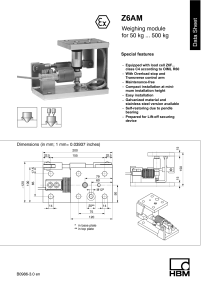

Analytical Balance

★★★

Readability:

An analytical balance measures masses

to within 0.0001 g. Use these balances

when you need this high degree of

precision.

Capacity: 100 ~ 220 g

Types of balances and principles of operation

Types of balance

Principles of operation

Mechanical balance

Equal-arm, double pan

Symmetric lever,

Triple beam dial

Pendulum

Dial

Unequal-arm, single pan

Substitution

Electronic balance

Top loading

Load-transfer mechanism,

Single pan analytical

electromagnetic force

Microbalance

compensation

Chemical Balance

Definition of terms

Mass : An invariant measure of the quantity of matter in an object.

Mass is constant.

Weight : The force of attraction exerted between an object and the earth.

Weight(w) equals mass(m) times the gravitational attraction (g=980.665 cm/s2).

w=gm

Balance : an instrument for weighing.

The word derived from the Latin bilanx =having two pans.

“scales” = old English, meaning dishes.

Capacity : the largest load on one pan for which the balance can be brought to

equilibrium

Sensitivity : the smallest increment of mass that can be measured

Readability ; Accurate, repeatable deflection at the smallest unit of measurement

Precision (standard deviation); Degree of agreement of repeated measurement of

the same object.

Accuracy ; The agreement between the result of measurement and the true value

of the quantity measured.

Resolution : number of scale division;

n = Max / d

Tare ; the mass of the empty vessel

Weights, Reference masses ;

The international prototype kilogram is a mass of platinum-iridium alloy made in

1887.

The International Bureau of Weights and Measures (Paris)

An ordinary set of analytical weights

100, 50, 30, 20, 10, 5, 3, 2, 1 g

500-100, 50-10, 5, 3, 2, 1 mg

Role of analytical balance : accuracy of analytical results depends on weight.

Table Classification of balances

Type

Reading to

Typical capacity(Max)

Ultramicroanalytical

0.1g

3g

Microanalytical

1g

3g

Semimicroanalytical

0.01mg

Macroanalytical

0.1 mg

100g~200g

Precision

1mg

160g~60kg

Rough weighing

0.01 g

350 g

0.1g

3500g

0.1g

6kg

30g

Weighing accurately = reading unit 0.1 mg

Vernier : A short auxillary scale placed along the main instrument scale to permit

accurate fractional reading of the least main division of the main scale, invented by

Pierre Vernier about 1630.

The vernier scale is graduated in one or both directions from the fiducial(index) mark

in numbered divisions, which are fractionally shorter than those on the main scale.

The position of the fiducial mark( the zero mark of the vernier scale) between

divisions on the main scale is indicated by the number of graduation on the vernier

scale which lines up exactly with a graduation on the main scale.

dm = l/n

dv = (l – dm) / n

Vernier caliper (G.S. Coyne, The Laboratory Handbook, Prentice Hall, 1992, p.68-69)

Coincidence

d

3

x

Index line

4

d’

Main scale

each division on the main scale is

1 mm

Vernier scale

each division on the Vernier scale is

0·9mm

0

10

7

x = d – d’ = 7 (1) mm – 7 (0.9) mm = 7 (1-0.9) mm = 0.7 mm

Reading : 3.17 cm = 31.7 mm

0.25 mm

Reading: 16.25 mm = 1.625 cm

locking screw

inside diameter jaws

main scale

depth probe

outside diameter jaws

slide piece with index scale

(Vernier scale)

Vernier scales of chemical balance

( reading weight =18.2505 g).

Vernier scales. Left, Direct (reading 3.6). Right,

retrograde (reading 12.7)

Source: McGraw-Hill Encyclopedia of Science

& Technology, Vol.19, p.198. 1987.

Vernier scales of dial balance

Certified analytical weights

Class M analytical weights are high precision standards used as reference standards for

analytical work.

Gram weights are normally made of brass and plated with gold, platinum or rhodium.

Class S weights are precise scientific working standards that are

chiefly used for calibration of other weights.

Class S-1 weights are routine analytical weights for general use.

Class P weights (formerly denoted by S-2 ) are rough weights.

Class J weights (up to 50mg) are used on microbalances.

Table

Tolerances of analytical weights provided by the NIST

Tolerance (mg)

Weight mass

Class M

Class S

Class S-1

10

Class P

1 kg

5.0

2.5

20

500g

2.5

1.2

5.0

100g

0.50

0.25

1.0

2.0

50g

0.25

0.12

0.60

1.2

10g

0.050

0.074

0.25

0.50

5g

0.034

0.054

0.18

0.36

1g

0.034

0.054

0.10

0.20

500mg

0.0054

0.025

0.080

0.16

100mg

0.0054

0.025

0.050

0.10

50mg

0.0054

0.014

0.042

0.085

20mg

0.0054

0.014

0.035

0.070

5mg

0.0054

0.014

0.028

0.055

2mg

0.0054

0.014

0.025

0.050

1mg

0.0054

0.014

0.025

0.050

10

All class J weights have a tolerance of 0.003mg

Cf. Standard specification for laboratory weights and precision standards

(1990 Annual Book of ASTM Standards)

Types

I & II

Grades

S, O, P, and Q

Classes

1, 2, 3, 4, 5, 6

Classification

표준 분동의 허용 오차: American Society of Testing & Measurement(ASTM E617)

(왼쪽) 백금(90%)-이리듐(10%) 합금으로 만들어진 국제 킬로그램 원기

(International Prototype Kilogram: IPK: Kilogram Standard: Le Gran K: 1 kg)

세브르(Sevres)에 위치한 국제도량형국(BIPM: Bureau International des Poids et

Mesures: International Bureau of Weights and Measures)에 보관

(오른쪽) 표준 분동

저울의 원리

1) Lever(지레) and pendulum(진자)

2) Newton’s 2nd law of motion (운동의 제 2 법칙)

3) Force moment(힘의 모멘트)

4) Hook’s law of elasticity (탄성력의 후크의 법칙)

4) Piezoeletric effect (압전기 효과)

5) Electromagnetic force compensator (전자기력 평형식)

W = F = 2rnBI

6) Load transfer mechanism (하중 전달 메커니즘):

압력 P를 힘 F로 변환

l1

l2

w1

w2

w1 = gm1

w2 = gm2

w1 l1 = w2 l2

if

l1 = l2

w1 = w2

m1 = m2

Principle of mechanical balance

Single-pan mechanical

analytical balance.

Sartorius 2842

balance

Single-pan mechanical balance. To weigh an object on the pan, we use the knobs on the

balance to detach removable weights until the balance beam is restored as near as

possible to its original position. Remaining small deflection is read on the optical scale.

P

Principles of electronic balance

1)

Alignment

marks

The load transfer mechanism

Pan surface area : A

Weighing load on the pan

backing

Transfer mechanism

Strain

sensitive

pattern

F = P dA

Pressure force (P)

Lever linkages ; elastic flexure pivots

Active

grid

length

Load cell

Translate

Solder

tabs

Electronic signal

Terminal (resistance legs)

Signal processing

and display

Measurable single force (F)

Strain gage load cell

2) The electromechanical transducer

Three part structure of

an electronic balance.

(= load cell)

Electromagnetic force compensator

Strain gage

(tension)

Maintain equilibrium

Weighing load

R1

Compensation force

W = P = F = l BI = n2rBI

B = magnetic flux density

I = current

3) The electronic signal processing part

R3

V

D

Where l = total length of coil wire

Strain gage

(tension)

A

B

R2

E = IR

Strain gage

(compression)

Rx

C

Strain gage

(compression)

An electronic balance (R.M. Schoonover, Anal. Chem. 1982, 54, 976A) and

top loading balance (K.M. Lang, American Lab., 1983, 15(3), 72)

Electronic balance. Displacement of the balance pan generate a correction current.

The electromagnet then restores the pan to its initial position. N and S are the north

and south poles of the permanent magnet.

Piezoelectric Effect

Crystals which acquire a charge when compressed, twisted or distorted are

said to be piezoelectric.

This provides a convenient transducer effect between electrical and mechanical

oscillations. Quartz demonstrates this property and is extremely stable. Quartz crystals

are used for watch crystals and for precise frequency reference crystals for radio

transmitters. Rochelle salt produces a comparatively large voltage upon compression and

was used in early crystal microphones. Barium titanate, lead zirconate, and lead titanate

are ceramic materials which exhibit piezoelectricity and are used in ultrasonic transducers

as well as microphones. If and electrical oscillation is applied to such ceramic wafers, they

will respond with mechanical vibrations which provide the ultrasonic sound source. The

standard piezoelectric material for medical imaging processes has been lead zirconate

titanate (PZT). Piezoelectric ceramic materials have found use in producing motions on the

order of nanometers in the control of scanning tunneling microscopes.

The word piezo is Greek for "push". The effect known as piezoelectricity was discovered

by brothers Pierre and Jacques Curie when they were 21 and 24 years old in 1880.

There is a magnetic analog where ferromagnetic material respond mechanically to

magnetic fields. This effect, called magnetostriction, is responsible for the familiar hum of

transformers and other AC devices containing iron cores.

http://hyperphysics.phy-astr.gsu.edu/hbase/solids/piezo.html

The diagram below provides an explanation of why the

piezoelectric effect exists. The diagram at the left depicts

six point charges (ions if you will), red being positive

charges and green negative. In a relaxed state with no

forces acting on them, they are arranged at the vertices of

an hexagon. If the electrical potential (V) at a point along

the x axes and distant from these charges one can see the

three positive charges will appear to act at the center of the

hexagon as will the three negative charges. The positive

and negative array of charges will cancel each other out

and the potential V, at a the distance along the x axes will

be zero.

If a compressive force is applied to the hexagon along the

Y axes direction, the array is distorted in such a way as to

bring two of the positive charges closer together at one end

and the negative charges at the other. This forms a dipole

where one end of the array is positive and the other

negative. A potential, V calculated at a distance along the

X axes will now be non-zero.

One can easily imagine a crystal structure made up of these

hexagonal arrangements of ions, all lined up in an orderly

matrix throughout the bulk of the crystal volume. When the

crystal is compressed, each hexagon would contribute to a

net polarization across the crystal.

http://www.tedlind.net/Piezoelectricity.htm

Electronic chemical

balance(left),

weights(center), top loading

balance(right) and

Rear weight is in the notch reading...… 70 g

Middle weight is in the notch................ 300 g

Front beam weight reads...................... 3.34 g

The object weighs

......................... 373.34 g

http://chemistry.rutgers.edu/genchem/balance3b.html

triple beam dial balance.

Using an Analytical Balance

Turn the balance on by pressing the control bar. The

display lights up for several seconds, then resets to

0.0000.

Place creased, small weighing paper on the balance pan.

Close the sliding glass doors. Wait for the green dot on

the left to go out. This is the stability indicator light,

indicating that the weight is stable.

http://www.dartmouth.edu/~chemlab/techniques/a_balance.html

Press the control bar to cancel out the weight of the

container or paper. The display will again read 0.0000.

Carefully add the substance to be weighed up to the

desired mass. Do not attempt to reach a particular mass

exactly.

Before recording the mass, close the glass doors and

wait until the stability detector lamp goes out. Record

mass of solid.

Don't pick up tare containers with bare hands since

your fingerprints add mass. Use Kimwipes or tongs to

prevent this.

Don't lean on the bench while weighing.

Do record the mass of your container, if you will need

it later.

Do check the level indicator bubble before weighing.

The two rear balance feet serve as leveling screws.

Clean-up

Use the brush provided to clean spills in the

weighing chamber. Discard any disposable tare

containers, weighing paper, or Kimwipes in the

nearest wastebasket.

Using a Top-loading Balance

Check if the balance is turned on. If

not, press the on/off button and wait

until the display reads 0.0 g.

Place a container or large, creased

weighing paper on the balance pan.

Push tare button to zero the balance.

Carefully add substance to the

container or paper. Record mass.

http://www.dartmouth.edu/~chemlab/techniques/top_balance.html

Clean-up

Use the brush provided

to clean any spills.

Discard any disposable

tare containers,

weighing paper, or

Kimwipes in the

nearest wastebasket.

Quantitative transfer of solid

sample.

Note the use of tongs to hold the

weighing bottle and a paper

strip to hold the cap to avoid

contact between glass and skin.

A, 종이로 말아서 칭량병(weighing bottle)

옮기기와

B, 칭량접시(weighing dish).

Errors in weighing mass :

1) Changes in moisture or CO2 content

2) Volatility of sample

3) Electrification

4) Temperature

5) Air buoyancy error :

This error is due to the weight of air displaced by the object

on the pan and is generally quite small.

There will be a buoyancy correction whenever the density of

the object is not equal to the density of the standard weights.

Buoyancy equation :

m = [m’{1 (da / dw)} / {1 (da / d )}]

where m = true mass, m’ = mass read from a balance,

da = density of air ( 0.0012 g/ml near 1atm and 25oC ),

dw = density of balance weights (typically 8.0 g/ml )

d = density of object being weighed

Weighing methods :

Weighing by directly

Weighing by difference hygroscopic reagents

Equipment and Manipulations Associated with Weighing

Weighing bottles

Desiccators and Desiccants

Manipulating weighing bottles

Weighing by difference

Weighing hygroscopic solids

Weighing liquids

Drying

Constant mass: In gravimetric analysis the product is heated and cooled to

room temperature in a desiccator until successive weighings are “constant”. It

is usually taken as about 0.3mg.

Drying oven: to dry (110~200oC) samples prior to weighing

Muffle furnace : to ignite(pyrolysis) samples to high temperature (500~1200oC)

Remember to keep the watch glass as a dust cover on and the weighing bottle

top off while drying in the oven or desiccator.

(a) Ordinary desiccator. (b) Vacuum desiccator that can be evacuated through

the sidearm at the top and then sealed by rotating the joint cintaining the

sidearm. Drying is more efficient at low pressure.

Allow the weighing bottle (top off) to equilibrate overnight in the desiccator.

The following period, place the top back on the weighing bottle and keep it

this way while storing in the desiccator.

Efficiencies of drying agents

Agents

Formula

Water left in atmosphere

(g H2O/L)

Alumina

Al2O3

2.9

Anhydrone

Mg(ClO4)2 1-1.5H2O

1.5

Ascarite

NaOH on asbestos

Barium oxide

BaO

Barium perchlorate

Ba(ClO4)2

Calcium chloride (dried at 127oC)

CaCl2

Calcium oxide

CaO

Calcium sulfate( Drierite )

CaSO4

67

Lithium perchlorate, anhydrous

LiClO4

13

Magnesium oxide

MgO

Magnesium perchlorate, anhydrous

Mg(ClO4)2

0.2

Phosphorous pentoxide

P4O10

3.6

Potassium hydroxide

KOH

939

Sodium hydroxide

NaOH

513

Sulfuric acid (98 %)

H2SO4

3

93

2.8

599

67

656

753

Intermission Break

Thanks.

To be continued (Chapter 2).