Lockout-Tagout

advertisement

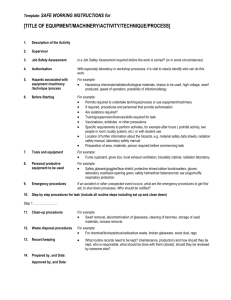

1 TABLE OF CONTENTS 1. Walking and Working Surfaces 2. Means of Egress (Exits, Exit Markings) 3. Occupational Health and Environmental Controls (Ventilation, Noise, Radiation) 4. Hazardous Materials (Compressed Gases, Flammable and Combustible Liquids, etc.) 5. Personal Protective Equipment (Eye and Face Protection, Respiratory Protection, etc.) 6. Fire Protection (Portable Fire Extinguishers, etc.) 7. Material Handling and Storage (Powered Industrial Trucks, Cranes) 8. Machinery and Machine Guarding (Mechanical Power Presses, Abrasive Wheels, etc.) 9. Hand and Portable Powered Tools 10. Welding, Cutting, and Brazing 11. Electrical 12. Toxic and Hazardous Substances NOTE: Although many shops may not have these particular hazards/issues/concerns many shops may have others not listed. This lesson does not contain information that addresses every shop hazard. It is the supervisor's responsibility to perform a Hazard Assessment to determine existing and predictable hazards. It is highly recommended the shop supervisor or designee contact EH&S for guidance at 480-965-1823 or ehs@asu.edu 2 Walking and Working Surfaces Housekeeping Shop floors shall be maintained in a sanitary, clean and, so far as possible, a dry condition. Where wet processes are used, drainage shall be provided, and false floors, platforms, mats, or other dry standing places should be provided where practicable. To facilitate cleaning make sure the floors, working place, and passageway are kept free from protruding nails, splinters, holes, or loose boards. 3 Walking and Working Surfaces Housekeeping If mechanical handling equipment is used, sufficient safe clearances shall be allowed for aisles, at loading docks, through doorways and wherever turns or passage must be made. Aisles and passageways shall be kept clear and in good repairs, with no obstruction across or in aisles that could create a hazard. 4 Walking and Working Surfaces Housekeeping If materials are stored on a mezzanine floor or if the mezzanine is used as office space the mezzanine floor must be load tested and a plate installed indicating the approved floor loading. The plates shall not be removed or defaced but, if lost, removed, or defaced, shall be replaced immediately! 5 Exits and Exits Markings An exit route must be permanent. Each exit route must be a permanent part of the workshop! Each exit and exit markings, at a minimum, shall be: Clearly identifiable Effectively illuminated Instructed to the occupants Free from obstructions For More Information and Guidance Contact The ASU Fire Marshal's Office at 480-965-1823 6 Occupational Health and Environmental Controls (Ventilation, Noise) An exhaust ventilation system for removing contaminated air from a space shall be comprised of two or more of the following elements: a. enclosure or hood, b. duct work, c. dust collecting equipment, d. exhauster, e. discharge stack. For More Information and Guidance Contact ASU EH&S at 480-965-1823 7 Occupational Health and Environmental Controls (Ventilation, Noise) ASU has an established (and maintains) an audiometric testing program for all employees whose exposures equal or exceed an 8-hour time-weighted average of 85 decibels. To determine your sound levels and requirements contact ASU EH&S at 480-965-1823. 8 Hazardous Materials (Compressed Gases, Flammable and Combustible Liquids) Each workshop supervisor shall determine that compressed gas cylinders under their control are in a safe condition to the extent that this can be determined by visual inspection. All cylinders, at a minimum, shall be: a. Identifiable as to the type of gas, b. Secured at the upper half of the cylinder, c. Capped when not in use. Incompatible gasses shall not be stored together. For More Information and Training Contact ASU EH&S at 480-965-1823 9 Hazardous Materials (Compressed Gases, Flammable and Combustible Liquids) "Flammable liquid" means any liquid having a flashpoint below 100 deg. F. (37.8 deg. C.), except any mixture having components with flashpoints of 100 deg. F. (37.8 deg. C.) or higher, the total of which make up 99 percent or more of the total volume of the mixture. ALL FLAMMABLE LIQUIDS SHALL BE PROPER STORED, CONTROLLED AND DISPOSED OF. For More Information and Guidance Contact The ASU Fire Marshal's Office At 480-965-1823 10 Hazardous Materials (Compressed Gases, Flammable and Combustible Liquids) "Combustible liquid" means any liquid having a flashpoint at or above 100 deg. F. (37.8 deg. C.) ALL COMBUSTIBLE LIQUIDS SHALL BE PROPER STORED, CONTROLLED AND DISPOSED OF. For More Information and Guidance Contact The ASU Fire Marshal's Office At 480-965-1823 11 Personal Protective Equipment (PPE) Protective equipment, including PPE for eyes, face, head, and extremities, protective clothing, respiratory devices, and protective shields and barriers, shall be provided, used, and maintained in a sanitary and reliable condition wherever it is necessary by reason of hazards of processes or environment, chemical hazards, radiological hazards, or mechanical irritants encountered in a manner capable of causing injury or impairment in the function of any part of the body through absorption, inhalation or physical contact. Contact ASU EH&S at 480-965-1823 for Assistance With Workshop Hazard Assessments and PPE Determinations. 12 Personal Protective Equipment (PPE) Where spraying operations take place be sure to have the operations evaluated for potential air contaminants, what respiratory PPE is required and other regulatory requirements! Respirator use requires a personal medical evaluation, training and respirator fit testing by a qualified person! Nuisance dust masks are not an effective means of respiratory protection where chemicals are used! = 13 Fire Protection Portable Fire Extinguishers The workshop shall provide portable fire extinguishers and shall mount, locate and identify them so that they are readily accessible to the users without subjecting the user to possible injury. The workshop shall not provide or make available in the workshop portable fire extinguishers using carbon tetrachloride or chlorobromomethane extinguishing agents. The workshop shall assure that portable fire extinguishers are maintained in a fully charged and operable condition and kept in their designated places at all times. For More Information, Guidance and Training Contact The ASU Fire Marshal's Office at 480-965-1823 14 Material Handling And Storage Storage of material shall not create a hazard. Bags, containers, bundles, etc., stored in tiers shall be stacked, blocked, interlocked and limited in height so that they are stable and secure against sliding or collapse. Storage areas shall be kept free from accumulation of materials that constitute hazards from tripping, fire, explosion, or pest harborage. X 15 Material Handling And Storage Forklifts , Cranes and Slings Formal Training Is Required Where Forklifts , Cranes and Slings Are Used! Contact ASU EH&S at 480-965-1823 for Training 16 Machinery and Machine Guarding Machines designed for a fixed location shall be securely anchored to prevent walking or moving. 17 Machinery and Machine Guarding “…but its old and it came this way!...” It Still Must Be Guarded! Internal Belts Internal Belts Examples Of Effective Shop Made Belt Guards 18 Machinery and Machine Guarding ANY machine part, function, or process which may cause injury must be safeguarded. WHERE the operation of a machine or accidental contact with it can injure the operator or others in the vicinity, the hazard must be either controlled or eliminated. So, one of the first things to do in determining machine guarding is to identify the different hazards associated with various types of machines and equipment 19 Machinery and Machine Guarding WHERE MECHANICAL HAZARDS OCCUR • POINT OF OPERATION is that point where the work is performed. • ALL PARTS OF THE MACHINE WHICH MOVE, SUCH AS: flywheels, pulleys, belts, couplings, chains, cranks, gears, etc. feed mechanisms and auxiliary parts of the machine. • IN-RUNNING NIP POINTS 20 Machinery and Machine Guarding • PREVENT CONTACT - prevent any part of the worker’s body (i.e., long hair, beard), clothing or jewelry from contacting hazardous moving parts. • SECURE - firmly secured to machine and not easily removed. • PROTECT FROM FALLING OBJECTS - ensure that no objects can fall into moving parts. 21 Machinery and Machine Guarding • CREATE NO NEW HAZARDS - must not have shear points, jagged edges or unfinished surfaces. • CREATE NO INTERFERENCE - must not prevent worker from performing the job quickly and comfortably. • ALLOW SAFE LUBRICATION - if possible, be able to lubricate the machine without removing the safeguards. 22 METHODS OF MACHINE SAFEGUARDING • GUARDS Fixed Interlocked Adjustable Self-adjusting • DEVICES Presence sensing Pullback Restraint Safety controls (tripwire cable, twohand control, etc.) Gates 23 Machinery and Machine Guarding HOLDING TOOLS - examples • USED to place and remove stock in the danger area. • NOT to be used instead of other machine safeguards, but as a supplement. 24 Machinery and Machine Guarding FIXED GUARDS - examples Auto Drill Press Belt And Pulleys 25 Machinery and Machine Guarding ADJUSTABLE GUARD Provides a barrier which may be adjusted to facilitate a variety of production operations. Guide Adjustment 26 Machinery and Machine Guarding SELF-ADJUSTING GUARD Provides a barrier which moves according to the size of the stock entering the danger area. 27 Machinery and Machine Guarding Woodworking routers are wonderful tools and are safe when properly guarded and used as shown above! 28 Machinery and Machine Guarding Wood Lathe Metal Lathe Be Sure To Securely Anchor The Lathes ! Lathes are also wonderful tools. Make sure anyone who uses these tools are properly trained in the safe operation and maintenance such as, but not limited to, stock guards! …and remember – lathe areas always need constant housekeeping! 29 Machinery and Machine Guarding LOCATION/DISTANCE • Locate the machine, or its dangerous moving parts, so that it is not accessible or does not present a hazard to a worker during normal operation. • Maintain a safe distance from the danger area. 30 Machinery and Machine Guarding ABRASIVE WHEEL MACHINERY TOOL RESTS must be kept with a maximum opening of 1/8-inch to prevent the work from being jammed between the wheel and the rest which may result in wheel breakage. 1/8” Machinery and Machine Guarding ABRASIVE WHEEL MACHINERY The distance between the wheel periphery and the adjustable tongue must never exceed 1/4” 1/4-inch. Ps…never use a wheel that has a damaged or uneven surface! 32 Hand And Power Tools All hand and power tools shall be provided and used in a safe manner in accordance with the manufacturer's specifications. All users shall be trained in the proper use and care of all power tools used. X …and always wear the appropriate PPE! 33 Hand And Power Tools Compressed Air Used For Cleaning Compressed air shall not be used for cleaning purposes except where reduced to less than 30 p.s.i. and then only with effective chip guarding X and personal protective equipment. 34 Welding, Cutting and Brazing Before cutting or welding is permitted, the area shall be inspected by the individual responsible for authorizing cutting and welding operations and shall designate precautions to be followed in granting authorization to proceed in the form of a written permit. Contact The ASU Fire Marshal’s Office For Information and Guidance at 480-965-1823 35 Electrical Electric equipment such as (but not limited to): Powered Hand Tools Flexible Cords Pedestal Equipment Bench Equipment …shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. WHERE REQUIRED ALL ELECTRICAL EQUIPMENT SHALL BE EFFECTIVELY GROUNDED! 36 Electrical Flexible cords and cables shall not be used: As a substitute for the fixed wiring of a structure; Where run through holes in walls, ceilings, or floors; Where run through doorways, windows, or similar openings; Where attached to building surfaces; Where concealed behind building walls, ceilings, or floors. X 37 Electrical Ground Fault Circuit Interrupters (GFCI) shall be provided at locations where the potential for wet operations are performed/exist. G F C I 38 Electrical The width of working space in front of the electric equipment shall be the width of the equipment or 762 mm (30 in.), whichever is greater. and Circuit breakers shall clearly indicate whether they are in the open (off) or closed (on) position. X 39 Toxic and Hazardous Substances Workshops shall maintain Material Safety Data Sheets (MSDS) for all chemicals in their possession. Storage and use of all chemicals shall meet the requirements of regulatory agencies and the manufacturer. All response to spills/exposures shall be in compliance with requirements provided in the MSDS and ASU’s policies and procedures. Contact ASU EH&S For Guidance and Information at 480-965-1823 40 Thank You For Your Participation! Click One More Time For Your Free Basic Machine Shop Safety Rules Poster! …and good luck with the quiz 41 Always wear personal protective equipment (PPE). Secure long hair, loose clothing and jewelry. Use only electrically safe cords and equipment. & Know the tools/equipment you operate! Maintain good housekeeping. Ensure effective machine guarding. For More Information and Guidance Please Call ASU EH&S at 480-965-1823