Batch Record- Assignment 1 (Initial) - Bio-Link

advertisement

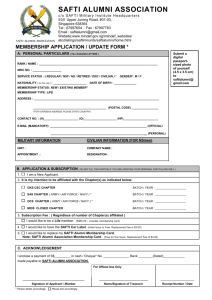

Bio-Link Courses-in-a-Box Batch Records SURVEY OF QUALITY REGULATIONS AND STANDARDS CLASSROOM ACTIVITIES: UNDERSTANDING BATCH RECORDS Submitted by Madison Area Technical College Contact Person: Diana Drier, Senior Research/Manufacturing Specialist Waisman BioManufacturing University of Wisconsin-Madison Drier@waisman.wisc.edu February, 2013 1 Bio-Link Courses-in-a-Box Batch Records PURPOSE This exercise is intended to teach students about batch records in a cGMP facility. The following are provided in this exercise: Introductory information along with an example batch record to guide discussion in the classroom. The example batch record is found in a separate file. It demonstrates the kinds of information that should be captured in the document and the level of detail that is required for cGMP compliance. While the format may vary from facility to facility the information captured is generally the same. A table with relevant terms for students to fill in (p. 5). Students are instructed to find definitions for these terms and fill in the table. Definitions of the relevant terms (“answer key” for the term table) (pp. 6-10). Assignment in which students prepare a batch record of their own (p. 4). Batch Record Assignment Checklist to guide students in setting up their batch record and to guide evaluating student work (p. 11). SUGGESTIONS TO THE INSTRUCTOR 1. Hand out to the class the Example Batch Record (from the separate file), Terminology Table (p. 5), and Batch Record Assignment Checklist (p. 11). 2. Explain that this exercise has several parts. In the first part students will examine and discuss an example batch record. They will also fill in a table with associated terminology. Filling in the table can be assigned as homework or it can be done during class. After students have explored the example batch record and completed the term table, they will create their own batch record for a task of their choice. 3. Describe the scenario on p. 4 to create a context for the Example Batch Record. Observe that this particular batch record is written within a contract cell manufacturing company, that is, a company that grows cells on a contract basis for clients. Discuss the importance of only using raw materials that have been approved by the company’s quality assurance/control team. Discuss the importance of traceability, that is, being able to determine the origin of every material that goes into manufacturing the cells. Discuss the importance of verification in assuring that the manufacturing technician performs each step properly. Have students evaluate the level of detail provided in the procedure. 2 Bio-Link Courses-in-a-Box Batch Records 4. Following classroom discussion, assign the students to write their own batch record. The example batch record defines what kinds of information should be captured in the document and the level of detail that is required for cGMP compliance. While batch record document format may vary among manufacturing facilities, the information captured remains the same. The actual procedure in the students’ batch records should be written with sufficient detail so that a person with a science background and relevant experience would be able to follow the outline of steps to successful completion. 5. Explain that students will hand in the first draft of their batch records and fellow classmates will do the initial document review, exchanging hard copies of batch records and editing them with red pens. This will simulate the actual batch record review process that occurs in the workplace and help students better understand what defines a well written versus a poorly written document. Students will then return these edited documents to the author for incorporating those changes that they see as valid improvements in the document. Students will be graded on both their own batch records and the thoroughness of their peer edits. Stress that these documents typically go through multiple edits and this is how authors craft the strongest (most technically well defined) batch records. The instructor can use the Batch Record Assignment Checklist for grading or can have students use this checklist to “grade” one another. 3 Bio-Link Courses-in-a-Box Batch Records Scenario: A client has contacted the business manager of Cells R Us with an inquiry about creating a Master Cell Bank. The client’s intention is to have Cells R Us culture HEK293 cells to manufacture a single 300 vial lot of cGMP grade cells to serve as a Master Cell Bank. The cells in the Master Cell Bank will be used in the future in the manufacture of a viral vaccine for clinical trial therapies. Following this inquiry, the Cells R Us business manager creates a proposal that details deliverables (300 vials at 1X106 cells/vial), costs, and projected time line. After negotiations, the contract is approved/signed and a deposit is received by Cells R Us. A Cells R Us project leader is assigned and following an internal meeting discussing contract details, a meeting with the client is scheduled. During this meeting, more details regarding production and testing of the final product are outlined. The project leader spends the next two weeks putting together a first draft of the batch record. Directions to students: 1. Review the example batch record and identify/highlight the terms listed in the terminology table. 2. Find the definitions and acronym translation for each term and fill in the table. The links below contain glossaries of cGMP terms but you may need to look for other sites on your own. http://www.gmp-quality.com/GMP_Definitions_J.html http://www.gmp-publishing.com/en/glossar.html# 3. Create your own cGMP batch record. Your batch record will detail a scientific protocol of your own choice and can be taken from actual laboratory experience or a book/online source. Batch record should be a minimum of 20 steps, demonstrate your understanding of the intent of the document, and include items listed in Batch Record Assignment Checklist. 4 Bio-Link Courses-in-a-Box Term cGMP Batch Records Acronym translation and definition GLP Batch Record SOP QCP Revision Client Project Code Lot/Batch Number Document Approval QA QC QA Issued Pagination Raw Material Bill of Materials C of A, C of C Room Release Verification- Operator, Verifier Equipment Identification Operator Comments Deviation QA Review websites used: _____________________________________________________________________________________ _____________________________________________________________________________________ 5 Bio-Link Courses-in-a-Box Batch Records cGMP GLOSSARY cGMP is an acronym for current Good Manufacturing Practices. These practices are defined by US Food and Drug Administration in a unified federal code of regulations Title 21 CFR 210,211. These documents outline expectations for the design, construction and operation of all facilities that manufacture drugs/devices for human clinical applications. The intent of these regulations is to assure the manufacture of a sterile, potent and uncontaminated product. http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfCFR/CFRSearch.cfm?CFRPart=210 http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfCFR/CFRSearch.cfm?CFRPart=211 GLP is an acronym for Good Laboratory Practices and deals with the organization, process and conditions under which laboratory studies are planned, performed, monitored, recorded and reported. These practices are defined by US Food and Drug Administration in a unified federal code of regulations Title 21 CFR 58. The intent of operating under GLP guidelines is to assure the quality and validity of test data by mandating that laboratory research or testing is well documented, that materials can be traced to their origin and that the research data gained can be translated to clinical manufacture. http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=58 Quality Management System is the broad management oversight of a cGMP facility. It refers to the system in place that ensures manufacture of a consistent and quality product and encompasses Quality Assurance, Quality Control, Facility Operations and Manufacture. All these facets of a cGMP facility must be strictly regulated in terms of documentation with the goal of meeting government mandates intended to control safety and efficacy of manufactured products as defined under cGMP guidelines. Quality Control refers to the process of reviewing or testing a product. Within a cGMP facility QC personnel are responsible for executing QCPs (Quality Control Procedures) that specifically outline a test protocol. Typically the intent of testing is to confirm the identity of the product, sterility, absence of contamination, concentration and activity or potency. A document called a QCS (Quality Control Specifications) is always created for each product manufactured. The QCS document dictates all the testing required and the specifications for passing those tests prior to product release. Quality Assurance refers to the process of controlling a facility with the intention of maintaining it in accordance with cGMP guidelines with the ultimate goal of manufacturing a reliably/consistently safe and effective product. QA personnel are responsible for overseeing 6 Bio-Link Courses-in-a-Box Batch Records documentation and maintaining records that demonstrate compliance with established guidelines. A batch record (BR) is a document written by a member of the manufacturing team that details the complete step by step protocol for the manufacture of a batch/ lot of a particular product. In the example provided the final product is an HEK293 Master Cell Bank. Note that the example is incomplete in that it shows only the beginning of the MCB production, namely the media preparation and initial thawing and seeding of cells. A batch record should be written with explicit details, allowing that the manufacturing scientists have the required skill set (s), in this case cell culture experience. The draft batch record is initially reviewed internally by facility management (typically the managers of manufacturing, quality control and quality assurance). After internal review and incorporation of identified edits, the batch record is given to the client for review. A revised and final draft must then be approved by all parties involved and officially issued prior to commencing manufacture. A Standard Operation Procedure (SOP) is a document that details a procedure performed repetitively within a cGMP facility. Unlike a batch record, an SOP is not client or product specific and is often embedded within a batch record. In the example BR provided, the procedures for release of clean room space based on proper preparation of the room for manufacture, cleaning of the BSC and labeling of prepared medium and seeded flasks are three examples that reference SOPs. SOPs can also be distinct from batch records; some examples are sample shipping, maintenance and calibration of equipment, routine monitoring of air quality in cleanroom space. SOPs are typically written by people most familiar with the operation or procedure and are approved by manufacturing and quality assurance managers. An essential step in the training of all cGMP employees is reading and comprehension of all SOPs that pertain to their position. All employees have training folders that include a comprehensive list of all SOPs read. A Quality Control Procedure (QCP) is a document that details the protocol for a specific test performed by members of the Quality Control (QC) team. These documents are typically written by the member of the QC group that is most familiar with the protocol. Verification is the initialing performed by the manufacturers after completion of a step that confirms that each specific step was performed. In all cGMP manufacturing two people must always be present in the cleanroom during production. One person is called the “operator” and actually performs the operation as detailed in the batch record. The other person is the “verifier” and confirms that the operator has performed the operation. Typically operations that involve specified volumes or quantities, calculations, recording of RM/lot numbers, or 7 Bio-Link Courses-in-a-Box Batch Records labeling require confirmation by a “verifier”. Other steps may require only an “operator” initial. This distinction is at the discretion of the client. Revision Designation applies to all cGMP documentation and is used to identify documents that have been changed after final approval. Typically the first version of a document will be designated Rev. A. To initiate a change in most cGMP documents n additional document (called a Document Control Change) must be completed. This describes the specific change(s) and an explanation or justification for the change(s). As with all cGMP documentation, revisions must route for review through Quality Management personnel. For example, a batch record might be changed if a client returns with the intention of a repeat production run but wants to alter some part of the process. An SOP might be changed to accommodate changes in catalog numbers for required reagents. A QCP might be changed to provide a more clear explanation of some step in the protocol. cGMP documentation should be viewed as dynamic in that changes or improvements may be necessary. Client Project Code (header) is a coded designation determined by QA that identifies the client, the product, and in some cases the specific manufacturing process. In the example BR the invented client is MATC and the product is an HEK293 master cell bank (MCB). The example BR does not include a manufacturing process because it is a relatively simple protocol. A more complicated protocol might be broken up into individual but related documents, for example, manufacture of a cGMP protein might have separate documents for specific chromatography steps, for buffer preparation, or for final formulation and packaging. All documents associated with the production and testing and release of a product will reference this code. Lot Number or Batch Number (header) is a code designation for the unique production of a product following a single batch record. In the case of a repeat of the same process (returning client) following the same batch record, a new lot number would be assigned to client project code ie. MATC-HEK-MCB-001, MATC-HEK-MCB-002. Document Approval Date is the date on which documents have routed through all necessary participants and signatures have been recorded. QA Issue Signature/Date (footer) is the signature/date of the QA personnel that issues the document to the manufacture project lead prior. No steps in the production process can be initiated without an issued/signed/dated BR. QA Review is the process by which all cGMP documents are approved. Personnel trained in this area are qualified to determine if a document passes cGMP regulations. In relation to batch record review, QA carefully goes over the entire document looking for any missing 8 Bio-Link Courses-in-a-Box Batch Records information or inconsistencies in recorded information. A manufactured product cannot be released without batch record review and approval by QA. Pagination (footer) must be included in the BR and specified as Page # of Total Page #. This can be included in the header or the footer of the BR. Raw Materials (RMs) are reagents or supplies used in a cGMP manufacturing process. Some clients specify that any item that comes in contact with the product be designated a raw material. This is intended to ensure a product that is both sterile and free from contaminants. Some items such as centrifuge tubes and pipets may not be classified as RMs. Unlike typical lab reagents/supplies, RMs are received, stored and documented under strict FDA guidelines to ensure product safety. They require a documented chain of traceability for ordering, receipt, quarantined storage and release storage. RMs also require a Certificate of Analysis or Compliance (C of A, C of C) from that manufacturer that lists material components, manufacturing details, storage details, expiration date, and testing specifications and testing results. Upon receipt, RMs are stored in a locked/quarantined area and designated “quarantined”. QA is tasked with the review of all associated documentation prior to the release labeling of RMs. “Released” RMs are stored in a separate locked storage area to prevent use of those RMs not reviewed and officially “released”. No RM can be used in manufacture until it is designated “released”. The Bill of Materials is a list placed at the beginning of the BR that itemizes all the RMs to be used in manufacture. The B of M should include the RM number (assigned by QA), it’s associated lot number (assigned by QA), expiration date, vendor and catalog number. During the manufacture process, the quantity of each RM used is captured in the batch record document and tallies of each item is recorded in the B of M. Equipment ID Numbers are numbers assigned by QA to each piece of equipment used within a cGMP facility. These ID numbers are always recorded within batch records. The intent is to capture information that will link manufacture with all equipment used and by association confirm that equipment used has been appropriately maintained ie. routine maintenance/calibration as specified in SOPs linked to specific pieces of equipment. Deviations are any changes in the manufacture of a product that are not specifically outlined in the batch record. While a well-crafted batch record should theoretically not require any deviations to the process, there are very few that do not require deviations of any kind. Common examples include simple typos in the document or wrong catalog numbers that are not caught by reviewers. In the case of cell culture, sometimes cell viability can cause changes in the culture strategy outlined in the batch record. In the case of protein manufacture, 9 Bio-Link Courses-in-a-Box Batch Records unforeseen problems in chromatography steps can result in the need for repurification. In the best case scenarios, clients are willing to spend the time and money required to trouble shoot a manufacturing process prior to cGMP manufacture but this is not always the case. Planned deviations (those anticipated beforehand) require signature approval of the client and internal approval by QA. Unplanned deviations that occur during the manufacture are more difficult in terms of timing. If at all possible, it is always best to consult with the client and obtain approval for any deviation that constitutes a significant change to the process. Operator Comments is a section in the batch record that allows for space to record data that is not specifically called for in the document. This is typically the area where unforeseen actions are recorded by the operator and often times this area will make reference to deviations associated with actions taken. Sometime this can serve as a space to record unexpected or unusual observations that might not necessarily required action. 10 Bio-Link Courses-in-a-Box Batch Records Batch Record Assignment Checklist Item Document title Revision designation Company name Client project code Lot number Document approval date Bill of Materials Non-RM Materials Ancillary equipment Manufacture room Date/time of manufacture Manufacture room release information Detailed protocol steps Raw data capture Raw material identification Equipment identification SOP references Signatures (operator/verifier), Page numbers Label information Operator comments QA review/approval notes Check Mark Deviation table Headers/Footers 11