Flow equations in various cases

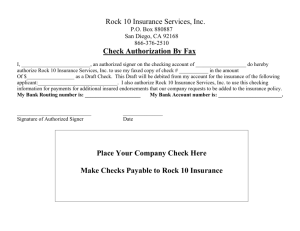

advertisement

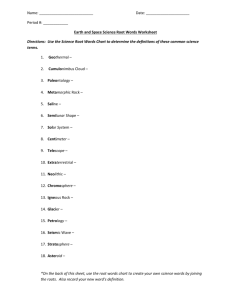

©MBDCI Rock Strength Maurice Dusseault Rock Strength ©MBDCI Common Symbols in RM E, n: Young’s modulus, Poisson’s ratio f, r, g : Porosity, density, unit weight c′, f′,To: Cohesion, friction , tensile strength T, p, po: Temperature, pressure, initial pres. UCS: Unconfined Compressive Str. (σ′3 = 0) sa, sr: Axial, radial stress (σ′ = eff. Stress) τ, σ1-σ3: Shear stress, deviatoric stress k: Permeability These are the most common symbols we use Rock Strength ©MBDCI Chalk Fracture Experiments… a. Three-point loading c. Pure axial tension 2P Surface of fracture ? Compressive stress Surface of fracture ? T P Tensile stress Fracture location directly under 2P b. Fourpoint loading P Fracture location indeterminate P P Compressive Surface of fracture stress T d. Pure torsion (moment) Surface of fracture is a helical shape M Tensile stress P Fracture location indeterminate, but between the two vertical loads Rock Strength P M Maximum tensile stress orientation ©MBDCI What is Strength? It turns out that strength of a geomaterial is a highly complex subject… There still remain issues on which the experts are not in full agreement (e.g. the scale dependency of tensile strength) Strength can be a simple measure, such as unconfined compressive strength (UCS) It can be complex (shear stress under a full 3dimensional stress state, under temperature and elevated pore pressure conditions, etc.) Rock Strength Yield Modes around a Borehole… sHMAX Brittle beam bucking under high uniaxial local loads Crushing in breakout apex breakout sHMAX Destabilized column is “popping” out Axial extension fractures: tensile failure when pw > s High MW – Low MW Shear failure in low cohesion rock precedes sloughing of cavings Rock Strength ©MBDCI High pw leads to slip of a joint or fault. Usually occurs only with high MW Slip plane Plus some others… Fissile shale sloughing if the borehole axis is close to parallel to fissility axis Swelling, weakening, turning to “mush” Borehole surface spalling from high s, perhaps arising from heating, low sʹ ©MBDCI Rock Strength Strength is the ability to sustain (support): Shear stress (shear strength) Compressive normal stress (crushing strength) Tensile stress (tensile strength) Bending (bending or beam strength) All of these depend on effective stresses (s), thus, we must know the pore pressure (p or po) Rock specimen strength is different than rock mass strength (joints, fissures, fissility…) Tests are done on cores, chips, analogues… Rock Strength ©MBDCI Rock Mass vs Sample Strength Field scale: grains to kilometers. Lab scale: grains to 100 mm diameter specimen. max planes Field stresses Z cores sa = s1 sr sr = s3 sa faults joints fractures grains bedding Rock Strength slip planes Triaxial Test Stresses Scale differences and flaws mean that direct extrapolation of test results to the field is difficult in Petroleum Rock Mechanics Sample damage can change properties! ©MBDCI How We Measure Rock Strength… Simple Measurements (no s3 – “index” tests) Compressive Strength (UCS), s3 = 0 Tensile strength (pure tension, hard for rocks!) Indirect tensile test (Brazilian test) Point-load, beam-bending, scratch test, needle… Uniaxial Direct shear tests of a planar surface A joint surface, bedding plane, fault plane, sheared plane, lithologic interface, etc. The surface is loaded, then sheared, and the resistance to shear loads is recorded sn rock Rock Strength slip plane ©MBDCI Beam Bending Tests Prepared specimen tests P/2 P/2 Beam-bending “tensile” test P/2 P/2 Core tests The “strength” of a rock in beam bending is strongly dependent on the specimen size and the “quality” of the surface finish! X-section Rock Strength ©MBDCI Effect of Flaws on To P/2 P/2 Beam-bending tensile test P/2 P/2 Surface finish A: notched B: rough C: polished Rock Strength Thus, To is flaw size dependent A B C To ©MBDCI Surface Finish and Flaws If the strength of rock in beam-bending depends on the surface finish… Beam-bending is of little value to engineering design issues The strength of rock in tension is dependent on the size of the flaw These observations, combined with the fact that rock masses have many discontinuities… Suggest that tensile strength may be inappropriate for many rock engineering problems Measurements of To are of questionable value Rock Strength ©MBDCI Nevertheless… Tensile Strength… Tensile strength (To) is extremely difficult to measure: it is direction-dependent, flawdependent, sample sizedependent, ... An indirect method, the Brazilian disk test, is used For a large reservoir, To may be assumed to be zero because of joints, bedding planes, etc. Rock Strength To = F/A F Prepared rock specimen Pure tension test: extremely rare A F F Brazilian indirect tension test, common usage F ©MBDCI Other Index Tests of Strength Index tests: strength “indices” only Point load tests on core disks or chunks Brinnell Hardness test, or penetration test Scratch test on slabbed core sections Sclerometer or steel bar rebound tests All these use correlation charts for strength estimates Rock Strength L L jack round flat rock load epoxy scriber pull slab rebound measure mandril Schmidt Hammer or Sclerometer core ©MBDCI Recommendation Include a strength index test program in all your core analyses Service companies can provide this systematically upon request The data bank can be linked to compaction potential, drillability, other factors… It may help identify particularly troublesome zones that could cause troubles Any systematically collected data will prove useful for correlations and engineering Rock Strength ©MBDCI Cautions! However, index values are estimates only! Scale is a problem! What is the scale of interest to the problem? Is testing a drill chip a test of sufficient scale? Is it possible to index test fractured reservoirs? Geometry is an issue! How is strength affected by a 2 mm thick shale lamination in an otherwise intact sandstone? Is strength anisotropic? What is orientation w.r.t. the anisotropy? Rock Strength ©MBDCI Core #2 ~27500′ below sea level 8000 Scratch test results Correlation to UCS (psi) 7000 6000 5000 4000 This core section is quite homogeneous throughout 3000 2000 ~ 1 foot (300 mm) length 1000 0 Rock Strength Red line is output from the load cell Blue line is an averaged value of the force ©MBDCI Core #1 ~28000′ below sea level 6000 Scratch test results 4000 Heterogeneous and damaged core UCS (psi) Correlation to UCS (psi) 5000 3000 2000 ~ 1′ (300 mm) 1000 0 27264.0 27264.1 Rock Strength 27264.2 27264.3 27264.4 27264.5 Depth (ft) 27264.6 27264.7 27264.8 27264.9 27265.0 Red line is output from the load cell. Blue line is an averaged value of the force ©MBDCI Core #2 ~27500′ below sea level 18000 Scratch test results Epoxy Spike 16000 12000 Heterogeneous, damaged core UCS (psi) Correlation to UCS (psi) 14000 10000 ~ 1 foot (300 mm) length 8000 6000 4000 2000 0 27348.0 27348.1 Rock Strength 27348.2 27348.3 27348.4 27348.5 Depth (ft) 27348.6 27348.7 27348.8 27348.9 27349.0 ©MBDCI How We Measure Rock Strength… Direct Measurements with confinement (s3) Compressive Strength: Triaxial Testing Machine Encase the core in an impermeable sleeve Confining stress is applied s3 first s =s σa is then increased while… max planes Pore pressure constant Record Δσa, εa, εr, ΔV sr = s3 a Δp, even Δchemistry ) Creep tests (constant σ, measure Hollow cylinders… Strain rate Rock Strength slip planes sr More exotic tests… ΔT, 1 sa Triaxial Test Stresses ©MBDCI Rock Strength- Shear Strength Shear strength: a vital geomechanics measure, used for design Shearing is associated with: σ′3 •Borehole instabilities, breakouts, failure •Reservoir shear and induced seismicity •Casing shear and well collapse •Reactivation of old faults, creation of new ones •Hydraulic fracture in soft, weak reservoirs •Loss of cohesion and sand production •Bit penetration, particularly PCD bits sn sn is normal effective stress is the shear stress,║to slip plane Rock Strength σ′1 sn slip plane rock ©MBDCI High Confining Pressure Frame Core Lab Inc. Frame σ′a Cell σ′r Rock Strength ©MBDCI The Triaxial Cell p control, ΔVp thin porous stainless steel cap for drainage strain gauges εa, εr seals load platen σ Rock Strengtha impermeable membrane CSIRO-Australia σr applied through oil pressure σa ©MBDCI Triaxial Test Apparatus A confining stress s3 is applied (membrane) The pore pressure is zero, or constant The axial stress is increased slowly until well past peak strength Deformation behavior is measured during test T, po… can be varied in sophisticated systems Rock Strength Triaxial test cell. ( a) Cell components including spherical seats A, end caps B, specimen C, fluid port D, Strain Gauges E (optional), and polyurethane rubber sleeve F. ( b) Insertion of sleeve. ( c) End cap removed to clean accumulated rock fragments. ( d) Triaxial test with cell in position, showing four-column load frame, 200-t hydraulic jack load cell and pressure transducer connected to cell for automatic plotting of stress path. (Franklin and Hoek, 1970.) Sing06.049 ©MBDCI Some Issues in Testing Sample disturbance Sample homogeneity Representativeness Specimen preparation Lateral data? DV? Δp response (shales)? Testing must be done by a commercial lab with good QC Even then, results are critically examined Rock Strength f = 30% in situ, 35% in the core lab damage σ′a σ′r Shaley zone, sheared Oil sand, intact ©MBDCI A σ′ ε Curve for a Rock Specimen s´1 = s´a stress difference σ1 - σ3 Y - peak strength massive damage, shear plane develops damage starts cohesio n breaking s´3 = s´r sudden stress drop (brittle) continued damage “elastic” part of σ′ε curve ultimate or residual strength seating, microcrack closure Rock Strength axial strain εa ©MBDCI Shear Failure of Sandstone sa = s1 Rock Strength High quality cylinder L = 2D Flat ends High angle shear plane Zone of dilation and crushing sr = s3 sa ©MBDCI Yield and Strain-Weakening… At one σ′3 value… s’ – behavior YP: peak shear strength YR: residual strength Red curve is at a high confining stress – s3 Blue curve, low s3 E.g.: high pore pressure = low s3, low strength, brittle behavior! Low po… higher strength, ductile Rock Strength ductile yield YR Stress – sa - sr YP strain-weakening YP brittle rupture YR Axial strain - a ©MBDCI Dilatancy During Rock Shearing When rocks shear under low s3, they dilate (+V) Dilation = +DV increase in pore V, microcracks Rock is weakened, but with higher f, k values For reservoirs and high p, s3 is low; dilation enhances permeability, an important factor in heavy oils… s’ – behavior Y Stress – sa - sr Axial strain - a +DV dilation = +ΔV -DV Axial strain - a compression Rock Strength ©MBDCI Full Triaxial Data Set Example 40 sa- sr ( MPa) s´1 = s´a s´3 = 14.0 MPa s´3 = s´r 30 20 10 s- curves s´3 = 7.0 MPa s´3 = 2.0 MPa UCS, s´3 = 0 Strain- % 0 +DV Strain- % -DV 1% Volume change measurement (dilation) Rock Strength ©MBDCI Rock Strength: the M-C Plot To plot a yield criterion from triaxial tests, on equally scaled , s axes, plot s1 and s3 at failure, join with a semicircle, then the tangent = Y Y 4 triaxial tests are plotted here, plus the tensile strength from other tests cohesion To c Rock Strength s3 Different s3 values s1 sn ©MBDCI Triaxial s′- Curves s1 - s3 stress difference Y This is extremely complex, and partly “machine dependent”… smax- peak strength massive damage, shear plane develops damage starts, ~0.60smax cohesion breaking E “elastic” part of s- curve specimen seating, microcrack closure Rock Strength sudden stress drop (brittle or strain-weakening) continued damage Yr ultimate or residual strength axial strain -a ©MBDCI Behavioral Model Representation DV (Deviatoric component) Deviatoric stress Constitutive models: A A: Linear elastic, no deviatoric dilation s- curves B B: Perfect plasticity, no deviatoric dilation E C D C: Instantaneously strainweakening, post failure dilation angle +ve D: Gradual weakening, post failure dilation E A C, D B -ve Strain (%) Rock Strength E: General response, simulated with more complex models… ©MBDCI Geomaterial Failure Modes -ve confinement (i.e. tension) Tensile rupture •Single plane •Minimal general damage •Fracture mechanics Rock Strength Low confinement Shear rupture •Bifurcation plane •Some general damage •Localization effects •Plasticity theory with shearing High confinement General damage •No bifurcation •Distributed general damage •Continuum damage mechanics best ©MBDCI Standard Approximation for Y Known as the Mohr-Coulomb (M-C) failure criterion - shear stress real Y cohesion c′ To Rock Strength Y - linear approximation f′ Rocks are weak in tension!! Y = M-C Yield Criterion: f = c + sn·tanf for sn ≥ To f = 0 for sn < To sn - normal stress ©MBDCI Use a Reasonable Y Approximation Mohr-Coulomb failure (or yield) criterion real Y - shear stress standard approximation cohesion f′ c′ To Rock Strength This is a better approximation for cases of low confining stress Rocks are weak in tension: assume To = 0? sn - normal stress ©MBDCI Different Methods to Present Y In the literature, there are > five different methods to plot rock yield (failure) criteria The next slides show other examples of MC yield criterion plots I prefer the Standard Mohr plot… Simple, clear, easy circle construction for s There are also many yield criteria: Lade, Druker-Prager, Modified Von Mises… I suggest: stick with the M-C criterion, it is robust, well understood, direct… Rock Strength s1 s3 Plotting Method Plot s1, s3 values at peak strength on axes Fit a curve or a straight line to the data points y-intercept is Co or UCS s1 - s3 ·tan2a - Co = 0 (Note that circles to solve for stresses can only be used on a conventional M-C plot, not on this one!) Rock Strength ©MBDCI s1 Curved or linear fit tan2a Uniaxial compressive strength, Co (not same as To) s3 ©MBDCI p q Plotting Method p = (s1 + s2)/2 q = (s1 - s2)/2 p is mean sn q is shear stress This method is most common in soil mechanics Sometimes used in petroleum rock mechanics Rock Strength q actual curve a straight line assumption q = Co/2 + p·tan a p ©MBDCI Why Approximations for Y? Linear approximations of Y are easy to understand: cohesion plus friction effects When yield (failure) criteria are plotted from real lab data, there is a lot of scatter Numerical modeling is the only way to use the full curvilinear Y envelopes… Thus, a linear approximation allows: Quick calculations and estimates A clearer picture of the physics But! Use the right stress range to improve Rock Strength results of simple calculations ©MBDCI Still the Best (in my view)! - shear stress- σ1 – σ2 Mohr-Coulomb yield criterion 2 Y f’ f s′a = s′1 σ′n cohesion f s′r = s′3 shear planes c’ sn - normal stress σ’3 To ~ 0.12·UCS Rock Strength UCS σ’1 σ′n ©MBDCI What is “Failure”? Be very careful!! Failure is a loss of function. Rock yield is a loss of strength. Don’t confuse them!! For example: Most boreholes have “yielded” zones But, the hole has not collapsed! …or “failed”! It still fulfills its function (allowing drill advance) sMAX Rock Strength smin Breakouts Rock Strength – Sophisticated Tests ©MBDCI Radial section Axial section Rock Strength More sophisticated rock tests are also possible and useful in some circumstances: Hollow cylinders, cavity tests Creep tests for salt and soft shales Thermal effects tests Shale properties with different geochemistry Drillability tests… etc. ©MBDCI Geomaterial Characteristics Strain-weakening (peak strength & residual strength, YP, YR, are different) strain, f = ƒ(s3 ): f as s3 YP, YR = ƒ(s3 ): YP, YR as s3 YP/YR = ƒ(s3 ): YP/YR as s3 failure Dilatancy with increasing s1 - s3 dilatancy suppressed as s3 +DV Thus we must link stresses, strains and failure behavior in our rock testing Rock Strength ©MBDCI List of Tests* from Core Lab Ltd.- A Triaxial and uniaxial testing for E, ν, UCS Sonic velocity testing for dynamic Young's Modulus and Poisson's Ratio (ED, νD) Mohr-Coulomb envelope analysis and construction Sonic velocity & acoustic impedance under σ′ Sonic velocity in crude oils and brines Seismic velocity testing at 10Hz Hydrostatic and uniaxial pore volume compressibility *Downloaded list from their website Calibration of sonic and dipole log Rock Strength ©MBDCI List of Tests from Core Lab Ltd. - B Fracture azimuth and max stress azimuth (sonic velocity anisotropy) Evaluation of natural fracture conductivity Thick wall cylinder test (sand production onset) Fracture toughness analysis Brinell hardness test for closure stress analysis Proppant embedment testing vs. closure stress Brazilian indirect tensile strength Point load tensile test for wellbore stability analysis Rock Strength www.corelab.com/PetroleumServices/Advanced/RockMech.asp ©MBDCI Strain and Shear Slip (Displacement) Rock Strength σ a = σ1 σr = σ3 As σa increased, εa took place as well However, when yield took place, deformation only along slip plane! We cannot speak about strain any more, only slip or deformation Also, there is elastic strain and plastic strain… σr = σ3 σ a = σ1 ©MBDCI Diagenesis and Strength sa = s1 slip max planes diagenesis planes shear stress effects on the Mohr-Coulomb sr sr = s3 strength envelope chemical cementation sa Triaxial Test Stresses densification (more interlock) cohesion diagenetic strength increase c Rock Strength s3 s1 original sediment normal stress Extreme Diagenesis Case… Xal overgrowths, interpenetrative structure! Rock Strength ©MBDCI ©MBDCI Rock Strength – Shear Box Tests Strength of joints or faults require shear box tests Specimen must be available and aligned properly in a shear box Different stress values (N) are used Rock Strength Area - A N - normal force S Shear box S - shear force N S A Linear “fit” Curvilinear “fit” data point c cohesion N A ©MBDCI Shearbox Apparatus Normal load (stress) Reaction frame with high stiffness Split box for rock specimens to be tested Different sizes can be mounted in the device Shear displacement on lower half of “box” Rails allow continuous “self-centering” Rock Strength ©MBDCI Yield Criterion in Shearbox Tests Also a MohrCoulomb plot N slip plane S •The points representing normal load and shear load are plotted on axes of equal •As with triaxial test data, a straight line fit is often used rock S = A Linear “fit” Y Curvilinear “fit” data point •This Y is for the surface only, not the rock mass… Rock Strength c cohesion N = sn A ©MBDCI Cohesion and Friction… Bonded grains Crystal strength Interlocking grains Cohesive strength builds up rapidly with strain But! Permanently lost with fabric damage and debonding of grains Rock Strength s1 - s3 complete s- curve stress difference cohesion mobilization friction mobilization a ©MBDCI Friction Frictional resistance to slip between surfaces Must have movement () to mobilize it Slip of microfissures can contribute Slip of grains at their contacts develops Friction is not destroyed by strain and damage Friction is affected by normal effective stress Friction builds up more slowly with strain mob = cohesion + friction Rock Strength f = c′ + sn This is merely the M-C curve ©MBDCI Estimating Rock Strength Laboratory tests OK in some cases (salt, clay), and are useful as indicators in all cases Problems of fissures and discontinuities Problems of anisotropy (eg: fissility planes) Often, a reasonable guess, tempered with data, is adequate, but not always Size of the structure (eg: well or reservoir) is a factor, particularly in jointed strata Strength is a vital factor, but often it is difficult to choose the “right” strength value Rock Strength ©MBDCI Strength Anisotropy UCS UCS Vertical core 0° 30° 60° 90° Bedding inclination Rock Strength ©MBDCI Crushing Strength Some materials (North Sea Chalk, coal, diatomite, high porosity UCSS*) can crush Crushing is collapse of pores, crushing of grains, under isotropic stress (minimal ) Tests involve increasing all-around effective stress (s′) equally, measuring DV/Ds′ Tests can involve reducing p in a highly stresses specimen (ie: s’ increases as p drops) *UCSS = unconsolidated sandstone Rock Strength ©MBDCI High-Porosity Chalk Hollow, weak grains (coccoliths) Weak cementation (dog-tooth calcite) Weak, cleavable grain mineral (CaCO3) Rock Strength ©MBDCI Cracks and Grain Contacts Point-to-point contacts are much more compliant than long (diagenetic) contacts Large open microfissures are compliant Oriented contacts or microfissures give rise to anisotropy of mechanical properties Rocks with depositional structure or exposed to differential stress fields over geological time develop anisotropy through diagenesis Rock Strength ©MBDCI Particle Contacts In granular media, macroscopic stresses are transmitted through grain contact forces (fn, fs) These particles may be crushable (coal, feldspars, coccoliths…) fs = shear force fn = normal force Rock Strength ©MBDCI A non-Crushing Rock Rock Strength 25% porosity SiO2 sandstone (99.5% Q) Contacts are diagenetic in nature… This gives a very high stiffness, even though… The rock is totally devoid of cohesion! Athabasca oil sands, Faja del Orinoco sands, are “similar” to this ©MBDCI Crushing Strength Apply p, s (s > p), allow to equilibrate (s = s - p) Increase s by increasing s or dropping p Ds = Ds - Dp Record ΔV/V, plot versus effective stress The curve is the crushing behavior with +Ds Rock Strength s ΔV s s p s s LE crushing material ΔV ©MBDCI Cracks and Grain Contacts E E1 2 E3 Microflaws can close, open, or slip as σ′ changes Flaws govern rock stiffness The nature of the grain-to-grain contacts and the overall porosity govern the stiffness of porous SS Rock Strength E1 ©MBDCI Griffith Flaw Theory Rock is a “flawed” material Flaws are stressed () by deviatoric loads Tensile s develops at tips Rock is weak in tension Tensile cracks form easily They propagate to s3 As L, acceleration Sudden rupture ensues Rock Strength induced tensile fracture initial flaw deviatoric loading ©MBDCI Low Confining Stress (Low σ′3) Low s′3: brittle rupture Fractures develop parallel to s′1 Specimen may separate into several “columns” When column L/w ratio becomes large, buckling or crushing Rupture is sudden energy is released Rock Strength s′1 Edge chipping Axial fractures L s′3 Surface spalls w ©MBDCI Yield at Higher s′3 Crystal debonding Stress-induced anisotropy At high stress, general damage occurs; much microfissuring, then coalescence takes place (“bifurcation”) Microfissure fabric at yield High s3 Intercrystalline forces at yield Rock Strength ©MBDCI Low s3, Jointing Dominates s1 s3 blocks loosened initial jointing fractures s3 Rock Strength s1 ©MBDCI How Do We “Test” This Rock Mass? Joints and fractures can be at scales of mm to several meters Large f core: 115 mm Core plugs: 20-35 mm If joints dominate, small-scale core tests are “indicators” only This issue of “scale” enters into all Petroleum Geomechanics analyses A large core specimen A core “plug” 1m Machu Picchu, Peru, Inca Stonecraft Rock Strength ©MBDCI Lessons Learned Strength is a complex issue We have to use “models” to understand strength and to apply it in practice Rock mass vs. rock specimen strength problem Problems of scale, heterogeneity… Nevertheless, rock strength can be measured and used to predict slip, crushing, triggering of fault movement, and so on. Combination of the field and the lab is best… Rock Strength