Living Anionic Polymerization of 1,4

advertisement

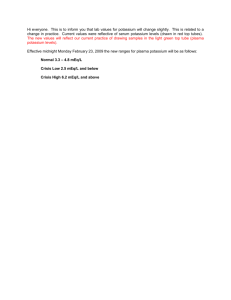

103 學年度台灣大學高分子科學與工程學系 高分子合成特論 Living Anionic Polymerization of 1,4-Divinylbenzene and Its Isomers Shunsuke Tanaka, Masayoshi Matsumoto, Raita Goseki, Takashi Ishizone, and Akira Hirao, Macromolecules, 2013, 46, 146 Advisor : Professor Guey-Sheng Liou Reporter : Tzu-Tien Huang Date : 2014 / 12 / 26 1 103 學年度台灣大學高分子科學與工程學系 高分子合成特論 Advisor : Professor Guey-Sheng Liou Reporter : Tzu-Tien Huang Date : 2014 / 12 / 26 2 Outline Introduction Motivation Polymerization of Divinylbenzene Cross-linked or Star-branched Polymer Soluble Polymer Stable Living Polymer Experiment Result and Discussion Summary 3 Introduction 4 Polymerization of Divinylbenzene Isomers Crosslinked Polymer Insoluble Polymer Ion exchange resin Column – Packing agents Pendent vinyl group 5 Cross-linked Polymer Flory-Huggins Theory Gel Point 6 D. J. Worsfold, Macromolecules, 1970, 3, 514 Star-branched Polymer Poly(isoprenyl) – lithium + m-divinylbenzene 7 L. J. Fetters, Macromolecules, 1978 11, 899 Soluble Polymer Lithium diisopropylamide (LDA) Growing carbanion ↑ → life time ↓ (Chain transfer by DPA) Reactivity Pendent vinyl groups < DVB monomer Growing carbanion ↑ → Reactivity ↓ (Stabilized 10 π -conjugation.) 8 Teiji Tsuruta, J. MACROMOL. SCI.-CHEM., 1989, A26(8), 1043 Pendent vinyl groupContent Charge Transfer (DPA) 9 Stable Living Polymer In THF at -78 ℃ for 1 min Initiator – Oligo ( α-methylstyryl ) lithium ( sec-BuLi / α-MeSt ) Additive - KOBut 10 Akira Hirao, Macromolecules, 2011, 44, 4579 Anionic Polymerization of 1 in THF at 78 C for 1 min SEC profiles of polymers DVB-1 Initiator sec-BuLi DVB-3 DVB-4 DVB-5 sec-BuLi/α-MeSt /KOBut sec-BuLi/α-MeSt /KOBut sec-BuLi/α-MeSt /KOBut 12 eq 12 eq 5 eq 11 Motivation Polymerization of Divinylbenzene Soluble Polymer Expected Polymerization Stable Living Polymer Avoid Crossliked or gel (Pendent vinyl group reation) High yield Pendent vinyl group reactivity Time vs Temperature Small PDI High molecular weight 12 Experiment 13 Synthesis of 1,4-Divinylbenzene Scheme O OH HO CH3 H3C OK H3C Potassium tert - butoixde H3C Br- O O P+ O HO (4) O THF, 40 ¢J O HO (2) (1) (7) OH Methyltriphenyl Phosphonium Bromide (6) (3) OH (5) (8) Divinylbenzene Phthaladehyde Procedure N2 (1) THF (2) R.T. (3) or (4) or (5) / THF 106 g 1500 ml 321 g stir 20 min 59.6 g / 500 ml Temp ¡Õ 40¢J R.T. stir 1 hr H2O / Ice Extraction (n-hexane) 1200 ml / 800ml Dry 14 Preparation of Additives Solution B Solution A R OH Phenol or Alochol K THF at −78 ℃ Colorimetric titration Potassium naphthalenide 0.5 ~ 0.8 M THF 0.3 M THF 0.05 ~ 0.1 M Potassium Alkoxides and Phenoxides 15 Polymerization Surrounding - THF -78℃ THF -95 ℃ Initiator - Oligo ( α-methylstyryl ) lithium ( sec-BuLi / α-MeSt ) N2 Additive - Potassium Alkoxides and Phenoxides N2 Monomer - 1,4 – Divinylbenzene 1,3 – Divinylbenzene 1,2 - Divinylbenzene Terminator - Methanol 16 Result and Discussion 17 Previous - KOBut Atom size : K+ >Li+ Salt effect > Solvation (Abound of K+ ) ( ion-pair > ion-dissociated ) Steric bulkiness (tert-Butyl) Main Chain ↑ → Pendant vinyl group reativity ↓ (The vinyl group of main chain is electron donating) DVB-1 DVB-3 DVB-4 DVB-5 18 Akira Hirao, Macromolecules, 2011, 44, 4579 Effect of Metal Alkoxides - Metal [Initiator] = 2~3 ×10-3 M ; [Monomer] = 0.2~0.9 M LiOBut NaOBut KOBut x 19 Effect of Potassium Alkoxides Reacting alcohol with potassium naphthalenide in THF at −78 ℃ (10 eq) Acetal Oxygen Atom R OR C R OR 20 Effect of Potassium Alkoxides Reacting alcohol with potassium naphthalenide in THF at −78 ℃ (10 eq) pKa small → The ion is stable → Ion-dissociated > Ion-pair Less of steric hindrance 21 Effect of Potassium Phenoxides and Potassium Pivalate Potassium Phenoxides Potassium Pivalate Pivalic acid pKa= 5 → 70% PDI = 1.04 Phenol pKa=10 < Alcohol pKa=16~18 22 Effect of 18-Crown-6, and P4-tBu 18-Crown-6 P4-tBu Strongly coordinate with K+ Steric bulkiness Soluble polymer but PDI large 23 Summary of Additive Steric bulkiness Increase the distance between chain end anion and pendent vinyl group. Basicity Effect the ion stability (Compare the Interaction between Ion-dissociated and ion-pair Reacting in THF at −78 ℃ Potassium Alkoxides Not Absolutely Soluble Polmer Small PDI Potassium Salt (Pivalic acid) Potassium Phenoxides 24 Effect of Temperature and Polymerization Time In THF at −78 ℃ for 5 min Mn ↑ In THF at −95 ℃ for 10~30 min PDI↑ 30 min 10 min 15 min 25 Anionic Polymerization of 1,2- and 1,3-Divinylbenzenes 1,2 - Divinylbenzene 1,3 - Divinylbenzene Bulky group protect ↓ 26 Anionic Polymerization of Divinylbenzenes Isomers 1,4 - Divinylbenzene 10 π, 5 resonace 1,2 - Divinylbenzene 10 π, 5 resonace 1,3 - Divinylbenzene 8 π, 4 resonace 1,4 and 1,2 - Divinylbenzene is more stable than 1,3 - Divinylbenzene 27 Stabilization of Chain-End Anion tert-butyl methacrylate 1,1-diphenylethylene -78 ℃ for 3hr (enolate anion) -78 ℃ for 5hr (diphenyl) 28 Summary 29 Additive Potassium Alkoxides Potassium Phenoxides Potassium Salt (Pivalic acid) Reaction Time and Temperature In THF at −78 ℃ for 1 min In THF at −95 ℃ for 10~30 min Divinylbenzenes Isomers 1,4 and 1,2 - Divinylbenzene is more stable than 1,3 - Divinylbenzene Stabilization of Chain-End Anion tert-butyl methacrylate 1,1-diphenylethylene Soluble Polymer Small PDI High Yield Stable Living Polymer 30 Thank you for your attention ! 31