Cellulosic Ethanol

advertisement

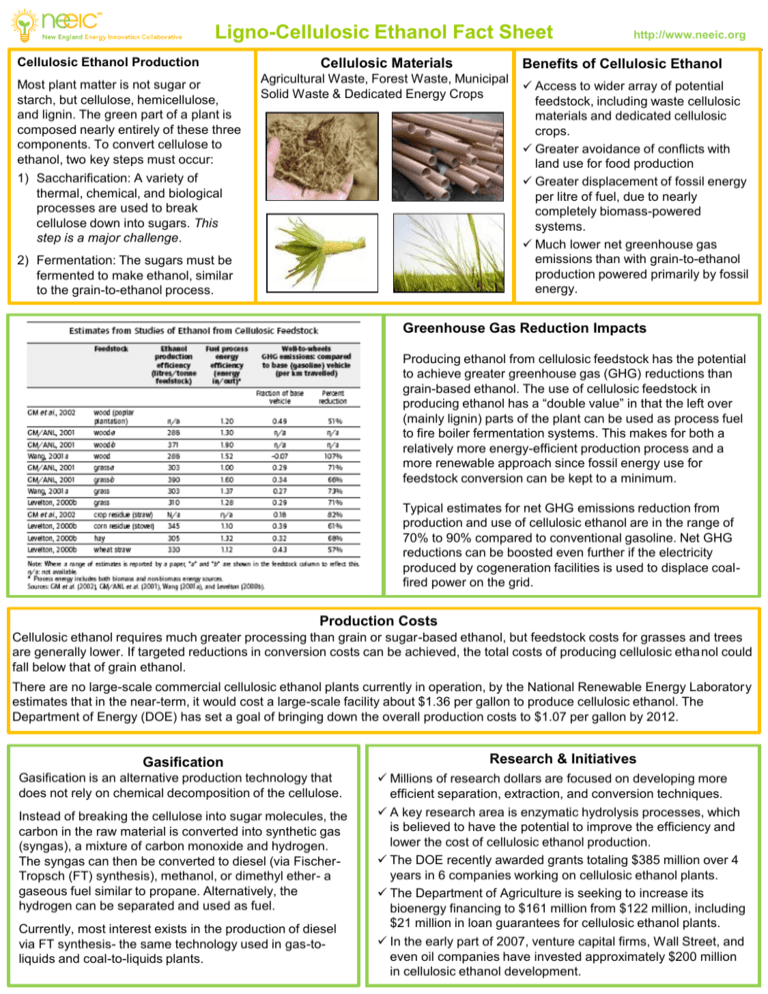

Ligno-Cellulosic Ethanol Fact Sheet Cellulosic Ethanol Production Most plant matter is not sugar or starch, but cellulose, hemicellulose, and lignin. The green part of a plant is composed nearly entirely of these three components. To convert cellulose to ethanol, two key steps must occur: Cellulosic Materials Benefits of Cellulosic Ethanol Agricultural Waste, Forest Waste, Municipal Solid Waste & Dedicated Energy Crops 1) Saccharification: A variety of thermal, chemical, and biological processes are used to break cellulose down into sugars. This step is a major challenge. 2) Fermentation: The sugars must be fermented to make ethanol, similar to the grain-to-ethanol process. http://www.neeic.org Access to wider array of potential feedstock, including waste cellulosic materials and dedicated cellulosic crops. Greater avoidance of conflicts with land use for food production Greater displacement of fossil energy per litre of fuel, due to nearly completely biomass-powered systems. Much lower net greenhouse gas emissions than with grain-to-ethanol production powered primarily by fossil energy. Greenhouse Gas Reduction Impacts Producing ethanol from cellulosic feedstock has the potential to achieve greater greenhouse gas (GHG) reductions than grain-based ethanol. The use of cellulosic feedstock in producing ethanol has a “double value” in that the left over (mainly lignin) parts of the plant can be used as process fuel to fire boiler fermentation systems. This makes for both a relatively more energy-efficient production process and a more renewable approach since fossil energy use for feedstock conversion can be kept to a minimum. Typical estimates for net GHG emissions reduction from production and use of cellulosic ethanol are in the range of 70% to 90% compared to conventional gasoline. Net GHG reductions can be boosted even further if the electricity produced by cogeneration facilities is used to displace coalfired power on the grid. Production Costs Cellulosic ethanol requires much greater processing than grain or sugar-based ethanol, but feedstock costs for grasses and trees are generally lower. If targeted reductions in conversion costs can be achieved, the total costs of producing cellulosic ethanol could fall below that of grain ethanol. There are no large-scale commercial cellulosic ethanol plants currently in operation, by the National Renewable Energy Laboratory estimates that in the near-term, it would cost a large-scale facility about $1.36 per gallon to produce cellulosic ethanol. The Department of Energy (DOE) has set a goal of bringing down the overall production costs to $1.07 per gallon by 2012. Gasification Research & Initiatives Gasification is an alternative production technology that does not rely on chemical decomposition of the cellulose. Millions of research dollars are focused on developing more efficient separation, extraction, and conversion techniques. A key research area is enzymatic hydrolysis processes, which is believed to have the potential to improve the efficiency and lower the cost of cellulosic ethanol production. The DOE recently awarded grants totaling $385 million over 4 years in 6 companies working on cellulosic ethanol plants. The Department of Agriculture is seeking to increase its bioenergy financing to $161 million from $122 million, including $21 million in loan guarantees for cellulosic ethanol plants. In the early part of 2007, venture capital firms, Wall Street, and even oil companies have invested approximately $200 million in cellulosic ethanol development. Instead of breaking the cellulose into sugar molecules, the carbon in the raw material is converted into synthetic gas (syngas), a mixture of carbon monoxide and hydrogen. The syngas can then be converted to diesel (via FischerTropsch (FT) synthesis), methanol, or dimethyl ether- a gaseous fuel similar to propane. Alternatively, the hydrogen can be separated and used as fuel. Currently, most interest exists in the production of diesel via FT synthesis- the same technology used in gas-toliquids and coal-to-liquids plants.