Chapter 05

advertisement

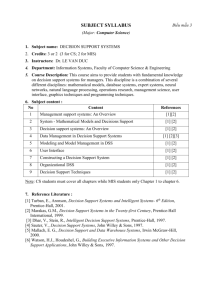

Chapter 1 Differing Perspectives on Quality S. Thomas Foster, Jr. Boise State University Slides Prepared by Bruce R. Barringer University of Central Florida ©2001 Prentice-Hall Chapter Overview Slide 1 of 2 • Recognizing Different Perspectives on Quality • What is Quality? • Differing Perspectives on Quality • Is Quality Management Its Own Functional Discipline? • The Three Spheres of Quality © 2001 Prentice-Hall Transparency 1-2 Chapter Overview Slide 2 of 2 • Other Perspectives on Quality • Arriving at a Common Understanding of Quality using a Contingency Perspective of Quality © 2001 Prentice-Hall Transparency 1-3 The reasons perceptions differ is 1. Backgrounds 2. Tastes and preferences 3. Attitudes and feelings © 2001 Prentice-Hall Transparency 1-4 Recognizing Different Perspectives on Quality Slide 1 of 3 • Different Perspectives on Quality – There are many different definitions and dimensions of quality. – For the present, you should view quality as a measure of goodness that is inherent to a product or service. – Employees working for the same firm often view quality differently as illustrated in the next slide. © 2001 Prentice-Hall Transparency 1-5 Recognizing Different Perspectives on Quality Slide 2 of 3 Different View of Quality that can Exist in the Same Firm Engineering A product engineer might associate quality with product design © 2001 Prentice-Hall Marketing A marketing executive might associate quality with quick design time Accounting An accountant might associate quality with low product cost Transparency 1-6 Recognizing Different Perspectives on Quality Slide 3 of 3 • As Illustrated in the Proceeding Slide, Perceptions on Quality Can Vary – In order to communicate effectively about quality, managers need to recognize that differences in perceptions of quality exist. © 2001 Prentice-Hall Transparency 1-7 Recognizing Different Perspectives on Quality • • • • Page 4 A Closer look at Quality 1.1 Which are Better, CDs or LPs? What is clear is that the meaning of quality varies drastically from person to person. • It is left to each of us to decide. • Which do we like best? © 2001 Prentice-Hall Transparency 1-8 Recognizing Different Perspectives on Quality • Perceptions affect every aspect of our world – including the business world. • Managers need to recognize that differences in perceptions of quality exist. • Many managers have strong opinions about what quality is. • These opinions can be variance with the beliefs of the majority of their customers. • This may hurt the competitiveness. © 2001 Prentice-Hall Transparency 1-9 Product Quality Dimensions (David Garvin) Slide 1 of 2 1. Transcendent Definition – Quality is something that is intuitively understood but nearly impossible to communicate such as beauty or love. 2. Product-Based Definition – Quality is found in the components and attributes of a product. 3. User-Based Definition – If the customer is satisfied, the product has good quality. © 2001 Prentice-Hall Transparency 1-10 Product Quality Dimensions Slide 2 of 2 4. Manufacturing-Based Definition – If the product conforms to design specifications, it has good quality. 5. Value-Based Definition – If the product is perceived as providing good value for the price, it has good quality. © 2001 Prentice-Hall Transparency 1-11 Garvin’s Product Quality Dimensions (David Garvin) Slide 1 of 4 ( Table 1.1) 1. Performance 2. Features 5. Durability 3. Reliability 6. Serviceability 4. Conformance 7. Aesthetics 8. Perceived Quality © 2001 Prentice-Hall Transparency 1-12 Garvin’s Product Quality Dimensions (David Garvin) Slide 2 of 4 1. Performance – Refers to the efficiency with which a product achieves its intended purpose. 2. Features – Attributes of a product that supplement a product’s basic performance. 3. Reliability – The propensity for a product to perform consistently over its useful design life. © 2001 Prentice-Hall Transparency 1-13 Garvin’s Product Quality Dimensions Slide 3 of 4 4. Conformance ( specifications and tolerance) – Numerical dimensions for a product’s performance, such as capacity, speed, size, durability, color, or the like.( easily quantified and difficult for a service to conform) 5. Durability – The degree to which a product tolerates stress or trauma without failing. © 2001 Prentice-Hall Transparency 1-14 Garvin’s Product Quality Dimensions 6. Serviceability – Ease of repair easily and cheaply. If service is rapid, courteous, easy to acquire, and competent, then the product have good serviceability. 7. Aesthetics – Subjective sensory characteristics such as taste, feel, sound, look, and smell. We measure quality as the degree to which product attributes are matched to consumer preferences. © 2001 Prentice-Hall Transparency 1-15 Garvin’s Product Quality Dimensions Slide 4 of 4 8. Perceived Quality – Quality is as the customer perceives it. Customers imbue products and services with their understanding of their goodness. This is perceived quality. © 2001 Prentice-Hall Transparency 1-16 Quality Dimensions • The Garvin list of quality dimensions, although it is the most widely cited and used, is not exhaustive. • Carol King identified dimensions of service quality such as responsiveness, competence, access, courtesy, communication, credibility, security, and understanding. © 2001 Prentice-Hall Transparency 1-17 Service Quality • Service quality is even more difficult to define than product quality. • This often results from wide variation created by high customer involvement. • The example is fountain pen and food service. © 2001 Prentice-Hall Transparency 1-18 Service Quality Dimensions ( Table 1.2) Slide 1 of 3 ( See Chapter 8 ) Parasuraman, Zeithamel, and Berry’s ( PZB) Service Quality Dimensions 1. Tangibles 2. Service Reliability 3. Responsiveness 4. Assurance 5. Empathy © 2001 Prentice-Hall 6. Availability 7. Professionalism 8. Timeliness 9. Completeness 10. Pleasantness Transparency 1-19 Service Quality Dimensions Slide 2 of 3 1. Tangibles – Include the physical appearance of the service facility, the equipment, the personnel, and the communication material. 2. Service Reliability – Differs from product reliability in that it relates to the ability of the service provider to perform the promised service dependably and accurately. © 2001 Prentice-Hall Transparency 1-20 Service Quality Dimensions Slide 3 of 3 3. Responsiveness – The willingness of the service provider to be helpful and prompt in providing service. 4. Assurance – The knowledge and courtesy of employees and their ability to inspire trust and confidence. © 2001 Prentice-Hall Transparency 1-21 Service Quality Dimensions 5. Empathy – the customer desires caring, individual attention paid to customers by the service firm. © 2001 Prentice-Hall Transparency 1-22 Service Quality Dimensions 6. There are several other dimensions of service quality ( please see above). 7. It should be noted that service design strives to address these different service dimensions simultaneously. 8. It is not sufficient for a service firm to provide only empathy if responsiveness and service reliability are inadequate. © 2001 Prentice-Hall Transparency 1-23 Why Does It Matter That Difference Definitions of Quality Exist? Understanding that definitions and dimensions of quality exist allows measures to be taken to provide a better basis for communication and planning in a firm. © 2001 Prentice-Hall Transparency 1-24 Why Does It Matter That Difference Definitions of Quality Exist? • By sharing a common definition of quality, each department within a company can work toward a common goal. • Understanding the multiple dimensions of quality desired by customers can lead to improved product and service design. • HP embarked on a “customer one-on-one” program that emphasized customer interaction with production workers. © 2001 Prentice-Hall Transparency 1-25 Differing Functional Perspectives on Quality • One of the important determinants of how we perceive quality is the functional role we fulfill organizationally. • It is difficult to communicate with information systems users and internal managers for several reasons. • User system requirements differ from analyst system requirements. © 2001 Prentice-Hall Transparency 1-26 Differing Functional Perspectives on Quality • This difference in the nature of the work performed by users and analyst causes them to see quality issues differently. • Differences between users and analysts are only one instance of different perspectives created by functional differences. • Firm must constantly improve their communication. © 2001 Prentice-Hall Transparency 1-27 Differing Functional Perspectives on Quality • Recognizing fundamental differences between difference function view quality is an important first step in understanding and resolving problems associated with mismatches of quality perceptions within organization. • Experience with cross-functional teams has been difficult for many firms because of poor communication skills among team members. © 2001 Prentice-Hall Transparency 1-28 Differing Functional Perspectives on Quality • • • • • • An Engineering Perspective An Operations Perspective A Strategic Management Perspective A Marketing Perspective A Financial Perspective The Human Resources Perspective © 2001 Prentice-Hall Transparency 1-29 Engineering Perspective on Quality Slide 1 of 4 • Nature of Engineering Perspective – Engineers are interested in applying mathematical problem solving skills and models to the problems of business and industry – Operational Research. – R. A. Fisher expanded the field of mathematical statistics to problems related to variation experienced in the production area. – Two of the major emphases in engineering are the areas of product design and process design. © 2001 Prentice-Hall Transparency 1-30 Engineering Perspective on Quality • Nature of Engineering Perspective - More and more engineers are being hired into services firms requiring a strong technical component. - Two of the major emphases in engineering are the areas of product design and process design. © 2001 Prentice-Hall Transparency 1-31 Engineering Perspective on Quality Slide 2 of 4 • Product Design Engineering – Involves all of those activities associated with developing a product from concept development to final design and implementation. – The next slide ( Figure 1.1) demonstrates the six steps in the engineering life cycle for the design of products. © 2001 Prentice-Hall Transparency 1-32 Engineering Perspective on Quality Slide 3 of 4 Design Life Cycle ( Figure 1.1) Idea Generation Prototype Iterations Preliminary Design Prototype Development Final Definition Product Design & Evaluation Implementation © 2001 Prentice-Hall Transparency 1-33 Engineering Perspective on Quality • Product Design Engineering – Concurrent engineering refers to the simultaneous performance of product and process design activities. – Engineers have also applied statistical thinking to the problem of reliability. – Reliability engineers use probability theory to determine the rate of failure a product will experience over its useful life. © 2001 Prentice-Hall Transparency 1-34 Engineering Perspective on Quality Slide 4 of 4 • Related Concepts – Life Testing • It is a facet of reliability engineering that concerns itself with determining whether a product will fail under controlled conditions during a specified life. • If a component has a relatively high probability for failure that will affect the overall function of a product, then redundancy is applied so that backup system can take over for the failed primary system. © 2001 Prentice-Hall Transparency 1-35 Engineering Perspective on Quality • Related Concepts – Another engineering-related contribution to quality management is the field of Statistical Process Control (SPC). – SPC is concerned with monitoring process capability ( meet specification) and process stability ( only exhibit random or common variation). – The control process as specified by Shewhart is shown in Figure 1.2. © 2001 Prentice-Hall Transparency 1-36 Engineering Perspective on Quality • Statistical Method from the Viewpoint of Quality Control by Shewhart (Figure 1.2) 1. Specify Hypothesis 3. Inspect Data for Consistency with Hypothesis © 2001 Prentice-Hall 2. Produce Data by Performing an Experiment Transparency 1-37 Engineering Perspective on Quality • In summary, the engineering view of quality is technically oriented, focusing on statistics and technical specification. • Only recently have engineers begun to interact with customers in meaningful ways. © 2001 Prentice-Hall Transparency 1-38 Operations Perspective on Quality Slide 1 of 6 • Nature of Operations Perspective – The operations management view of quality is rooted in the engineering approach. © 2001 Prentice-Hall Transparency 1-39 Operations Perspective on Quality • Nature of Operations Perspective – Like engineers, operations managers are very concerned about product and process design. However, rather than focusing on only the technical aspects of these activities, operations concentrates of the management of these activities. © 2001 Prentice-Hall Transparency 1-40 Operations Perspective on Quality • Nature of Operations Perspective - Today, operations management has developed into an integrative field, combining concepts from engineering, operations research, organizational theory, organizational behavior, and strategic management. © 2001 Prentice-Hall Transparency 1-41 Operations Perspective on Quality Slide 2 of 6 • Systems View – Operations management (OM) utilizes the systems view that underlies modern quality management thinking ( see Figure 1.3). – The systems view involves the understanding that product quality is the result of the interactions of several variables such as machines, labor, procedures, planning, and management. © 2001 Prentice-Hall Transparency 1-42 Operations Perspective on Quality-- The Systems View of Operation Management Slide 3 of 6 The Conversion Systems Model of Operation Management ( Figure 1.3) Planning Inputs Organizing Conversion Process Outputs Customer Process Control Controlling © 2001 Prentice-Hall Customer Feedback Transparency 1-43 Operations Perspective on Quality-- The Systems View of Operation Management • This systems view focuses on interactions between the various components that combine to produce a product or service. • The systems view also focuses management on the system as the cause of quality problems. © 2001 Prentice-Hall Transparency 1-44 Operations Perspective on Quality Slide 4 of 6 • Operations/Marketing Interface – In recent years, a major advance in operations management has been the improved understanding of the operations/marketing interface. – The interface has resulted in an increased focus on the customer. © 2001 Prentice-Hall Transparency 1-45 Operations Perspective on Quality • Operations/Marketing Interface - This has helped operations manager externalize their views to the customer as well by making the customers part of the design process. © 2001 Prentice-Hall Transparency 1-46 Operations Perspective on Quality Slide 5 of 6 • Strategic View of Operations Management – Among the recent advances in operations management has been a migration towards a more strategic view. – Ferdows and Demeyer linked this strategic view of operations management to quality management by proposing the model shown in Figure 1.4. © 2001 Prentice-Hall Transparency 1-47 Operations Perspective on Quality--Strategic View of Operations Management An Operations Management Competence Model --The Sand Cone Model ( Figure 1.4) Cost Efficiency Speed Dependability Quality © 2001 Prentice-Hall Transparency 1-48 Operations Perspective on Quality--Strategic View of Operations Management • This strategic view of OM to quality management identified quality as base on which lasting improvement in other competitive dimensions established. • This strategic view has also led to a better understanding of the relationship between quality and other competitive variables such as profitability, cost leadership, and operational success. © 2001 Prentice-Hall Transparency 1-49 Operations Perspective on Quality--Strategic View of Operations Management • One common complaint among critics of operations management is that too much credence is given to fads of the day rather than honestly improving the fundamentals of the business. • OM has elevated quality management as a key area of business study. © 2001 Prentice-Hall Transparency 1-50 Strategic Management Perspective on Quality Slide 1 of 3 • Nature of the Strategic Management Perspective – When the concept of strategic planning first arose practitioners treated quality-related strategic planning as if it were a separate exercise from firm-level strategic planning. – However, we soon realized that quality management, to become pervasive in a firm, needed to be included in all of the firm’s business practices, including strategic planning. © 2001 Prentice-Hall Transparency 1-51 Strategic Management Perspective on Quality • Company strategies are rooted in the building blocks of mission and core values. • An organization’s mission states why the organization exists. • The core values of an organization refers to guiding operating principles that simplify decision making in the organization. © 2001 Prentice-Hall Transparency 1-52 Strategic Management Perspective on Quality • Companies go to great effort to establish, communicate, and reinforce a sense of mission and values in an organization, because mission and values strongly influence organizational culture. • Organizational culture is often seen as a major determinant to the successful implementation of quality improvement. • The quality movement has greatly influenced strategy process in recent years. • Figure 1.5 shows a generic strategic planning process and its components. © 2001 Prentice-Hall Transparency 1-53 Strategic Management Perspective on Quality Slide 2 of 3 A Generic Strategic Planning Process ( Figure 1.5) Firm Mission and Goals External Analysis Strategic Options Internal Analysis Business Level Strategy Corporate Level Strategy Operational Subplans Organizational Design Conflict Politics and Change Org. Reward Systems Strategic Alignment Between Structure and Goals © 2001 Prentice-Hall Transparency 1-54 Strategic Management Perspective on Quality Slide 3 of 3 • Goal of Strategic Quality Planning – The ultimate goal of strategic quality planning is to aid an organization to achieve sustainable competitive advantage. © 2001 Prentice-Hall Transparency 1-55 Strategic Management Perspective on Quality • In many markets, like the auto industry, it is becoming difficult to sustain a competitive advantage based on quality alone. • The quality/cost combination can be used as an order winner. • Madu and Kuei propose a strategy process based on plan-do-check-act (see Figure 1.6). © 2001 Prentice-Hall Transparency 1-56 Strategic Management Perspective on Quality • Page 15, Figure 1.6 A Plan-Do-CheckAct Approach to Strategic Quality Planning © 2001 Prentice-Hall Transparency 1-57 Strategic Management Perspective on Quality • As quality has become integral to competitiveness, strategic planning for quality has become more important. • Research shows that quality is still the major competitive concern of CEOs. • Quality Highlight 1.1 (page 16) show how General Electric has made quality a key strategic imperative. © 2001 Prentice-Hall Transparency 1-58 Marketing Perspective on Quality • In a trend known as relationship management , marketing has directed its attention toward satisfying the customer and delivering value to the customer. • Studies show that the value of the loyal customer is much greater than an individual transaction. • If all customers are satisfied, sales increase exponentially! • This increases the importance of high levels of customer service and after-sales support. © 2001 Prentice-Hall Transparency 1-59 Marketing Perspective on Quality Slide 1 of 3 • Nature of Marketing Perspective – Marketing efforts are often focused on managing perceptions of quality. – The primary tools for influencing customer perceptions of quality are price and advertising. © 2001 Prentice-Hall Transparency 1-60 Marketing Perspective on Quality • The link between price and quality could be significant if all products were priced based on cost of materials and production only. • The relationship between advertising and quality is not as straightforward as one would hope. • Marketing is also concerned about systems. • The marketing system involves the interactions between the producing organization, the intermediary, and the final consumer ( see Figure 1.7). © 2001 Prentice-Hall Transparency 1-61 Marketing Perspective on Quality Slide 2 of 3 A Marketing System ( Figure 1.7) Organization Offering Payment Intermediary Offering Offering Payment Payment Customer © 2001 Prentice-Hall Transparency 1-62 Marketing Perspective on Quality • Because of the relationship, it is often very difficult for firms and organizations to agree on who the customer is. • Although it might always seem obvious who the customer is to the casual observer, it is not always clear to those who are involved with the business. © 2001 Prentice-Hall Transparency 1-63 Marketing Perspective on Quality Slide 3 of 3 • Focus on Service – Another important contribution of the marketing perspective has been the focus on service. – This focus is on service at the time of the transaction and after-sales support. – Customer service surveys are important tools for assessing the multiple dimensions of quality. © 2001 Prentice-Hall Transparency 1-64 Marketing Perspective on Quality • The role of marketing in design has been to bring the voice of the customer into the design process. • Customer service surveys are important tools for assessing the multiple dimensions of quality. © 2001 Prentice-Hall Transparency 1-65 Marketing Perspective on Quality • The marketing perspective on quality is unique because the customer is the focus of marketing-related quality improvement. • In trying to satisfy customer needs, marketing often wants to develop specialized products for different customers to perfectly satisfy customer needs. • This can make life more difficult for producers. © 2001 Prentice-Hall Transparency 1-66 Financial Perspective on Quality Slide 1 of 4 • Nature of the Financial Perspective – One of the most commonly asked questions about quality management is “will it pay us financial benefits?” – The Answer to this question is an unqualified”maybe”. – Management was pursuing quality improvement as a means of reducing waste and increasing profitability. © 2001 Prentice-Hall Transparency 1-67 Financial Perspective on Quality • Nature of the Financial Perspective - Implemented correctly, improved quality reduce waster and can lead to reduce cost and improved profitability. - However, these returns tend to be long term rather than short term. © 2001 Prentice-Hall Transparency 1-68 Financial Perspective on Quality • Nature of the Financial Perspective – W. Edwards Deming made the first theoretical attempt to link quality improvements to financial results through the “Deming Value Chain.” ( see Figure 1.8) © 2001 Prentice-Hall Transparency 1-69 Financial Perspective on Quality Slide 2 of 4 The Deming Value Chain ( Figure 1.8) Improve Quality Cost decrease ( see next slide) Productivity Improves Capture the Market Stay in Business Provide Jobs and More Jobs © 2001 Prentice-Hall Transparency 1-70 Financial Perspective on Quality--The Deming Value Chain ( Figure 1.8) - Deming linked quality improvement to reduction of defects and improved organizational performance. - He also stressed quality as a way to increase employment. - Cost decrease because of less rework, fewer mistakes, fewer delays, snags; better use of machine-time and materials © 2001 Prentice-Hall Transparency 1-71 Financial Perspective on Quality • The goal of finance is to maximize return for a given level of risk. • Juran stated that “the language of management is money.” • One way to translate quality concerns is to identify and measure the costs of quality. • Trade-off and break-even analyses can be performed using the various costs of quality. © 2001 Prentice-Hall Transparency 1-72 Financial Perspective on Quality • The relationship between quality improvement and financial success is confounded by several intervening variables. • Top management involvement that is limited to lip service often results in great expenditure, and great effort, but eventually failure. • The pursuit of quality does not safeguard a company against bad management. © 2001 Prentice-Hall Transparency 1-73 Financial Perspective on Quality • Another concept that affects financial officers’ perceptions of quality improvement is the law of diminishing marginal returns. © 2001 Prentice-Hall Transparency 1-74 Financial Perspective on Quality Slide 3 of 4 • Law of Diminishing Marginal Returns – According to this law, there is a point at which investments in quality improvement will become uneconomical. – The figure on the next slide ( Figure 1.9) shows a quadratic economic quality level model. – We will resolution this issues for chapter 4. © 2001 Prentice-Hall Transparency 1-75 Financial Perspective on Quality Slide 4 of 4 Basic Economic Quality Level Model ( Figure 1.9) Cost Minimum Cost Total Quality Costs = Sum of Losses and Costs Losses due to poor quality Optimum Quality Level © 2001 Prentice-Hall Costs of Improving Quality Quality Transparency 1-76 © 2001 Prentice-Hall Transparency 1-77 Financial Perspective on Quality • According to this law, the pursuit of higher levels of quality will result in higher expenditures. • To invest beyond the minimum cost level will result in non-economic decisions. • In summary, the financial perspective on quality relies more on quantified, measurable, result-oriented thinking. © 2001 Prentice-Hall Transparency 1-78 Human Resource Perspective on Quality Slide 1 of 3 • Nature of Human Resource Perspective – Understanding the human resource perspective on quality is essential as it is impossible to implement quality without the commitment and action of employees. © 2001 Prentice-Hall Transparency 1-79 Human Resource Perspective on Quality • Nature of Human Resource Perspective - Although leadership is an important antecedent to successful quality efforts, the involvement and participation of employees is just as key. © 2001 Prentice-Hall Transparency 1-80 Human Resource Perspective on Quality Slide 2 of 3 • Related Concepts – Employee Empowerment • Empowering employees involves moving decision making to the lowest level in the organization. • The topic of empowerment is closely related to Organizational Design. • Quality management flourishes where the workers’ and the company’s needs are closely aligned. © 2001 Prentice-Hall Transparency 1-81 Human Resource Perspective on Quality • Related Concepts – Job Analysis • Involves collecting detailed information about a particular job. • The information is used to define a job description that is used in setting pay levels. © 2001 Prentice-Hall Transparency 1-82 Human Resource Perspective on Quality • Training allows firms to standardize the approaches their employees use in solving unstructured problems. • Vertical deployment of quality management – top manager and low-ranking employees within a department will use similar processes for solving problems. • Horizontal deployment of quality management – Different departments and units within a firm will use similar approaches to solving problems, © 2001 Prentice-Hall Transparency 1-83 Human Resource Perspective on Quality Slide 3 of 3 • Related Concepts (continued) – 360-Degree Evaluation • Human resources departments typically administer and oversee performance appraisal and evaluation. • Although some critics , such as Deming , have found this system ineffective ,many companies believe performance evaluations are a key method for motivating employees. © 2001 Prentice-Hall Transparency 1-84 Human Resource Perspective on Quality • Related Concepts (continued) – 360-Degree Evaluation • A performance measurement system in which an employee’s peers, supervisors, and subordinates are involved in evaluating the worker’s performance. • This approach seems to be effective in improving teaching performance. © 2001 Prentice-Hall Transparency 1-85 Human Resource Perspective on Quality • Related Concepts (continued) – Total Quality Human Resource Management (TQHRM) • Table 1.3 shows differences between traditional HR and TQHRM. • TQHRM involves many of the concepts of quality management to provide a more supportive and empowered environment. © 2001 Prentice-Hall Transparency 1-86 Human Resource Perspective on Quality • Table 1.3 HRM versus TQHRM Traditional HRM TQHRM Process Characteristics Unilateral role Centralization Pull Administrative Consulting role Decentralization Release Developmental Content Characteristics Nomothetic Compartmentalized Worker-oriented Performance measures Job-based Pluralistic Holistic System-oriented Satisfaction measures Person-based © 2001 Prentice-Hall Transparency 1-87 Is quality management its own functional discipline? • Wall Street Journal reveal job openings for quality managers and engineers. • The role of these departments and specialists are changing in the new century of quality. • Historically, the quality management department performed a policing function in the firm. • Quality managers will responsible for quality conformance and spent their time ferreting out causes of defects. © 2001 Prentice-Hall Transparency 1-88 Is quality management its own functional discipline? • In the late 1950s, Armand Feigenbaum and others showed the limitations of this approach. • The movement began toward the total involvement of employees spawning total quality management (TQM). • With total involvement, the role of the quality department moved from a technical, inspection role to a supportive training and coaching role. © 2001 Prentice-Hall Transparency 1-89 Is quality management its own functional discipline? • As a manager or a quality specialist, you will be ask to either arrange or perform qualityrelated training. • The ability to conduct effective training and to facilitate teams are important tools for the quality professional. © 2001 Prentice-Hall Transparency 1-90 Is quality management its own functional discipline? • Is quality management its own discipline? Yes and no. • Consultants, quality engineers, trainers, coaches, and managers are still needed. • A strong knowledge of quality is best coupled with technical experts in other areas such as materials management, finance, accounting, operations management, human resources management, strategy, industrial engineering, or myriad other disciplines. © 2001 Prentice-Hall Transparency 1-91 The Three Spheres of Quality • One way to conceptualize the field of quality management is known as three spheres of quality. • These spheres are quality control, quality assurance, and quality management, and their functions overlap as seen in Figure 1.10. © 2001 Prentice-Hall Transparency 1-92 The Three Spheres of Quality Slide 1 of 4 ( Figure 1.10) Quality Management Quality Assurance © 2001 Prentice-Hall Quality Control Transparency 1-93 The Three Spheres of Quality Slide 2 of 4 • Quality Control – The control process is based on the scientific methods. – Includes phases of analysis, relation, and generalization. – Activities relating to quality control include: • • • • • • Monitoring process capability and stability Measuring process performance Reducing process variability Optimizing processes to nominal measures Performing acceptance sampling Developing and maintaining control charts © 2001 Prentice-Hall Transparency 1-94 The Three Spheres of Quality Slide 3 of 4 • Quality Assurance – Refers to activities associated with guaranteeing the quality of a product or service. – These activities are design-related. – Quality control is reactive rather than proactive by detecting quality problems after they occur. – The best way to assure quality is in the design of product, service, and processes. © 2001 Prentice-Hall Transparency 1-95 The Three Spheres of Quality • Quality Assurance - Quality assurance activities include tasks such as: • • • • • • • Failure mode and effects analysis Concurrent engineering Experimental Design Process improvements Design team formation and management Off-line experimentation Reliability/durability product testing © 2001 Prentice-Hall Transparency 1-96 The Three Spheres of Quality Slide 4 of 4 • Quality Management – The management processes that overarch and tie together the control and assurance activities make up quality management. – Quality Highlight 1.2 ( see page 24) is an example of a company with effective quality management. – Quality is the responsibility of all management, not just quality managers. © 2001 Prentice-Hall Transparency 1-97 The Three Spheres of Quality • Quality Management - For this reason, a variety of managers, supervisors, and employees are involved in quality management activities such as next slide. © 2001 Prentice-Hall Transparency 1-98 The Three Spheres of Quality • Activities of Quality Management - Planning for quality improvement - Creating a quality organizational culture - Providing leadership and support - Providing training and retraining - Designing an organizational system that reinforces quality ideals - Providing employee recognition - Facilitating organizational communication © 2001 Prentice-Hall Transparency 1-99 Other Perspectives on Quality Slide 1 of 2 • The Value-Added Perspective on Quality – A customer-based perspective on quality that is utilized by services, manufacturing, and public sector organizations involves the concept of value. – Involves a subjective assessment of the efficacy of every step of the process for the customer. © 2001 Prentice-Hall Transparency 1-100 Other Perspectives on Quality • The Value-Added Perspective on Quality - A value-added activity can be pinpointed by asking, “would this activity matter to the customer?” - A value-added activity will have economic value to the customer. © 2001 Prentice-Hall Transparency 1-101 Other Perspectives on Quality Slide 2 of 2 • Cultural Perspectives on Quality – International marketers have long noted that there are differences in tastes and preferences between cultures and nations. – As a result, approaches to quality improvement may differ across culture. © 2001 Prentice-Hall Transparency 1-102 Other Perspectives on Quality • Cultural Perspectives on Quality – It is not so obvious that approaches to quality improvement may differ according to culture. – Cultures that are more class-conscious or command-and-control oriented might have trouble delegating decision making to lower levels of employees. © 2001 Prentice-Hall Transparency 1-103 Contingency Approach to Quality • Arriving at a Common Understanding of Quality Using a Contingency Approach – Contingency theory presupposes that there is no theory or method for operating a business that can be applied in all situations. – As a result, a coherent quality strategy will need to address key environmental variables. © 2001 Prentice-Hall Transparency 1-104