Technician Powerpoint Presentation

advertisement

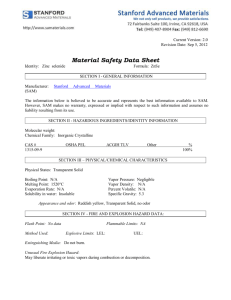

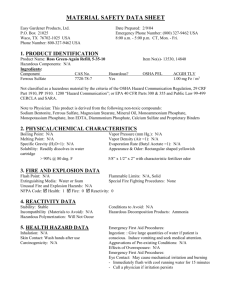

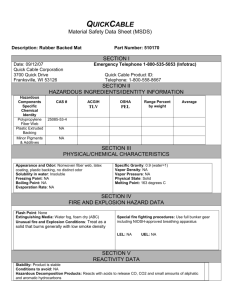

Welcome to Hazardous Materials Technician - Part 1 General • Without reference determine general principles of the Hazardous Materials Technician with at least 80% accuracy. INTRODUCTION • Hazardous materials technicians shall be trained to meet all competencies at the first responder awareness and operational levels and the competencies of this chapter. Hazardous materials technicians also shall receive any additional training to meet applicable … appropriate state, local, or provincial occupational health and safety regulatory requirements. DEFINITIONS • Hazardous materials technicians are those persons who respond to releases or potential releases of hazardous materials for the purpose of controlling the release. • Hazardous materials technicians are expected to use specialized chemical protective clothing and specialized control equipment. GOAL • The goal of this chapter shall be to provide the hazardous materials technician with the knowledge and skills to perform the following tasks safely. Therefore, in addition to being competent at both the first responder awareness and operational levels, the hazardous materials technician shall be able to: GOALS – Analyze – Plan – Implement – Evaluate Analyzing the Incident • Given scenarios of facility and transportation hazardous materials incidents, identify the principles for analyzing a hazardous materials incident at the technician level with at least 80% accuracy. Chemical Terms & Their Significance in the Risk Assessment Process • Describe the following terms and explain their significance in the risk assessment process. – Acid, caustic – Air reactivity – Biological agents and toxins – Boiling point Chemical Terms & Their Significance in the Risk Assessment Process – Catalyst – Chemical interactions – Chemical reactivity – Compound, mixture – Concentration – Corrosivity – Critical temperature and pressure Chemical Terms & Their Significance in the Risk Assessment Process – Expansion ration – Flammable range (LEL & UEL) – Fire point – Flash point – Halogenated hydrocarbon – Ignition (auto-ignition) temperature – Inhibitor – Instability Chemical Terms & Their Significance in the Risk Assessment Process – Ionic and covalent compounds – Irritants (riot control agents) – Maximum safe storage temperature (MSST) – Melting point/Freezing point – Miscibility – Nerve agents – Organic and inorganic Chemical Terms & Their Significance in the Risk Assessment Process – Oxidation potential – pH – Physical state – Polymerization – Radioactivity – Saturated, unsaturated, and aromatic hydrocarbons – Self-accelerating decomposition temperature Chemical Terms & Their Significance in the Risk Assessment Process – Solution, slurry – Specific gravity – Strength – Sublimation – Temperature of product – Toxic products of combustion Chemical Terms & Their Significance in the Risk Assessment Process – Vapor density – Vapor pressure – Vesicants (blister agents) – Viscosity – Volatility – Water reactivity – Water solubility Toxicological Terms & Exposure Values & Their Significance in the Risk Assessment Process • Describe the following toxicological terms and exposure values and explain their significance in the risk assessment process: – Parts per million (ppm) – Parts per billion (ppb) – Lethal dose (LD 50) – Lethal concentration (LC 50) Toxicological Terms & Exposure Values & Their Significance in the Risk Assessment Process – Permissible exposure limit (PEL) – Threshold limit value time weighted average (TLV-TWA) – Threshold limit value short-term exposure limit (TWA-STEL) – Threshold limit value ceiling (TLV-C) – Immediately dangerous to life and health value (IDLH) Radiological Terms & Their Significance in the Risk Assessment Process • Describe the following radiological terms and explain their significance in predicting the extent of health hazards and environmental impact in a hazardous materials incident: – Alpha – Beta – Gamma Radiological Terms & Their Significance in the Risk Assessment Process – Activity – Quantity gamma – Absorbed dose – Half-life – Inverse square law – Time, Distance, and Shielding TECHNICIAN PERFORMANCE TEST • Given examples of various hazardous materials facility and transportation containers, identify each container by type and identify at least one material and its hazard class within 60 minutes IAW DOD Instruction & DOD Manual 6055.6. TECHNICIAN PERFORMANCE TEST • Given examples of various hazardous materials facility and transportation containers and the appropriate reference guide, identify the capacity and basic design and construction features, including closures, for each container within 60 minutes IAW DOD Instruction & DOD Manual 6055.6. Container Capacities • Given three examples of facility and transportation containers, identify the approximate capacity of each container. NOTE: This information may be presented when each container is taught. Container Capacities • Using markings on the container, identify the capacity (by weight and/or volume) of the following examples of transportation vehicles. NOTE: This information may be presented when each container is taught. Basic Design and Construction Features, Including Closures • Identify the basic design and construction features, including closures, of the following bulk containers. NOTE: This information may be presented when each container is taught. Non-bulk Container Materials & Hazard Classes • Given examples of the following nonbulk containers, identify at least one material, and its hazard class, that is typically found in each container NOTE: This information may be presented when each container is taught. Railroad Tank Car Identification • Given examples of the following railroad cars, identify each car by type and identify at least one material, and its hazard class, that is typically found in each car. Railroad Tank Car Identification • Cryogenic liquid tank cars – Type – Material/Hazard Class – Capacity & Markings – Design/Construction – Closures Railroad Tank Car Identification • High-pressure tube cars – Type – Material/Hazard Class – Capacity & Markings – Design/Construction – Closures Railroad Tank Car Identification • Nonpressure tank cars – Type – Material/Hazard Class – Capacity & Markings – Design/Construction – Closures Railroad Tank Car Identification • Pneumatically unloaded hopper cars – Type – Material/Hazard Class – Capacity & Markings – Design/Construction – Closures Railroad Tank Car Identification • Pressure tank cars – Type – Material/Hazard Class – Capacity & Markings – Design/Construction – Closures Intermodal Tank Identification • Given examples of the following intermodal tanks, identify each intermodal tank by type and identify at least one material, and its hazard class, that is typically found in each tank. Intermodal Tank Identification • Intermediate bulk containers – Type – Material/Hazard class – Design/Construction – Closures – Capacities & Markings Nonpressure Intermodal Tanks • IM-101 (IMO Type 1 internationally) portable tank. – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures Non-Pressure intermodal tank Nonpressure Intermodal Tanks • IM-102 (IMO Type 2 internationally) portable tank. – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures Pressure Intermodal Tanks • DOT 51 or IMO Type 5 – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures Specialized Intermodal Tanks • Cryogenic intermodal tanks (IMO Type 7). – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures Specialized Intermodal Tanks • Tube module. – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures Cargo Tank Identification • Given examples of the following cargo tanks, identify at least one material, and its hazard class, that is typically found in each tank. Cargo Tank Identification • Dry bulk cargo tanks – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures Dry bulk cargo tank Cargo Tank Identification • MC-306/DOT-406 cargo tanks – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures MC-306 cargo tank MC-406 cargo tank Cargo Tank Identification • MC-307/DOT-407 cargo tanks – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures MC-307 cargo tank MC-407 cargo tank Cargo Tank Identification • MC-312/DOT-412 cargo tanks – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures MC-312 cargo tank MC-412 cargo tank Cargo Tank Identification • MC-331 cargo tanks – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures MC-331 cargo tank Cargo Tank Identification • MC-338 cargo tanks – Type – Material/Hazard class – Capacity & Markings – Design/Construction – Closures MC-338 cargo tank Facility Tank Identification • Given examples of the following facility tanks, identify at least one material, and its hazard class, that is typically found in each tank. Facility Tank Identification • Non-pressure tanks – Type – Material/Hazard class – Capacity & Markings – Design/construction – Closures Non-pressure facility tanks Facility Tank Identification • Pressure tanks – Type – Material/Hazard class – Capacity & Markings – Design/construction – Closures Low-pressure & pressure vessels Facility Tank Identification • Cryogenic tanks – Type – Material/Hazard class – Capacity & Markings – Design/construction – Closures Non-bulk Tank Identification • One ton containers – Type – Material/Hazard class – Capacity & Markings – Design/construction – Closures Pipelines • Pipelines – Type – Material/Hazard class – Capacity & Markings – Design/construction – Closures Non-bulk Containers • Bags – Type – Material/Hazard class – Design/Construction – Closures – Capacities & Markings Bags (nonbulk) Non-bulk Containers • Carboys – Type – Material/Hazard class – Design/Construction – Closures – Capacities & Markings Carboys (non-bulk) Non-bulk Containers • Cylinders – Type – Material/Hazard class – Design/Construction – Closures – Capacities & Markings Cylinders Non-bulk Containers • Drums – Type – Material/Hazard class – Design/Construction – Closures – Capacities & Markings Drums Container Capacities • Given three examples of facility and transportation containers, identify the approximate capacity of each container. NOTE: This information may have been presented when each container was taught. Container Capacities • Given examples of transportation vehicles using the markings on the container, identify the capacity (by weight and/or volume). NOTE: This information may have been presented when each container was taught. Basic Design and Construction Features, Including Closures • Identify the basic design and construction features, including closures, for bulk containers. NOTE: This information may have been presented when each container was taught. Non-bulk Container Material & Hazard Classes • Given examples of the following nonbulk containers, identify at least one material, and its hazard class, that is typically found in each container NOTE: This information may have been presented when each container was taught. Radioactive Material Packages • Given examples of the following radioactive materials packages, identify each package by type and identify at least one typical material found in each package. Radioactive Material Packages • Identify basic design and construction features of the following radioactive materials containers Radioactive Material Packages • Type A – Type – Material/Hazard class – Design/Construction – Closures Radioactive Material Packages • Type B – Type – Material/Hazard class – Design/Construction – Closures Radioactive Labels • Given a label for a radioactive material, identify vertical bars, contents, activity, and transport index, then describe the labeled item and its significance in surveying a radioactive materials incident. Detecting Weapons of Mass Destruction (WMD) Agents • For each of the following, describe a method that can be used to detect them. – Nerve agents – Vesicants (Blister agents) – Biological agents and toxins – Irritants (riot control agents Classifying by Hazard(s) Unknown Materials • Given at least three unknown materials, one of which is a solid, one a liquid, and one a gas, identify or classify by hazard each unknown material. Analysis Process Steps for Unknown Materials • Identify the steps in an analysis process for identifying unknown solid and liquid materials. – Wear appropriate protective clothing – Approach cautiously from uphill and upwind – Measure in this order or simultaneously; 1 2 3 4 Radioactive Combustibility Oxygen Availability (deficiency) pH 5 Hydrogen Sulfide 6 Carbon Monoxide 7Organic Vapor Analysis Process Steps for Unknown Materials • Identify the steps in an analysis process for identifying an unknown atmosphere. – Wear appropriate protective clothing – Approach cautiously from uphill and upwind – Measure in this order or simultaneously; 1 2 3 4 Radioactive Combustibility Oxygen Availability (deficiency) pH 5 Hydrogen Sulfide 6 Carbon Monoxide 7Organic Vapor Identifying Monitoring Equipment Used to Determine Hazards • Identify the type(s) of monitoring equipment, test strips, and reagents used to determine the following hazards. Identifying Monitoring Equipment Used to Determine Hazards – Corrosivity, pH – Flammability – Oxidation potential – Oxygen deficiency – Radioactivity – Toxic levels Capabilities and Limiting Factors Associated With the Selection and Use of Monitoring Equipment • Identify the capabilities and limiting factors associated with the selection and use of the following monitoring equipment, test strips, and reagents. Capabilities and Limiting Factors Associated With the Selection and Use of Monitoring Equipment – Carbon monoxide meters – Colorimetric tubes – Combustible gas indicator – Oxygen meters – Passive dosimeters Capabilities and Limiting Factors Associated With the Selection and Use of Monitoring Equipment – Photo-ionization detectors – pH indicators and/or pH meters – Radiation detection instruments – Reagents – Test strips Monitoring & Detection Equipment • Given monitoring equipment and three unknown materials demonstrate field maintenance and testing of the monitors, select the appropriate monitors, and classify, identify, and quantify three unknown materials within 60 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Collecting & Interpreting Hazard & Response Information • Given various hazardous materials scenarios and necessary materials, collect hazard, response, and exposure information not available from the North American Emergency Response Guidebook or MSDS within 60 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Collecting & Interpreting Hazard & Response Information • Identify and interpret the types of hazard and response information available from each of the following resources and explain the advantages and disadvantages of each resource. Collecting & Interpreting Hazard & Response Information – Hazardous materials data bases – Maps and diagrams – Monitoring equipment – Reference manuals – Technical information centers – Technical information specialists Heat Transfer Process with Cryogenic Liquids • Describe the heat transfer processes that occur as a result of a cryogenic liquid spill. – Rapid Vaporization – Expansion Ratios Signs, Symptoms and Target Organ Effects of Exposure to Hazardous Materials • Given five hazardous material scenarios and the appropriate reference materials, identify the signs and symptoms of exposure to each material and the target organ effects of exposure to that material. Domestic Gas Line Breaks/Leaks • Given examples of domestic gas line breaks and the locations of combustible gas indicator readings, plot the readings and work zones using EPA guidelines, within 30 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Domestic Gas Line Breaks/Leaks • Given a scenario of a domestic gas line break and the readings from a combustible gas indicator, determine the area of evacuation. Determining Pressure in Bulk & Facility Containers • Identify two methods for determining the pressure in bulk packaging or facility containers. – Pressure Gauges – Temperature of Contents – Pop-off or Safety Vent release pressures – Test or Maximum Allowable Working Pressures (MAWP) printed on container Amount of Lading Remaining in Damaged Bulk Packaging of Facility Containers • Identify one method for determining the amount of lading remaining in damaged bulk packaging of facility containers. – Shipping Papers – Container Specification markings – Gauging Devices – Frost line on container Sample Collection • Demonstrate a method for collecting samples of the following: – Solid - brush, scrap, scoop, core, & forceps – Liquid - jars, coliwasas, bailers, dippers, bombs, & drum thiefs – Gas - sample bags Multiple Products in Pipeline • Describe how a liquid pipeline can carry different products. Pipeline Identification & Information • Given an example of a pipeline, identify the following: – Ownership of the line – Procedures for checking gas migration – Procedures for shutting down the line or controlling the leak – Type of product in the line Pressure Container Damage Terms & Definitions • Identify the types of damage that a container including pressure containers could incur. – Cracks – Scores – Gouges – Dents Identifying Tank Car Damage • Given examples of tank damage, identify the type of damage in each example by name. – Cracks – Scores – Gouges – Dents Mixed Chemical Incidents • Identify at least three resources available that indicate the effects of mixing various hazardous materials. – Guide to Hazardous Chemical Reactions NFPA 491 – Handbook of Reactive Chemical Hazards Bretherick – Hazardous Chemicals Desk Reference Lewis Fire & Safety Features for Fixed Facility Storage Locations • Identify the impact of the following fire and safety features on the behavior of the products during an incident at a bulk storage facility and explain their significance in the risk assessment process: Fire & Safety Features for Fixed Facility Storage Locations – Fire protection systems – Monitoring and detection systems – Product spillage and control (impoundment and diking) – Tank spacing – Tank venting and flaring systems – Transfer operations Dispersion Pattern Prediction Resources • Identify local resources for dispersion pattern prediction and modeling including computers, monitoring equipment, or specialists in the field. – – – – Weather Service Computer Models (Cameo, Aloha, EIS) Colleges & Universities County, State, & Federal Agencies Determining Extent of Hazard within the Endangered Area • Given the concentrations of the released material, identify the steps for determining the extent of the hazards (e.g., physical, safety, and health) within the endangered area of a hazardous materials incident. Methods for Predicting Areas of Potential Harm • Identify two methods for predicting the areas of potential harm within the endangered area of a hazardous materials incident. – Computer Modeling – Monitoring Equipment – Technical Assistance Estimating the Outcomes within an Endangered Area • Identify a method for estimating the outcomes within an endangered area of a hazardous materials incident. – Analyze the following incident data • Physical • Cognitive • Technical Estimating the Outcomes within an Endangered Area • Components – Product – Container – Environment • Subgroups – Damage – Hazard – Vulnerability Risk • Additional Elements to consider – Spill – Leak – Fire Response Objectives • Given simulated facility and transportation problems, the hazardous materials technician shall describe the response objectives for each problem. The hazardous materials technician shall be able to describe the steps for determining response objectives (defensive, offensive, nonintervention) given an analysis of a hazardous materials incident. Action Options • Given simulated facility and transportation hazardous materials incidents, the hazardous materials technician shall identify the possible action options (defensive, offensive, and nonintervention) by response objective for each problem. The hazardous materials technician shall be able to identify the possible action options to accomplish a given response objective. Administer CerTest End Part I Technician TECHNICIAN PART II Personal Protective Equipment • Identify the four levels of personal protective equipment (EPA/NIOSH or NFPA 471) and describe the equipment for each level and the condition under which each level is used. Level A - Vapor-Protective Suits • Fully-Encapsulated Vapor Protective Suit selected based on chemical w/ positive pressure SCBA • Worn in presence of incompletely ID’d vapors, or gases • One-piece suit w/double glove & boot, hard hat • Highest Level of protection Level B - Liquid Splash-Protective Suit • Multi-piece or FullyEncapsulated Liquid Protective Suit selected based on chemical w/ positive pressure SCBA • Double glove & boot, hard hat • Vapor or gases present will not affect exposed skin • Lesser Level of skin protection Level C - Liquid Splash-Protective Suit • Multi-piece Liquid Protective Suit selected based on chemical w/ positive pressure SCBA • Atmospheric, liquid splashes or direct contact will not adversely effect the wearer • Same clothing as Level B, Airpurifying Respirator • Lesser Level of Respiratory Protection Level D - Normal Protective Clothing • Normal work clothing • Work exposures prohibit splashes, immersion, or the potential for unexpected inhalation or contact with hazardous levels of chemicals • Coveralls, Safety Boots/Shoes, Safety Glasses/goggles, hard hat • No Respiratory protection, Minimal Skin protection Factors in Choosing Respiratory Protection • Identify the factors to be considered in selecting the proper respiratory protection for a specified action option. – Primary Key is the Hazard of the chemical • Correlates to the level of PPE (i.e. Level A or C) – Use highest level of Respiratory protection until level of concentration has been determined Advantages & Disadvantages of Various Styles of Respiratory Protection • Describe the advantages, limitations, and proper use of the following types of respiratory protection at hazardous materials incidents. – Positive pressure self-contained breathing apparatus – Positive pressure air line respirators with required escape unit – Air purifying respirators Selecting Proper Respiratory Protection • Identify the process for selecting proper respiratory protection at hazardous materials incidents. – Identify the Name of Chemical – Concentration – Hazard of Chemical (i.e. inhalation, absorption, etc.) – Expected Exposure – OSHA Requirements Components of Air-purifying and Air-line Respirators • Identify the operational components of air purifying respirators and air line respirators by name and describe their functions. – Air-purifying Respirator • Mask • Filter Cartridge • Head Harness – Supplied Air Respirator • Mask • Manifold w/Airline • Escape Unit • Air Supply Factors in Selecting Proper ChemicalProtective Clothing • Identify the factors to be considered in selecting the proper chemical-protective clothing for a specified action option. Factors in Selecting Proper ChemicalProtective Clothing • Risk Assessment – – – – Identify the Hazard Present Estimate the likelihood of exposure Understand the consequence of exposure Determine the risk • Selection – Overall Suit Integrity – Design Features – Materials Chemical Resistance – Service Life – Materials Physical Properties – Cost Damage to Chemical Protective Clothing • Describe the following terms and explain their impact and significance on the selection of chemical-protective clothing. – Degradation – Penetration – Permeation Indications of Degradation of Chemical Protective Clothing • Identify at least three indications of material degradation of chemical-protective clothing. – Stiffness – Excess Pliability – Tears, Cuts or Abrasions – Damage to Zippers or Closures – Discoloration – Other Visible Suit Damage Types of Chemical Protective Clothing Vapor & Splash • Identify the three types of vapor-protective and splash-protective clothing and describe the advantages and disadvantages of each type. – Type I - Fully Encapsulated, SCBA inside suit – Type II - Non-Encapsulated, SCBA outside suit – Type III - Fully Encapsulated, SCBA inside suit with Air-line supply hose passing through suit Chemical Protective Clothing Cooling Devices • Identify the relative advantages and disadvantages of the following heat exchange units used for the cooling of personnel in chemical-protective clothing. – Air cooled – Ice cooled – Water cooled Process for Selecting Proper Protective Clothing • Identify the process for selecting the proper protective clothing at hazardous materials incidents. – – – – Utilize EPA/OSHA Guidelines for Levels Insure Compatibility Observe Breakthrough times Follow Manufacturers Recommendations Select Appropriate Protective Clothing • Given three examples of various hazardous materials, determine the appropriate protective clothing construction materials for a given action option using chemical compatibility charts within 30 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Physical & Psychological Stresses on Wearers of Specialized Protective Clothing • Identify the physical and psychological stresses that can affect users of specialized protective clothing. – – – – – – Low Dexterity & Mobility Low Visibility Poor Communications Heat Stress Physical Stress Claustrophobia Decontamination Advantages/Disadvantages • Identify the advantages and limitations and describe an example where each of the following decontamination methods would be used. Decontamination Advantages/Disadvantages – Absorption - Tools & Equipment, Limited for personnel – Adsorption - Tools & Equipment, flat surfaces – Chemical degradation - Tools, Equipment & Personnel – Dilution - Most Common, Tools, Equipment, & Personnel – Disposal - Tools, Equipment, & Clothing when decontamination is not practical or cost effective Decontamination Advantages/Disadvantages – Evaporation - Volatile or easily evaporative liquids – Neutralization - Tools & Equipment (creates heat) – Solidification - Hard, flat surfaces – Vacuuming - Solids, water reactive materials – Washing - Very commonly used with tools, equipment, & personnel Technical Information Sources on Decontamination • Identify three sources of technical information for selecting appropriate decontamination procedures and identify how to contact those sources in an emergency. – – – – CHEMTREC/CANUTEC/SETIQ Manufacturers/MSDS’s National Response Center Local or Regional Poison Control Centers • Given a simulated hazardous materials incident, the local emergency response plan and standard operating procedures, develop a plan of action to include safety considerations within 60 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Technician Level Offensive Control Techniques • Describe the purpose of, procedures for, equipment required, and safety precautions used with the following techniques for hazardous materials control. Purpose of, Procedures for, Equipment Required, and Safety Precautions for: – Absorption – Neutralization – Overpacking – Patching – Plugging Common Methods for Product Transfer • Given MC-306/DOT-406, MC-307/DOT407, MC-312/DOT-412, MC-331, and MC-338 cargo tanks, identify the common methods for product transfer from each type of cargo tank. Safety Considerations Included in the Plan of Action • Given a simulated hazardous materials, develop the safety considerations that must be included in the plan of action. Safety Considerations Included in the Plan of Action – The plan of action describes response objectives, action options, personnel, and equipment. – The site safety plan develops from the plan of action. – Needs to be consistent with the LERP and SOP’s. Plan of Action Safety Considerations • List and describe the safety considerations to be included…in the plan of action. Safety Briefing • Identify the points that should be made in a safety briefing prior to working at the scene. Confined Space Safety Hazards • Identify the atmospheric and physical safety hazards associated with hazardous materials incidents involving confined spaces. Confined Space Safety Hazards • Atmospheric Hazards – Oxygen-deficient – Oxygen-enriched – Flammable/explosive – Toxic Confined Space Safety Hazards • Physical Hazards – Engulfment – Falls/slips – Electrical – Structural – Mechanical Pre-Entry Activities • Identify the pre-entry activities to be performed. Collecting Legal Evidence • Identify the procedures, equipment, and safety precautions for collecting legal evidence at hazardous materials incidents. Implementing the Planned Response • Given simulated hazardous materials incidents, describe the principles for implementing the planned response to a hazardous materials incident at the technician level with at least 80% accuracy. Duties of the Technician at a Hazardous Materials Incident • Given the local emergency response plan or organization‘s standard operating procedures and a simulated hazardous materials incident, the hazardous materials technician shall demonstrate the duties of an assigned hazardous materials branch position within the local incident management system (IMS). Role of the Hazardous Materials Technician • Identify the role of the hazardous materials technician during an incident involving hazardous material. Duties & Responsibilities of the Technician within Hazardous Materials Incident & IMS • Identify the duties and responsibilities of the following hazardous materials branch functions within the incident management system. Duties & Responsibilities of the Technician within Hazardous Materials Incident & IMS – Backup – Decontamination – Entry – Hazardous materials branch management – Hazardous materials branch safety – Information/research – Reconnaissance – Resources Duties & Responsibilities of the Technician within Hazardous Materials Incident & IMS – Incident commander – Command staff – Planning – Logistics – Operations – Staging – Finance and administration • Given a simulated hazardous materials scenario, as a team, demonstrate the ability to set up a contamination reduction corridor and perform decontamination within 30 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Setup of the Decontamination Corridor • Demonstrate setup of the decontamination corridor as specified in the planned response. The Decontamination Process • Demonstrate the decontamination process specified in the planned response. • Given specialized personal protective equipment and appropriate respiratory protection inspect, record, don, work in, and doff the clothing within 60 minutes DoD Instruction 6055.6 & DoD Manual 6055.6. Safety Procedures for Personnel Wearing Vapor-protective Clothing • Describe three safety procedures for personnel wearing vapor-protective clothing. Emergency Procedures for Personnel Wearing Vapor-protective Clothing • Describe three emergency procedures for personnel wearing vapor-protective clothing. – Loss of air supply – Loss of suit integrity – Loss of verbal communication – Buddy down in hot zone Procedures for Donning, Working In, and Doffing Respiratory Protection • Identify the procedures for donning, working in, and doffing the following types of respiratory protection: – Air line respirator with escape unit – Air purifying respirator Demonstrate Donning, Working In, and Doffing Chemical-protective Clothing • Demonstrate donning, working in, and doffing chemical-protective clothing in addition to any other specialized protective equipment provided by the authority having jurisdiction. Record the Use, Repair, and Testing of Chemical-protective Clothing • Demonstrate the ability to record the use, repair, and testing of chemicalprotective clothing according to manufacturer’s specifications and recommendations. Maintenance, Testing, Inspection, and Storage Procedures for Personal Protective Equipment • Describe the maintenance, testing, inspection, and storage procedures for personal protective equipment provided by the authority having jurisdiction according to the manufacturer‘s specifications and recommendations. • Given necessary materials, select, maintain, and inspect the appropriate tools, and demonstrate the ability to contain various leaks on a pressure vessel within 60 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Containing Leaks in Pressure Vessels • Given a pressure vessel, select the appropriate material or equipment and demonstrate a method(s) to contain leaks from the following locations. Containing Leaks in Pressure Vessels specifically: – Fusible metal of plug – Fusible plug threads – Side wall of cylinder – Valve blowout – Valve gland – Valve inlet threads – Valve seat – Valve stem assembly blowout Closing Valves, Replacing Plugs, Tightening Loose Plugs • Given the fittings on a pressure container, demonstrate the ability to perform the following. – Close open valves – Replace missing plugs – Tighten loose plugs • Given a 55-gal drum and an 85-gallon overpack drum, necessary tools and equipment, as a team, contain various leaks on the drum, and demonstrate three methods of overpacking, within 30 DoD Instruction 6055.6 & DoD Manual 6055.6. Drum Leak Control • Given a 55-gal (208-L) drum, demonstrate the ability to contain the following types of leaks using appropriate tools and materials. – Bung leak – Chime – Forklift puncture – Nail puncture Drum Overpacking • Given a 55-gal (208-L) drum and an overpack drum, demonstrate the ability to place the 55-gal drum into the overpack drum using the following methods. – Rolling slide-in – Slide-in – Slip-over Tool & Equipment Maintenance & Inspection • Identify the maintenance and inspection procedures for the tools and equipment provided for the control of hazardous materials releases according to the manufacturer’s specifications and recommendations. Assessing Leaks & Spills within Confined Spaces • Identify three considerations for assessing a leak or spill inside a confined space without entering the area. • Given a MC-306/DOT-406 cargo tank and dome cover clamp, as a team, install the clamp on the dome and stop various leaks, within 30 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Product Transfer Safety Consideration • Identify three safety considerations for product transfer. – Bonding – Grounding – Elimination of ignition sources – Shock hazards Install a Dome Cover Clamp • Given a MC-306/DOT-406 cargo tank and a dome cover clamp, demonstrate the ability to install the clamp on the dome properly. Fire Involving MC 306/DOT 406 Aluminum Shell Cargo Tanks • Identify the methods and precautions used when controlling a fire involving an MC-306/DOT-406 aluminum shell cargo tank. Containing Leaks in Various Cargo Tank Trucks • Describe at least one method for containing each of the following types of leaks in MC-306/DOT-406, MC307/DOT-407, and MC-312/DOT- 412 cargo tanks: Containing Leaks in Various Cargo Tank Trucks – Dome cover leak – Irregular-shaped hole – Puncture – Split or tear Product Removal & Transfer from Cargo Tank Trucks • Describe three product removal and transfer considerations for overturned MC-306/DOT406, MC-307/DOT-407, MC-312/DOT-412, MC-331, and MC-338 cargo tanks. – Inherent risk associated with such operations – Procedures and safety precautions – Equipment required • Given a copy of the local emergency response plan, identify the element of the plan necessary to implement the planned response within 60 minutes IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Evaluating Progress • Given a scenario and a plan of action, identify the effectiveness of control functions with at least 80% accuracy. Evaluating Effectiveness of Control Functions • Given various simulated facility and transportation hazardous materials incidents involving nonbulk and bulk packaging and the plan of action, the hazardous materials technician shall evaluate the effectiveness of any control functions listed in the plan of action. Terminating the Incident • Given various simulated hazardous materials incidents, identify the principles associated with terminating an incident at the technician level with at least 80% accuracy. Components of a Debriefing • Describe three components effective debriefing. of an Key Topics of an Effective Debriefing • Describe the key topics of an effective debriefing. When to Perform a Debriefing • Describe when a debriefing should take place. Who Should attend the Debrief • Describe who should be involved in a debriefing. Components of an Effective Critique • Describe three components effective critique. of an Who Should Attend the Critique • Describe who should be involved in a critique. Necessity of an Effective Critique • Describe why an effective critique is necessary after a hazardous materials incident. Written Documents as a Result of the Critique • Describe which written documents should be prepared as a result of the critique. Reports & Documentation Required to Conclude a Response • Identify the reports and documentation required by emergency response plan organization’s standard procedures. supporting the local and the operating Complete Required Reports • Demonstrate the proper completion of the reports required by the local emergency response plan and the organization’s standard operating procedures. Incident Reports • Identify the steps to be taken in compiling incident reports that meet federal, state, local, and organizational requirements. Exposure Records • Describe the importance of personnel exposure records. Debriefing Records • Describe the importance of debriefing records. Critique Records • Describe the importance of critique records. Activity Log & Exposure Records • Identify the steps in keeping an activity log and exposure records for hazardous materials incidents. Entry & Exit Logs • Identify the requirements for compiling hot zone entry and exit logs. PPE Logbooks • Identify the requirements for compiling personal protective equipment logs. Filing Documents & Maintaining Records • Identify the requirements for filing documents and maintaining records. • Given a scenario, as a team, demonstrate the ability to direct resources, terminate the incident, provide a debriefing, conduct a critique, and document the incident within 4 hours IAW DoD Instruction 6055.6 & DoD Manual 6055.6. Administer CerTest End Part II Technician