USDC Seafood Inspection Program Policy on Filtered Smoke

advertisement

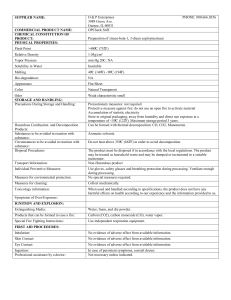

USDC Seafood Inspection Program Policy on Filtered Smoke Process Background USDC Involvement Began in 1997 GRAS Petition (1998) USDC Inspection Policy (1998) FDA Import Bulletin – 16B-95 Response to GRAS Petition USFDA Concerns Labeled as Processed Food That Has Been Treated with Tasteless Smoke or Carbon Monoxide Not Misrepresented as Fresh Frozen Seafood by Their Label Near Normal in Flesh Color Verification Protocol Request for Service Review Documentation Site Visit (Twice per Year) Color Measurements Analytical Analysis – – – Histamine Protein Swabs Microbiological Swabs Letter and Report Approved List of Facilities – http://seafood.nmfs.noaa.gov Collection of Color Data Collected at Selected Process Points – – Day 1 – 5 for Each Set (Thawed) – First Cut, After Exposure (Chilled State) 30 Days, 60 Days, 90 Days, 120 Days, 150 Days (Frozen Storage) To Replicate Retail Storage Conditions Control Data Collected Additional Analysis Photographs at Each Stage Gas Analysis Sensory Analysis Histamine Analysis Color Theory Color Can Be Separated Into Three Stimulus Points (CIELab Scale—L*, a*, b*) – – – L* -- Black to White a* -- Green to Red b* -- Blue to Yellow Each Measurement Stimulus Can Be Statistically Manipulated Possible to Set a Standard Using Only One Stimulus Color Scale Statistical Design Limited Operator Variability Standard Methodology Define Curve of Untreated Data Included Bloomed Tuna Data Deleted Two Outliers Performance Characteristics Highest Value Setting of the Colormetric Standard Define “Near Normal” Tuna Color Commercial Factor a* Value Dramatically Affected by the Process Recommended Standard: a* = 16.2 Policy Status Standard Field Tested No Adjustments to Standard Warranted Meetings – – – – Industry Importers and Retailers Regulatory Agencies Consumer Organizations Enforcement of Standard Present Results – – AFDO Meeting (June 2002) Publications Federal Register Notice Final Standard Set (September 2002) Decomposition Study Answer Three Key Questions – – – Can this process mask decomposition? What will decomposed tuna look like if subjected to this process? Can sensory analysis be used reliably for this product? Decomposition Study Approach Evaluate Four Quality Levels – Three CO Concentration Levels – 1-5%, 20%, 50% or greater Two Exposure Times – High Pass, Borderline Pass, Borderline Fail, High Fail 24 Hours, 48 Hours Two Decomposition Temperatures – Iced, Ambient Decomposition Study Milestones Sample Preparation – March 2002 Sensory Panel Analyses – April 2002 Final Report – June 2002 Labeling Issues Processed Product – – Any Statement on the Label, Must Fully Comply with Labeling Laws (Net Weight) Nutritional Labeling Bulk Pack vs Retail Pack – – – Under 2lbs—Possible Retail Pack Individual Steak Packs Selling to Wholesale Consumer Clubs