Folie 1 - Lorentz Center

advertisement

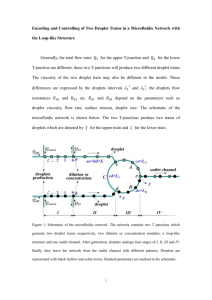

Fluid dynamics of droplet impact on porous membranes. Molecular diagnostics Biomicrofluidics 2 044101 (2008) Frits Dijksman and Anke Pierik Philips Research Europe Eindhoven Workshop Contact Line Instabilities Lorentz Centre Leiden University January 4-8, 2010 Trends in Molecular Diagnostics • Multiple parameter testing on molecular level (DNA, RNA, proteins, enzymes, hormones, cells,…) • Point of Care Rapid Diagnostic Testing – Sensitive – Fast – Integrated – 24h/7d access – Easy to use – High multiplex grade Use of microarrays CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 2 Microarrays •Microarray: substrate containing multiple spots (DNA-fragments, proteins, …) that can each specifically capture a single target Advantages of microarrays •Highly parallel, especially important for complex diseases low price per result •Small sample volumes can be used •More sensitive due to miniaturization •Shorter reaction times due to shorter diffusion distances CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 3 Use of microarrays in biomedical devices Developing very sensitive detection techniques for biomedical devices Microarray containing ink jet printed capture probes Sample Integrated systems Cartridge Measurement equipment Sample preparation and detection equipment CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 Example of microarrays: DNA arrays CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 Applications of microarrays • Genotyping – Identification: food, diagnostics • Gene / protein expression – Personalized prognosis, patient stratification • Pharmacogenomics – Personalized medicine CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 Introduction on micro arrays Microarray (5 by 6 mm) with capture probe spots Before hybridisation Today: Dot size 150-200 m, Permeation depth 100 m Dot pitch 254-400 m Number of dots: 100-400 CONFIDENTIAL After hybridisation Near future: Dot size 50-100 m, Permeation depth 50 m Dot pitch 100-200 m Number of dots: > 1000 Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 7 Manufacturing process of micro arrays 3D distribution of probes depends on: Nylon membranes, neutral or positively charged •Volume of droplet Vdroplet •Total volume of dot Vtotal Average pore size: 450 nm Thickness of membranes: 150 m •Velocity of droplet vdroplet •Print frequency •(Auto) diffusion of capture probes •Surface properties membrane (charge) and properties solution and oligo-(dye) Cross-section Nytran membrane CONFIDENTIAL Flow through direction Membrane with printed spots containing oligonucleotide probes Unit operations dot formation / capture probes Velocity print head Nozzle front Droplet formation Evaporation of free flying droplet Slowing down due to air friction Evaporation at surface membrane Spreading on surface of membrane Print head Air Surface of substrate Penetration into porous structure of membrane Diffusion of capture probes towards inner surface membrane Substrate Evaporation from inner structure of membrane CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 Timing of: •Droplet formation •Flight •Evaporation •Spreading •Penetration •Diffusion •Drying 9 Issue: print heads Single nozzle pipette Droplet volume: 100-150 pl Droplet speed: 1-3 m/s Max frequency: 1 kHz Volume: 25 l Linear array 16 nozzle print head. Droplet volume: 10 pl Droplet speed: 5-10 m/s Max frequency: 4-6 kHz Cartridge volume: 1.5 ml CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 10 Issue: printers Single nozzle printer: large droplets Total QC A. Pierik et al, J. Biotechnology Vol 3, 12, 2008 CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 High speed multi-fluid printer: small droplets 11 Main issue Wet dot size 500-1000 pl Dimatix: Droplet volume 10 pl 50-100 droplets, 4 kHz Microdrop: Droplet volume 120-150 pl 7-10 droplets, 100 Hz Are dot dimensions dependent on droplet size, jetting frequency and number? Is the capture probe distribution dependent on droplet size and number? CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 12 Dot spreading upon impact Nozzle front Droplet formation Evaporation of free flying droplet Slowing down due to air friction Evaporation at surface membrane Spreading on surface of membrane Print head Air Surface of substrate Penetration into porous structure of membrane Diffusion of capture probes towards inner surface membrane Substrate Evaporation from inner structure of membrane CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 13 Results Christophe Le Clerc and Michel Bruyninckx Impact of a water droplet with R = 42.3 m (317 pl) and velocity 5.1 m/s. The delay between each droplet is 3 sec. C. Le Clerc and D.B. van Dam Phys. Fluids 16, 3403 (2004) CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 14 Results Christophe Le Clerc and Michel Bruyninckx Impact of a water droplet with R = 33 m (150 pl) and velocity 11.4 m/s. The delay between each droplet is 0.25 sec. CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 15 Impacting droplets in a pixel. Movie made by Thijs van der Zanden Eindhoven University of Technology CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 16 Results Bayer and Magarides (2004) Impact of a water droplet with R = 0.69 mm (1.38 l) and velocity 0.5 m/s. Ilker S. Bayer and Constantine M. Magarides at XXI ICTAM 15-21 August 2004 Warsaw Poland Wetting surface CONFIDENTIAL Neutral surface Anti-wetting surface Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 17 Computational results Pasindideh et al 1996 Impact of a water droplet with R = 1mm and velocity = 1 m/s. M. Pasandideh-Fard, Y.M. Qiao, S. Chandra and J. Mostaghimi, “Capillary effects during droplet impact on a solid surface: Physics of Fluids 8 (3), March 1996, 650-659. CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 18 Static wetting E Dome h Surface of substrate Rd a Hütte Mathematische Formeln und Tafeln I Szabo Berlin 1959 1 1 h(3a 2 h 2 ) h 2 (3Rd h) 6 3 O 2Rd h (this is the surface area of the curved part of the dome) V cos Rd 3 CONFIDENTIAL Rd -h , Rd sin a Rd 3V (2 3 cos cos 3 ) Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 19 Definition of dynamic contact angle Jiang, Oh and Slattery formula U: velocity of moving contact line Ca U cos( E ) cos( D ) tanh( 4.96 Ca 0.702 ) cos( E ) 1 Terence D. Blake and Kenneth J. Ruschak, “Wetting: static and dynamic contact lines”, Liquid Film Coating edited by Kistler and Schweitzer, Chapman & Hall 1997 CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 20 Dimensionless numbers We = 2ρRv 2 Dimatix, 16 nozzle 10 pl print head γ , Re = η η , Oh = , K =We Oh 2Rγρ -2 / 5 Yarin no-splashing criterion on wet surface: v < Vos = 18( /)1/4(/)1/8f 3/8 Volume Radius Velocity [pl] [m] [m/s] 10 R = 13.4 6 143 R = 32.4 3 Microdrop single nozzle 143 pl print head CONFIDENTIAL 2ρvR We Re Oh 19 12 160 198 0.03 0.02 K <650 dry 81 59 Vos Ca wet U=3/4 v 6 0.09 1.5 0.045 A.L. Yarin: Annual Review Fluid Mechanics 38 (2006) A.L. Yarin and D.A. Weiss, J. Fluid Mech. 1995 Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 21 Energy consideration to calculate max. spreading We 2 Rv 2 , Re 2 vR fluid vapour surface 2Rd h fs fluid solid surface a 2 Loss surface energy air solid interface 1 4 3 2 R v 4R 2 Rs2 ( f s SL SO ) 2 3 Kinetic energy droplet CONFIDENTIAL Surface energy droplet Surface energy dome dot Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 Gain surface energy fluid solid interface 22 Energy consideration to calculate max. spreading With Young' s relation : 1 4 3 2 R v 4R 2 Rs2 ( f s cos E ) 2 3 Rs We 12 Energy considerat ion : (?????) R 3( f s cos E ) Rs We 12 Pasandideh - Fard et al model : We R 3(1 cos D ) 4 Re 26 < We < 642, 213 < Re < 35339 M. Pasandideh-Fard, Y.M. Qiao, S. Chandra and J. Mostaghimi, “Capillary effects during droplet impact on a solid surface: Physics of Fluids 8 (3), March 1996, 650-659. CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 23 Pancake model R v Rs hs SO Situation before impacting of droplet CONFIDENTIAL Substrate SL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 Situation after impacting of droplet 24 Pancake model with dynamic contact angle for U = ¾ v Incoming kinetic energy excess surface energy Espreading (-Rs2 cos D Rs2 2Rs hs - 4R 2 ) 1 4 3 2 Ekinetic R v 2 3 Rs 3 Rs E1 8 ( ) 0 2 R (1 cos D )R R 3(1 cos D ) Hütte Mathematische Formeln und Tafeln I Szabo Berlin 1959 E1 Ekinetic 4R 2 (being the total energy of the droplet) CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 25 Results of the pancake model with dynamic contact angle compared to other models Dynamic spreading of droplets impacting on a solid surface. Droplet volume 150 pl, surface tension 50 mN/m, equilibrium contact angle 40 degrees, density 1000 kg/m^3, viscosity 1 mPas. Dymanic spreading Rs/R 14.0 12.0 10.0 Static Energy consideration Pasandideh-Fard Dynamic 8.0 6.0 4.0 2.0 0.0 0 1 2 3 4 5 6 7 8 9 10 Droplet speed in m/s CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 26 Results of the pancake model with dynamic contact angle compared to other models Dynamic spreading of droplets impacting on a solid surface. Droplet volume 10 pl, surface tension 50 mN/m, equilibrium contact angle 40 degrees, density 1000 kg/m^3, viscosity 1 mPas. Dymanic spreading Rs/R 9.0 8.0 7.0 6.0 Static 5.0 Energy consideration 4.0 Pasandideh-Fard Dynamic 3.0 2.0 1.0 0.0 0 1 2 3 4 5 6 7 8 9 10 Droplet speed in m/s CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 27 Timing of spreading • In order to calculate the timing of the spreading event we consider the following model: M.J. de Ruijter, Axis of J. de Coninck and symmetry Velocity of Pancake of G. Oshanin, contact line Velocity expanding dot profile Lamgmuir 15 (1999) Substrate Velocity of centre of gravity of dot, pointing in negative direction Generalised co-ordinates: position and velocity of centre of gravity of expanding dot. CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 28 Velocity field expressed in terms of generalised co-ordinates and definition of latent energy or Lagrangian L 1 24Z centre 2 vr r ( z 2hs z ) 3 2 5hs 24Z centre 1 3 2 vz ( z h z ) s 3 5hs 3 hs Rs 1 T 2rdrdz (vr2 vz2 ), U excess surface energy 2 0 0 L T U CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 29 Lagrange’s equation • Joseph-Louis, comte de Lagrange (17361813). • Opus magnus: Mécanique Analytique (1787) d L L 0 dt Z centre Z centre Results in an equation of motion. *2 Z 0 . 512 1 *3 Z* ( *3 4.827428) 0.768 *4 [ ( 1 cos ) 6 Z ]0 D 2 3 *2 Z Z R Z With initial conditions we solved this equation numerically. CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 30 Timing of spreading according to Lagrange Time evolution of spreading radius and velocity and position of centre of gravity of a spreading dot after impacting of a 150 pl dot. Droplet velocity 3 m/s, surface tension 0.05 N/m, equilibrium contact angle 40 degrees and viscosity 1 mPas. 3.00 0.80 Position of centre of gravity 0.60 0.40 2.00 0.20 1.50 0.00 -0.20 1.00 -0.40 Velocity of centre of gravity 0.50 -0.60 0.00 -0.80 0 First touch of droplet with substrate CONFIDENTIAL Dimensionless position and velocity of centre of gravity Dimensionless spreading number Rs/R 2.50 Spreading radius 0.5 1 1.5 2 2.5 3 Dimensionless time vt/R Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 31 Comparison with experimental results of Le Clerc End of dynamic spreading process CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 Spreading ratio =Rs/R 32 Permeation model according to De Gennes Hole Washburn equation (1921) Rpore Unit cell x Hmembrane L CONFIDENTIAL L 1 cos E x R pore t , 2 2 x2 t cos E R pore Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 33 Diffusion of capture probes (1) • Diffusion time given by: td 2 R pore DAB • We have three cases (tp : permeation time): • t d t p : capture probes flows along with the fluid, dot distribution in membrane = capture probes distribution, evaporation can influence capture probe distribution • t d t p : capture probes caught in upper part of the membrane, dot distribution not equal capture probes distribution • t d t p : capture probe distribution equal to fluid distribution, evaporation does not change capture probe distribution CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 34 Diffusion of capture probes (2) • Diffusion coefficient literature: • R.B. Bird. W.E. Stewart and E.N. Lightfoot, “Transport Phenomena”, Second Edition, John Wiley & Sons, 2002. W. Eimer, J.R. Williamson, S.G. Boxer and R. Pecora, “Characterisation of the Overall and Internal Dynamics of short Oligonucleotides by Depolarized Dynamic Light Scattering and NMR Relaxation Measurements, Biochemistry 1990, 29, 799-811. W. Eimer and R. Pecora, “Rotational and translational diffusion of short rodlike molecules in solution: Oligonucleotides”, J. Chem. Phys. 94 (3), 1 febrauray 1991, 2324-2329. R. Pecora, “DNA: A Model Compound for Solution Studies of Macromolecules”, Science, Vol. 251, 22 February 1991, 893-898. D. Brune and S. Kim, “Predicting protein diffusion coefficients”, Proc. Natl. Acad. USA, Vol. 90, pp 3835-3839, May 1993. G. F. Bonifacio, T. Brown, G.L. Conn and A,N. Lane, “Comparison of the Electrophoretic and Hydrodynamic Properties of DNA and RNA Oligonucleotide Duplexes”, Biophysical Journal Volume 73 September 1997 1532-1538. Hongmei Jian, Alexander V. Vologodskii and Tamar Schlick, “A Combined Wormlike-Chain and Bead Model for Dynamic Simulations of Long Linear DNA”, Journal of Computational Physics 136, 168-179 (1997). Lenigk et al, "Plastic biochannel hybridization devices: a new concept for microfluidic DNA arrays", Anal. Biochem. 311 (2002) 40-49 • • • • • • • CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 35 Diffusion of capture probes (3) Translational diffusion coefficients of short and long oligonucleotides as function of the number of base pairs 1.00E-09 1 10 100 1000 10000 Diffusion coefficient Our case 1.00E-10 1.00E-11 y = 7E-10x-0.6421 R2 = 0.9938 1.00E-12 Number of base pairs CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 36 3 D dot shape 7 143 pl droplets Droplet 7 Thickness membrane Penetration depth per droplet: xpenetration Droplet 1 Total penetration depth fluid column in membrane core: x0 CONFIDENTIAL Wetting radius of dry substrate membrane: Rs Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 37 3 D dot shape 100 10 pl droplets Fluid on surface Penetration depth outer ring core: x2 Static wetting radius of Vexcess on membrane: a Thickness membrane Droplet 3 Penetration depth outer ring core: x1 Droplet 2 Droplet 1 Fluid on surface Penetration depth inner core: x0 Fluid distribution in membrane during printing Thickness membrane Fluid distribution in membrane after printing CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 38 Timing results CONFIDENTIAL Droplet size 10 pl 143 pl Spreading time of one droplet on dry substrate 7.17 s 31.9 s Penetration time of one droplet on virgin substrate 8 s 57.66 s Penetration depth first droplet 6.2 m 16.6 m Penetration time last droplet Stays at surface 0.792 ms Total process time for 1000 pl 100 droplets at 4 kHz 25 ms (per droplet 0.25 ms) 7 droplets at 100 Hz 70 ms (per droplet 10 ms) Final spreading (diameter) 125 m 153 m Final permeation depth 150 m 116 m Total drying time 40 s 34 s Diffusion time of capture probes in water 0.625 ms 0.625 ms Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 39 Conclusions • There is quite some difference between high frequency spitting of 10 pl droplets and low frequency jetting of large droplets. • High frequency jetting of small droplets leads to a more confined spot of which the capture probes are more concentrated at the surface compared to low frequency jetting of large droplets • The pancake model gives good correspondence with experimental results. Lagrange’s equation (and method) leads to a correct estimate of the timing of the spreading event • Timing of spreading is important in relation to other phenomena taking place on and in the membrane • Diffusion time of capture probes interfere with processes associated to printing, such as spreading, permeation and jetting frequency CONFIDENTIAL Dijksman/Pierik, Workshop Lorentz Centre January 4-8 , 2010 40