supplemental material

advertisement

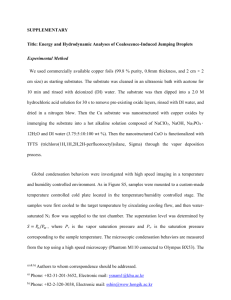

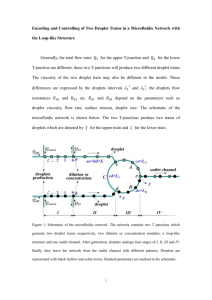

Supplemental material Approaching the theoretical contact time of a bouncing droplet on the rational macrostructured superhydrophobic surfaces Y. Shen, J. Tao, H. Tao,* S. Chen, L. Pan and T. Wang College of Material Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, P. R. China Corresponding author: Prof. Jie Tao Email: taojie@nuaa.edu.cn 1 Experimental procedure Manufacturing Macrotextures and Preparation of Superhydrophobic Ti6Al4V Surfaces. The ridge macrotextures were designed and manufactured using a hyperfine CNC milling machine on the Ti6Al4V (composition (wt-%): ≤ 0.3% Fe, ≤ 0.1% C, ≤ 0.05% N, ≤ 0.015% H, ≤ 0.2% O, 5.5~6.8% Al, 3.5~4.5% V, and the rest is Ti) substrate with the size of 10 mm × 10 mm × 5 mm. In this work, the designed ridge macrotextures were in the shape of circular array of an equilateral triangle cylinder. The surface was then thoroughly cleaned ultrasonically with acetone, ethanol, and distilled water. Subsequently, sand blasting with 150-grit alumina at 0.5 MPa for 10 s was performed to build microscale pits. After being cleaned again, the sample was placed in an autoclave with 30 ml 1 M NaOH aqueous solution at 220 °C for 8 h, and then sufficiently rinsed with distilled water and immersed in a dilute 0.1 M HCl aqueous solution for 0.5 h. Furthermore, annealing at 500 °C (heating rate is 2 °C s-1) for 3h was necessary to produce TiO2 nanowire arrays on the surface of microscale pits. Finally, the sample was modified in 1 wt % FAS-17 ethanol solution for 24 h and dried for 2 h at 120 °C to obtain superhydrophobic surfaces. Characterizations of Superhydrophobic Surfaces. The morphologies of the sample were observed using a field emission scanning electron microscopy (FE-SEM; Hitachi S4800, Japan). The apparent contact angle (APCA) and contact angle hysteresis (CAH) of a 4 μL water droplet on the superhydrophobic surface were measured by a contact angle analyzer (Kruss DSA100, Germany). APCA could be directly obtained from the contact angle analyzer. CAH was the difference between advancing contact angle and receding contact angle. Advancing contact angle was recorded by the computer, when the contact area of the droplet with surface changed owing to expansion of the droplet. If the contact area decreased via shrinking the droplet, receding contact angle could be 2 recorded. The average value of three measurements was determined. In order to ensure that the 4 μL water droplet successfully dripped on the surfaces, we chose the ultrafine syringe needle with the inner diameter of only 0.03 mm, which was also hydrophobized with FAS-17. Filming the Contact Process of Impact Water Droplets. The high-speed cameras (Photron Mini 100 and Olympus i-speed 716), each filming at a 10,000 frames per second, were used to capture the contact process of the impact water droplets on the superhydrophobic surfaces. In this measurement, the droplets were released from a fixed height of 50 mm over the sample surface, as shown in Figure S1. 3 Figure S1. Schematic diagram of filming the contact process of the impact water droplets. 4 Calculating the time of water droplet spreading out to maximal deformation using the law of conservation of mass Figure S2. Model of the impact water droplet spreading. According to the law of conservation of mass, the time (t) required for a water droplet spreading out to maximal deformation can be also calculated by assuming the water droplet spreads into a cylinder of diameter D and thickness h (see Figure S2). This spreading process is followed by the law of conservation of mass, and the relationship can be expressed by: 1 d 2V0 DhVR 4 S1 Where d is the diameter of the truncated sphere, V0 is the impact velocity, and VR is the velocity at the edge of the splat during spreading. And the equation S1 can change to VR d2 V0 4 Dh S2 At the time of the impact water droplet spreading out to maximum diameter (Dmax), the height of the flattened water droplet can be given by h 2 D03 2 3Dmax S3 5 It can be considered to be a constant value owing to a little variation of the height (h). Equation S2 and S3 can give 2 Dmax dD 3 1 2VR V0 dt 16 D0 D S4 Integrating equation S4 can deduce t 8 D0 D 2 2 3V0 Dmax S5 Thus, when the diameter D of the spreading cylinder reaches the maximum diameter (Dmax), the time (t) can be obtained by t 8 D0 3 V0 S6 Thus, the time (t) of water droplet spreading out to maximal deformation is also calculated as about 5.4 ms following the law of conservation of mass. 6