Polycondensation Processes Step-Growth Polymerization

advertisement

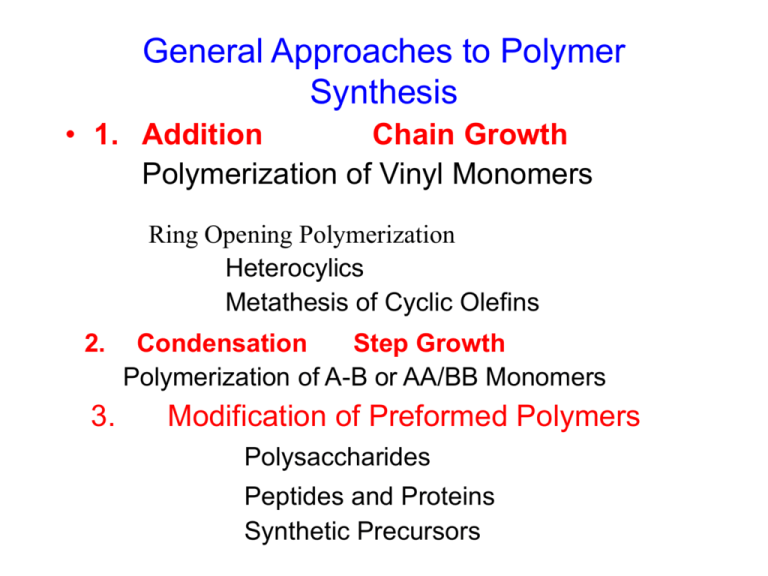

General Approaches to Polymer Synthesis • 1. Addition Chain Growth Polymerization of Vinyl Monomers Ring Opening Polymerization Heterocylics Metathesis of Cyclic Olefins 2. 3. Condensation Step Growth Polymerization of A-B or AA/BB Monomers Modification of Preformed Polymers Polysaccharides Peptides and Proteins Synthetic Precursors Major Developments in the 1950-60's Living Polymerization (Anionic) • Mw/Mn 1 • Blocks, telechelics and stars available (Controlled molecular architecture) • Statistical Stereochemical Control • Statistical Compositions and Sequences • Severe functional group restrictions Ziegler-Natta (Metal-Coordinated) Polymerization • • • • Stereochemical Control Polydisperse products Statistical Compositions and Sequences Limited set of useful monomers, i.e. olefins • SINGLE SITE CATALYSTS Additional Developments in the 1980's • "Immortal" Polymerization (Cationic) – – – – – Mw/Mn 1.05 Blocks, telechelics, stars (Controlled molecular architecture) Statistical Compositions and Sequences Severe functional group restrictions Free Radical Initiated Polymerization • Controlled Free Radical Polymerization • Broad range of monomers available • Accurate control of molecular weight • Mw/Mn 1.05 --Almost monodisperse • Blocks, telechelics, stars • (Controlled molecular architecture) • Statistical Compositions and Sequences Current Strategies in Polymer Synthesis • Objectives: Precise Macromolecular Design • 1 – – – – . Control of: Molecular Weight Molecular Weight Distribution Composition Sequence of repeat units Stereochemistry • 2. Versatility – Genetic Approaches via Modified Microorganisms • • • • • Monodisperse in MW Monodisperse in Composition Sequentially Uniform Stereochemically Pure Diverse set of functional groups possible through synthesis of novel amino acids Step-Growth or Condensation Polymerizations Molecular Weight predicted by Carothers Equation: A-A + B-B -[A-B-]x + x C [A-A] = [B-B] = No # of functional groups remaining at anytime = N Extent of reaction = p No - N p = _____ or N = No (1 - p) No Degree of Polymerization, D.P. = No / N = 1 / (1 - p) Problems in Achieving High D. P. 1. Non-equivalence of functional groups a. Monomer impurities 1. Inert impurities (adjust stoichiometry) 2. Monofunctional units terminate chain b. Loss of end groups by degradation c. Loss of end groups by side reactions with media d. Physical losses e. Non-equivalent reactivity f. Cyclization . Unfavorable Equilibrium Constant Impact of percent reaction, p, on DP Degree of Polymerization, D.P. = No / N = 1 / (1 - p) Assuming perfect stoichiometry if p = 0.5 DP = 2 0.7 0.9 0.95 3.3 10 20 0.99 0.999 100 1000 DPmax= (1 + r) / (1 - r) where r molar ratio of reactants if r = [Diacid] / [diol] = 0.99, then DPmax= 199 Cyclization 1. Thermodynamic stability Rings of: 3,4,8 < 11 < 7, 12 << 5 << 6 2. Kinetic Control Propagation more rapid than cyclization Reduce probability of collision for rings 12 Non-reversible propagation process Equilibrium in Polyesterification Reaction in closed system OH OH + O O Keq = Keq = O [-COO-] [H2O] [COOH] [OH] p2 (1-p)2 p = fraction esterified DP = 1/(1-p) = + H2O (p [M]o)2 ([M]o - p([M]o)2 p= K1/2 1-K1/2 1/2 DP = 1 + K Equilibrium in Polyesterification Effect of Keq on extent of reaction and DP 1/2 DP = 1 + K transesterification esterification amide formation Keq p Xn 0.01 0.1 1.11 1 0.5 2 16 0.8 5 81 0.9 10 361 0.95 20 9800 0.99 100 39,600 0.995 200 Driving reaction to completion in open, driven system Keq DP [H2O] 1 2 20 50 100 2.5 0.0132 0.00204 0.000505 200 5 20 0.000126 4.0 0.211 50 100 200 0.0327 0.0081 0.00201 16 Types of Condensation Reactions 1. Polyesters O HO R OH + - n CH3OH O + H3CO O R O OH O O * R' HO HO R OH O - n H2O O * R' R' O O O R O R' OCH3 O H2O HO trace * n O O -n H2O (CH2)5 C OH (CH2)5 C O -n H2O HO R OH + O O O O O HO R O O OH * O R O O O * n * n Preparation of Aromatic Polyesters O H3C O C O C O CH3 Dimethyl Terephthalate (DMT) O H O C Terephthalic Acid + CH3OH xs HO-CH2CH2-OH O C O H O O C O C O CH2 CH2 CH2OH CH2OH 1 mm Hg O O C O C O CH2 CH2 CH2OH CH2OH 280 C O O C O C O SbO3 or Ti(OR)4 CH2 CH2O + HOCH2CH2OH Stoichiometry and DP controlled by extent of glycol removed. Types of Condensation Reactions 2. Polyamides O H2N R NH2 + OH O H2N R NH2 + - n HCl O * R' Cl NH H2N H R N O R' N * H n O O R' Cl O H2O trace H R N * R' HO O O - n H2O O (CH2)5 C OH -n H2O O (CH2)5 C N H N * H n Polyamides via Condensation -- Nylon 66 O O H O O C-(CH2)4-C O O C-(CH2)4-C OONH3+ NH3+ CH2 CH2 (CH2)4 H + NH2 CH2-(CH2)4-CH2 NH2 slight excess Nylon Salt 60% Slurry 200 C, 15 Atm. 1 hr O O NH3+(CH2)6-NH-C-(CH2)4-C-NH-(CH2)6-NH-C-(CH2)4-C O 8-10 O O mp. 265C, Tg 50C, MW 12-15,000 Unoriented elongation 780% 270-300 C, 1hr - H2O O NH-(CH2)6-NH-C-(CH2)4-C O Nylon 6 6 Types of Condensation Polymers O O O R O C R' C O Polyesters n R' C O C Polyanhydrides O O O O O Polycarbonates O n R Polyacetals n n Lexan Polycarbonate Interfacial Process O Na+ -O Na+ CH3 CH3 + Cl-C-Cl O Tm = 270C, CHCl2 O C Tg = 145-150C 10-40 % Crystalline, Brittle Temp. - 10C Ester Interchange O Aq NaOH CH3 CH3 x Lexan OH C O 1) 200 C/20mm + Lexan + 2) 300 C. <1mm O H CH3 CH3 + NaCl O O H O O No Solvent, Pure Polymer with MW > 30,000 Formed Types of Condensation Polymers R O H N R' N C H O CH3 O O O CH3 polyurethanes polyphenylene oxide O Ar O R S polyarylenes O O polyarylene ether sulfones Low Temperature Condensation Polymerization • Interfacial or Solution in Polar Aprotic Solvents Parameter Low Temp High Temp Moderate Not Essential Not Essential Highly Reactive High High Essential Essential Thermally stable Moderate Intermediates Purity Stoichiometry Heat Stability Structure Cost Interfacial or Solution Polymerization in Polar Aprotic Solvents (Con’t) Conditions Low Temp High Temp Time Temperature Pressure Yield By-products Solvents Minutes to hours 0 – 150 C Atmospheric Low to moderate Salts Required Hours to days >250 C High to vacuum Quantitative Volatiles None Applications of Low Temperature Condensations • Prep. of Infusible Thermally Stable Polymers • Prep. of Thermally Unstable Polymers Prep. of Polymers Containing Functional Groups with Differing Reactivity Formation of Block or Ordered Polymers (No equilibration of polymer in melt allowed) Direct Production of Polymer Solutions for Coatings, Spinning into Fibers, Solvent Blending to form Composites Types of Condensation Polymers O O O O H R N C R' C N H N N O polyamides O polyimides O O S S Ar N N polybenzoxazoles Ar N N polybenzthiazoles Aromatic Polyamides “Aramids” C-Cl O NH2 + NH2 O M-isomers favor formation of soluble polymers C-Cl Unique solvent combination DMF, LiCl S O O O C-NH O O NH-C O C-NH C-NH Nomex NH-C O M.p. > 350 C Can be Dry Spun to Fiber As Spun: Elongation, 23-34%, Tenacity, 4.6-5.3 g/Denier 70% Strength Retained in Ionizing Radiation Polyimides for Electronic Applications O O O 2 (CH3)2CHOH HO-C O O O PMDA O C-O O-C O C-Cl O C-OH O syn and anti isomers Cl-C-C-Cl O O Cl-C C-O O-C O O O O NH2 O DMAC ODA NH2 O C-O O NH-C O-C O C-NH O O Fabricate in soluble form soluble O heat or O N N O O insoluble Kevlar amine catalyst O Post treat to final form POLYETHERSULFONES K2CO3 HO Bis-Phenol-A K+-O Bis-nucleophile O- K+ OH K+-O + - O K O S Cl O Polymerize by SnAr2 + DMSO/Toluene 160 C 2) CH Cl 3 CH3O O O S O Cl Monofunctional terminator to stabilize polymer Use Temperature 100 to + 175C Stable in air to 500C, Self Extinguishing Molecular Weight = 65,000 - 250,000 Amorphous Material, Tg 200C, Films pressed at 280C Polyphenylene Oxide (PPO) Oxidative Coupling Process R1 R1 OH + n/2 O2 R1 O O cat R2 R2 R2 + n H2O cat = or N 10:1 CH3 N CH3 CH3 N CH3 Cu + Amine Complex 3:1 Noryl is a blend with polystyrene Mn 30,000 to 120,000 Amorphous , Tg 210C Crystalline, Tm 270C Brittle point -170C Thermally Stable to 370C Noryl is Unique Blend • • • • Single Phase, Tg dependent upon composition Maximum tensile strength at 80 wt% PPO Other properties; volume fraction weighted average Blend compatible with rubber modified polystyrene (high impact resistance) • Applications of Noryl Engineering Thermoplastics • Useful properties • High impact resistance • Flame retardant • High chemical stability • Low moisture absorbance (0.07%0 • Use in appliance housings • Automobile dashboards • Radomes, fuse boxes, wiring splice devises