Lecture 8

advertisement

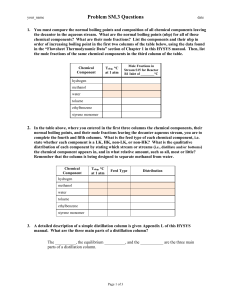

CENG 221 Lecture 4. Multi-component Distillation (4.5 h) Learning Objectives: (1) Multi-component flash distillation calculation (2) Multi-component column distillation Fenske Equation Underwood Equation Gilliland Correlation (3) Column sizing Column diameter Column height (4) Introduction to packed column Learning Guides: (1) Lecture handouts (2) Chapters 3.3, 7.1, 9.1-9.3, 12.1, 12.3, 13.3 of Textbook: Equilibrium-Staged Separations Multi-component Column Distillation QC Total Condenser D, xDi R Q=0 F, hf zi (n) Partial Reboiler QR B, xBi A 2000 kmole/h feed containing benzene (0.2), toluene (0.3) and xylene (0.5) are to be separated using the distillation column shown above. 90 percent of the toluene is to be recovered at the distillate and 98 percent of xylenes is produced at the bottom. (a) label the key and non-key components (b) what is the value of D and B? (b) what is the distillate and bottom composition? Column Distillation QC Total Condenser D, xDi R Q=0 F, hf zi (n) Partial Reboiler QR B, xBi A 100 kmole/h feed containing methanol (0.3) and water (0.7) is to be separated using the distillation column shown above. 90 percent of the methanol is to be recovered at the distillate and 90 percent of water is produced at the bottom. (a) label the key and non-key components (b) what is the value of D and B? (c) what is the distillate and bottom composition? Fenske Equation (Total Reflux) Calculates for Nmin Nmin = Ln [(xA/xB)d/(xA/xB)b] Ln aAB where xA is concentration of key component A (usually LKC) xB is concentration of key component B (usually HKC For binary components Nmin = Ln [(xA/1-xA)d/(xA/1-xA)b] Ln aAB Underwood Equation (Minimum Reflux) Calculates for Rmin DVfeed = F(1-q) = S aiFzi ai - f S aiDxi ai - f Calculates for Vmin Vmin = Column Distillation QC Total Condenser D, xDi R Q=0 F, hf zi (n) Partial Reboiler QR B, xBi Given that the amethanol/water = 3.5, determine the minimum number of equilibrium stages (Nmin) needed for the separation. - Use McCabe-Thiele method - Use Fenske Equation McCabe-Thiele Method y (mole frac. methanol) 1 a =3.5 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 0.8 1 x (mole frac. methanol) y (mole frac. methanol) 1 a =3.5 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 x (mole frac. methanol) 0.8 1 Column Distillation QC Total Condenser D, xDi R Q=0 F, hf zi (n) Partial Reboiler QR B, xBi Given that feed is saturated liquid, determine the minimum reflux (Rmin) - Use McCabe-Thiele method - Use Underwood Equation McCabe-Thiele Method y (mole frac. methanol) 1 a =3.5 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 0.8 1 x (mole frac. methanol) y (mole frac. methanol) 1 a =3.5 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 x (mole frac. methanol) 0.8 1 Column Distillation QC Total Condenser D, xDi R Q=0 F, hf zi (n) Partial Reboiler QR B, xBi Given that the reflux is 2 Rmin find the number of trays needed for the separation (N) - Use McCabe-Thiele method - Use Gillaland Correlation McCabe-Thiele Method y (mole frac. methanol) 1 a =3.5 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 0.8 1 x (mole frac. methanol) y (mole frac. methanol) 1 a =3.5 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 x (mole frac. methanol) 0.8 1 Example 25: The distillation column shown in the figure below was used for the separation of 0.5 mole fraction methanol-water solution. The desired distillate and bottom products are 0.20 and 0.9, respectively. The feed enters the column as a subcooled liquid that condenses 2 moles of vapor per mole of feed. Condenser QC D, xD= 0.9, hD Reflux ratio = L0/D = 2 Rmin Q=0 (a) What is q-value of the feed? Plot the F, z, hf 10 Kmole/min, 0.5 Subcooled liquid (n) feed line. (b) What is the number of equilibrium stages? (c) What is the actual number of stages if the EMV = 0.5? (d) Solve the problem using Fenske, Gilliland and Underwood methods. Reboiler QR B, xB= 0.2, hB Boilup ratio = Vn+1/B Multi-component Column Distillation Example 26. A mixture containing 0.2 mole frac. Benzene (aBT = 2.25), 0.3 toluene (aTT = 1.0), 0.1 xylene (aXT = 0.33) and 0.4 cumene (aCT = 0.21) is to be separated by a distillation column equipped with partial reboiler and total condenser. The 2-phase feed contains 30 % vapor. 99.8 % of the cumene is to be recovered at the bottom and 99.5% of the toluene is to be recovered at the distillate. If the reflux ratio is fixed at 3Rmin determine the number of stages needed for the separation. QC Total Condenser D, xDi R Q=0 F, hf zi (n) Partial Reboiler QR B, xBi Sizing of Distillation Column Number of separation trays (N) Height of column (hC = N*tray spacing) Column diameter (dc) QC Total Condenser D, xDi R Q=0 F, hf zi (n) Partial Reboiler QR B, xBi Sizing of Distillation Column Diameter (1) decide on the tray spacing values using increases by increment of 6 inches from 6”-36” (2) use the graphical correlation that relates the constant Csb for different tray spacing to Flv Flv = WL/Wv [rL/rV]0.5 note: W is mass flow rates (3) calculate the flooding velocity. This is the maximum flowrates allowable that will prevent excessive entrainment of liquid. uflood = K [(rL - rV)/rV]0.5 ft/s (4) actual operation velocity is usually lower than flooding velocity where 0.65 < (fraction) < 0.9 uop = (fraction) uflood ft/s (5) finally, uop is related to the column diameter by: uop = V(MWav)/3600rVAnet ft/s Sizing of Distillation Column Example 27a. Ethanol-water solution was to be separated using a tray distillation column equipped with a total condenser and a partial reboiler. 50 Kmole/h of saturated liquid feed (0.4 mole frac. ethanol) was to be separated to obtain a distillate containing 0.6 mole frac. Ethanol and a bottom of 0.1 mole frac. The reflux ratio is 1.8 Rmin. The distillation company suggested a tray spacing of 24” for optimum operation. Please calculate the diameter and height of the distillation column if sieve trays were used as separation stage. QC Total Condenser D, xDi R Q=0 F, hf zi (n) Partial Reboiler QR B, xBi VLE Data 1 Y (ethanol) 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 0.8 1 0.8 1 X (ethanol) 1 Y (ethanol) 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 X (ethanol) Multi-component Flash Distillation Vapor product V, yi, Hv TF, PF, hF Feed F, zi, T1, P1 Ta ~ Tb < Tc Td heater Pa > Pb > Pc >> Pd Q throttle valve pump Tdrum Pdrum Liquid product L, xi, hL Rachford-Rice Equation c f(V/F) = (Ki-1)zi Si=1 1 + (K -1)(V/F) = 0 i Solution Methods for Rachford-Rice Equation c f(V/F) = (Ki-1)zi Si=1 1 + (K -1)(V/F) = 0 i (1) Secant method (a) choose (V/F)1 such that f(V/F)1 < 0 (V/F)2 such that f(V/F)2 > 0 (b) use linear interpolation to determine V/F at f(V/F) = 0 (c) repeat (a) using new V/F value from (b) until f(V/F) =0 (2) Newtonian convergence read page 55 of Textbook for details Multi-component Flash Distillation Example 26: Determine the amount and composition of the products leaving the flash distillation shown below. V, yi T = 50°C P = 200 kPa F = 1000 kmole/h zc3 = 0.3 znC4 = 0.1 znc5 = 0.15 znc6 = 0.45 L, xi VLE Data Multi-component Flash Distillation Example 27: Determine the operating temperature for the flash drum if the composition of propane in the vapor is 0.7. V, yc3 = 0.7 T=? P = 200 kPa F = 1000 kmole/h zc3 = 0.25 znC4 = 0.15 znc5 = 0.15 znc6 = 0.45 L, xi VLE Data