Chapter 13: DISTRIBUTION AND PRICING

advertisement

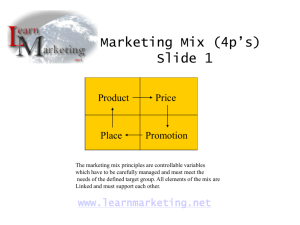

CHAPTER 13: DISTRIBUTION AND PRICING Right Product, Right Person, Right Place, Right Price DISTRIBUTION: GETTING YOUR PRODUCT TO YOUR CUSTOMER Distribution is a key element of the marketing mix Where should the product be sold? How will it get to the location(s) from the factory? Producer Wholesaler Consumer Channel of Distribution – the network of organizations and processes that links producers to consumers DISTRIBUTING DIRECTLY TO THE CONSUMER Producer Consumer Direct Channel – Distribution process that links the producer and the customer with no intermediaries. For example, Dell CHANNEL INTERMEDIARIES Producer Wholesaler Consumer Channel Intermediaries – informally called middlemen. They facilitate the movement of products from the producer to the consumer. THE ROLE OF DISTRIBUTORS: ADDING VALUE (Utility) Form Utility: Turning inputs into finished goods Time Utility: Providing products at the right time Place Utility: Offering products at the right place Ownership Utility: Providing credit, cashing checking, delivering Pay Pal products Information Utility: Offering helpful information Service Utility: Providing fast, friendly, personalized service Jamba Juice Vending Machines ATM’s, Gas Stations Home Depot Service Makeover stations DISTRIBUTORS: STREAMLINING CONSUMER TRANSACTIONS THE MEMBERS OF THE CHANNEL Wholesalers – distributors that buy products from producers and sell them to other businesses or non-final users. Retailers – the distributors that sell products directly to the ultimate users WHOLESALERS: SORTING OUT THE OPTIONS Merchant Wholesalers Take legal possession/title Full-service Limited Service Drop Shippers Cash and Carry Truck Jobbers Amazon Sam’s Club Coke Distributor Agents/Brokers Don’t take title of the goods RETAILERS: THE CONSUMER CONNECTION Store Retailers Non-Store Retailers Online eBay, Amazon Direct Catalogs, telemarketing Response Direct Selling Vending Door-to-door Best Buy at airports DISTRIBUTION STRATEGY EXCLUSIVE DISTRIBUTION Placing your products with only one retail outlet in a given area Tiffany, Bentley automobiles SELECTIVE DISTRIBUTION Placing your products with “preferred retailers” Paintball equipment INTENSIVE DISTRIBUTION Price / Product Placing your product in as many stores as possible Starbucks, People magazine MULTICHANNEL RETAILING Store Retailers are encouraging consumers to buy through multiple channels Online PHYSICAL DISTRIBUTION: PLANES, TRAINS, AND MUCH, MUCH MORE Determining the best distribution channels for your product is only half the distribution strategy. Supply Chain Management – planning and coordinating the movement of products along the supply chain Logistics – focuses on the tactics involved in moving the products How will the product flow through the channel from producer to consumer? ELEMENTS OF THE SUPPLY CHAIN SUPPLY CHAIN MANAGEMENT DECISIONS Warehousing Materials Handling Inventory Control Order Processing Customer Service Transportation Security TRANSPORTATION DECISIONS MODES OF TRANSPORTATION: Mode Percentage of U.S. Volume Speed On-Time Dependability Flexibility in Handling Frequency of Shipments Cost Availability Rail 40.2% Medium Slow Medium Medium Low Extensive Truck 40.0% High Fast High Medium High Most Extensive Ship 9.0% Lowest Slowest Lowest Highest Lowest Limited Plane 0.2% Highest Fastest Medium Low Medium Medium Pipeline ** Low Slow Highest Lowest Highest Most Limited PRICING : A HIGH STAKES GAME Pricing plays a key role in the demand for products Price is a tough variable Legal constraints Intermediary pricing (ie. wholesalers, distributors) Stable pricing is not the norm Prices must constantly be evaluated PRICING OBJECTIVES AND STRATEGIES Building Profitability Matching the Competition Creating Prestige Skimming Pricing Prestige pricing – offering a new product at premium price – attract price insensitive buyers Boosting Volume Usually for newly introduced items, rockPricing bottom pricing to drive high volume Every-day-low Pricing WalMart, need I say more! Special sales on limited items (to attract High/Low Pricing customers), higher prices on the rest Pricing selected items below cost to attract Loss Leader Pricing Penetration customers PRICING IN PRACTICE: A REAL WORLD APPROACH Total fixed cost (FC) Breakeven Point (BP) = Price/Unit (P) – Variable cost/unit (VC) Breakeven analysis – the process of determining the number of units that must be sold to cover costs. USING BREAKEVEN ANALYSIS Businesses make decisions to adjust the product price and/or costs. Raise prices Decrease variable costs Outsource labor, use cheaper components? Decrease fixed costs Move your plant to Mexico, advertise less? FIXED MARGIN PRICING Profit Margin – the gap between cost and the price per product. Cost-Based Pricing Demand-Based Pricing CONSUMER PRICING PERCEPTIONS: THE STRATEGIC WILD CARD Consumer price perceptions can defy logic! The link between price and perceived quality can be powerful Consumers will use price as a quality indicator Does odd pricing like $196 or $199 always mean a bargain? PSYCHOLOGICAL PRICING CHAPTER 17: OPERATIONS MANAGEMENT Putting It All Together OPERATIONS MANAGEMENT: IT ISN’T GLAMOROUS, BUT IT MATTERS…. Operations Management – planning, organizing, leading and controlling all the activities in creating value by producing goods and services and distributing them to customers Good Operations Management: Most efficient and effective processes Produce the right goods and services Produce the right quantities Distribute products to the right customers at the right time EFFECTIVENESS VS. EFFICIENCY Efficiency – producing output or achieving a goal at the lowest cost. Effectiveness – completing tasks and producing products that create the greatest value. Doing things right Doing the right thing “There is nothing so useless as doing efficiently that which should not be done at all” Peter Drucker, Management Expert GOODS VS. SERVICES GOODS SERVICES Tangible, physical form, can be touched, seen, handled Intangible, they can be “experienced”, no physical form Can be stored and inventoried Must be consumed when they are produced Can be shipped Must be consumed, where they are provided Are produced independently of the Often require customer involvement consumer Can measure some aspects of quality Quality is based on customer perceptions WHAT DO OPERATIONS MANAGERS DO? Facility Location Process Selection and Facility Layout Inventory Control Scheduling Quality FACILITY LOCATION General Location Factors Examples of Specific Considerations Adequacy of utilities Is the supply of electricity reliable? Is clean water available? Land Is adequate land available for a facility? How much does the land cost? Labor market conditions Are workers with the right skills available? How expensive is labor? Transportation factors Is the location near customers and suppliers? Is appropriate transportation nearby? Quality of life What is the climate like? Are adequate health care facilities available? Legal and political environment Does the local government support new business? What are the local taxes, fees, and regulations? GOING OVERSEAS Low-wage labor is a key reason firms focus overseas but, low wages do not always translate into low cost There are a variety of opportunities in rapidly growing foreign markets Key to balance advantages with drawbacks: Different laws and customs Inadequate infrastructure Inexperienced workers Political instability PROCESS SELECTION AND FACILITY LAYOUT Flow Shops Produce Large Batches Standardized Products Specialized Machinery Standardized Tasks Assembly Line is a Flow Shop Process Job Shops Produce Small Batches Variety of Products General-purpose Machinery Flexible Processes TECHNOLOGY OF OPERATIONS AUTOMATION: LET THE MACHINES DO IT Automation – replacing human operations and control of machinery and equipment with some form of programmed control. Robot – a programmable machine that is capable of manipulating materials in order to perform tasks. ROBOTS • Robots are well suited for dangerous, tedious, dirty and physically demanding tasks. • Robots don’t get tired • Robots are flexible INVENTORY CONTROL: DON’T JUST SIT THERE Why hold inventories… Smooth out production schedules Meet demand increases Reduce switching costs Compensate for forecast errors Why not… Unsold inventory ties up funds Inventory must be warehoused and managed Risk of losses due to spoilage, obsolescence and pilferage REDUCING INVESTMENT IN INVENTORY: JUSTIN-TIME TO THE RESCUE Produce goods and services to meet actual demand. Minimize inventories at all stages of the supply chain through coordination. MANAGING SUPPLY CHAINS Supply chains can be complex Wide range of functions Involve many firms Heavy use of technology RFID Chips Internet has provided great tools for supply chain management TRADE-OFF BETWEEN VERTICAL INTEGRATION AND OUTSOURCING Vertical Integration Gain control over supply chain Begin producing its own parts Buying suppliers Outsourcing Use outside firm for producing supplies Focus on key production areas Cost savings The trend has been to rely more on outsourcing which has become a controversial issue. ENTERPRISE RESOURCE PLANNING (ERP) : CREATING ONE BIG SYSTEM The goal of ERP is to integrate the flow of information ERP systems can be costly and challenging to implement Most firms that complete implementation of ERP systems, report being satisfied with the results FOCUS ON QUALITY Quality improves effectiveness and efficiency Quality helps achieve competitive advantage Lower costs, increases value Poor quality costs DEMING CHAIN REACTION Improve Quality W. Edwards Deming, viewed as the father of the quality movement, first proposed the relationship between quality and business in the early 1950s. Costs decrease because of less rework, fewer mistakes, fewer delays and snags, and better use of time and materials Productivity Improves Capture the market with better quality and lower price Stay in business Provide jobs and more jobs HOW AMERICAN FIRMS RESPONDED TO THE QUALITY CHALLENGE A broad concept of quality: Total Quality Management: Customer Focus Build quality throughout the organization Empowerment of employees Focus on prevention of errors Long-run commitment to continuous improvement INTERNATIONAL ORGANIZATION FOR STANDARDIZATION Founded in 1947 Network of national standards institutes in 150 nations ISO 9000 Certification Generic quality standards Updated and modified, latest version is ISO 9000:2005 Environmental management focused standards: ISO 14000 THE BALDRIGE NATIONAL QUALITY PROGRAM Created by Congress in 1987 to encourage global competition Participating firms are extensively evaluated Detailed reports of company strengths and weaknesses The 2014 Baldrige Award recipients—listed with their category—are: PricewaterhouseCoopers Public Sector Practice, McLean, Va. (service) Hill Country Memorial, Fredericksburg, Texas (health care) St. David’s HealthCare, Austin, Texas (health care) Elevations Credit Union, Boulder, Colo. (nonprofit) Back to the Beginning