HVLS Fans - College of Engineering | SIU

advertisement

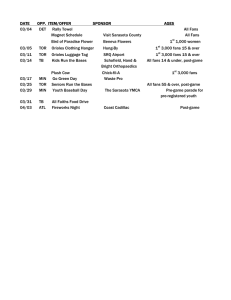

PROPOSAL HVLS FANS Alex Kee Bill Ennis to AISIN MFG. ILLINOIS by SALUKI ENGINEERING COMPANY, TEAM 48 Joel Chaplin Micah Buchanan Kyle Florian Ryan Riffel HVLS Fans: Aisin Mfg. Illinois Page 1 of 47 November 18, 2010 Saluki Engineering Company Senior Engineering Design Center College of Engineering – Mailcode 6603 Carbondale IL 62901-6603 618-453-7031 Jim McReynolds Facilities Engineer 11000 Redco Drive Aisin Manufacturing Illinois Marion, IL 62959 Mr. McReynolds, This letter is in response to your request for proposals concerning the overall comfort of the employees at your facility. Our company has assembled an impressive and competitive proposal for your project, which you will find attached to this letter. Furthermore, I would like to personally thank you for giving us the opportunity to submit a design proposal for this project. The proposal is based on the need for an effective and economical system to provide a comfortable working environment. Design goals include improvements in thermal comfort and heating/cooling costs. Once again, thank you for your consideration. Respectfully, Alex Kee Project Manager, TEAM 48 Saluki Engineering Company HVLS Fans: Aisin Mfg. Illinois Page 2 of 47 Executive Summary The Saluki Engineering Company (SEC) proposes to study three design options for the current Heating, Ventilation, and Air Conditioning (HVAC) systems at AISIN Manufacturing Illinois (AMI) to reduce temperature and energy costs, and to make a recommendation as to which design should be implemented into AMI’s facility. The criteria for the design are cost, effectiveness, and economical benefit. The primary reason for modifying the current HVAC system is to create a system to maintain a comfortable environment through the hot summer months. During research for this proposal, certain standards from the American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) were found regarding thermal comfort, and the design recommendations will be based on these standards. Design 1 will consist of adding a new chiller to the current HVAC system. The size of the new chiller needed will be calculated based on the difference between the current load capabilities and the load requirements during the hot summer months. This addition will create a greater chiller efficiency and lower temperatures for a better work environment in the facility. Design 2 will consist of adding High Volume Low Speed (HVLS) fans to the facility to supplement the current HVAC system to improve the humidity level and air flow, which will increase comfort even if the temperature stays the same. If Designs 1 or 2 will not provide the desired conditions cost-effectively, then the two options will be combined to make up Design 3. An energy audit and economic analysis will also be included in the study. The projected date of completion for the proposed engineering study and design recommendation is April 26th, 2011. It is estimated that there will be no cost to the Client for the study and design recommendation, since this project will be carried out from a consulting standpoint, and all resources and instruments needed are on hand. HVLS Fans: Aisin Mfg. Illinois Page 3 of 47 RESTRICTION ON DISCLOSURE OF INFORMATION The information provided in or for this proposal is the confidential, proprietary property of the Saluki Engineering Company of Carbondale, Illinois, USA. Such information may be used solely by the party to whom this proposal has been submitted by Saluki Engineering Company and solely for the purpose of evaluating this proposal. The submittal of this proposal confers no right in, or license to use, or right to disclose to others for any purpose, the subject matter, or such information and data, nor confers the right to reproduce, or offer such information for sale. All drawings, specifications, and other writings supplied with this proposal are to be returned to Saluki Engineering Company promptly upon request. The use of this information, other than for the purpose of evaluating this proposal, is subject to the terms of an agreement under which services are to be performed pursuant to this proposal. HVLS Fans: Aisin Mfg. Illinois Page 4 of 47 Table of Contents Transmittal Letter (AK) ............................................................................................................... 2 Non-Disclosure Statement ............................................................................................................ 4 List of Figures ................................................................................................................................ 7 List of Tables ................................................................................................................................. 7 Introduction (AK) ......................................................................................................................... 8 Literature Review (MB) ............................................................................................................... 8 HVLS FANS (JC/RR) ............................................................................................................................. 8 Table 1: Comparison of HVLS Fans [1-3] (RR)................................................................................... 9 Concepts (JC) ........................................................................................................................................ 9 Figure 1: Typical Air Foil Design for Fan Blade [4] (JC) .................................................................. 10 Figure 2: HVLS Fan Air Circulation [4] (JC) ..................................................................................... 10 Benefits (JC) ....................................................................................................................................... 11 HVAC SYSTEMS (AK/BE) ................................................................................................................. 11 Chillers - Background (BE) ................................................................................................................ 12 Chiller Controls (BE) ..................................................................................................................................... 12 Advantages of Chillers (BE)........................................................................................................................... 13 Current Setup (AK) ............................................................................................................................. 13 Figure 3: Aisin HVAC Layout ( ) ...................................................................................................... 14 III. THERMAL COMFORT (MB) ..................................................................................................... 15 Figure 4: Thermal Interaction of the Human Body with the Environment [12] (MB) ....................... 16 Figure 5: ASHRAE Summer and Winter Comfort Zones [12] (MB) ................................................ 16 Figure 6: Air Speed to Offset Temp above Warm-Temp Boundaries of Figure 2 [12] (MB) ............ 17 Figure 7: Air Velocities and Operative Temperatures at 50% RH Necessary for Comfort of Persons in Summer Clothing at Various Levels of Activity [12] (MB) ........................................................... 17 Figure 8: Draft Conditions Dissatisfying 15% of Population [12] (MB)............................................ 19 Figure 9: Percentage of People Dissatisfied as Function of Mean Air Velocity [12] (B) ................... 19 IV. SUMMARY (MB) ........................................................................................................................... 20 Basis of Design (RR) ................................................................................................................... 21 Table 2: Design Basis (RR) ................................................................................................................ 21 Project Description (AK/MB) .................................................................................................... 21 Figure 10: Block Diagram (MB) ......................................................................................................... 22 Engineering Specification (MB)................................................................................................. 22 Scope of Work (BE) .................................................................................................................... 22 Subsystems (MB/JC) ................................................................................................................... 23 HVLS Fans: Aisin Mfg. Illinois Page 5 of 47 Current Load Capabilities (MB) ......................................................................................................... 23 Deliverables (MB) .......................................................................................................................................... 23 Energy Audit (MB) ............................................................................................................................... 23 Figure 11: Example for Energy used in Cooling (MB)....................................................................... 24 Deliverables (MB) .......................................................................................................................................... 24 Required Load Calculations (MB) ...................................................................................................... 24 Application for Cooling Load (MB) ................................................................................................... 24 Description of Heat Gain (MB) ...................................................................................................................... 24 Description of Cooling Load (MB) ................................................................................................................ 25 Figure 12: Schematic Relation of Heat Gain to Cooling Load [13] (MB) .......................................... 25 Design Conditions (MB) ................................................................................................................................ 25 Infiltration (MB) ................................................................................................................................. 26 Air Change Method (MB) .............................................................................................................................. 26 Auxiliary Heat Sources (MB) ............................................................................................................. 28 Occupancy (MB) ............................................................................................................................................ 28 Lights (MB) .................................................................................................................................................... 28 Equipment (MB) ............................................................................................................................................. 28 Conduction (Thermal Transmittance) (MB) ....................................................................................... 29 RTSM for Cooling Load Calculations (MB) ...................................................................................... 31 Design Activities (MB) .................................................................................................................................. 31 Load Calculation Based on History of Energy Consumption and Ambient Temps. (MB)................. 31 Deliverables (MB) .......................................................................................................................................... 32 Design 1: Additional Chiller (AK) ....................................................................................................... 32 Design 2: HVLS Fans (JC) ................................................................................................................... 32 Deliverables (JC) ............................................................................................................................................ 33 List of Activities (JC) ..................................................................................................................................... 33 Design 3: Combined System (MB)....................................................................................................... 34 Control System (AK) ............................................................................................................................ 34 Economic Analysis (MB) ...................................................................................................................... 34 References (MB - compile/edit).................................................................................................. 35 Commercial (MB) ....................................................................................................................... 36 Resources Needed (MB) ....................................................................................................................... 36 Organizational Chart (MB) ....................................................................................................... 36 Draft Schedule (MB) ............................................................................................................................. 38 Draft Schedule - Detailed (JC/MB) ..................................................................................................... 39 AIL (MB) ............................................................................................................................................... 40 Appendix - Resumes HVLS Fans: Aisin Mfg. Illinois 41 Page 6 of 47 List of Figures Figure 1: Typical Air Foil Design for Fan Blade [4] ............................................................. 10 Figure 2: HVLS Fan Air Circulation [4] ............................................................................... 10 Figure 3: Aisin HVAC Layout .............................................................................................. 14 Figure 4: Thermal Interaction of the Human Body with the Environment [12].................... 16 Figure 5: ASHRAE Summer and Winter Comfort Zones [12] ............................................ 16 Figure 6: Air Speed to Offset Temp above Warm-Temp Boundaries of Figure 2 [12] ........ 17 Figure 7: Air Velocities and Operative Temperatures at 50% RH Necessary for Comfort of Figure 8: Draft Conditions Dissatisfying 15% of Population [12] ........................................ 19 Figure 9: Percentage of People Dissatisfied as Function of Mean Air Velocity [12] ........... 19 igure 10: Block Diagram ....................................................................................................... 22 Figure 11: Example for Energy used in Cooling ................................................................... 24 Figure 12: Schematic Relation of Heat Gain to Cooling Load [13] ...................................... 25 List of Tables Table 1: Comparison of HVLS Fans [1-3] .............................................................................. 9 Table 2: Design Basis ............................................................................................................ 21 HVLS Fans: Aisin Mfg. Illinois Page 7 of 47 Introduction In the summer months, when temperatures reach well above 90°F, buildings turn into ovens. To counteract the outside conditions, most buildings are fitted with an air conditioning/ventilation system. In some industrial settings with large machines creating a large amount of heat, these systems are not sufficient to maintain a comfortable environment which creates a problem for industrial production. Production requires employees to do the work needed to maintain a steady process, but when employees are uncomfortable productivity can decrease. American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE) provides optimum environmental conditions for worker comfort. The goal of this project is to find a way to provide such an environment to not only help to increase production through supplying thermal comfort, but also cut down on energy costs. Literature Review HVLS FANS High Volume Low Speed (HVLS) fans are a relatively new technology that is starting to gain momentum in the HVAC world. Since the technology is so new, there are only a few major producers of these fans which include Macro Air, BigAssFans, and Rite-Hite. Table 1 shows some specifications of fans comparable in maximum displacement and horsepower from these companies. HVLS Fans: Aisin Mfg. Illinois Page 8 of 47 Company MacroAir Model Name MaxAir24 Diameter (ft.) # of Blades Power of Motor (HP) Max Displacement (CFM) Max Speed (RPM) Max Effective Area (ft2) Fan Weight 24 6 2.0 376,804 65 20,000 236 Big Ass Fans Powerfoil X 24 10 2.0 345,941 42 20,000 439 Big Ass Fans Powerfoil X Plus 24 10 2.0 368,516 39 30,000 446 Rite-Hite Rite-Hite Rite-Hite Revolution Revolution Revolution 24 4 2.0 428,000 48 22,000 300 20 4 2.0 400,000 58 20,000 292 16 4 2.0 365,000 72 20,000 284 Table 1: Comparison of HVLS Fans [1-3] Because Aisin has decided to test out a fan from Marco Air, this is where the project will start. Macro Air has a wide range of fans from which to choose. They have a fan for any situation and available in every electrical voltage, so they can be implemented into the existing electrical system with minimal work. Currently, Aisin is using the MaxAir24 (see Table 1) as a demonstration model on the floor. Concepts HVLS fans were designed by looking at the physics of air movement and at how to improve overall efficiency. The first thing that was addressed was how to make a fan that needed a less powerful motor. Since the laws of physics dictate that the power needed to drive a fan is proportional to the speed of the fan cubed, the logical answer would be to create a low speed fan. Using this logic engineers began looking at ways to design low speed fans. To do this they turned their attention to the field of aviation. This is from where the idea came to use an airfoil shape for the blades of the fan. HVLS Fans: Aisin Mfg. Illinois Page 9 of 47 Figure 1: Typical Air Foil Design for Fan Blade [4] These airfoil blades let the fans move large quantities of air at very low speeds. The fan blades use an air foil design with greater pitch on the blade to get air flow upwards of 300,000 cfm and produce around 100 lbf of thrust. The chord length also affects the performance of the blade (in general, the longer the chord length the more lift the blade will have). The design is especially impressive as this air movement is all done at a low velocity, allowing workers to remain undisturbed by windy conditions. Instead the fans produce low speed columns of air that hit the ground and spread out along the floor, reaching well beyond the footprint of the fan. This effect is called the floor jet and has a height that is directly proportional to the diameter of the fan. Under ideal conditions a 24ft fan would produce a floor jet of 108 inches. The figure below illustrates the air movement of the fan in a large room. Figure 2: HVLS Fan Air Circulation [4] Another carry over from aviation is the concern for weight. Since weight is the enemy when one is trying to make something fly, the wings and rotors are made of lightweight strong materials such as aluminum and advanced alloys. Using this technology in the fans helped reduce the HVLS Fans: Aisin Mfg. Illinois Page 10 of 47 rotating mass and hanging weight of the fan, and since the technology is already there, costs are kept reasonable. The efficient design along with a small rotating mass allows these fans to be powered by 1-2hp electric motors. This translates to more economical operating costs since fewer fans would be required to keep conditions comfortable. Benefits HVLS fans result in decreased energy costs in relation to heating and cooling in every facility that has been looked into. From research, the actual energy savings have varied based on the size of the building, layouts, and individual comfort levels, but seem to range from 10 to 30%. Besides energy savings, there are also many other benefits of HVLS fans. When installed in buildings, people report that the humidity levels have decreased significantly, the air quality has improved due to better mixing of the air, and worker productivity has also improved. In the summer months, these fans are best used at a high speed setting, pushing a lot of air down from the ceiling. In the winter, most people want to reverse the fans to get the best effect. However, this is actually counterproductive. The most effective way to use these fans during cold months is to keep them blowing down but at a very slow speed. This gradually moves the hot air down to the workers without creating any draft effect or wind chill, as discussed later. [4-8] HVAC SYSTEMS In order to study the effects of adding HVLS fans to the environment, it is important to have a solid understanding of HVAC (heating, ventilating, and air-conditioning) systems – both of how they work and what the current setup at Aisin is. If the addition of fans is insufficient to reach requirements, it is possible that additional cooling will be required via a new chiller or some other method of HVAC. HVLS Fans: Aisin Mfg. Illinois Page 11 of 47 Chillers - Background HVAC chillers are refrigeration systems that provide cooling for industrial and commercial applications. Chillers consist of a compressor, condenser, thermal expansion valve, evaporator, reservoir, and stabilization assembly. Chilled water systems operate like a normal air conditioning unit except they use water instead of refrigerant in the condenser unit. A watercooled air chiller works by pumping refrigerant through coils that cool the water, filling the condenser coils with the circulating cool water. Refrigerant is compressed, creating a high pressure gas. The condenser uses cool water to condense the compressed gas turning it into a warm liquid. The warm liquid goes through the thermal expansion valve releasing refrigerant into the evaporator while converting the warm liquid into a cool, dry gas. A hot gas bypass is generally used to warm up the evaporator to stabilize the temperature of the chilled water. The water is then pumped from the reservoir to the compressor to restart the cycle. The temperature of the water pumped through the coils is determined by the set point of the chiller. The temperature change through the chiller is typically around 10oF. The normal temperature of the water leaving the chiller is generally around 45oF, so the water returning to the chiller is generally around 55oF. [9] Chiller Controls There are three different sizes for the power sources of the chiller controls. These power sources are given by three numbers separated by forward slashes, which refer to the voltage, frequency and phase. The power sources for the controls come in the following sizes: 208-230/60/3, 380/50/3, and 460/60/3. HVAC chillers can have a local or a remote control panel with temperature and pressure indicators. Some control units also have microprocessor controls, emergency alarms, and an integral pump. HVAC chillers can also be used to cool plastics, HVLS Fans: Aisin Mfg. Illinois Page 12 of 47 printing equipment, laser cutting machines, and magnetic resonance imaging equipment. The microcomputer control panel includes all controls necessary for safe and reliable operation of the chiller. There are many types of controls available for chillers. Fastforward adaptive control is a predictive control strategy used to compensate for load changes. Soft loading is a control used to accommodate load changes or temperature set point by gradually applying these changes, preventing unnecessary cycling by the chiller. Multi-objective limit arbitration keeps the chiller focused on its main priority (evaporator exit temperature) until it can no longer obtain its ideal temperature, then it switches to the chiller’s second priority. The adaptive frequency drive control mathematically figures the best position for the inlet guide which allows the system to run longer with higher efficiency. The variable primary flow control reduces the energy consumed by pumps. Variable flow compensation improves the chiller’s ability to accommodate variable flow. With this information, it will be possible to look into coupling the systems (HVLS fans and chillers) to find the best method for controlling the systems. [9-11] Advantages of Chillers Air chillers are convenient as they permit components of the system to be sold separately, allowing the engineer to strategically place different parts of the system to accommodate space specifications. Chilled water refrigeration systems are preferred because of their contained use of refrigerant. The refrigerant in these units is centralized minimizing the risk for leaks or making them easier to contain if one does arise. Current Setup HVAC systems are used to make for a more comfortable indoor environment and are employed by many different sizes of indoor environments ranging from an automobile to a 290,000 square foot automobile component manufacturing plant such as Aisin Mfg. There are also different HVLS Fans: Aisin Mfg. Illinois Page 13 of 47 types of HVAC systems. Trane offers a Direct-Expansion Unitary System, where an evaporator is in direct contact with the air stream, and a Chilled Water Applied System, which is the system currently in use at Aisin. A chilled-water applied system uses “chilled water to transport heat energy between the airside, chillers and the outdoors” (Trane). Trane is not the only HVAC manufacturer on the market; during a period of expansion, Aisin doubled the size of its manufacturing facility and added an Aaon HVAC system to the addition which is similar to the existing Trane setup. The chillers at Aisin have a capacity of 400 tons, and are set to cool the water to 42 oF. They are connected to seventeen roof top units that pump the cooled air. Twelve of the roof top units are responsible for providing conditioned air to the main manufacturing section of the building that is being studied (See Figure 3 – not to scale). Figure 3: Aisin Manufacturing HVAC Layout With temperatures topping around 83 to 85oF inside the manufacturing section, these chillers run at maximum capacity 24 hours a day. During the summer months, the temperature level in the plant often reaches unacceptable levels, and since the chillers are running at full capacity, there is no way for the current system to keep the environment at a comfortable temperature. HVLS Fans: Aisin Mfg. Illinois Page 14 of 47 In such situations, many companies have made the decision to simply add another chiller to the equation. However, chillers that are the size of those at Aisin are quite expensive, and there are other ways to deal with these uncomfortable temperatures. In looking for a solution to the problem at Aisin, the effect of airflow through the plant to make for a more comfortable working environment will be studied. One way to improve the airflow is the addition of the HVLS fans in order to circulate the cool air from the AC units to all employees on the plant floor. THERMAL COMFORT Thermal comfort, as stated by ASHRAE Standard 55, is “that condition of mind that expresses satisfaction with the thermal environment”. In itself, thermal comfort is not quantifiable but is based on one’s physical, psychological, physiological, as well as other processes. However, it is possible from an engineering standpoint to procure quantitative stipulations for an environment that will provide for thermal comfort for an estimated percentage of satisfied population. These standards are based on combined calculations of a heat transfer energy balance of the human body in varying conditions as well as results of surveys taken of people in these environments. The environmental factors affecting a person’s thermal balance and therefore his or her thermal comfort include the surrounding air dry bulb temperature, humidity, relative velocity, and radiation [13]. Besides these, personal variables including the amount of activity and clothing of a person also affect thermal comfort. While some aspects of thermal comfort from the biological standpoint are beyond the scope of this review, providing a comfortable work environment is essential for employee satisfaction. Estimating thermal comfort can be simplified by doing an energy balance on the body (see Figure 3), taking into consideration the majority of methods of heat transfer to and from the body. [12] HVLS Fans: Aisin Mfg. Illinois Page 15 of 47 Figure 4: Thermal Interaction of the Human Body with the Environment [12] The most applicable portion of thermal comfort for this project deals with the effect of wind speed and humidity on thermal comfort (in relation to temperatures), both of which could potentially be affected by the installation of HVLS fans and/or an additional HVAC unit. Although based on a nearly sedentary level of activity, Figure 4 gives an estimate of acceptable levels of operative temperature and humidity for environments of little to no air movement for people wearing clothing appropriate for the season (1.0/0.5 clo winter/summer). Figure 5: ASHRAE Summer and Winter Comfort Zones [12] HVLS Fans: Aisin Mfg. Illinois Page 16 of 47 With the addition of the HVLS fans, the hope is that the HVAC units will run at a lower load and that a higher temperature will be acceptable with the increased air movement. This would allow for potential energy saving. Figure 5 displays the air speed required to offset temperatures above ideal operative temperature [12]. Similarly, Figure 6 shows necessary air velocities for operative temperatures at 50% relative humidity to maintain comfort for different levels of activity measured in mets. Figure 6: Air Speed to Offset Temp above Warm-Temp Boundaries of Figure 2 [12] Figure 7: Air Velocities and Operative Temperatures at 50% RH Necessary for Comfort of Persons in Summer Clothing at Various Levels of Activity [12] HVLS Fans: Aisin Mfg. Illinois Page 17 of 47 It should also be mentioned that fans potentially could reduce dissatisfaction due to radiant temperature asymmetry and vertical air temperature difference, as a significant amount of mixing and more even conditions would occur throughout the plant, as discussed earlier. With an increase in air speed, it is possible to cause discomfort due to drafts, especially during winter months. Active persons are much less sensitive to these discomforts, [13] and it can be assumed that the majority of workers on the floor that would be affected by HVLS fans will be somewhat active. However, in the winter months for workers doing near sedimentary work, draft could potentially become an issue. For this reason, it is important to examine effects of air movement. As stated earlier, in the winter HVLS fan manufacturers recommend running the fans at lower speeds. This will cause warm air near the ceiling to be slowly pushed downward. Figure 7 shows the effects of wind speeds and turbulences causing 15% of the population to be dissatisfied. It would be wise to keep this concept in mind in determining operating conditions of HVLS fans or the HVAC system as a whole. Along these same lines, Figure 8 shows the percentage of people dissatisfied for different temperatures as air velocities increase [12]. HVLS Fans: Aisin Mfg. Illinois Page 18 of 47 Figure 8: Draft Conditions Dissatisfying 15% of Population [12] Figure 9: Percentage of People Dissatisfied as Function of Mean Air Velocity [12] HVLS Fans: Aisin Mfg. Illinois Page 19 of 47 Using this gathered information and applying it while making calculations and modeling installation of the HVLS fans and/or a new HVAC system/chiller, it will be possible to create an environment that will be comfortable for team members working on the floor at Aisin. Knowing these requirements will allow modeling to be done in such a manner as to provide a comfortable work environment while potentially reducing heating and cooling costs. While this information is for standard acceptable conditions, it should be noted that Aisin has their own requirements. The plant area where the study will be done is required to be in the range of 68 to 82oF. While a specific humidity range is not required, a comfortable working environment is necessary for team members working on the floor. SUMMARY From what this information gathered, the thought is to create three possible solutions using a combination of systems researched. Using the current chiller setup and knowing current conditions, it will be possible to find the load of which Aisin is currently capable. Also, it will be possible to perform calculations to find the load required of the HVAC system in a worst case scenario (using data from the hottest days of the year). Knowing the difference between these two loads, the load required to fulfill the need at Aisin will be known. From this point, it will be possible to choose an appropriate system or combination of systems to make up this difference. Three design systems will be investigated and set forth as options to Aisin: an additional chiller to supplement the current chiller, a setup of HVLS fans, and a combination of these. For choosing the additional chiller size, the information gathered in the load calculations can be used directly. For the HVLS fans option, conditions for thermal comfort based on wind speeds, humidity, temperature gradient, etc. will be used to determine the number and placement of fans. HVLS Fans: Aisin Mfg. Illinois Page 20 of 47 For the combined system, the possibility of using both of the systems on a smaller level will be investigated. Cost analyses can then be applied to each setup to help determine the best design. Basis of Design The documents listed in Table 2 provide the basis for the designs of SEC Team 48. In the event of a conflict between the Request for Proposal (RFP) and the Client’s design requests stated in the project definition, the Client’s design requests control. As new data becomes available, Client may supply additional data and criteria that will be incorporated into the designs. All designs will comply with the 2011 National Electric Code. Request for Proposal (RFP) 16-Sept-10 SEC RFP Project Definition – Attachment 1 SEC RFP Design Report Deliverables Checklist – Attachment 2 16-Sept-10 16-Sept-10 2011 National Electric Code (NEC) 16-Sept-10 Proposal for Project # F10-48-AISINFAN 18-Nov-10 Table 2: Design Basis Project Description The purpose for modifying the current HVAC system is to create a more comfortable work environment when the current system cannot keep up with the ambient conditions. This modification must keep the environment at a comfortable temperature while reducing energy usage to cool the facility. Three designs to fix Aisin’s cooling problem will be submitted to Aisin for consideration, as described below, along with a brief economic analysis of each. Prior to these designs, a look at current load capabilities at Aisin will be investigated, as will a load size required to maintain acceptable conditions during peak cooling. Also, an energy audit of the current system will be done as a basis for the economic analysis. The layout of these subsystems is shown below in a block diagram. HVLS Fans: Aisin Mfg. Illinois Page 21 of 47 The block diagram is composed of three levels, the design activities of each to be done simultaneously. Figure 10: Block Diagram Engineering Specification The output of this project will be three proposed designs to solve Aisin’s problem of cooling to comfortable temperatures during peak cooling times. Designs will be done so as to produce yearround comfort, keeping temperatures between 68 and 82oF as required by Aisin, or at equivalent conditions according to ASHRAE’s definitions of thermal comfort based on incorporated wind speeds and other conditions. Scope of Work The following subsystems give in some detail what will be designed and presented to Aisin. For anything beyond what is stated, Team 48 is not responsible though additional work may be done HVLS Fans: Aisin Mfg. Illinois Page 22 of 47 as time allows. Team 48 will be working only as a consulting group and will not make a final decision as to which direction Aisin should go. Team 48 will be merely submitting suggested designs needed. Subsystems Current Load Capabilities In order to determine what will be needed to maintain thermal comfort throughout the year, it will first be important to examine the current system and find what it is capable of cooling (and heating – to be used to later examine energy savings). To do this, the ratings of the current chillers will be taken to find cooling ability. Also, temperatures at which the chiller becomes unable to keep up will be examined, and conditions at which this occurs will be noted. Deliverables Deliverables will include a report of the calculated total load capabilities. Energy Audit Using past energy bills, an energy audit will find current costs of heating and cooling. This will be done by plotting average monthly gas and electrical usages from 2005 to 2010. For heating, the approximated base load will be taken to be the amount of gas used during summer months, and for cooling, the base load can be approximated by finding the electrical usage during the winter months. This will allow for calculating the approximate energy used in both heating and cooling by finding the amount under the curve but above the baseline (see example Figure 10.) HVLS Fans: Aisin Mfg. Illinois Page 23 of 47 950000 Electricity Used Monthly BTU 900000 850000 COOLING LOAD 800000 750000 BASE LOAD 700000 Figure 11: Example for Energy used in Cooling Deliverables From the calculations done, all spreadsheets will be submitted to Aisin showing results of the energy audit. Required Load Calculations To determine the unit size needed to offset the current chiller system for year-round thermal comfort at Aisin, an approximation of the actual load required to cool to desired temperatures will be calculated. This load calculation will be based on a time when Aisin is running at full production and when ambient temperature is at a design temperature of 100°F (99% of the time, the ambient temperature in Southern Illinois is below this temperature). [13] Application for Cooling Load Description of Heat Gain Heat gain is the rate at which energy is generated or transferred within a space. This energy can be sensible or latent heat and must be computed separately. This heat gain can be in the form of HVLS Fans: Aisin Mfg. Illinois Page 24 of 47 heat conduction through boundaries, sensible heat convection and radiation from surfaces within the space, latent heat generation within the space, solar radiation into the space, and ventilation and infiltration air. Description of Cooling Load Cooling load is the rate at which energy must be removed from a conditioned space in order to maintain the conditions with the space. It is different from the heat gain because radiation from inside wall surfaces and objects inside do not directly heat the air inside the space. The contribution to the cooling load from this radiant energy is delayed because the energy is first absorbed by floors and interior walls and later released to the space by convection. This is displayed in the following schematic. Figure 12: Schematic Relation of Heat Gain to Cooling Load [13] Design Conditions Design conditions are given by ASHRAE, and will be used in load calculations. These conditions include dry bulb and mean coincident wet bulb temperatures that equaled or exceeded 0.4, 1, and 2% of the hours during a year. Also, daily range of dry bulb temperatures is given for the difference between the average maximum and minimum for the warmest month, which has an effect on the energy stored by the building structure. Also given are mean wind speed and HVLS Fans: Aisin Mfg. Illinois Page 25 of 47 wind direction for the 0.4% design condition. However, for summer conditions the local wind velocity is generally assumed to be about 7.5 mph or 3.4 m/s [13]. Depending on the time of day, the hourly outdoor temperature is assumed to vary between the outdoor design temperature and a minimum value of temperature. Thus is given by the following equation: 𝑇𝑜 = 𝑇𝑑 − 𝑋(𝐷𝑅) (1) where 𝑇𝑑 is the design dry bulb temperature, 𝑋 is the percentage of daily range, and 𝐷𝑅 is the daily range. [12, 13] Infiltration Outside air leaks into a building no matter how well constructed it may be and an equal amount of conditioned air leaks out of the building. This leakage of air through cracks and openings around doors and windows is called infiltration air, which results in heat loss or gain. Because Aisin has many bay doors which may be opened at different times, an estimate will be found based on the average number of pickups/deliveries with associated time doors are spent open for infiltration calculations. Although not part of the project per se, it would be suggested that Aisin that air curtains be looked into for any bay doors that are often in use. This may help to reduce heat gain/loss from these points. Also, it may be possible to tie in rooftop units or proposed HVLS fans to the doors to allow them to be automatically turned off in the vicinity of the door when opened. Air Change Method For cooling load calculations, infiltration and required ventilation will be combined and estimated as close as is possible from further investigation. The air-change method will be used to calculate what effect this has on heat gain/loss. For this method, the flow rate of outdoor air HVLS Fans: Aisin Mfg. Illinois Page 26 of 47 that crosses the boundary of the building and requires conditioning is expressed in terms of air changes per hour (ACH). This relationship is shown in the following equation: 𝑄̇ = 𝐴𝐶𝐻 × 𝑉 𝐶𝑇 (2) where 𝑄̇ is infiltration in cfm or m3/s, 𝑉 is building volume in ft3 or m3 and 𝐶𝑇 is 60 for English units and 3600 for SI units. ACH depends on construction, building type and use. Newer buildings, such as Aisin, generally are in a range of 0.3 to 0.7 ACH. However, losses from the bay doors may need to be added into this, as will any values from ventilation. Also, this number can vary based on local chemical use. Infiltration is usually based on volume flow rate at outdoor conditions. Therefore, the equation for calculating latent heat transfer due to infiltration is 𝑞̇ 𝑎𝑖𝑟,𝑙𝑎𝑡𝑒𝑛𝑡 = 𝑄̇ (∆𝑊)ℎ𝑓𝑔 𝑣𝑜 (3) where ∆𝑊 = (𝑊𝑖 − 𝑊𝑜 ) or ∆𝑊 = (𝑊𝑜 − 𝑊𝑖 ) depending whether the HVAC system is heating or cooling, 𝑣𝑜 is the specific volume of the outdoor air, hfg is latent heat of vaporization at outdoor conditions and 𝛥𝑊 is the difference in design humidity ratio. Similarly, sensible heat transfer due to infiltration is 𝑞̇ 𝑎𝑖𝑟,𝑠𝑒𝑛𝑠 = 𝑄̇ 𝑐𝑝 (∆𝑇) 𝑣𝑜 (4) where ∆𝑇 = (𝑇𝑖 − 𝑇𝑜 ) or ∆𝑇 = (𝑇𝑜 − 𝑇𝑖 ) depending whether the HVAC system is heating or cooling, 𝑐𝑝 is the specific heat of the air, and ∆𝑇 is the difference in design temperature. HVLS Fans: Aisin Mfg. Illinois Page 27 of 47 Auxiliary Heat Sources Another large source responsible for heat gain is auxiliary heat sources from within the plant. Being a manufacturing plant with several plastic injection lines and steam ovens, Aisin has several large sources of heat from equipment as well as from its team members and lighting. Occupancy Having over 700 employees, split up over 3 shifts, Aisin will definitely have a heat gain due to occupancy. This heat gain is made up of sensible and latent heat, the proportions of which depend on the level of physical activity. Typical values of these ratios are given by ASHRAE and will be used in these calculations. Also, for occupancy, it is generally assumed that sensible heat gain is 70% radiative (which will be slightly delayed) and 30% is convective (instant cooling load). [13] Lights Lighting is divided into radiative and convective loads. Lights are often turned off at times to conserve energy. When lights are turned off, the cooling load will decrease, but it does not immediately go to zero due to the radiative component. The instantaneous rate of heat gain is given by the following equations: 𝑞̇ = 3.41(𝑊 𝐹𝑢 𝐹𝑠 ) Btu [ hr ] (5) 𝑞̇ = (𝑊 𝐹𝑢 𝐹𝑠 ) [𝑆𝐼] (6) where 𝑊 is the total light wattage, 𝐹𝑢 is the use factor, and 𝐹𝑠 is the ballast factor. Heat gain to a conditioned space from fluorescent lighting is assumed to be 59% radiative and 41% convective. Equipment For cooling load calculations, heat gain from miscellaneous equipment is generally assumed to be 70% radiative and 30% convective. [13] HVLS Fans: Aisin Mfg. Illinois Page 28 of 47 Likely the largest source of heat gain at Aisin is due to equipment. To find this portion of gain, the different types of equipment will be researched to find estimated amounts of heat given off. If this cannot be found, heat gain will be estimated based on energy used in the process, assuming that a given percentage is eventually turned to heat (i.e., for a plastic injection machine) nearly all electricity used to run the machine ends up as heat either emitted from the machine and barrel or by the process. Some energy is used to open and close the mold, and this would be estimated. There are two basic forms of calculating heat gain from equipment. Evaluation-Based-onOperating-Schedule will be used if possible, which examines each piece of equipment individually [13]. Equations can be used for electrical motors and other types of equipment. When not enough information is given, the maximum hourly heat gain can be estimated using 50% of the catalog input rating. Otherwise, a simpler method is the Wattage-Per-Square-Foot Basis which is generally employed when not enough data is available for the use of the first method. This method uses estimate factors established by experience for a given type of building and multiplies this by the square footage. [13] Conduction (Thermal Transmittance) This portion of the load calculation incorporates the effects of solar radiation, thermal radiation, and convection. To calculate this heat gain, the hourly outdoor air dry bulb temperature To and the effective temperature of outdoor air (sol-air temperature) are first calculated as shown: 𝑇𝑒 = 𝑇𝑜 + HVLS Fans: Aisin Mfg. Illinois 𝛼𝐺𝑡 − 𝑇𝑐𝑜𝑟𝑟 ℎ𝑜 (7) Page 29 of 47 where 𝑇𝑜 is the hourly outdoor air dry bulb temperature, 𝛼 is solar absorptivity, 𝐺𝑡 is total solar irradiation incident on the surface, ho is the exterior surface heat transfer coefficient/conductance, and 𝑇𝑐𝑜𝑟𝑟 is thermal radiation correction term (7°F for horizontal surfaces and 0°F for vertical surfaces). [13] Because there are basically no windows on the floor at Aisin, conduction heat gains due to windows will be negligible. For the walls and roof, after hourly 𝑇𝑜 and 𝑇𝑒 for a surface have been determined for all the 24 hours of the design day, the heat conduction at the inside surface of the walls and roof is obtained from the equation 𝑛=23 𝑞̇ = 𝐴 ∑ 𝑌𝑃𝑛 (𝑇𝑒,𝑛𝛿 − 𝑇𝑟𝑜𝑜𝑚 ) (8) 𝑛=0 where 𝐴 is surface area, 𝑌𝑃𝑛 is the nth periodic response factor, 𝑇𝑒,𝑛𝛿 is the value of 𝑇𝑒 , n hours ago and 𝑇𝑟𝑜𝑜𝑚 is the room temperature. Periodic response factors for multilayer walls will be found using a computer program (HvacLoadExplorer) which is associated with [13]. Alternatively, a simpler method of finding thermal transmittance may be used, which is not applicable to the Radiant Time Series Method (RTSM) for cooling but will allow for an easy method of finding heat gain due. This is the following. 𝑞 = 𝑈𝐴∆𝑇 (9) where 𝑈 is the U-factor equal to the inverse of the resistance and ∆𝑇 is the temperature difference of the conditioned space and the ambient. HVLS Fans: Aisin Mfg. Illinois Page 30 of 47 RTSM for Cooling Load Calculations This method applies a radiant time series to the radiative portion of the heat gain. For this reason, all gains must be divided into radiative and convective parts. The hourly cooling load due to the radiative portion of each heat gain is obtained using the following equation. 𝑞𝐶𝐿,𝑡 = 𝑟𝑛 𝑞̇ 𝑡−𝑛𝛿 = 𝑟0 𝑞̇ 𝑡 + 𝑟1 𝑞̇ 𝑡−𝛿 + 𝑟2 𝑞̇ 𝑡−2𝛿 + 𝑟3 𝑞̇ 𝑡−3𝛿 + ⋯ + 𝑟23 𝑞̇ 𝑡−23𝛿 (10) where rn is the nth radiant time factor, 𝑞𝐶𝐿,𝑡 is the cooling load at the current hour, and 𝑞̇ 𝑡−𝑛𝛿 is the heat gain, n hours ago. [13] Design Activities List of activities for the RTSM calculation for load requirement include: Determination of exterior boundary conditions-incident solar radiation and sol-air temperatures Calculation of heat gains Splitting heat gains into radiative and convective portions Determining cooling loads due to the radiative portion of heat gains Summation of loads due to convective and radiative portions of heat gains Load Calculation Based on History of Energy Consumption and Ambient Temps. This method will be used as a check of the previous approach to load sizing calculations. This method uses the history of energy usage as well as corresponding average ambient temperatures along with the seasonal energy efficiency ratio rating of the system to calculate expected loads given an ambient temperature. Using a design temperature, it will then be possible to find the required load. This method will give the expected cooling load at a given temperature. To find the maximum load, an error analysis will be done, and the maximum load will be estimated based on a chosen HVLS Fans: Aisin Mfg. Illinois Page 31 of 47 prediction interval; e.g. at 90% confidence, the predicted cooling load at 95/78oF (typical design conditions) is 225 Btu/ft2 +/-50Btu/ ft2. Deliverables Deliverables for the Load Calculation subsystem will include spreadsheets produced using the RTSM procedure, listing the load requirement found as well spreadsheets produced for load calculation requirements based on the history of energy consumption. This information will be incorporated into the final design report submitted to Aisin. Design 1: Additional Chiller In order for the HVAC system to keep up with the troubling conditions, the feasibility of an additional chiller added to the current chiller system will be investigated. The size required will be determined from the difference in current and required load calculations, described in subsystems 1 and 3. The current chiller systems’ manufacturers will be kept in mind in looking at possible units to install. A report will be submitted to Aisin containing the recommendations for this chiller. Design 2: HVLS Fans This subsystem will be used to supplement the HVAC system to provide more efficient heating, cooling and ventilation year round. This will lead to increased thermal comfort, better air circulation, lower humidity, and lower energy costs. The fans will be integrated into the current HVAC system. When running, they will circulate the cold air from the A/C system down to the workers on the floor. As the name implies, they will do this at very low air speeds. An average air speed for a 24ft fan is 600 ft/min where a 30in fan would produce air speeds near 4800 ft/min. This slower airspeed gives workers the cooling HVLS Fans: Aisin Mfg. Illinois Page 32 of 47 effect of a light breeze without overly windy conditions. This added cooling effect will make the workers feel cooler without changing the ambient temperature of the plant. We will consult ASHRAE standards to determine the optimum air speed and the relative cooling effect it will have. Factors to be considered with HVLS fans: Design of fan o Airfoil blade design and chord length o Construction of fan o Estimated life span Placement of fans Obstructions on floor CFM ratings and how they were obtained RFI and EMI compliancy Deliverables Fan specifications Expected energy usage Fan placement in factory Suggested operation during heating, cooling and ventilation Projected energy savings and return on investment List of Activities Collect data from temporary fan in building Estimate effective area with current conditions on floor Build model to estimate fan interaction Design fan layout in factory Estimate effect on heating and cooling Calculate operation cost on annual basis HVLS Fans: Aisin Mfg. Illinois Page 33 of 47 Design 3: Combined System Combining attributes of designs 1 and 2, design 3 will be a proposal for a system composed of HVLS fans and smaller chiller to supplement the current HVAC system. A balance will be found that will create the environment needed for thermal comfort. A cost summary will be compiled to be used in the economic analysis, and all design information will be submitted in the final design report to Aisin as an option to correct the current problem. Control System In the event of the HVLS fans being able to provide for a comfortable environment, a control system for the fans will need to be put in place. Research will be done to provide a choice of three different control systems for the HVLS fans. A report of the findings will be submitted to Aisin in the final design report. Economic Analysis When designs 1, 2, and 3 have been completed, a cost analysis will be done on each. This may include simple payback period calculations, life cycle cost/savings analysis, and/or benefit to cost ratio. Calculations will be done to find net present values and/or net future values of cash flows created for each design. These will be compared to find the most economical choice. All results will be incorporated into the final design report submitted to Aisin. HVLS Fans: Aisin Mfg. Illinois Page 34 of 47 References HVLS FANS [1] "Installation and Warranty." MacroAir Technologies, Inc., 2010. Web. 4 Oct. 2010. <http://www.macro-air.com/products/installation-and-warranty>. [2] "Literature - Rite Hite - Revolution HV/LS Fans." Rite Hite - Revolution HVLS Fans. Rite Hite HVLS Fans, 2010. Web. 4 Oct. 2010. <http://www.ritehitefans.com/pages/literature>. [3] "Technical Downloads." Big Ass Fan Co. Delta T Corp., 2010. Web. 4 Oct. 2010. <http://www.bigassfans.com/page/technical_downloads>. [4] Macro air. (2010). Retrieved from www.macro-air.com, 1 Nov. 2010. [5] DeGaspari. "A fan for all seasons." Mechanical Engineering 121.12 (1999): 58. MasterFILE Premier. EBSCO. Web. 11 Oct. 2010. [6] "HVAC manufacturer finds a cool solution with HVLS fans." Plant Engineering 63.9 (2009): 37-39. Academic Search Premier. EBSCO. Web. 30 Sept. 2010. [7] "HVLS Fan." Material Handling Management 65.7 (2010): 34. Business Source Complete. EBSCO. Web. 30 Sept. 2010. [8] Oleson, Rick. "The top 10 myths about HVLS fans." Plant Engineering 62.7 (2008): 40. Academic Search Premier. EBSCO. Web. 30 Sept. 2010. HVAC SYSTEMS [9] “Chilled Water Applied Systems - HVAC Systems”. Trane, 2010. Web. 4 Oct. 2010. <http://www.trane.com/COMMERCIAL/HvacSystems/1_1_ChilledWater.aspx?i=863> [10] “Water Chiller System”. Web. 5 Oct. 2010. <http://www.air-conditioning-and-refrigeration-guide.com/water-chiller-system.html> [11] “HVAC Chillers”. Global Spec, 2010. Web. 5 Oct. 2010. <http://www.globalspec.com/LearnMore/Building_Construction/HVAC/Cooling/HVAC_Chillers> THERMAL COMFORT [12] 2009 ASHRAE Handbook - Fundamentals (SI Edition). American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc, 2009. [13] McQuiston, Faye C, Jerald D Parker and Jeffrey D Spitler. Heating, Ventilating, and Air Conditioning Analysis and Design. 6th Edition. Hoboken: John Wiley & Sons, 2005. HVLS Fans: Aisin Mfg. Illinois Page 35 of 47 Commercial Saluki Engineering Company hereby offers to do the work defined in this proposal for the costplus-award-fee determined by Aisin Mfg. Illinois, equal to zero dollars or greater ($0.00 +). This project will be conducted as a consulting service offered to Aisin free of charge, with the understanding that all expenses arising that Aisin deems acceptable for equipment, travel, etc. will be covered by Aisin. This proposal is valid for a period of 30 days from the date of the proposal. After this time, Saluki Engineering Company reserves the right to review it and determine if any modification is needed. Resources Needed The following is a table of items to be used in this project. All of the items are either on hand or will be borrowed. ITEM 1 2 3 4 5 DESCRIPTION Anemometer Psychrometer Pyrometer Infrared Camera HvacLoadCalc Software QUANTITY 1 1 1 1 1 $ EACH Borrowed Borrowed Borrowed Borrowed On Hand $ 0.00 0.00 0.00 0.00 0.00 Organizational Chart Below is an organizational chart for Team 48, which includes team members’ names, discipline, and principle responsibility, as well as the name of the faculty technical advisor. HVLS Fans: Aisin Mfg. Illinois Page 36 of 47 TEAM 48 - Organizational Chart NAME Alex Kee Bill Ennis Joel Chaplin Kyle Florian DICIPLINE ME EE ME EE Micah Buchanan ME Ryan Riffel ME PRINCIPLE RESPONSIBILITY Current Load Capabilities Control System Design 2, Economic Analysis, Design 3 Control System Current Load Capabilities, Energy Audit, Load Requirements, Design 3 Design 2, Design 3 Faculty Technical Advisor - Dr. James Mathias The following pages contain two schedules, the first being an overall chronological schedule of events for the Spring 2011 semester. Following this is a more detailed schedule of these events with targeted and actual due dates given. Finally, after the schedules is an Action Item List for the Spring 2011 semester. . HVLS Fans: Aisin Mfg. Illinois Page 37 of 47 Draft Schedule DRAFT SCHEDULE - TEAM 48 1-Jan 31-Jan 2-Mar 1-Apr 1-May Data Collection - AK, MB, KF Energy Audit - MB Estimate Current System Capacity - MB Unit Sizing/Load Required - MB Design 1 - MB Create Controller System - BE, KF Explore HVLS Fans - JC, RR Design 2 - JC, RR Design Reviews - ALL Progress Reports Posted - ALL Design 3 - JC, MB Economic Analysis - JC Demonstrations - ALL Design Report - MB Build Integrated Fan Model - AK, KF Design Poster Presentation - ALL Design Oral Presentation - ALL Completed HVLS Fans: Aisin Mfg. Illinois Remaining TEAM MEMBERS: Alex Kee (AK), Bill Ennis (BE), Joel Page 38 of 47 Draft Schedule - Detailed Aisin Fan Project Schedule - Team 48 X Class Deadline Group Deadline Estimated W orking Time As W orked Deliverable Team Members Alex Kee (AK) Bill Ennis (BE) Joel Chaplin (JC)Kyle Florian (KF) Ryan Riffel (RR) Micah Buchanan (MB) Project Deliverables Design Report 2-May 25-Apr 18-Apr 11-Apr 4-Apr 28-Mar 21-Mar 14-Mar 7-Mar Design Poster Presentation - ALL 3-May X Design Oral Presentation - ALL 3-May X Demonstrations - ALL 28-Apr X Design Reports - ALL 26-Apr X Progress Reports posted to W eb Space - ALL 24-Feb Design Reviews - ALL X 3-Mar X Design 1 - MB X Design 2 - JC, RR X Design 3 - JC, MB X Energy Audit - MB 17-Jan Estimate Current System Capacty - MB Unit Sizing - Load Required - MB Design Tasks 28-Feb 21-Feb 14-Feb 7-Feb 31-Jan 24-Jan 17-Jan DUE DATE 10-Jan PROJECT TASKS 3-Jan W eek of - Starting with Monday Data Collection - AK, MB, KF 1-Jan Create Controller System - BE, KF Explore HVLS Fans - JC, RR Economic Analysis - JC Build Integrated Fan Model - AK, KF HVLS Fans: Aisin Mfg. Illinois Page 39 of 47 AIL ACTION ITEM LIST PROJECT: HVLS FANS - AISIN MFG. ILLINOIS For Beginning of Spring 2011 TEAM MEMBERS Alex Kee, ME Micah Buchanan, ME Joel Chaplin, ME Ryan Riffel, ME Bill Ennis, EE Kyle Florian, EE DATES ITEM # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 ACTIVITY TM Current HVAC Load Calculations MB Energy Audit MB Load Calculation Based on Energy Usage History MB Thermal Transmittance Calculations MB Infiltration/Ventilation Calculations MB Auxiliary Heat Sources Heat Gain MB Total Required Load Calculations - From 2,3,4 MB Additional Load Required Calculations MB Design 1 MB Create Controller System Design 2 Design 3 Economic Analysis HVLS Fans: Aisin Mfg. Illinois BE/KF JC/RR MB/JC JC ASSIGN ED 7-Nov 7-Nov 7-Nov 7-Nov 7-Nov 7-Nov 7-Nov 7-Nov 7-Nov DUE NEW DUE STATUS COMMENTS Find current load capabilities. 15-Dec 20-Dec 25-Dec 30-Dec 5-Jan 10-Jan 15-Jan 25-Jan Find current energy usage for heating and cooling based off of energy bills. Investigate procedure. Based on energy usage coorelated with ambient condition Conduction heat gain through walls, roof, etc. Use Air-Change method - approximation. Due to people, lights, equipment. Based on operating schedule. Use RTSM for cooling load calculations. Find current and required load differences. Find appropriate chiller unit to offset load difference. 25-Jan 7-Feb 21-Feb 21-Feb Page 40 of 47 William Arthur Ennis E-mail: ennis747@siu.edu Permanent: 933 Glenda Lane Taylorville, IL 62568 Telephone: (217)824-5494 Objective: Local: 1205 S. Wall St. Carbondale, IL 62901 Telephone: (217)825-5801 An entry level electrical engineering position with a focus on power systems. Education: Lincoln Land Community College- Springfield, Illinois Associates Degree in Business Administration, 2004 Southern Illinois University- Carbondale, Illinois Bachelor Degree in Electrical Engineering, expected December 2011 Skills: Excellent written and verbal communication skills Experienced with Excel and spreadsheets Very hard working and excellent with team work Some experience with computer programming Quick learner and dedicated employee Experience: May 2006-May 2008 May 2005-May2006 Culligan Water Service- Decatur, Illinois Route Salesman and Service Technician Built and repaired electrical components for water softener control units Serviced and installed water softeners and drinking water systems on both a commercial and residential level Organized and managed routes for new and existing customers Delivered water and water softener salt while maintaining a good relationship with customers GSI group- Assumption, Illinois Machine Operator Used computer programs to cut metal components for distribution and production Organized and shipped steel components to other plants for production MBM- Taylorville, Illinois Puller/Loader Pulled packages from pallets to fill orders for restaurants Organized and stacked pallets to be pulled or to be shipped Checked pallets ready for shipment for damage and accuracy Strategically loaded pallets of product and loose product into semi trailers to be shipped June 2004-May 2005 Relevant Coursework: Computer Systems and Business Applications Introduction to Business Organizations Problem Solving with Computers Discrete Logic and Digital Systems Introduction to Management Kyle Matthew Florian E-mail: kylef10@siu.edu Permanent: Local: 1602 W. Maplewood 12417 N. Hwy 51 Marion, IL 62959 Murphysboro, IL 62966 Telephone: 618-925-3722 Telephone: 618-925-3722 ______________________________________________________________________________ Objective: To obtain an entry-level electrical engineering position to focus on power and energy systems. Education Associate Degree in Science, May 2007 John A. Logan College, Carterville, IL 62918 Bachelor of Science in Electrical Engineering, December 2011 Southern Illinois University, Carbondale, IL 62901 Relevant Coursework FTP Clients Controls and Systems Java Platform Experience Food Service Worker, Marion VA Medical Center September 2005 - present Provide excellent service and support to customers and veterans Am now a Supervisor of Food Service Operations(from September of 2009) Run diet reports on all veterans in the Marion VA Medical Center Once awarded “Best Canteen in the Nation” Gained many friends from different departments at the Marion VA Skills PSpice and MATLAB Microsoft Visio and Microsoft Vista Xilinx and AutoCAD Problem Solving with Computers Electronics Digital Circuit and Design Work Activities Adult League Softball with the Marion VA team Adult League Soccer Recreational Tennis and Golf Micah Buchanan 920 Kathryn Lane, Carterville, IL 62918 P: (618) 943-0123 E: micahbuchanan@gmail.com SUMMARY OF QUALIFICATIONS Proficient team player with a positive and task-oriented attitude, as well as an excellent team leader, proven through design projects and past work experiences. Highly adaptable and able to learn and apply engineering concepts quickly and completely. Excellent communication skills (oral and written) demonstrated through group work, experimental lab work, and course work. Ability to multi-task and work with diverse people and organizations. EDUCATION Southern Illinois University Carbondale (SIUC), Carbondale, IL Bachelor of Science in Mechanical Engineering, Minor in Mathematics G.P.A.: 3.81/4.0 EMPLOYMENT HISTORY Aisin Mfg. Illinois, Marion, IL Manufacturing Engineer Intern Farmhand Jan 2003 – Jan 2010 May – Aug 2008, 2009 Gained experience in feeding/care of hogs (managed a set of hog barns - 5,000 head), feeding/care and milking of cattle, planting/harvesting of corn, soybeans, and wheat Learned to resolve unexpected conflicts in order to maintain a steady process of production Gained knowledge of how to accomplished large tasks through organized team work Branching Out, Inc., Lawrenceville, IL Foreman April 2010-Present Learning in depth the processes associated with plastic injection molding for automotive components Setting up new robot systems, running mold trials, and preparing line setups for the 2012 Camry Constructing new regrind systems to recycle scrap and mix with virgin material to reduce waste Using teamwork to collaborate and solve problems in a manufacturing atmosphere Buchanan Dairy Farm, St. Francisville, IL Lazy B Farms, Lawrenceville, IL May 2011 May 2003 – July 2005 Managed the planting, care, harvesting, and sale of trees and shrubs Increased profits by 10% through selective hiring and marketing strategies Hired and oversaw a team of eight during planting and harvesting seasons VOLUNTEER WORK Mission Trip to Ecuador Summer 2007 & 2008 Involved in preparations and management of multiple events at a children’s Bible camp Visited several underprivileged communities to hand out evangelistic literature Landscaper April 2003 – July 2008 Volunteered landscaping services for both a nearby church and an elderly neighbor Consisted of mowing, trimming, landscaping, and painting AWARDS Dean’s List Fall 2007-Spring 2010 Awarded University of Evansville Trustee Scholarship ($18,000) ACTIVITIES American Society of Heating, Refrigeration, & A/C Engineers (ASHRAE), Vice-President 2010-2011 Tau Beta Pi, in the process of being inducted December 2010 American Society of Mechanical Engineers (ASME) member since 2007 SKILLS SolidWorks, Matlab, Simulink, SolidEdge, Maple, Microsoft Office Platform (Word, Excel, PowerPoint) Joel M Chaplin 416 s Washington St. Carbondale, IL. 62901 (573)579-4390 jchaplin@siu.edu Objective To pursue a career in Mechanical Engineering that is challenging with opportunity for professional advancement. Education Southern Illinois University Carbondale (fall 2007-spring 2011) Bachelor of Science Major: Mechanical Engineering Elective studies: Internal Combustion Engines Hydraulic systems Penn State University (fall 2006-spring2007) Major: Mechanical Engineering Experience Beck Bus transportation, Carbondale IL. (January 2010-present) Successfully troubleshoot complex electrical and mechanical problems Gained valuable knowledge of heavy duty equipment reliability issues Maintained fleet of city and school buses Outdoor turf professionals, Carterville IL. (March 2009-June 2010) Maintained and operated turf equipment Marathon Petroleum LLC, Robinson, IL. (summer 2008) Updated equipment files and documentation Made excellent progress on an internal reliability program Created a training program on this issues that addressed installation, safety and reliability issues Assisted engineers in troubleshooting problems J&N Auto salvage and recovery, Coatesville, PA. (May 2003-June 2007) Troubleshoot mechanical and electrical failures in automobiles, commercial trucks and heavy equipment. Inventoried used parts to ensure efficient and up to date information for customers Fabricated recovery equipment to ensure safer operation of tow truck H&H Nursery, Thorndale, PA. (spring-summer 2007) Maintained and operated agricultural equipment to ensure efficient operation Demonstrated Abilities: Analyze research and apply corrective action to mechanical problems. Highly skilled in the use of AutoCAD 2D&3D Modeling, over 6 years experience with various versions dating back to AutoCAD 2000 Confident in basic functions in Solid Works and MatLab programs Skilled in the use of Visio. Highly Experience with the use of Microsoft office, including Word, Access, PowerPoint, and advanced knowledge of Excel. Work well in a team environment Learn extremely fast and anticipate where help is needed before being asked. Advanced hands on skill set and knowledge base with vast array of mechanical equipment Ryan M. Riffel ryan.riffel11@gmail.com Permanent Address: School Address: 485 Shadow Valley Ln. Buncombe, IL 62912 618.833.4125 606 E. Park St, Apt. N Carbondale, IL 62901 618.697.4749 _____________________________________________________________________________________ OBJECTIVE An entry level position in mechanical engineering EDUCATION Southern Illinois University Carbondale Carbondale, IL Bachelor of Science in Mechanical Engineering, May 2011 Minor: Mathematics GPA: 3.73/4.00 Southeast Missouri State University Cape Girardeau, MO Major: Engineering Physics August 2006-May 2008 GPA: 3.7/4.0 AWARDS/ ACTIVITIES SKILLS AISIN Mfg. Illinois, LLC (AMI) Scholarship, SIUC, 2010-2011 College of Engineering Dean’s Scholarship, SIUC, 2009-2010 Dean’s List Status, SIUC, 2008-2010 American Society of Mechanical Engineers, Student Member, 2010 Proficient in Microsoft Excel, Word, and PowerPoint Experience with AutoCAD and MATLAB Experience with C++ and Python programming Sales Clerk, Larry’s House of Cakes (July 2010-Present) Carbondale, IL Responsible for growth in volume, rate, and quality of sales Improve customer satisfaction with excellent customer service Increase bakery production rate and quality of goods with team of bakers Clerical Work & Laborer, Earthwork (May 2005-June 2010) Carbondale, IL Gained a strong work ethic by managing and maintaining customer properties Worked with a team on major landscaping projects Responsible for bookkeeping and invoicing WORK EXPERIENCE Alex Kee 1408 Newton Ave. Johnston City, IL 62951 618-889-1762 akee_11@msn.com OBJECTIVE Seeking full time employment as a Mechanical Engineer Qualifications Strong people, problem-solving, and group skills Attention to detail, accuracy, and deadlines Education Southern Illinois University Carbondale, Carbondale, IL Bachelor of Science, Mechanical Engineering, expected graduation May 2011 Blackburn College, Carlinville, IL, Aug 2006-May 2008 Transferred to SIUC Experience Blackburn College, New Construction Crew Aug 2006-May 2007 Building maintenance including: drywall, brickwork, and wood-work Working with hand-tools and power-tools Wiring and reading/working with building plans Blackburn College, Utilities Crew Aug 2007-May 2008 Building maintenance including: electricity and plumbing Working with hand-tools and power-tools while rebuilding many plumbing and electrical appliances Wiring and reading/working with building/piping plans Aisin Manufacturing, Manufacturing Engineering Intern Feb 2010-present Injection molding and specialized maintenance on injection machines Designing machine and mold modifications Hands on modifications to machines and molds using many different tools Some machining work Documentation i.e. capacity studies for new product launches Employment The Mattress Store, Delivery/Stock November 2004-May 2006 Marion, IL Franklin County Country Club, Maintenance West Frankfort, IL Summer 2006-Summer 2007 General maintenance around the course, clubhouse, and swimming pool Supervise 3-5 employees, making sure they perform daily duties along with special projects around the course. Kroger Co. Courtesy Clerk/Produce Clerk Feb 2009-Feb 2010 Awards/Activities Blackburn College Honor Scholarship Blackburn College Baseball Carbondale, IL