New and Improved Green Experiments for the Organic Chemistry Lab

advertisement

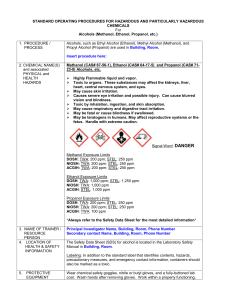

New and Improved Green Experiments for the Organic Chemistry Lab Brian L. Groh Jason F. Pendleton, Duane M. Anderson, Mariya Nasiruddin, and Joel Heuton Department of Chemistry and Geology Minnesota State University, Mankato brian.groh@mnsu.edu July 30, 2006 Presentation Outline Lab Facilities and Constraints Experiment Evaluation Modified and New Experiments Lab Facilities Students work on open bench tops Have access to hood space as needed Limited to 12-14 students simultaneously New facility to be occupied in 2 years Plan for similar lab without need for routine individual hood space Three Phase Transition to Greener Experiments 1. Evaluate current and proposed labs objectively 2. Modify existing labs with greener alternatives 3. Develop new, greener lab alternatives Lab Structure Multiple sections of 24 students 3h lab periods Preparative, reduced and microscale experiments “Cleaner” experiments done on larger scales “Dirtier” or more “hazardous” labs done on smaller scales Minimizes waste Minimizes waste and cost Increased safety Students work independently and are taught to properly treat and dispose of their own waste Experiment Evaluation Examine all solvents and reagents and score current labs using objective criteria Create scores based on – NFPA codes factor in hazard points (e.g. mutagens, carcinogens, etc. not included in NFPA rating) factor in use of bio-based or renewable reagents and solvents Consider total waste generated Modification Process Find known modifications or propose reasonable substitutions Consider experiments that produce considerable waste Replace with catalytic reactions Modifications vary from simple to complex Better procedures, solvents or reagents Solvent change (bromination experiment) Redesign of experiment (Glaser reaction) Experimentally verify modifications Glaser-Eglinton-Hayes Coupling Original Glaser-Eglinton-Hayes procedure1 Longer, involved an additional filtration and water wash, required 4h Alternative procedures2,3 require heating Modifications: Simplify isolation procedure Solvent change: Ethanol vs. methanol Base change: TMEDA vs. pyridine O2 CH3 HO C C C H CuCl CH3 ethanol, TMEDA methanol CH3 CH3 HO C C C C C C OH + H2O CH3 CH3 N 1. Kenneth Williamson, Macroscale and Microscale Organic Experiments, 4th ed., Houghton Mifflin Co, Boston, MA, 2003. Ch 24, pp. 335-337. 2. Ken Doxsee, Jim Hutchinson, Green Organic Chemistry, Thompson Learning Custom Publ., Mason, OH, 2002, pp 143-152. 3. Charles Wilcox, Jr. and Mary Wilcox, Experimental Organic Chemistry, 2nd Ed., Prentice-Hall Publ. Englewood Cliffs, NJ, 1995. pp 349-352 Experiment Evaluation Score current labs using objective criteria NFPA health fire react. OSHA PEL 1 3 0 200 ppm TWA Pyridine 3 3 0 5 ppm ceiling Specific hazards LD 50 / LC 50 flashpoint 11 C Inhal. rat: 64000 ppm/4H flashpoint 17C; ACGIH: A3 Confirmed animal carcinogen with unknown relevance to humans;California Prop 65: known to the state of California to cause cancer. Inhal. rat: 9000 ppm/1 H 2-propanol Ethanol; 95% TMEDA 1 1 3 3 3 3 0 0 0 400 ppm TWA 1000 ppm TWA none listed flashpoint 12 C flashpoint 17 C flash point 19C Methanol Inhal. rat: 16000 ppm/8H Inhal. rat: 20000 ppm/4H Inhal. rat: 1318 ppm/4H haz. Ct. renewable score 4 1 -1 0 Exp Total -1 Exp Total 7 11 4 2 6 8 Experiment Evaluation Comparison of NFPA ratings: No Net Change NFPA health fire react. OSHA PEL 1 3 0 200 ppm TWA Pyridine 3 3 0 5 ppm ceiling Specific haz flashpoint 11 flashpoint 17 Confirmed a unknown re humans;Cal to the state cancer. 2-propanol Ethanol; 95% TMEDA 1 1 3 3 3 3 0 0 0 400 ppm TWA 1000 ppm TWA none listed flashpoint 12 flashpoint 17 flash point 1 Methanol Experiment Evaluation Comparison of PELs and Specific Hazards: Net Change (-2) Methanol OSHA PEL 200 ppm TWA Specific hazards flashpoint 11 C flashpoint 17C; ACGIH: A3 Confirmed animal carcinogen with unknown relevance to humans;California Prop 65: known to the state of California to cause cancer. (+1) Pyridine 5 ppm ceiling 2-propanol Ethanol; 95% TMEDA 400 ppm TWA flashpoint 12 C 1000 ppm TWA (-1) flashpoint 17 C none listed flash point 19C Experiment Evaluation Experiment totals: Methanol/pyridine = 11 Ethanol/TMEDA = 8 Methanol NFPA health fire react. OSHA PEL 1 3 0 200 ppm TWA Specific hazards LD 50 / LC 50 flashpoint 11 C Inhal. rat: 64000 ppm/4H flashpoint 17C; ACGIH: A3 Confirmed animal carcinogen with unknown relevance to humans;California Prop 65: known to the state of California to cause cancer. (+1) Inhal. rat: 9000 ppm/1 H Pyridine 3 3 0 5 ppm ceiling 2-propanol Ethanol; 95% TMEDA 1 1 3 3 3 3 0 0 0 400 ppm TWA flashpoint 12 C 1000 ppm TWA (-1) flashpoint 17 C none listed flash point 19C Inhal. rat: 16000 ppm/8H Inhal. rat: 20000 ppm/4H Inhal. rat: 1318 ppm/4H haz. Ct. renewable score 4 1 -1 0 Exp Total -1 Exp Total 7 11 4 2 6 8 Improved Glaser-Eglinton-Hayes Coupling Modifications Ethanol (95%) with TMEDA Simplified isolation procedure Benefits: Reduced amount of solvent for isolation Reduced amount of aqueous waste Homogenous reaction Stunning color change (light green to midnight blue by completion) Reaction time: 40-60 min at room temperature (heating noted w/other procedures)* Generally cleaner product in comparable yields This reaction can also be run in 75% ethanol! Ken Doxsee, Jim Hutchinson, Green Organic Chemistry, Thompson Learning Custom Publ., Mason, OH, 2002, pp 143-152. Charles Wilcox, Jr. and Mary Wilcox, Experimental Organic Chemistry, 2nd Ed., Prentice-Hall Publ. Englewood Cliffs, NJ, 1995. pp 349-352 Improved Glaser-Eglinton-Hayes Coupling Modifications Ethanol (95%) with TMEDA Simplified isolation procedure Benefits: Reduced amount of solvent for isolation Reduced amount of aqueous waste Homogenous reaction Stunning color change (light green to midnight blue by completion) Reaction time: 40-60 min at room temperature (heating noted w/other procedures)* Generally cleaner product in comparable yields This reaction can also be run in 75% ethanol 50% ethanol Ken Doxsee, Jim Hutchinson, Green Organic Chemistry, Thompson Learning Custom Publ., Mason, OH, 2002, pp 143-152. Charles Wilcox, Jr. and Mary Wilcox, Experimental Organic Chemistry, 2nd Ed., Prentice-Hall Publ. Englewood Cliffs, NJ, 1995. pp 349-352 Improved Glaser-Eglinton-Hayes Coupling Modifications Ethanol (95%) with TMEDA Simplified isolation procedure Benefits: Reduced amount of solvent for isolation Reduced amount of aqueous waste Homogenous reaction Stunning color change (light green to midnight blue by completion) Reaction time: 40-60 min at room temperature (heating noted w/other procedures)* Generally cleaner product in comparable yields This reaction can also be run in 75% ethanol 50% ethanol 25% ethanol Ken Doxsee, Jim Hutchinson, Green Organic Chemistry, Thompson Learning Custom Publ., Mason, OH, 2002, pp 143-152. Charles Wilcox, Jr. and Mary Wilcox, Experimental Organic Chemistry, 2nd Ed., Prentice-Hall Publ. Englewood Cliffs, NJ, 1995. pp 349-352 Improved Glaser-Eglinton-Hayes Coupling Modifications Ethanol (95%) with TMEDA Simplified isolation procedure Benefits: Reduced amount of solvent for isolation Reduced amount of aqueous waste Homogenous reaction Stunning color change (light green to midnight blue by completion) Reaction time: 40-60 min at room temperature (heating noted w/other procedures)* Generally cleaner product in comparable yields This reaction can also be run even in water! Ken Doxsee, Jim Hutchinson, Green Organic Chemistry, Thompson Learning Custom Publ., Mason, OH, 2002, pp 143-152. Charles Wilcox, Jr. and Mary Wilcox, Experimental Organic Chemistry, 2nd Ed., Prentice-Hall Publ. Englewood Cliffs, NJ, 1995. pp 349-352 % Ethanol vs % Isol. Yield (45 min) 100 % Yield 80 60 53 54 42 40 40 43 28 20 0 100 95 75 50 % Ethanol 25 0 Yield vs Reaction Time (50% Ethanol) 100 % Isol. Yield 80 57 60 40 40 20 0 45 60 minutes % Isol. Yield vs Temp. and Time 100 100 80 80 60 53 48 53 40 60 40 28 16 20 20 0 % yield temp °C 0 45 45 60 time (min) 90 120 temp (°C) % yield (water) Crude vs Recrystallized (50% Ethanol, 120 min.) 100 % Yield 80 60 40 20 0 71 53 Experiment Evaluation Experiment totals: Methanol/pyridine = 11 Water/TMEDA = 6 Methanol NFPA health fire react. OSHA PEL 1 3 0 200 ppm TWA Specific hazards LD 50 / LC 50 flashpoint 11 C Inhal. rat: 64000 ppm/4H flashpoint 17C; ACGIH: A3 Confirmed animal carcinogen with unknown relevance to humans;California Prop 65: known to the state of California to cause cancer. (+1) Inhal. rat: 9000 ppm/1 H Pyridine 3 3 0 5 ppm ceiling 2-propanol Ethanol; 95% TMEDA 1 1 3 3 3 3 0 0 0 400 ppm TWA flashpoint 12 C 1000 ppm TWA (-1) flashpoint 17 C none listed flash point 19C Inhal. rat: 16000 ppm/8H Inhal. rat: 20000 ppm/4H Inhal. rat: 1318 ppm/4H haz. Ct. renewable score 4 1 -1 0 Exp Total -1 Exp Total 7 11 4 2 6 8 New Experiment Candidate: Adipic Acid Synthesis Current experiment sequence: OH NaOCl O CH3COOH O O KMnO4, NaOH, H2O HO O OH 33%, often impure Drawbacks: Requires excess KMnO4 (3g /g ketone!) Large quantities of MnO2 (oxidizer) produced (1.8g /g ketone) Contaminated product (isolate by NaCl precipitation) Low yields (ave 33% est. on last step; ave 20% overall) New Experiment: Catalytic Oxidation A Green Adipic Acid Synthesis Propose1 – 1 g scale oxidation O O H2O2 (30%) HO O OH Na2WO4, H+ co-cat heat Advantages Catalytic oxidation By-products: O2, H2O Higher yields 1. Zhang, Shi-gang; Jiang, Heng; Gong, Hong; Sun, Zhao-lin Petroleum Science and Technology 2003, 21 (1-2), 275-282. Experiment Evaluation NFPA health fire react. OSHA PEL 5 mg/m3 Ceiling for Mn 5 mg/m3 none listed 2 mg/m3 Ceiling KMnO4(s) NaHSO3(s) Norit 3M NaOH 3 1 1 3 0 0 1 0 0 1 0 1 conc HCl NaCl 3 0 0 0 0 CEIL: 5 ppm 0 Specific hazards strong oxidizer!; eye and skin irritation (+1) Allergic respiratory reaction mechanical eye and skin irritation corrosive Danger! Poison! Causes severe eye and skin burns. irritant LD 50 / LC 50 oral-rat 1090 mg/kg oral-rat 2000 mg/kg oral, rat 500 mg/kg Inhl mus:1108 ppm/1H haz. Ct. renewable score 1 4 2 2 4 1 4 0 16 Total H2O2 Na2WO4 sulfosalicylic acid 3 1 1 0 0 1 Strong Oxidizer!; ACGIH: A3 - Confirmed animal carcinogen with unknown relevance to 1 1ppm TWA; 1.4 mg/m3 (+1) humans; human mutagen (+1) Oral, rat: 1518 mg/kg 0 n/a stable; irritant oral mouse: 240mg/kg 1 na may cause burns Oral, rat: 1850 mg/kg; 2 -1 Total Scores: KMnO4 method: Includes KMnO4, NaOH, NaHSO3, celite H2O2 method: 16 9 Includes H2O2, Na2WO4, sulfosalicylic acid 5 1 3 9 New Experiment: Catalytic Oxidation A Green Adipic Acid Synthesis Reaction – 1 g scale oxidation O O 30% H2O2 HO 2.5mol% Na2WO4, H+ co-cat, heat O OH 70-80% isol. Heat: Steam bath, overnight No residual peroxide 75% average isolated yield of pure adipic acid from cyclohexanone Co-catalysts Sulfosalicylic acid (23 mg) Best yields – ave 75% Cleanest product Very water soluble Sodium bisulfate (30 mg) Reduced yields (by ~ 60%) Discolored product Narrowed reaction time Ascorbic acid (40 mg) Reduced yields (~ 30%) Discolored product Ligand can be neutralized and sewered % Isol. Yield vs H2O2 Conc. 80 70 67 67 66 61 % Isol. Yield 60 50 45 isol. corrected 40 30 24 20 10 5 mL 7.5 mL 15 mL 0 30 20 % H2O2 10 New Experiment: Catalytic Oxidation A Green Adipic Acid Synthesis Reaction – 1 g scale oxidation O O 30% H2O2 HO 2.5mol% Na2WO4, H+ co-cat, heat O OH 70-80% isol. But, synthetic cyclohexanone sometimes gave poorer yields… Side reaction responsible for low yields According to procedure: OH O NaOCl CH3COOH Analysis by GC and GCMS indicates OH NaOCl CH3COOH O O + Cl Vigorous reaction gives 2-chlorocyclohexanone High amounts correlate with poor yields of adipic acid Catalytic Oxidation: A Green Adipic Acid Synthesis Proposed reaction pathway1 O O [O] O O H 2O OH HO [O] O HO O OH O [O] HO O H 1. Based upon the work of Noyori and Fischer: Sato, K.; Aoki, M.; Noyori, R.; Science 1998, 281, 1646. Fischer, J.; Holderich, W.F. Appl. Cat. A: General 1999, 180, 435. Catalytic Oxidation: A Green Adipic Acid Synthesis Waste reduction: Na2WO4 KMnO4 no solids 6 mL aqueous waste incl 80 mg Na2WO4 1.8 g MnO2 (ox) solids 35+ mL aqueous waste incl. 11+ g NaCl 26 mg sulfosalicylic acid NaHSO3 Summary: Green Adipic Acid Synthesis Advantages Disadvantages Improved Evaluation Score (9 vs. 16) Use of corrosive peroxide Yields are more than double Complex reaction mechanism Simple isolation Long heated reaction time Expt Atom Economy 60% vs 37% (theory) 45% vs 12% (observed) Waste reduction SN2 Experiment Candidate Synthesis of n-butyl bromide from n-butanol NaBr OH Br H2SO4 Drawbacks: Low yields on a small scale Impure product Odor problems Use of concentrated sulfuric acid Goals: Develop new experiment that still teaches the SN2 reaction High yields of pure product Simple experiment suitable for a beginning 3 h lab Proposed SN2 Experiment Use of PCl5 Proposed reaction scheme OH 1. PCl5 Cl 2. H2O mp 40°C mp -3°C Potential Advantages Solventless reaction One step Short reaction time Clean, high yield reaction Introduce column chromatography for purification RCl NFPA health fire react. OSHA PEL Specific hazards LD 50 / LC 50 haz. Ct. renewable score Causes reproductive system effects in laboratory animals Oral rat: 3500 mg/kg 2 Material causing immediate and serious toxic effects;Classified A2 (Suspected carcinogen for human.) by ACGIH; Tests on laboratory animals for reproductive effects are cited in Registry of Toxic Effects on Chemical Substances (RTECS). (+1) (LC50): 320 mg/m3 2 hour(s) [Mouse]. 1 6 1 Flashpoint 37C Oral rat LD50: 790 mg/kg;inhalation rat LC50: 8000 ppm 4 Flashpoint -9C Oral rat LD50: 2670 mg/kg; 5 Total 18 Experiment Evaluation NaBr 2 0 0 na H2SO4 NaHCO3 1-butanol 1-chlorobutane 3 1 1 2 0 0 3 3 2 0 0 100 ppm 0 PCl5 pentane NaHCO3 tetradecanol tetradecyl chloride 3 1 1 1 1 0 4 0 1 0 2 1 mg/m3 TWA (+1) 0 TWA: 350 mg/m3 10 hour(s). 0 0 0 No OSHA Vac ated PELs reacts vioently with water; Flammable; fp -50°C Oral rat : 660 mg/kg (LD50): 400 mg/kg [Rat]. 1 Flashpoint 140C; water insol. (-1) Flashpoint 109C LD50: >5000 mg/kg (rat) -1 Total Scores: NaBr/H2SO4 method: 18 Includes NaBr, H2SO4, H2O, NaHCO3, 1-butanol, 1-chlorobutane PCl5 method: 14 Includes PCl5, pentane, H2O, NaHCO3, 1-tetradecanol, 1chlorotetradecane (note: hexane score = 4) 6 5 1 1 1 14 Synthesis of 1-chlorotetradecane from 1-tetradecanol OH 1. PCl5 Cl 2. H2O Results: high yield – up to 92% (ave 80%) Highly pure >98% by GC analysis (crude) Short reaction time (40 min) No need to introduce column chromatography! Product can easily be analyzed by IR, GC By-products can easily be neutralized Solventless reaction – visual reaction Reaction Mechanism is Relevant [PCl4]+ + [PCl6]- 2 PCl5 H O [PCl4]+ + HO CH2R Cl3P CH2R Cl S N2 RCH2-Cl + Cl3PO O Cl3P Cl CH2R + H Cl- PCl5 Gerrard, W.; Phillips, R. J. Chemistry & Industry 1952, 540-1. Reaction Highlights Analyze by GC for purity but… no need to introduce column chromatography! IR, H & 13C NMR indicate high purity Reaction Highlights Combine solid reagents Reaction Highlights Mix with cooling Reaction Highlights Heat in steam bath Reaction Highlights Isolate by extraction Experiment Summary Advantages Solventless reaction High yield, pure (% AE*yield = 44 vs 30) Improved evaluation score (14 vs 18) Visual reaction Minimal waste Disadvantages % Atom Economy (55 vs 50 for n-butyl bromide) More complex mechanism Summary Evaluated labs objectively with respect to safety and green character Redesigned experiments while maintaining good yields Designed new experiments that minimize waste, reagent or solvent use Continue to look for greener alternatives and improvements – this is a continuing transition! Acknowledgements Undergraduate Student researchers: Jason Pendleton Duane Anderson Mariya Nasiruddin Joel Heuton Organic Chemistry students for their participation and feedback. Minnesota State University, Mankato Center for Education, Teaching and Learning for partial funding of this work New and Improved Green Experiments for the Organic Chemistry Lab Brian L. Groh Jason F. Pendleton, Duane M. Anderson, Mariya Nasiruddin, and Joel Heuton Department of Chemistry and Geology Minnesota State University, Mankato brian.groh@mnsu.edu July 30, 2006 Website: http://www.intech.mnsu.edu/groh Experimental Procedures Procedures for the experiments outlined in this presentation may be requested from Brian Groh by email at brian.groh@mnsu.edu . The experiments will be available in a photo-essay type format on my website hopefully by fall semester 2006. Follow the “LabViews” link on the home page. Website: http://www.intech.mnsu.edu/groh