2. Pictorial Depiction

LEARNING FROM INCIDENT

Division : TPDDL

Date of Incident : 1 ST June 2014

Type of incident : LWDC (Burn & Head Injury)

1

CONTENTS

1. Description Of Incident

2. Pictorial Depiction

3. Events Leading To Incident

4. Events After Incident

5. Observations

6. Analysis

7. Root Causes

8. Recommendations

2

1. DESCRIPTION OF INCIDENT

IRIS Reference : 14-15/BA/NF/01

Location : 315 kVA DT installed at Pole No HT522-27/48/7-8, Narela

Industrial Area, Zone 522

Incident : LWDC (Burn & Head Injury)

Incident Date : 1 st June, 2014.

Incident Time: 13:30 Hours approximately

Description of

Incident :

While tightening HT fuse of 315 kVA D.T at Pole No. HT522-

27/48/7-8, a flashover took place and the Lineman (Sanjay) fell down striking his head against the pole and ground. He sustained burn injuries on hands and legs as well as head injury.

Initially he was taken to Raja Harish Chandra Hospital from where he was referred to ESI Hospital.

Later he was referred to Safdarjang Hospital as Safdarjang Hospital is having better neurological and burnt treatment facilities

3

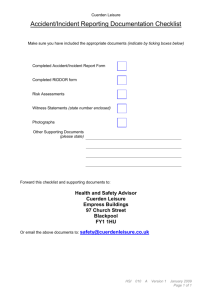

2. Pictorial Depiction

River Rose

HT FUSE

BLOWN AT

THIS POINT

SLD OF THE SECTION AND THE TRANSFORMER

4

2. Pictorial Depiction

Actual Path

Path without gloves

2. Pictorial Depiction

TRANSFORMER - F - 1962 One G.O blade did not disengage properly

6

2. Pictorial Depiction

The G.O blade of the same phase for which HT fuse blew, did not disengage

Helmet of the victim after accident

7

2. Pictorial Depiction

Gloves of the victim after accident

8

3. EVENTS LEADING TO INCIDENT

1. Lineman Snjay and A/L/M Buchan were on morning shift and on NCC duty. Mr.

Sandeep Gupta, ZSO was on duty.

2. At approximately 12:30 hours, a No Current Complaint (NCC) received from Factory

No. F-1962, Narela Industrial area which was handed over to Lineman Sanjay (Victim) who was accompanied by A/L/M Buchan

3. After attending four complaints, all involving replacement of fuses of 3 phase HVDS

DTs, violating PTW norms, both reached the site and found that the HT fuse of B phase of the 315 kVA DT installed at Pole No HT522-27/48/7-8 feeding the premises was blown off.

4. The said DT (Sl No 73428, Make : Nucon) caters to the load of three premises. There is no LT side protection on this DT.

5. The victim attempted to replace the fuse by opening G.O switch without calling for

ZSO or any other Zonal representative. So there was no PTW or supervision involved.

6. He was using hand gloves, helmet but did not use ladder, safety belt or D.D fuse operating rod.

7. It was gathered from A/L/M that the victim first checked with the three connected premises about condition of supply and then tried to open the GO.

9

3. EVENTS LEADING TO INCIDENT

8. Although two blades of R and Y phase were disconnected, it is gathered that the blade of the B phase did not disengage properly. The same was pointed out to the

L/M by his A/L/M. L/M tried to disengage the said blade with DD fuse operating rod, instead of informing ZSO to discharge the entire circuit.

9. After the reported attempt to disengage G.O blade, the victim wore his helmet and gloves and climbed the pole without using ladder or safety belt or safety rope in spite of repeated plea of the A/L/M not to do so. He also did not use safety chain at any point required to create safety zone to avoid backfeeding. And since the ZSO was not accompanying him, there is no possibility of using Neon tester or discharge rod.

10. It is reported that he used one hand to tie the fuse to the top contact of DD fuse assembly and the other to hold the GO handle.

11. As soon as he tried to tighten fuse of the affected phase, there was a flashover and he fell down striking his head against the pole and ground during which the strap of his helmet snapped.

10

4. EVENTS AFTER INCIDENT:

1. He sustained burn injuries on hands and legs and head injury.

2. He was first taken to Raja Harish Chandra Hospital from where he was referred to

ESI Hospital, Sec 15. From there he was referred to Safdarjang Hospital after initial assessment , the doctors advised CT scan and referred the victim to Safdarjang

Hospital which is having better neurological and burnt treatment facilities.

3. His CT scan was found normal and burn percentage of around 15% and he was again transferred back to ESI Hospital, the same day.

4. The victim is presently recuperating at ESI Hospital, Rohini.

11

5. OBSERVATIONS

1. As per contract terms and conditions signed between TPDDL and the BA representative, the scope of work in LT and HT line is clearly mentioned and the terms of working in adherence to PTW cases are unambiguously stated.

2. Safety trainings are conducted on regular basis during induction of new BAs and refresher training are also conducted regularly in a timely manner.

3. Competency assessment tests are also conducted at the initiation of Contract and thereafter as per schedule.

4. The G.O blade of the B phase of the transformer in question was found to be defective. How much gap was achieved could not be ascertained as by the time this inspection took place, the G.O blade was completely removed by Zonal team which also resulted in complete de-alignment of the assembly of B phase insulator and blade, which needs to be repaired / replaced in due course.

5. No evidence of back-feeding from secondary side of transformer found.

6. The victim’s tool-bag was checked and was found having all necessary PPEs, tools and equipments required for attending no current complaints.

12

5. OBSERVATIONS

7. Helmet of the victim was not broken but the strap snapped from one end. (Helmet issued was of standard make and was confirming to IS and checked with regular interval)

8. The victim was using LT gloves during the accident which probably avoided fibrillation and the passage was through hand and leg.

9. One of the gloves was found to be flashed and ruptured.

10. The victim was not authorized for 11 kV operations and did not possess neon tester, discharge rod and other breakdown attending equipment.

11. PM was carried out on 21 st September 2013 for the entire section

13

6. ANALYSIS

1. The site was visited on the day of accident by SHE&DM team and subsequently by Accident Enquiry Committee team.

2. Written statements of the following witnesses have been recorded by accident investigation team constituted.

a) A/L/M of M/s IEC present with the victim during accident.

b) ZM, Zone 522.

c) ZSO during the shift in which the accident occurred.

4. The victim is still recuperating in hospital till date. On 23.06.14 an attempt was made by member of Accident Enquiry Committee, to record his statement but he said he could not recollect all details.

5. Other than the above, the accident enquiry committee also discussed the sequence of events, general safety awareness and relevant issues with

BA Supervisor of Zone 522, DM (Narela), ZM(521) and DM (Bawana).

6. The accident investigation committee also visited the site and spoke with a general public who works in factory number F-1962, an eye witness and noted his observations.

14

6. ANALYSIS

4. The analysis was done considering the network topography, its difficulty and the condition subsequent to the natural catastrophe on 30.05.2014

affecting the area.

5. The condition and practices of similar zones in terms of network topography was also analyzed and compared.

6. The historical data of all such zones for the Financial Year FY 13-14 was also considered to assess, identify and alleviate further risks and point out root causes at granular level.

15

7. ROOT CAUSES

Human Factors:

1.1

Violation by Individual - PTW process was not followed, Ladder not used, DD fuse operating rod used for wrong purpose, safety chain not used for grounding

1.4

Operation of equipment without authority - The victim was not authorized for 11 kV operations.

3.2

Personal protective equipment not used – Safety Belt not used

Physical Factors

5.7

Inadequate isolation of process or equipment - PTW process was not followed to ensure safety zone / complete isolation

7.3

Energized electrical systems The victim attempted to replace the fuse by opening G.O switch without calling for ZSO or any other Zonal representative

16

7. ROOT CAUSES

System Factors:

6.2

Inadequate practice of skill - There was a definite lack of domain knowledge and knowledge for identifying risks of the victim. He could not acknowledge the risk posed by one G.O Blade having insufficient gap with a charged contact.

11.6

Inadequate Monitoring - The work in question required supervision by an authorized personnel which was not asked for by the lineman as per contract.

12.0

Material Control – Control of consumable / spares based on authorization for working on LT/HT equipment

13.5

Inadequate repair / maintenance - The G.O blade of the B phase of the transformer in question was found to be defective

14.3

Inadequate implementation of PSP (Policy, Standards and Procedures)

T he scope of work in LT and HT line is clearly identified in C ontract terms and conditions including requirement of PTW

17

1

2

3

4

8. RECOMMENDATION

Sl No CAPA details suggested Responsibility Centre Timelines

Ensure usage of all PPEs, proper ladder and prescribed tools and tackles at all times

Ensure Adherence to PTW guidelines

Ensure supervision for all fuse blown cases in

Industrial HVDS areas.

Focused training to L/M attached activities to Breakdown

All E.I.Cs

All E.I.Cs

Internal resources to be explored for further training and provide authorization as per requirement for enhanced supervision.

All EICs to explore internal resources and recommend for training for authorization.

Competency rechecking of all L/M and identify personnel for re training and knowledge improvement. The identification process is presently being done through “Kamzor Kadhee” sessions, site audits as per Annual Safety Plan, Practice at Safety

Yards.

Additionally personal interaction with all

Lineman and ALM can be done.

E.I.

C’s to identify such personnel and recommend to

DOSEC for training. On completion of training a certification to be issued, for identification of LM authorised for LT / HT

Immediate

Immediate

Immediate

Immediate

18

6

7

Sl

No

5

8. RECOMMENDATION

CAPA details suggested Responsibility Centre

Mapping of competency of lineman and issuing badges according suitability in functions in which Lineman are fit to serve like Breakdown, NCC, Maintenance, Street

Lighting

A systematic process shall be in place to ensure that consumable / spares based on authorization for working on LT/HT equipment is issued to appropriate personnel

Implementation of Contractors Safety

Management – Consequence Management

Policy

DOSEC and BA Legal Cell

All ZRDMOs/ All E.I.Cs

All ZRDMOs/ All E.I.Cs

Timelines

Immediate

Immediate

Immediate

19