MFGT2250

advertisement

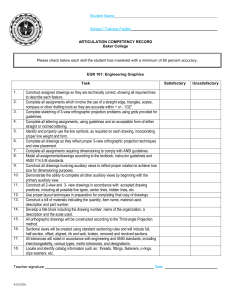

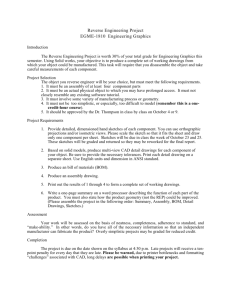

MASTER SYLLABUS 2014-2015 A. Academic Division: Business, Industry and Technology B. Department: Technology Discipline: Manufacturing C. Course Number and Title: MFGT2250 Stamping Operations and Die Design D. Course Coordinator: Chris Barker Assistant Dean: Lynn Jones Instructor Information: Name: Office Location: Office Hours: Phone Number: E-Mail Address: E. Credit Hours: 3 Lecture: 2 hours Laboratory: 2 hours F. Prerequisites: MFGT2010, MFGT1110 G. Syllabus Effective: Fall, 2012 H. Textbook(s): Die Design Fundamentals Author: Vukota Boljanovic Copyright Year: 2005 Edition: 3rd ISBN: 9780831131197 I. Workbook(s) and/or Lab Manual: Compilation of Die Design Instructions and Projects, E-Book and compilation of technical readings in Press Maintenance & Operations: The Stamping Journal J. Course Description: This course is designed to give students knowledge of press operations. An overview of standard frame structures and press accessories including stock feeders and de-coilers as well as new press technology and current developments in the stamping industry will be presented. The second part of the course covers material strips, sheet metal models, die design, and tonnage calculations. Students will use solid modeling software to develop and troubleshoot die designs. K. Core Learning Outcomes: Core Learning Outcome Communication – Written Assessments – How it is met & When it is met All assignments are graded Worksheets, technical drawings, research project, at various sessions throughout the semester Assessments – How it is met & When it is met All assignments are graded Core Learning Outcome Communication – Speech Intercultural Knowledge and Competence Critical Thinking Information Literacy Computation L. Worksheets, student generated technical drawings, at various lab sessions throughout the semester E-Book material reading—throughout the semester Worksheets, technical drawings, at various lab sessions throughout the semester Course Outcomes and Assessment Methods: Upon completion of this course, each student shall be able to: Outcomes Describe and identify types of presses. Student will demonstrate knowledge of press accessories. Student will demonstrate knowledge of safety in press operations and manufacturing environment. Identify and describe specialized work holding devices and their benefits and applications. Identify and specify acceptable tool materials, application and components in design projects. Use solid modeling software such as Inventor as a tool to design and troubleshoot special tooling used in manufacturing situations. Use CAD software to create technical drawings of sheet metal products in compliance with ANSI standards. Use CAD software to aid in tonnage calculations and determine physical data properties of dies. M. Assessments – How it is met & When it is met Week 1 to week 16 Exam and worksheets Week 1 to week 16 Written papers, exam Week 1 to week 8 OSHA and Industry standards Exam and worksheets Week 8 to week 16 Written papers, exam Exam and worksheets Week 8 to week 16 Industry standards, ANSI standards CAD drawings and Exam Week 8 to week 16 Industry standards, ANSI standards CAD drawings and Exam Week 8 to week 16 Industry standards, ANSI standards CAD drawings and Exam Week 8 to week 16 Industry standards, ANSI standards, OSHA regulations, CAD drawings and Exam Course Topical Outline: Part I: Presses Basic Construction Principles, Press types and operations Introduced at the start of the semester. Review press manual, articles from the Stamping Journal and other resources to identify and describe types of presses. Set up and operation of press accessories Introduced at the start of the semester. Review press manual, articles from the Stamping Journal and other resources to identify and describe types of press accessories. Complete safety inspection worksheet and create other maintenance documents to evaluate safety conditions of press(es). Modern developments in Press Design Fluids, lubricants and mechanics in press applications Review press manual, articles from the Stamping Journal and other resources to identify and describe holding devices and their benefits and applications. Part II: Die Design Fundamentals Tool drawings and material strips Introduced second half of semester Review press manual, articles from the Stamping Journal and other resources to identify and specify acceptable tool materials, application and components in design projects. Design projects, including use of Tool Libraries and Web Downloads Second half of semester. Create solid models of material strips. Create technical drawings to ANSI standards. Specify tonnage from calculations and calculate weight from iproperties resources. Design Economics Use of Tool Libraries and Web Downloads Ergonomic Considerations and other operator safety issues N. Course Assignment: A. B. C. D. E. F. O. Identify type of tooling needed to accomplish manufacturing problem solving. Develop tooling plan to accomplish manufacturing problem solving. Complete written homework assignments and scheduled tests. Review selected topics and current events from the Stamping Journal and complete written assignments. Complete manufacturing documents to industry standards. Develop detailed technical prints to industry standards. Recommended Grading Scale: 100-95 94-92 91-89 88-86 85-83 82-80 A AB+ B BC+ 79-77 76-74 73-71 70-68 67-65 64-Below C CD+ D DF