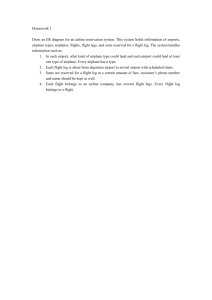

Certification of Structure

advertisement

FEDERAL AVIATION ADMINISTRATION

TRANSPORT AIRPLANE AND ENGINE

SAFETY REQUIREMENTS

A GENERAL OVERVIEW

Certification Process Study Team Meeting #6

Museum of Flight, Seattle WA

June 26-27, 2001

TABLE OF CONTENTS

• Introductory Remarks (D. Cheney)

• Flight: Airplane Performance, Stability and

Control, Related Support (T. Archer/J. Neff)

• Structures: Loads, Design and Construction

(H. Offerman)

• Equipment: Mechanical (R. Jones)

• Equipment: General, Electrical, Avionics

(S. Boyd)

• Propulsion: Engine/APU (M. Fulmer)

• Propulsion: Engine Installation (K. Rask)

• Cabin Safety (F. Tiangsing)

• Human Factors (S. Boyd)

CERTIFICATION FLIGHT TEST

Tom Archer - FAA Flight Test Pilot

John Neff - FAA Flight Test Engineer

Flight Test Branch

Seattle Aircraft Certification Office

CERTIFICATION FLIGHT TEST

• Overview

–

–

–

–

Flying Qualities

Systems and Equipment

Aero. Performance

Airplane Flight Manual

CDL

– Operations Manual / MMEL

CERTIFICATION FLIGHT TEST

• Flying Qualities (FAR 25, Subpart B)

• Aircraft Systems (FAR 25, Subparts D, E, & F)

– Aircraft Systems

– Installed Equipment

• Performance (FAR 25, Subpart B)

• Airplane Flight Manual (FAR 25 Subpart G)

FLIGHT TEST - GOAL

• Ensure aircraft meets minimum standards

– Fully operational aircraft or

– with any foreseeable failures (more probable

than 1x10E-9)

– with a pilot of average skills

– throughout the operational envelope:

Speed

Altitude

Gross Weight / Center of Gravity

Temperature

Limit head/tail/cross winds

FLYING QUALITIES (FQ)

• General Requirements– The airplane must:

Be safely controllable and maneuverable

Not require exceptional piloting skill,

alertness or strength

Be capable of continued safe flight and

landing following any single failure or

combination of failures not shown to be

extremely improbable.

– The flying qualities requirements must be

demonstrated throughout the flight envelope

FLYING QUALITIES (FQ) (cont’d)

• Stability

– Static

– Dynamic

•

•

•

•

•

Controllability

Maneuverability

Stall Characteristics

High Speed Characteristics

Degraded Modes

FLIGHT ENVELOPE

• The airplane must exhibit acceptable flying

qualities at the most critical loading within

the ranges of speed and altitude for which

certification is requested.

– The airline pilot is provided with a safe

operational flight envelope (bounded by

certificated limits) that has been thoroughly

explored during flight testing.

– The airplane is test flown outside of it’s

operational envelope to account for inadvertent

excursions beyond the certificated limits.

Gross Weight (Pounds)

C.G./GROSS WEIGHT ENVELOPE

Center of Gravity (%MAC)

Pressure Altitude (Feet)

FLIGHT ENVELOPE

Airspeed (KCAS)

V-N DIAGRAM

SPECIFIC FQ FLIGHT TESTS

• General (25.101-.143)

• Maneuvering stability

(25.143, .251, .255)

• Longitudinal control

(25.145)

• Directional and lateral

control (25.147)

• Minimum control speed

(25.149)

• Trim (25.161)

• Static longitudinal

stability (25.173-.175)

• Static lateral-directional

stability (25.177)

SPECIFIC FQ FLIGHT TESTS (Con’t)

• Dynamic stability

(25.181)

• Stall characteristics

(25.203)

• Ground handling

(25.231-.235)

• Cross wind (25.237)

• Vibration and buffeting

(25.251)

• High-speed

characteristics (25.253)

• Out-of-trim

characteristics (25.255)

TEST CONDITIONS

TEST

General

Man stab

LOADING

(wt/cg)

Full range

“

DATA

Qual, forces

Fs/g

Long control

Heavy/fwd, aft Qual, forces

Lat-dir control

Heavy/fwd, aft

“

TEST CONDITIONS (Con’t)

TEST

LOADING

DATA

Min cont spd

Light/aft

Hdg, grd track

Trim

Full range

Control forces

Stat long stab

Light/aft

Fe/V

Stat lat/dir stab Light/aft

Fa/, Fr/

TEST CONDITIONS (Con’t)

TEST

LOADING

DATA

Dyn stability

Light/aft

Oscillations

Grd handling

Full range

Qualitative

Stall char

Light/aft

, response

Vib/buffet

Heavy/aft

Fs/g, Vc, Mach

TEST CONDITIONS (Con’t)

TEST

LOADING

DATA

High spd char

Full range

Fs/g, Vc, Mach

Out-of-trim

Full range

characteristics

Fs/g, Vc, Mach

ADDITIONAL APPROVALS

• Human Factors- continuous evaluations

conducted concurrently with other tests

• Operating Limitations (FAR 25, Subpart G)sufficient to define the envelope

demonstrated during flight tests

• Airplane Flight Manual (FAR 25, Subpart G)information validated during flight testing

SYSTEMS

• Systems and equipment evaluated by

Flight Test

– All Systems

– Virtually every piece of equipment on the A/C

Three categories of equipment

> Equip. required by FAR Part 25

> Equip. NOT required by FAR 25, but IS by FAR 91,

121, 125, or 135,

> Equip. not required by any FAR

SYSTEMS

• ALL equip. MUST meet the following rules

– Perform it’s intended function/function

properly

– Not provide any misleading information to

crew

– Not interfere with any other equipment

– Specifically applicable rules (if any)

– No failure condition may preclude continued

safe flight and landing

AIRCRAFT SYSTEMS

•

•

•

•

•

Flight Controls

Landing Gear

Powerplant

Fuel

Auto Flight

–

–

–

–

Flight Director

Auto Pilot

Auto Throttle

HUD

• Hydraulics

•

•

•

•

Electrical

Pressurization/Environ.

Fire Protection

Flight Deck

– Controls

– Displays

•

•

•

•

Lights

Safety

Comm/Nav

De-ice/Anti-ice

FLIGHT TEST - FIRE/SMOKE

WATER IMPINGEMENT

COLD / HOT ENVIRONMENT

WINDOWS / DOORS

INSTALLED EQUIPMENT

• Operational

Requirement

–

–

–

–

–

–

–

–

TCAS

GPWS/EGPWS

RWS/PWS

CVR

FDR

HF

3rd Comm/Nav

Standby Instruments

• Optional

–

–

–

–

–

–

–

ACARS

GPS

IFE

Telephones

SAT Comm

Lavatories

Prayer Rooms

PERFORMANCE

• Phase of Flight

– Takeoff (FAR 25.105 - .107)

Accelerate - Go

Accelerate - Stop (FAR 25.109)

– Climb (FAR 25.113 - .117, .121)

First / Second / Third / Final segment

– En Route (FAR 25.123)

– Descent

– Approach

Approach climb (FAR 25.121)

– Landing (FAR 25.125)

Landing climb (FAR 25.119)

T.O. PERFORMANCE

• Takeoff Speed Schedule Development

(FAR 25.107)

• Takeoff Field Length Requirements

(FAR 25.113)

HIGH ALTITUDE TAKEOFF PERF.

LaPaz, Bolivia, field elevation 13,100 ft. MSL

TAKEOFF SPEEDS

• Definitions for speed schedule

development

– V1 Takeoff “decision speed”

Brake Release

Min. speed, following critical engine failure, from which

T.O. can continue and achieve 35’ within T.O. distance

Max speed to initiate the first action in an abort and

stop within accel-stop distance

less than V1MBE

Vef

Vmcg

V1

Vmca

Vr

Vlof

Vmbe Max. tire

speed

Vmu

>V2

35 feet

(15’ if wet)

TAKEOFF SPEEDS

(cont’d)

• Definitions for speed schedule development

– Vr Rotation speed

Brake Release

Equal to, or greater than, V1, and 1.05 Vmca

result in a minimum Vlof of 1.05 OEI Vmu & 1.1 AEO Vmu

Allow reaching V2min by 35’, OEI

5 knot abuse (OEI) will not significantly extend the

takeoff distance

Vef

V1

Vmca

Vr

Vmu

Vlof

35 feet

>V2

TAKEOFF SPEEDS

(cont’d)

• Definitions for speed schedule

development

– V2 Takeoff Safety Speed

Meet minimum EO climb gradient

Greater than V2min

– V2min

1.1Vmca

1.13Vs

Brake Release

V1

Vs

Vmca

Vr

35 feet

V2

ADDITIONAL SAFETY MARGINS

• T.O. Tests @ each flap setting

–

–

–

–

–

–

Light / mid / heavy weights

All engine / one engine inoperative

Several T/W at each flap setting

Fuel cut conditions

Overspeed

Abuses

Rapid rotations (rate)

Over rotations

5 knot Vr abuse

Mis-trim

• Over 60 Takeoffs

FAR TAKEOFF FIELD LENGTH

All engine, “full up” airplane

>V2

Vr

Vlof

35 feet

Demonstrated All Engine Distance

Takeoff Distance = 1.15 X All Eng. Dist. To 35 feet

“AFM” Takeoff Distance Required

FAR TAKEOFF FIELD LENGTH

(cont’d)

Critical Engine Fails at Vef

“Balanced” field length

V2

“GO”

V1 Vr

Vlof

35 feet

Vef

Throttles / max. brakes, speed brakes

AFM expansion, incl. 2 sec. At V1

“RTO”

Dry Runway - NO credit for thrust reversers

Wet Runway - Credit given for thrust reversers

FAR TAKEOFF FIELD LENGTH

(cont’d)

Dispatch Runway Requirement, the longest distance of:

Vr

Vlof

35 feet

Takeoff Distance = 1.15 X All Eng. Dist.

“GO”

V1 Vr

Vlof

Vef

Vef

Throttles / max. brakes, speed brakes

“RTO”

35 feet

REFUSED TAKEOFF - STOPPING

• 100% MBE RTO

– Demonstrated performance with:

90% (min.) worn brakes (accident

investigation)

> FAR 25.109

Pre-heated, 3 mile taxi w/ three stops

full stop - 5 minutes

ANTI SKID - INOPERATIVE

CLIMB PERFORMANCE

• Takeoff Path Segments (FAR 25.115)

–

–

–

–

1st = Liftoff to gear up

2nd = gear up to 400 ft.

3rd = 400 ft. to 1500 ft. (accel/cleanup)

Enroute = Greater of: 1500 ft. or clean, MCT &

at final climb speed

• Min. climb requirements based on:

–

–

–

–

Weight

Altitude

Temperature

Most unfavorable CG

TAKEOFF PATH

• Minimum Climb Gradient (FAR 25.117)

– Based on total number of engines

– Takeoff segment

– All engine / OEI, and two EI for quads

• Operational Requirements (FAR 121, Subpart

I)

ENROUTE PERFORMANCE

• Enroute (FAR 25.123)

– Following data must be determined and

published

Climb performance, all engine and OEI

Drift down

Procedures associated with the above

APPROACH PERFORMANCE

• Approach Climb (FAR 25.121)

– Min. climb gradient, based on:

Approach configuration

Total number of engines

Critical engine inoperative

Max. landing weight

FAR LANDING FIELD LENGTH

Vref “landing threshold speed”

Vref min = 1.23Vsr

FAR 25.125

Vref

Touch down

Full stop

50 feet

landing flare

transition

deceleration in full braking config.

FAR 25 Landing Field Length

FAR 121 Landing Distance = demonstrated

0.6

FAR 121 “FACTORED” Landing Distance (121.195)

AIRPLANE FLIGHT MANUAL

• AFM (FAR 25.1581)

– Four sections

Limitations

Normal procedures

Non-normal procedures

Performance

– Appendices

Configuration Deviation List

Derated thrust operations

Engine intermix

Alternate Weight

AFM / CDL

• CDL contains additional limitations

required for operations with missing

secondary parts

–

–

–

–

PIC notified and provided a list of all parts

Each limitation listed by placard in flight deck

Logbook entry

Cumulative performance decrements via

weight penalty

OPERATIONS MANUAL / MMEL

• Flight Crew Operations Manual (FCOM)

(FAR 121.141)

– Permits OM in lieu of the FAR Part 25 AFM

– Must contain Limitations from AFM

– Perf. data / procedures can be modified from

AFM

– NOT FAA Approved, “Accepted” by POI

• Master Minimum Equipment List (FAR

121.627)

– Permits operation of the aircraft in a “nonstandard” configuration

– owned by AEG

FLIGHT TEST - CONCLUSION

• Huge improvements in recent years

– Analytical Methods

– Dynamometer Testing

– Simulation

• Only Flight Test

– Total Integrated Package

– Real World Environment

– Human Factors

• Questions?

PART 25 STRUCTURES RULES

Hank Offerman

Airframe Branch

Transport Airplane Directorate

CERTIFICATION OF STRUCTURE

• CFR 14, Part 25 - Airworthiness Standards

– Subpart C, Structure

Loads, design conditions, proof of structure

– Subpart D - Design & Construction (Structure)

Material & process specifications, special

factors, design criteria, special considerations

– Subpart G - Operating Limitations & Information

Airspeed, weight, center of gravity

> Limits can not exceed values used for design in

Subpart C

Instructions for Continued Airworthiness

> Inspection requirements

» Locations, intervals, methods, acceptance criteria

DESIGN LOADS

• Flight Maneuver & Gust (25.331 - 25.351)

• Ground Loads (25.471 - 25.519)

– Landing loads

– Ground handling loads

Taxi & ground maneuver

– Towing loads

– Jacking & tie-down loads

• Control Surface & System Lds (25.391 25.459)

• Emergency Landing Conditions (25.561 25.563)

• Supplementary Conditions (25.361 - 25.373)

• Fatigue Evaluation (25.571)

• Lightning Protection (25.581)

MANEUVER LOADS

• Response to Control Input or Command

– Pilot

– Automatic flight control system

• Symmetric

– Balanced maneuvers

Steady state

> Zero pitching acceleration

– Checked maneuvers

Rational pitch vs. time profile

– Unchecked maneuvers

Maximum control deflection

MANEUVER LOADS

• Asymmetric

– Rolling conditions

Sudden deflection of controls

Steady state roll maximum control deflection

– Yaw maneuver conditions

Sudden deflection of controls

Overswing yaw maximum control deflection

Steady sideslip maximum control deflection

Sudden return to neutral

MANEUVER LOADS

• Airplane Flight Configuration

– Cruise configuration

With and without in-flight lift and drag

devices

– Takeoff, approach & landing

• Airplane Weight Configuration

– All critical weight & center of gravity

combinations on or within the C.G. envelope

– All critical fuel load combinations

• Airplane Speed & Load Factor

– All critical speed & load factor combinations

on or within the maneuver envelope

MANEUVER LOADS

• Load Factor - “n”

– The inertial or acceleration forces acting on a

body (f) is the load factor times the weight (w)

of the body

f = n x w

• Sign Convention - Airplane Axis System

– Positive - push you into your seat

– Negative - lift you out of your seat

DESIGN V-N ENVELOPES

• Defined by Experience

– Based upon extensive flight measurement

60 year history - on-going programs

– Values selected such that probability of

exceedance is small

– Relationships defined to ensure safe operation

in usage environment

– Does not constrain airplane usage in the

operational environment

– Enables minimum weight design

MANEUVER LOADS

• Maneuver Design Load Factors

– V-n diagram

GUST LOADS

• Gust is an Atmospheric Disturbance

– Direction - change in angle of attack

– Velocity - change in local airspeed

• Result of Gust is Change in Aerodynamic

Force Acting on Airplane

– Acceleration - change in load factor

• Two Structural Load Components

– Rigid body response

– Dynamic response due to airplane flexibility

and gust velocity profile

GUST LOADS

• Present Evaluation Requirements

– Discrete gust

Excites rigid body response

> Provides a dynamic component

Single encounter - defined gust profile

Includes airplane dynamic response

– Continuous gust

Atmosphere model - power spectral density

> Atmospheric energy vs. frequency

Excites dynamic components

> Provides a rigid body component

Envelope design - high loads

Mission analysis - fatigue spectrum

GUST ENVELOPE

• Gust Design Load Factors

– V-n diagram

GROUND LOADS

• Ground Loads are Computed using

Weights and Centers of Gravity Which

Result in Maximum Design Loads in Each

Landing Gear Element

– Forward, aft, vertical and lateral centers of

gravity locations must be considered

GROUND LOADS

• Landing Loads

– Applied to landing gear and airplane

• Landing Parameters

– Descent velocity

Maximum landing weight - 10 feet per

second

Maximum takeoff weight - 6 feet per second

– Landing load factors

Function of landing gear energy absorption

characteristics

Must be validated by tests

GROUND LOADS

• Landing Conditions

– Level landing (nose landing gear arrangement)

Main gear in contact, nose gear clear

All three gear in contact

– Tail down landing

– One-gear landing

– Drift landing

– Rebound landing

GROUND LOADS

• Ground Handling Loads

– Taxi, takeoff and landing roll

Roughest ground reasonably expected

– Braked roll

Main gear in contact, nose gear clear

All three gear in contact

– Turning

Side load due to centrifugal load factor

– Nose wheel yaw & steering

Side load on nose gear

– Pivoting

Landing gear torque

– Reversed braking

GROUND LOADS

• Towing Loads

– Defines loads to be applied to the towing

fittings

– 30% of the towed weight for airplanes

weighing less than 30,000 pounds

– 15% of the towed weight for airplanes

weighing more than 100,000 pounds

– Linearly varying between 30,000 and 100,000

pounds

GROUND LOADS

• Jacking & Tie-Down Loads

– Airplanes must have jacking provisions

– Loads computed at maximum ramp weight

– Airplane

Loads resulting from a vertical load factor of

1.33 plus a horizontal load factor of 0.33 in any

direction

– Fittings & local structure

Loads resulting from a vertical load factor of

2.00 plus a horizontal load factor of 0.33 in any

direction

– Tie-down fittings and local structure (IF provided)

Loads resulting from a 65 knot horizontal

wind in any direction

CONTROL SURFACE & SYSTEM

LOADS

• Control Surfaces Must be Designed for

Loads Resulting From

– Flight conditions

Loads need not exceed those resulting from

the application of maximum pilot effort loads

– Ground gust conditions

– Loads parallel to hinge line

Load factor of 12 for horizontal surfaces and

24 for vertical surfaces

• Must Consider

– Pilot effort effects

– Trim tab effects

– Unsymmetrical loading

CONTROL SURFACE & SYSTEM

LOADS

• Control System Must be Designed for

Maximum Pilot Effort Loads

– Aileron, wheel

80 x wheel diameter pound-inches

– Elevator, wheel

300 pounds

– Rudder

300 pounds

• Criteria for Dual Control Systems

– Pilots acting together

– Pilots acting in opposition

EMERGENCY LANDING

CONDITIONS

• Protection of Occupants

• Protection of Systems Which Could Cause

Fire or Explosion

• Design Load Factors

–

–

–

–

–

Up - 3.0

Forward - 9.0

Sideward - 3.0 for airframe, 4.0 for seats

Downward - 6.0

Aft - 1.5

• Dynamic Conditions for Seats

– “16 g seats”

SUPPLEMENTARY CONDITIONS

• Engine Torque

– Operating torque

– Engine acceleration

– Sudden engine stoppage

• Side Loads on Engine Mounts

• Pressurized Compartments

• Unsymmetrical Loads Due to Engine

Failure

• Gyroscopic Loads

• Speed Control Devices

DAMAGE TOLERANCE & FATIGUE

EVALUATION OF STRUCTURE

• “An evaluation of the strength, detail

design, and fabrication must show that

catastrophic failure due to fatigue,

corrosion, manufacturing defects, or

accidental damage, will be avoided

throughout the operational life of the

airplane” FAR 25.571(a)

DAMAGE TOLERANCE & FATIGUE

EVALUATION OF STRUCTURE

• Damage Tolerance Evaluation

– Address catastrophic failures due to fatigue,

corrosion & accidental damage

Crack growth analysis and/or tests

Residual strength evaluation

Inspection & maintenance procedures

– Applied to single load path structure

– Applied to multiple load path and crack arrest

“fail safe” structure where it cannot be

demonstrated that failure will be detected

during normal maintenance

DAMAGE TOLERANCE & FATIGUE

EVALUATION OF STRUCTURE

• Damage Tolerance Evaluation (Cont’d)

– Wide spread fatigue damage will not occur

during the design service life of the airplane

Supported by full scale fatigue test evidence

• Damage Tolerance (Discrete Source)

–

–

–

–

Bird impact

Uncontained fan blade impact

Uncontained engine failure

Uncontained high energy rotating machinery

failure

DAMAGE TOLERANCE & FATIGUE

EVALUATION OF STRUCTURE

• Fatigue (Safe Life) Evaluation

– May be used when the application of the damage

tolerance requirements is impractical

• Sonic Fatigue Strength

– Sonic fatigue cracks are are not probable in

flight structure subject to sonic excitation, or

– Catastrophic failure is not probable if sonic

fatigue cracking occurs

• Instructions for Continued Airworthiness

– The data developed to demonstrate compliance

with this requirement forms the basis for the

airframe instructions for continued airworthiness

LIGHTNING PROTECTION

• The Airplane Must be Protected Against

Catastrophic Effects of Lightning

– Electrical bonding

– Design of components to preclude the effect of

a strike

– Diverting electrical current

PROOF OF STRUCTURE

• 25.303 through 25.307

• Computed Loads - Limit Loads

• Limit Loads Times Factor of Safety Ultimate Loads

– Factor of safety - 1.5

Very low number - commercial machine

design applications use 6 and up

Usage is justified by material and process

controls imposed by Subpart D and

maintenance programs required by

operating rules

> Part 91, 121, 125, 135

PROOF OF STRUCTURE

• Requirement

– Limit load

No detrimental permanent deformation

Deflections may not interfere with safe

operation

– Ultimate load

Structure must be able to support the load

for 3 seconds

– Dynamic testing may be used

PROOF OF STRUCTURE

• Compliance Demonstration

– Static tests to limit load

May require ultimate load testing where limit

load testing is determined to be inadequate

– Structural analysis

May only be used if the structure conforms

to that for which this method has been

shown to be reliable

DESIGN AND CONSTRUCTION

• Material & Process Specifications

– 25.603, 25.605, 25.613

• Special Factors

– 25.619 - 25.625

• Design Criteria

– 25.607 - 25.611, 25.651 - 25.735

• Special Considerations

– 25.629 - 25.631, 25.843(a)

MATERIAL & PROCESS

SPECIFICATIONS

• The Suitability and Durability of Materials

Must – Be established on the basis of experience or

tests

– Conform to approved specifications

Ensure having the strength and other

properties assumed in the design data

Take into account environmental conditions

expected in service

> Temperature

> Humidity

MATERIAL & PROCESS

SPECIFICATIONS

• Manufacturing Processes

– The method of fabrication used must produce

a consistently sound structure

– If a fabrication process requires close control

to produce consistently sound results it must

be performed under an approved process

specification

– Each new fabrication method must be

substantiated by tests

MATERIAL & PROCESS

SPECIFICATIONS

• Material Specifications

– Material strength properties must be based on

enough tests of material meeting approved

specifications to establish design values on a

statistical basis

“A-basis” – 99% probability, 90% confidence

“B-basis” – 90% probability, 90% confidence

– Effects of temperature must be considered

where thermal effects are significant under

normal operating conditions

SPECIAL FACTORS

• The Factor of Safety of 1.5 Must be

Multiplied by the Highest Pertinent Special

Factor of Safety for Each Part of the

Structure Whose Strength is

– Uncertain

– Likely to deteriorate in service

– Subject to appreciable variability

Uncertainties in manufacturing process

Uncertainties in inspection methods

SPECIAL FACTORS

• Casting Factor – Process Variables

– Critical castings

Failure would preclude continued safe flight

and landing or cause injury

1.25 to 1.5

> Based upon testing and inspection

– Noncritical castings

All others

1.0 to 2.0

> Based upon testing and inspection

SPECIAL FACTORS

• Fitting Factor – Uncertainties in Stress

Analysis

– Applied to fittings whose strength has not been

proven by limit and ultimate load tests

– 1.15

• Fitting Factor – Wear and Deterioration

– Seats, seatbelt fittings

– 1.33

• Bearing Factor – Wear and Deterioration

– Control surface hinges

– 6.67

SPECIAL FACTORS

• Bearing Factor – Clearance Fits Subject to

Vibration

– Judgment

• Joints Subject to Angular Motion – Wear

– 3.33

– Not applicable to ball or roller bearings

DESIGN CRITERIA

• Fasteners

– Locking devices

• Protection of Structure

– Protection against loss of strength in service

due to any cause, including

Weathering

Corrosion

Abrasion

– Provisions for ventilation and drainage

DESIGN CRITERIA

• Control Surfaces

– Limit load tests required

– Compliance with special factor requirements

must be shown by analysis or test

• Control System Stops

– Must be able to withstand any load

corresponding to design conditions for the

control system

• Control system Limit Load Static Tests

– Testing required in which

Each fitting, pulley and bracket is loaded

Compliance with special factors may be by

analysis

DESIGN CRITERIA

• Landing Gear

– Shock absorption tests

Limit drop tests

> Landing load factors

Reserve energy absorption drop tests

> 12 foot per second descent velocity

• Landing Gear Retracting Mechanisms

– Loads from flight conditions, gear retracted

– Loads from flight conditions in landing

configuration, gear retraction operating

DESIGN CRITERIA

• Landing Gear Doors

– Design for yawing conditions

• Wheels and Tires

– Requirements for load ratings

SPECIAL CONSIDERATIONS

• Aeroelastic Stability Requirements

– Flutter, divergence, control reversal

– Loss of stability and control as a result of

structural deformation

– Must be shown by

Analysis

Wind tunnel tests

Ground vibration tests

Flight tests

Other means found necessary by the

Administrator

SPECIAL CONSIDERATIONS

• Aeroelastic Stability Requirements

(Cont’d)

– Aeroelastic stability envelope

Normal conditions

> VD + 15%

Failure, malfunction & adverse conditions

> VC + 15%

> Failures, malfunctions & adverse conditions

defined

– Flight test requirements

• Bird Strike

– Empennage

8 pound bird at VC

MECHANICAL SYSTEMS

Robert C. Jones

Mechanical Systems Branch

Transport Airplane Directorate

MECHANICAL SYSTEMS

• Flight Controls

• Hydraulic Systems

• Landing Gear Systems

• Cabin Environmental Systems

• Cargo Fire Protection Systems

• Ice Protection Systems

FLIGHT CONTROL SYSTEMS

Flight Control Systems (25.629, .671, .672, .1309 et al)

• Ensure airplane controllability for

– All flight and load conditions in flight envelope

– Environmental conditions (temp, precip, salt, deice contamination, etc)

– In the presence of failures (including A/P)

All single failures & combinations of

failures Pf > 10^-9 and certain dual failures

Jams Pj > 10^-9

– Ensure availability of functions that rely on FC

Stability: Flutter, speed, mach, dutch roll; load

allev.

Safe pilot interface (feel systems, disconnects,

indications, warnings, motions, procedures)

• Methods: Test, analysis redundancy, separation, monitoring,

maintenance

FLIGHT CONTROL SYSTEMS

Safety Objectives

• Provide control system capable of safely maneuvering airplane

through all phases of flight within the flight envelope and that

has effective residual control for safe flight and landing after

failures and jams.

• The system must be designed to allow to control airplane

without exceptional piloting skill or strength even after failures.

• System design must account for human factors to ensure pilot

has suitable warnings, can disconnect or override interfacing

systems, and that movement of controls in the normal sense

results in normal airplane response.

• Where automated functions (A/P, SAS, LAS) implemented thru

flight controls ensure system has acceptable reliability,

annunciation, disconnects, and that procedures are available to

permit CSF&L.

• Ensure the airplane without engines remains controllable

down to certain landing speeds.

FLIGHT CONTROL SYSTEMS

Upcoming Improvements

Harmonized flight control rule (25.671/672)

• Addresses NTSB recommendation for reliable

redundancy

• Ensure that failures of dual redundant control

paths do not fail latent without meeting specific

guidelines

HYDRAULIC SYSTEMS

Hydraulic Systems (25.1309, 1435, 1438, 1461)

• Ensure hydraulics for critical & essential

services

• Equipment req’d to meet specific pressure

loads in combination with limit structural loads

and to withstand 1.5 X design operating

pressure load

• Fire safety requirements

• Integrity of pressure vessels

• Containment of failed rotors

• Methods: Test, analysis, separation, redundancy,

monitoring, maintenance

HYDRAULIC SYSTEMS

Safety Objective

• Ensure hydraulics for critical & essential

services, as required, to allow continued safe

flight and landing even after hydraulic failures

LANDING GEAR SYSTEMS

Landing Gear Systems (25.721, 729, 735, 1309,

JAR 25.745)

• Provide capability for airplane ground

maneuvering,

• Braking/stopping,

• Gear retraction and gear extension in the

air.

LANDING GEAR SYSTEMS

Safety Objective

• Provide capability for airplane ground

maneuvering, braking/stopping, plus gear

retraction and gear extension in the air

– Landing gear systems include nose and main

gear retraction/extension mechanisms

including doors, wheels, tires, brakes and

brake controls (antiskid), steering, brake wear

& temperature monitoring, and tire pressure

indication systems

LANDING GEAR SYSTEMS

Note

• Worn Brake Rejected Take-Off (RTO)

– A DC-10 went off the runway. Brakes had been

tested in a new condition for RTO in accordance

with the certification rules in effect at that time.

AD required airplanes over 75,000 pounds to

perform a worn brake demonstration

(dynamometer)

– Latest rule requires airplane demonstration for

all gross weights

CABIN ENVIRONMENTAL SYSTEMS

Cabin Environment (25.831, 25.832, 25.841,

25.1438, 25.1441, 25.1443, 25.1445, 25.1447,

25.1450, 25.1309)

• Ensure passengers and crewmembers have:

– an acceptable environment during normal

operating conditions

– adequate protection to enable survival

without permanent physiological damage

after any system failure

• Methods: Test, analysis, redundancy, maintenance

CABIN ENVIRONMENTAL SYSTEMS

Safety Objective

• Provide the means to keep the occupants

of the aircraft alive and comfortable

– Oxygen, pressurization, pneumatic, heating,

ventilation, and air conditioning systems

CABIN ENVIRONMENTAL SYSTEMS

• The pressurization and temperature

controlled environments protect the

occupants from the cold temperatures at

high altitudes and provides an atmosphere

with enough oxygen to maintain life

• The high operating altitudes of modern

aircraft necessitate oxygen systems that

can sustain life for a limited period of time

should cabin pressurization fail

CARGO FIRE PROTECTION

SYSTEMS

Cargo Fire Protection (25.851(b), 25.855,

25.857, 25.858, 1309)

• Ensure that – Detection systems detect a fire before it

damages airplane structure & provides visual

indication within 1 minute

– Built-in fire extinguishing system does not

introduce a hazard to occupants or the

airplane structure & is adequate to control any

fire likely to occur

• Methods: Test, analysis, redundancy, maintenance

CARGO FIRE PROTECTION

SYSTEMS

Safety Objectives

• Provide safety features to detect/combat fires

• Minimize the impact of fire and extinguishing

agent on occupants

CARGO FIRE PROTECTION

SYSTEMS

• Cargo Compartments

– Requirements to keep hazardous quantities of

smoke/flame from entering into crew/passenger

compartments

– Most are required to have smoke/fire detectors and

an annunciator in the flightdeck

• Fire Suppression

– Cargo compartment fires are not “extinguished,”

they are “suppressed and controlled”

– The suppressing agent is Halon

CARGO FIRE PROTECTION

SYSTEMS

• Information on Class D to C Cargo Compartments

– FAA eliminated Class D cargo compartments for future type

certification from commercial transport airplanes

March 19, 2001

Class D cargo compartments must meet the standards for

Class C or Class E compartments

These changes came about because of a number of

accidents, including Valujet

ICE PROTECTION SYSTEMS

Ice Protection (25.1419, 1403, 1309)

• Ensure Airplane Safety by:

– Detection ice or icing conditions

– Anti-ice or deice capability

– Windshield and probes heating

– Provide acceptable flight characteristics for

intercycle ice and ice accreted on

unprotected surfaces

• Methods: Test, analysis, redundancy, separations

ICE PROTECTION SYSTEMS

Safety Objectives

• For airplanes that intend to operate in icing

conditions the ice detection and protections

systems must be designed to ensure timely

activation and capability of ice protection system,

the airplane must be shown to safely operate with

ice accreted on unprotected surfaces and

intercycle ice on protected surfaces, and the

airplane must be shown safe for trajectories of

shed ice to ensure they do not negatively impact

propulsion, instruments, or structures

• Clear windshield in icing conditions

• Instruments operable in icing conditions

ICE PROTECTION SYSTEMS

• Developments

– Definition of SLD conditions for certification.

Current FAR/JAR do not cover this condition.

(rule in development)

– Detection of ice formations aft of the protected

surfaces. Current FAR/JAR do not require this.

(OPS rule in development)

– Ensuring stall margins met with intercycle ice

and ice on unprotected surfaces (SFAR in

work)

PART 25 EQUIPMENT RULES

Steve Boyd

Systems & Flight Crew Interface Branch

Transport Airplane Directorate

OVERVIEW

•

•

•

•

•

•

•

•

General Remarks

Equipment Installation Requirements

Safety Standards and Objectives

Operational Environment

Instruments

Electrical Systems

Lighting

Recording Systems

GENERAL REMARKS

• Subpart F addresses most systems

installed in the airplane

• Examples include

–

–

–

–

–

avionics

flight and navigational equipment

environmental control

lighting

power generation

EQUIPMENT INSTALLATION

REQUIREMENTS

• Overall Purposes

– Establish safety standards for installed

equipment

Equipment must perform its intended

functions

Regulate frequency of failures based on their

severity

Protect aircraft and persons against effects of

environmental and operational hazards

Provide means to alert the crew

– Standardize certain flight deck display

information

– Provide airworthiness standards for certain

equipment required by operating rules

SAFETY STANDARDS: PERFORM

INTENDED FUNCTION

• The equipment’s functionality, capability,

and limitation must be deliberately

incorporated, i.e. no hidden functionality

(25.1301)

• Certain levels of reliability for safetycritical systems are required,…

• However, equipment is not expected to

always work

• Therefore, the effects of failures are also

regulated (25.1309)

SAFETY OBJECTIVES

• Failure effects are regulated by requiring

an inverse relationship between the

severity of the failures and their frequency

of occurrence

Catastrophic

Effect

Reduced Crew

Ability to Cope

with Adversity

Minor Effect

Extremely

Improbable

Improbable

More

Frequent

SAFETY OBJECTIVES

(continued)

In addition…

• Fail Safe Design = No single failure

can result in a catastrophic condition

(AC25.1309-1A)

SAFETY OBJECTIVES

(continued)

• The regulations governing system safety

are based on the “fail-safe” design

concepts which typically include:

–

–

–

–

–

Design integrity and quality (design practices)

System redundancy (protect from first failure)

Proven reliability (service experience)

Error tolerance (designer, maintainer, operator)

Flight/maintenance crew procedures (mitigate

failure effects)

– Others (not listed for brevity)

SAFETY OBJECTIVES

(continued)

• The safety objectives are defined at the

airplane level, not at the components

themselves [a component failure does not

always result in a hazard to the airplane,

crew, or occupants]

• To meet these objectives, the methods of

compliance routinely involve qualifying

components by rigorous industry-wide

guidelines:

– Hardware RTCA/DO-160D

– Software RTCA/DO-178B

SAFETY OBJECTIVES

(continued)

• Alerting is necessary to meet the overall

safety objectives (25.1309 (c))

– When flight crews are expected in intervene to

mitigate the effects of failures

– Alerting can be by design (warnings/cautions)

or by intrinsic characteristics (e.g. deterrent

buffet)

• Lighted messages are standardized by

color coding: red or Amber, depending on

the hazard level and urgency (25.1322)

SAFETY OBJECTIVES

(end)

• Certification Maintenance Requirements

(CMR) are established during certification

as an operating limitation of the Type

Certificate (AC25-19)

– CMR is failure finding task to detect safetysignificant latent system failures that, in

combination with other failures, result in a

hazardous or catastrophic condition

– CMR is not MSG-3 which are tasks that prevent

failures

– CMR is not structural inspection required by

25.571, 25.1529, Appendix H25.4

THE OPERATING ENVIRONMENT

• Effects due to operational and

environmental conditions (internal and

external) are considered

– Specific rules for:

lightning protection (25.1316)

ice detection and protection (25.1403, 1419)

life support systems (25.1438-1453)

– Other conditions (altitude, temperature, rain,

wind, vibration, glare, etc…) are considered in

specific methods of compliance which

typically involve testing

INSTRUMENTS

• The regulations provide the minimum

standards for displaying safety-critical

information in the flight deck (25.1303,

1305)

• Certain instruments must be installed

– Safety-critical flight and navigation

instruments (specific navigation systems are

required by operating rules)

– Powerplant instruments

• The “basic T” arrangement (25.1321)

INSTRUMENTS

• Specific regulations levied against flight

critical system to ensure:

– Safety of design (under failure conditions, for

flammability, system status indications, etc.)

– Human factors issues (control accessibility,

consistency of operation, consistent use of

color, etc.) have been addressed

– Adequate means to detect system failures

– Adequate system capacity (for electrical

power)

INSTRUMENTS

• General requirements levied against flight

critical instruments ensure:

– Means are provided to connect required

instruments to opposite side of cockpit

– Display of information essential to safety of

flight will remain available to pilots after single

failure

– Other systems may not be connected to these

flight critical systems, unless provisions are

made to ensure correct operation after failure

AIRSPEED INDICATING (25.1323)

STATIC PRESSURE (25.1325)

• Other specific instrumentation

requirements intended to deal with past

problem areas:

– System arrangement to prevent malfunction

due to entry of moisture, dirt, or other

substances

– Heated to prevent malfunction due to icing

– Redundant systems separated to prevent

single event (e.g., birdstrike) from disabling

multiple systems

– Positive drainage to avoid corrosion, correct

use of materials, correct installation to avoid

chafing

AUTOPILOT/FLIGHT DIRECTOR

SYSTEMS (25.1329)

• Must be able to be disengaged quickly and

positively to prevent interference with pilot

control of airplane

• Must be designed to prevent hazardous loads

on airframe or hazardous flight path deviations

during normal flight or failure condition

• Must be designed to provide positive and

unambiguous annunciation of current operating

mode

• Human factors issues (operation of controls,

location of displays and controls, etc.)

POWERPLANT INSTRUMENTS

(25.1337)

• Provides installation requirements for the

instruments required by other sections

– Minimize hazards from escape of flammable

fluids

– Ensure proper calibration of fuel quantity

indication systems

– Minimize affects of fuel flowmeter

malfunctions

– Other specific issues associated with oil

quantity, propeller position, and fuel pressure

indication systems

ELECTRICAL SYSTEMS

• General Requirements

• Generating Systems

• Distribution System

• Circuit Breakers

GENERAL REQUIREMENTS

• The airplane must be capable of operation

without normal electrical power sources at

maximum altitude for at least 5 minutes

(25.1351d)

• Electrical equipment, controls and wiring

must be installed to ensure non-interference

with other electrical units and systems

essential to safe operations (25.1353a)

• Electrical cables must be grouped, spaced

and routed to minimize damage to essential

systems due to faults in heavy currentcarrying cables (25.1353b)

GENERAL REQUIREMENTS

• Electrical Systems Laboratory Tests

(25.1363)

– system should have a high degree of fidelity

with actual equipment installed on the airplane

– for flight conditions not simulated adequately

in the laboratory, flight tests must be made

example: effect of zero g and negative g’s on

generator function

GENERATING SYSTEMS (25.1351)

• Electrical Loads analysis determines the

generating capacity and number and kind

of power sources

• No failure of a power source can create a

hazard or impair the ability of remaining

sources to supply essential loads

• There must be a means to disconnect

power sources from the system and

indicate power available

BATTERIES (25.1353C)

• Most aircraft need a battery to power critical

systems or start the auxiliary power unit in

case normal generator power is lost in flight

• Battery requirements include:

– temperature and pressure safeguards

– protection from explosion and toxic gas

emissions

– meet 5 minute loss of primary power requirement

– charge rate, temperature monitored with

associated warning to crew and ability to

disconnect

CIRCUIT PROTECTION (25.1357)

• Circuit breakers or fuses are required to

protect wiring and airplane power busses

– automatic devices required to minimize hazard

to airplane in event of wiring faults

– protective devices necessary for generating

system

– if resetting is required for safety of flight,

circuit breaker must be located and identified

so it can be easily reset in flight

LIGHTING REQUIREMENTS

• External requirements include:

– Position lights (red, green, white on tail)

(25.1385, 1387, 1389)

– Anti-collision lights (25.1401)

– Wing ice detection lights (25.1403)

– Landing lights (25.1383)

• Specific requirements for coverage, color,

position and intensity (25.1389, 1391,

1393, 1395, 1397)

LIGHTING REQUIREMENTS

• Internal lighting requirements include:

– means provided to control intensity (25.1381)

– meet intended function (25.1301)

– emergency lightning for evacuation (25.812)

• Cockpit lighting evaluation by pilots for all

operational conditions

• No requirements for cabin lights, except

for emergency lighting

RECORDING SYSTEMS

• Recording systems must not impact the

safe operation of the airplane and are

mandated by the operating rules (91.609

c,e)

• Design and installation requirements

addressed in Part 25, subsection F

– Cockpit Voice Recorder (CVR)

– Flight Data Recorder (FDR)

• Additional requirements in operating rules

(121.359, 121.343)

MISCELLANEOUS EQUIPMENT

REQUIRED BY OPERATING RULES

• Airworthiness standards for certain

equipment required by operating rules are

provided

–

–

–

–

Windshear systems (121.358, AC25-12)

Protective breathing equipment (25.1439)

Oxygen equipment (25.1441-1453)

Terrain Awareness & Warning (TAWS) (121.354,

AC25-23)

– Traffic Alert & Collision Avoidance System

(TCAS) (121.356)

ENGINES AND APU’S

Mark Fulmer

Manager, Engine Certification Office

Engine and Propeller Directorate

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Safety is defined at the Aircraft level

– Engine and APU Contributors

Burst

Fire

Loads

Loss of Thrust Control

Toxic Products in Bleeds

In-flight Shutdown

Propeller Release

THE OLD WAY

Resources Expended on Initial & Ongoing Evaluation (Type & Production)

Typical average

by PAH type

Resource

Expenditure

(degree of

attention

paid)

Wide variation

subjective criteria

Priority

No Distinction for Same Production Approval

Holder (PAH) types PMA/TSO/PC)

THE NEW WAY

Resources Expended on Initial & Ongoing Evaluation

(Type & Production)

{

Designees &

Eval. Method

{ Self Audit

System Adequacy

{

Criteria

Focus

Non-Priority

Non-Critical

Resource

Expenditure

Priority

Non-Critical

Priority

Critical

PI/PE

Evaluations

ACSEP & Product

Specific Evaluations

Old Avg.

(degree of

safety based

attention

paid)

Smaller variation

defined by resource

targeting

Priority

Determined by: - SVC Exper Safety Data

- Product Safety Assessment

Causal Factors of Disk Fractures

Accident (level 4)

~ 5 per 100 Million Flights

Hazardous events:

~ 16 per 100 M flights

Part Fractures

All uncontained:

~ 32 per 100 M flights

Opportunities

Opportunities

Examples

low cycle

fatigue

high cycle manufact.

fatigue

defect

material

defect

Forging

Titanium

Machining Inconel

Peening

Steel

Other

maint. &

overhaul

fretting/

rubbing

Assembly error

Inspection

Repair

troubleshooting

erosion/

corrosion

bearing

failure

Design

Prod.

Maint.

overspeed

overtemp

Shaft failure Loss of disk

Fuel Control cooling,

Closed VSVs Limitation

exceeded

FOD

Birds

A/C ice shed

Blue ice

BMOD

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Some common considerations

– Likely single and multiple failures

– Likely improper operation

– Likely improper maintenance

– Likely inservice damage

– Minimize and cover latent failures

– Human factors assessed

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Burst

– Minimize failures that can release debris,

particularly high energy debris

– Contain failures where possible

– Uncontainable failures are predictable

– Effects on aircraft minimized (redundancy,

isolation, shielding)

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Fire

– Minimize occurrence and spread

Contain flammable fluids

> Assess structural integrity and materials of

components and fire wall

Isolate ignition sources

Control usage of flammable materials such

as Titanium and Magnesium

Coordination with aircraft installation to

minimize effects

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Loads

– Ultimate and limit capability defined

Mounts

Major load carrying structure

– Vibratory (internal and external effects)

Component criticals and induced

– Failure conditions

Instantaneous, rundown, windmilling

– Engine induced loads coordinated with aircraft

installation

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Loss of Thrust Control

– Control system reliability and safety

assessment (hardware and software)

– Redundancy

channels, mode, models, hydro-mechanical

backup

– Auto-shutdown for APU’s

– Limiting

topping, overspeed, overtemp

– Fail safe options

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Toxic Products in Bleeds

– Bleed air quality testing

– HazMats and VOC assessment

– Minimize ingress for likely failures

– Aircraft level isolation

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• In-flight Shutdown

– Reliability and durability

Random independent vs. common cause threat

Damage tolerance

ETOPS

Control system time limited dispatch

– Environmental

Weather, birds, HIRF, lightning

– Stability

Fan and compressor stall

Combustor stability

– Human factors in operations and maintenance

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Propeller Release

– Propeller mount flange and shaft loads

– Propeller installation and flight strain

survey evaluated for suitability

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Outcomes of Certification

– Ratings and Operating Limitations

Power

Rotor speeds

Temperatures and pressures (gas path, fuel,

oil, etc.)

– Installation Requirements

Component temperatures

Loads (steady & vibratory)

Inputs/Outputs

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Outcomes of Certification

– Operating instructions

Altitude, attitude, speed, temperature

Procedures (in-flight relight, environmental,

ground handling, etc.)

– Airworthiness Limits

Component life, inspections, maintenance

– Instructions for Continued Airworthiness

On-wing preventative maintenance and

off-wing overhaul

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

• Production Certification

– Production process definition, process

controls, defect characterization, inspectability,

surveillance

• Operational and Maintenance Certifications

– Based on ability to adhere to type certification

data, limitations, and conditions

• Ongoing Management of Production,

Operability and Maintainability

FA ACT SECTION 603

• To be eligible for an airworthiness

certificate, an aircraft must:

– Conform to its type certificate, and

– Be in a condition for safe operation

• Type Certificate (FAR 21.41) includes the

type design (FAR 21.31) plus operating

limitations, TCDS, and applicable FAR

compliance conditions and limitations

PERFORMANCE OF MAINTENANCE

AND ALTERATION

• Repair Stations must perform work in accordance with

the manufacturers ICA (FAR 43.13a), an aircarrier's

manuals (FAR 145.2) or other FAA approved data.

• Maintenance may be conducted using other methods,

techniques and practices acceptable to the

Administrator that accomplish the same end result

with respect to airworthiness i.e.; conformity to the

type design and safe for operation

• Repairs, alterations, or deviations from the

Manufacturers ICA which are major require FAA

approved data

• Maintenance must return the product to either its

original or properly altered configuration

(FAR 43.13b)

FUNDAMENTAL CERTIFICATION CONCEPTS

ENGINES AND APU’S

•

In Closing:

– Don’t confuse compliance with safe nor

non-compliance with unsafe

– There is no such thing as an isolated event

POWERPLANT INSTALLATIONS

Kathrine Rask

Senior Engineer, Propulsion Branch

Seattle Aircraft Certification Office

PROPULSION SYSTEM

• Overview

– System Definitions

– Fundamental Certification Concepts

– Fuel Systems

– Engine Ice Protection

– Thrust Reverser

– Engine Operating Characteristics

– Fire Protection

– Uncontained Engine Failure

– Powerplant Instruments

SYSTEM DEFINITIONS

• Multi-Engine Installation

– Engines are Part 33 certified

Objective is “stand alone” type certificate;

generally not airframe specific

• Auxiliary Power Unit (APU) Installation

– APU’s qualified to technical standard order

Also “stand alone” certification objective

• Fuel System

– Tanks, pumps, plumbing, wiring, etc.

§§ 25.901(a), 25.903

FUNDAMENTAL CERTIFICATION

CONCEPTS

• No Single Failure or Probable

Combination of Failures will Jeopardize

Safe Operation

– A single failure is assumed without

consideration as to its probability of failing

– If a failure event cannot be readily detected, it

is counted as a latent existing failure in

addition to the first failure

– “Probable” - expected or foreseeable

Term often confused with 25.1309

terminology; quantitatively means “not

extremely improbable”

§ 25.901(c)

FUNDAMENTAL CERTIFICATION

CONCEPTS

– “Jeopardize safe operation”

Continued safe flight and landing from brake

release through ground deceleration to stop

Safe flight is determined by both qualitative

and quantitative analysis

Consider service experience of similar failures

§ 25.901(c)

FUNDAMENTAL CERTIFICATION

CONCEPTS

• No Single Failure or Probable Combination

of Failures will Jeopardize Safe Operation

– Accomplished By

Isolation

Independence

Redundancy

Reliability

– Four Exceptions To Rule

Uncontained Engine Failures

Combustor Case Burn Through

Propeller Failure

Certain Structural Failures

§§ 25.901(c), 25.903(b), 25.903(d)(1), 25.905(d)

FUEL SYSTEMS

• Fuel System Independence/Redundancy

• Fuel Flow

– Normal operation

– Hot/cold weather, negative “G,” gravity feed

• Lightning Protection

• Crashworthiness

• Failure Modes

– Ignition sources/flammability

– Function of automated fuel system

§§ 25.943, 25.951-25.1001

FUEL SYSTEM

• New Outlook on Fuel System Safety

– Part 21 Special Federal Aviation Regulation

Retroactive design review of in-service

airplanes

– New Part 25 Regulation Changes

Improved safety analysis

Minimized fuel tank flammability

– Operating Rule Changes

Mandate improved maintenance

SFAR No. 88; §§ 25.981, 91.410, 121.370, 125.248, 129.32

ENGINE ICE PROTECTION

• Engine Installation Shall Continue to

Operate in Severe Environmental

Conditions

– Review ice accumulations on engine, inlet, and

other airframe surfaces that could be ingested

Freezing fog on ground

Falling and blowing snow on ground

Late activation of ice protection by crew in

flight

Fan ice shedding and procedures

– No engine icing limitations

Engine power/thrust always required to exit

inadvertent icing conditions

§ 25.1093

THRUST REVERSER

• Demonstrate compatibility with engine

• Demonstrate compatibility with airplane

– Significant change in philosophy since the

Lauda 767 accident

Exposed vulnerability to certain aircraft

during high speed flight

Long Strut/Low Mount

T/R pattern under wing - no stall

Short Strut/High Mount

T/R pattern over wing - stall

THRUST REVERSER

• Two Options to Meet Part 25 Safety Intent:

– To demonstrate that the airplane must be

controllable under any possible position of the

thrust reverser

Thorough flight test controllability

demonstration

Demonstrate operable reverser can be

restored to the forward thrust position

Minimize potential for in-flight deployment

§ 25.933

THRUST REVERSER

• Two Options to Meet Part 25 Safety Intent

(continued):

– To demonstrate the possibility of an inflight

thrust reverser deployment will not occur

within the life of the airplane fleet

Rigorous qualitative and quantitative

analysis with more conservative

assumptions

Typically results in three independent

thrust reverser restraints

Review minimum dispatch configurations

THRUST REVERSER

• Maintenance has played a significant role in

the majority of inflight thrust reverser

incidents

– Review safety analysis assumptions to ensure

they are tolerant to human error

– Review general thrust reverser maintenance

procedures

– In depth review of thrust reverser lock-out

configuration and procedures

• Vast majority of in-service thrust reverser

uncommanded deployments resulted from

improperly de-activating system

associated with MEL activity

ENGINE OPERATING

CHARACTERISTICS

• Engines should continue to safely operate

throughout the airplane flight envelope

• Engine operation demonstrated at

airplane’s limits of :

– Ambient temperature

– Altitude/airspeed/angle of attack

– Tailwind/crosswind

– Rapid and slow power lever movements

– Mechanical/electrical loading

§§ 25.939, 25.931

POWERPLANT FIRE PROTECTION

• General intent is to provide redundant

design:

– Minimize potential for fire

Ventilation required to minimize potential of

flammable vapor

Managing zone temperatures and sources

of ignition

– Minimize effects/duration if a fire should occur

Fire walls

Quick acting detectors

Flammable fluid shut off provisions

Drainage provisions

Extinguishing

§§ 25.863-25.869, 25.1181-25.1207

UNCONTAINED ENGINE FAILURE

B-747; 2000

DC-10; 1973

UNCONTAINED ENGINE FAILURE

• Uncontained engine failure threat too

great to be completely addressed by

failsafe philosophy

– Some of the threat addressed by prescriptive

requirements

Differential compartment loads

Damage tolerant structure

Decompression

§§ 25.365(e)(1), 25.571(e)(2)-(3), 25.841(a)(3), 25.903(d)(1)

UNCONTAINED ENGINE FAILURE

– Remainder of airplane threat minimized in the

event of an uncontained engine or APU failure

Isolation

> hydraulic check valves

> flammable fluid shut-off provisions & dry bays

Redundancy & Separation

> hydraulic line, flight control wires/cables & electric

power

> flammable fluid shut-off valves

Shielding

> critical structure & systems

> auxiliary fuel tanks

> APU containment devices

POWERPLANT INSTRUMENTS

• Intent is to provide indication of engine

parameters, limits, and failures to enable

the crew to always maintain control of

engine

– Limit exceedances (protect rotor integrity)

– Fault enunciation - critical failures

Messaging system consistent with flight

deck philosophy

Minimize flight crew workload

– Pop-up displays

– Standby indication

– Trend monitoring

§§ 25.1305

OTHER SYSTEM REQUIREMENTS

• Part 25 also addresses:

–

–

–

–

–

Propeller installation

Oil system

Thrust augmentation

Starting

Component cooling

–

–

–

–

–

Controls

APU

Performance

Powerplant accessories

Inlets/Exhaust

All follow the fundamental concept

of fail-safe and isolation

CABIN SAFETY

Frank Tiangsing

Manager, Airframe/Cabin Safety Branch

Transport Airplane Directorate

DEFINITION

• Cabin Safety, the discipline that deals

with:

– Occupant protection/survival

– Escape from crashes or other emergency

events

Electrical

Systems

Mechanical

Systems

Cabin Safety

Operations

(Flight Standards)

Airframe

MAIN ELEMENTS

• Occupant protection

• Evacuation

• Fire protection

• Emergency equipment

OCCUPANT PROTECTION

• Occupant protection is provided by

having:

– Seats approved to static and dynamic loads

(§§ 25.561, 25.562, 25.785)

– Items of mass retained (§ 25.789)

– Padding on projecting objects (§ 25.785(k))

– Handholds along aisles (§ 25.785(j))

– Slip resistant floors (§ 25.793)

– Access to oxygen during a decompression event

(§ 25.1447)

OCCUPANT PROTECTION

• Static testing of seats

– Seats are tested to loads in the forward, aft,

sideward, up and down directions

– Maximum loads from the ground, flight and

emergency landing conditions are applied

OCCUPANT PROTECTION

• Dynamic testing of seats

– Two test conditions

16g forward load

14g downward load

– Includes occupant injury criteria

Head Injury Criteria (HIC)

Lumbar load

Femur load

– TSO-C127 prescribes minimum performance

standards for dynamically tested seats

MAIN ELEMENTS

• Occupant protection

• EVACUATION

• Fire protection

• Emergency equipment

EVACUATION

Evacuation addresses the means for

occupants to safely travel from their seats

to the ground or water

EVACUATION

• Effective evacuation is accomplished by

providing:

– Appropriate type and number of exits (§ 25.807)

– Access to exits (§ 25.813)

– Assist means from the aircraft to ground or water

(§ 25.810, TSO C69c)

EVACUATION

• Effective evacuation is accomplished by

providing:

– Emergency lighting (§ 25.812)

– Emergency evacuation demonstration (§ 25.803, App. J)

– Ditching capability (§ 25.801)

MAIN ELEMENTS

• Occupant protection

• Evacuation

• FIRE PROTECTION

• Emergency equipment

FIRE PROTECTION

• Interior fire protection is accomplished

by addressing the following areas:

– Interior materials (§ 25.853, App. F)

Bunsen burner test

(Part I)

Seat cushion test

(Part II)

Heat release test

(Part IV)

Smoke emission test

(Part V)

– Cargo compartments (§ 25.855, App. F)

Bunsen burner test

Oil burner test for Class C compartment liners

(Part III)

FIRE PROTECTION

– Lavatories (§§ 25.853(h), 25.854)

Waste receptacles

> Must have built-in fire extinguishers

> Must be capable of containing fire

Smoke detectors are required

– Portable fire extinguishers must be distributed

throughout the aircraft (§ 25.851)

MAIN ELEMENTS

• Occupant protection

• Evacuation

• Fire protection

• EMERGENCY EQUIPMENT

EMERGENCY EQUIPMENT

• Emergency Equipment Required by

Part 25

– Fire extinguishers, oxygen bottles, floatation seat

cushions or life vests (§§ 25.851, 25.1415, 25.1447,

121.333(e))

– Overwater operation: life rafts, life vests, survival

kits, emergency transmitters, life lines (§ 25.1415)

• Emergency Equipment Required by

Part 121

– Megaphones, first aid kits, smoke hoods, crash ax,

flashlights (§§ 121.309, 121.337, 121.549)

EMERGENCY EQUIPMENT

• Emergency equipment must be:

– Readily accessible (§ 25.1411(a))

– Reasonably distributed and arranged so that

its location is obvious, well identified and

appropriate for its intended use

(§§ 25.851(a), 25.1411)

– Protected from inadvertent damage

(§25.1411(b))

HUMAN FACTORS IN PART 25

Steve Boyd

Airplane & Flight Crew Interface Branch

Transport Airplane Directorate

HUMAN FACTORS IN PART 25

• Definition (unofficial) - Human Factors, as it

applies to aircraft certification:

– The application of scientific theory, principles,

data and methods...

– about human abilities, limitations, and other

characteristics...

– to the establishment of minimum safety-related

design requirements for flight crew interfaces,

tasks, and procedures,...

– and then ensuring that those requirements are

met,

– in order to promote overall system performance

and safety

UNDERPINNING FOR THE CREW

INTERFACE REQUIREMENTS

• We base the requirements on knowledge

and/or assumptions about:

– The “human” capabilities and limitations of the

people who will fly the airplanes

– Their level of training

– Their roles and responsibilities

– The demands of the mission

• Note: Requirements for items 2 and 3 are

contained in the operating rules

PRIMARY HF AREAS

• Human factors issues are integrated into

the rules in various subparts

• Main areas include:

–

–

–

–

The controls and displays that the pilots use

The physical geometry of the flight deck

Integrated aspects of the flight crew interfaces

The evaluation of performance and handling

qualities

COMPETING REQUIREMENTS

Tall Pilots

All controls

reachable,

displays readable

Weight. Panel

space

Additional

functionality

Comfortable

seats

Information

Overload

Situation

Awareness

Commonality

16g seats

External vision

Short Pilots

Space necessary

for controls and

displays

CONTROLS AND DISPLAYS

• Specific controls and displays are called

out for certain functions

• Some are based on “assumed” pilot

responsibilities

• Some are required to deal with failures

– Driven by failure modes and effects

– Pilot actions are intended to mitigate the

failure effects

CONTROLS AND DISPLAYS

• Design to support pilot performance and

reduce errors in the use of controls/displays

– Arrangement - convenient accessibility and use,

no confusion, standardization

– Direction of movement - matches the function

– Control shape - standardization for certain

controls

– Control labeling - except when function is

obvious

– Preventing inadvertent activation - location,

guarding

– Color coding - standardization for alerts/limits

FLIGHT DISPLAY

ARRANGEMENT

• The technology and formats change,

but….

Attitude

Airspeed

Altitude

Heading

FLIGHT DECK GEOMETRY

• Accommodate a range of pilot sizes

– Short pilots can reach everything they need

– Tall pilots can fit in the flight deck

• Pilots can see what they need to see

– Installation location of the displays/controls

– Windows provide adequate visibility

• Reflections and glare

• Emergency egress

INTEGRATION ASPECTS OF THE

FLIGHT DECK

• Workload

– Workload must be acceptable for the minimum

flight crew

– No unreasonable concentration or fatigue

• Crew response to failures

• Environmental conditions

– Noise and vibration

– Lighting

• Intended function - assessed in context

EVALUATION OF PERFORMANCE

AND HANDLING QUALITIES

• HF considerations are embedded in

numerous requirements related to

performance and handling qualities.

Examples:

– ...can be “consistently executed in service by

crews of average skill.”

– …may not “require exceptional piloting or

alertness.”

– “Reasonably expected variations in service

from the established takeoff procedures… may

not result in unsafe flight characteristics…”

EVALUATION OF PERFORMANCE

AND HANDLING QUALITIES

• Requirements are based on experience

– Human performance “margins” are usually in

guidance material

• Test pilots are the key players in

evaluating performance/HQ

– Subjective assessment (including

consideration of line pilot capabilities and line

operations)

– Performance data - measuring airplane

performance with pilots in the loop

– Close coordination between Certification and

Flight Standards (Aircraft Evaluation Group)

pilots