MFGT 124

Solid Design in Manufacturing

CAD Standards

Professor Joe Greene

CSU, CHICO

Reference: The Mechanical Process, 3rd Edition, David Ullman,

McGrall Hill New York (2003)

MFGT 124

Copyright 2003 Joseph Greene All Rights Reserved

1

Design Standards

• Topics

–

–

–

–

–

Introduction

History

ANSI Standards

ISO Standards

Examples

Copyright 2003 Joseph Greene All Rights Reserved

2

Introduction

• Standards are necessary in CAD design since designs are

typically complex.

– Designers create drawings for others to make..

– Engineering and Manufacturing needs common symbols, fonts,

dimensions, call outs, section views to reduce cost of reading

drawings and producing parts from them.

– American

• ANSI standard

• ASME standard

– European

• ISO standard

Copyright 2003 Joseph Greene All Rights Reserved

3

Introduction

• History

– Design standards are thought to have been used in ancient Egypt for the

pyramids.

– Drafting Standards started in England in the 1940s

• Stanley Parker

– English worker in a torpedo factory in Scotland, devised a method of

specifying cylindrical tolerance zones surrounding an absolute location from

what was previously specified as rectangular plus/minus tolerances. This

became true position.

– 1935: American Standards Association (ASA) published first standard for

engineering drawings.

• Only 20 pages in length with 5 pages devoted to dimensioning.

– 1940: SAE Draftsman handbook

• Chevrolet division at GM detailed standards for automotive draftsmen.

– 1945: US Army publication of ordinance manual specified dimensioning and

tolerance for the US Army.

– 1949: Military Standard 8 was published to specify dimensioning and

tolerancing standards for US Army.

• Little coordination between ASA, SAE and Military

Copyright 2003 Joseph Greene All Rights Reserved

4

Introduction

• History

– 1957: American Standards Association

• Approved first American standard devoted to dimensioning and tolerancing.

• Britain and Canada cooperated.

– 1966: First unified standard published by American National

Standards Institute (ANSI)

• Standard ANSI 14.1 to 14.5

– Updated in 1973 and 1982

– 1994 and 1995 updated and published by the ASME

• 95% in agreement with ISO global standards.

– ISO is the European standards (metric)

Copyright 2003 Joseph Greene All Rights Reserved

5

ANSI/ASME Y14 Design Drafting Standards

• Standard

– Establishes a series of recommended drawing sizes and basic

format for engineering drawing in the United States.

• Provides common standards to aid in the interchange of drawings between

companies, government, and other users.

– Started in 1975 in Detroit, MI, and revised every 5 years or so.

• 1994 and 1995 updated and published by the ASME

– ANSI Y14.1

Drawing Sheet Size and Format

– ANSI Y14.2

Line Conventions and Lettering

– ANSI Y14.3

Multi and Sectional View Drawings

– ANSI Y14.4

American Drafting Standards Manual

– ANSI Y14.5

Dimensioning and Tolerancing

– ANSI Y14.6

Screw Thread Representation

– ANSI Y14.7

Gear Drawing Standard

– ANSI Y14.8

Castings

– ANSI Y14.9

Forgings

– ANSI Y14.1

Metal Stampings

– ANSI Y14.13 to Section 36 Springs, electrical, Title and Notes, …

Copyright 2003 Joseph Greene All Rights Reserved

6

ANSI/ASME Y14.1Standards

• Drawing Sheet Size and Format Standards (ASME and

SAE)

• Renamed ASME Y14.1-1995

– Scope

– Definitions

• Drawing size

–

–

–

–

–

–

–

Standard Drawing sheet sizes

Basic Formats

Title Blocks

Revision Block

Parts List or Bill of Materials (BOM)

Supplementary Blocks

Drawing Numbers

Copyright 2003 Joseph Greene All Rights Reserved

7

ANSI/ASME Y14.1Standards

• Scope

– Defines standard sheet sizes and formats for engineering drawings

• Definitions

– Drawing refers to original sheet on which information is supplied

• Standard Drawing sheet sizes

– Letter size designations are listed below.

• Fig 1 Flat size Formats A through F. Note: Roll sizes are not used at GM today.

• Only flat sizes

Size

Width

Length

Margin H Margin V

A (H)

8.5

11

0.38

0.25 GM Approved Sizes

– Mostly 8.5” x 11”

• Basic Formats

– Basic Arrangement Fig 1

– Size of Blocks

A (V)

B

C

D

E

F

11

11

17

22

34

28

8.5

17

22

34

44

40

0.25

0.38

0.75

0.5

1

0.5

0.38 GM Approved Sizes

0.62 GM Approved Sizes

0.5

1

0.5

0.5

• Title Block Fig 4 and Continuation sheet Fig 5

– Lettering- ANSI 14.2

– Lines

• Thick (0.030 in) for Borderline, outline, and main division of blocks.

• Thin (0.015 in) for division of parts list and revision blocks, minor subdivision of

title blocks and zone markers.

Copyright 2003 Joseph Greene All Rights Reserved

8

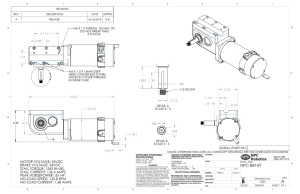

ANSI/ASME Y14.1Standards

• Title Blocks- Fig 4 & 5 (MFGT124 drawings must follow this!)

– Location- lower right corner

– Contents

•

•

•

•

•

•

•

•

•

•

•

Block A: Name and address of the company or design activity

Block B: Drawing Title

Block C: Drawing number

Block D: Drafts-person, checker with dates

Block E: Approval with Date

Block F: Approval from other sources with Date (optional)

Block G: Predominate Scale of Drawing

Block H: Drawing number or filename number

Block J: Drawing size letter designation

Block K: Actual or estimated weight of item

Block L: Sheet number for multiple sheet drawings.

Copyright 2003 Joseph Greene All Rights Reserved

9

ANSI/ASME Y14.1 Standards

• Revision Block

– Location: Located in upper right hand corner of the drawing

– Contents: Provides space for revision number or symbol, description or

identification of change authorization, date, and approvals.

• Parts List or Bill of Materials (BOM)

– Location: Located on lower right corner near title block, Additional lists may be

located at the left of and adjacent to original block.

– For large assemblies, BOM is located in a specified layer of the model.

• Example,

– Layer 1 is title page with revisions, title block, revision list, and exploded view

of assembly

– Layer 2 is assembly 1 with detailed dimensions.

– Layer 99 is Bill of Material. Layer number of BOM can be standardized on all

documents to a layer that is never used for design.

– BOM is the order list that the purchase order is written to.

– BOM will list those items that are purchased and those items that are

manufactured in house.

Copyright 2003 Joseph Greene All Rights Reserved

10

ANSI/ASME Y14.1 Standards

• Supplementary Bocks

– Information covering GD&T notes, material treatment, finish,

general notes.

• Drawing Numbers

– Location: Lower right corner of the title block and in at least one

other location.

• Fig 1, 2, and 3

• Fig 9: block descriptions

– Revision symbol block

– Numbering multiple sheets

• Second and subsequent sheets of drawings consisting of more than one sheet

are identified by same basic drawing number ant the applicable sheet

number.

• Example, Sheet 1 of 4, sheet 2 of 4, sheet 4 of 4, etc…

Copyright 2003 Joseph Greene All Rights Reserved

11

ANSI/ASME Y14.2-1995Standards

• Line Conventions and Lettering

• Renamed ASME Y14.2-1995

– Scope

– Line Conventions

Use

mm

Drawing Number in Title

Block

Drawing Title

Section and Tabulation

Letters

Zone Letters and

numerals in borders

Dimensions, tolerances,

limits, notes, subtitles.

inch

Drawing size

7

7

0.24 17x22

0.24 all

7

0.24 all

5

0.175 all

• Line Widths

3.5

0.12 17x22

• Visible lines, hidden lines, section lines, center lines, break lines, etc.

– Arrowheads

– Section Lining for cut surfaces of sectional views. Figure 9

– Lettering in Table 1

• One style of lettering should be used throughout a drawing.

• Upper case letters on drawings unless lower case is needed with approved

equipment or special characters.

• Lettering should not be underlined except when special emphasis is required

Copyright 2003 Joseph Greene All Rights Reserved

12

ASME Y14.2-1995 Standards

• Line Conventions and Lettering

• Developed from ANSI Scope

– Types of Lines

V

V

Line Type

Visible or Object

Hidden

Section

Center

Dimension

Extension

Leader

Cutting Plane

Short Break

Long Break

Phantom

Application

Visible Edges of parts

Hidden edges of parts

Cut surfaces of a cross section

Center positions of holes, shafts, radii, arcs

Size and location of part features

Locate and the extent of the dimension

Special details, notes, or specifications

Position and path of an imaginary cut made to form a sectional view

End of partially illustrated portion of a small detail

End of partially illustrated portion of a large detail

Position and relationship of adjacent parts and alternate positions on moving parts

Copyright 2003 Joseph Greene All Rights Reserved

13

ANSI/ASME Y14.3-1995 Standards

US Standard

Quadrants

• Multi and Sectional View Drawings

• From ANSI Y14.3-1980

– Multiview System of Orthographic Drawings

1st 2nd

4th 3rd

Top

European Standard

Front

Front

Top

• Establishes orthographic views for shape descriptions

– Refers to the trigonometric quadrants relative to front and top viewing planes of

the part. (See Figure)

• 6 principal orthographic views have third angle projection in US

– Front view is under the top view (Figure Handout)

– Most common views are right, top, front, (plus isometric)

– Others are left, bottom, rear.

• 6 principal orthographic views have first angle projection in Europe

– Top view is under the front view

– Multiview Drawing Applied

• Number of views required to describe a part.

• For complex parts, three or four views are required with one being orthographic.

– Standard layout includes Front, top, side, and isometric views.

Copyright 2003 Joseph Greene All Rights Reserved

14

ANSI/ASME Y14.3-1995 Standards

• Multi and Sectional View Drawings

– Auxiliary Views

• Used to show the true size & shape of features not parallel to principal views.

• Projected from a principal view.

– Sectional Views

• Shows interior details that are clearer than exterior views due to hidden lines.

• Location of sectional view is indicated by a cutting plane line and arrows.

• Used to show the solid materials with thin lines at 45°. Figure 16-6

– More than one line may occupy the same position in a view. Fig 16-7

•

•

•

•

Line Order of Preference

Object lines take preference over hidden lines and centerlines.

Hidden lines take preference over centerlines.

Cutting planes take preference over centerlines when showing path of sectional

view.

• Notice in the right-side-view that when ever a hidden line has precedence over a

centerline, the centerline is still drawn in the view by leaving a space and then

extending it beyond the edge.

Copyright 2003 Joseph Greene All Rights Reserved

15

ANSI/ASME Y14.5-1994 Standards

• Dimensioning Standards

– Dimensions describe the details of a part so it can be constructed to

the proper size.

– Dimensions options in SolidWorks

• Determine the display and position of text and extension lines

• Reference dimensions require parentheses

– Parentheses can be added to a dimension at anytime through Property

option.

– Guidelines for dimension spacing

• Space between the first dimension line and the part outline should not be less

than 10mm.

• Space between subsequent parallel dimension lines should not be less than 6

mm.

• Spacing may be different depending upon drawing size and scale.

• Set the offset distance from last dimension to 6 mm.

• Set offset distance from model to 10 mm.

• Specify that unless otherwise stated, dimensions are in millimeters of inches

– Arrowheads is recommended to be solid filled arrow

Copyright 2003 Joseph Greene All Rights Reserved

16

ANSI/ASME Y14.5-1994 Standards

• Dimensions and Tolerances

– All dimensions are subject to tolerancing (amount of permissible variability)

– Guidelines for dimensions

• Basic dimensions are identified by an enclosing frame symbol. [40]

– Is exact size and shape of object which will resize the object if changed

• Reference dimensions are identified by a parentheses (40)

– Is intended size and for information only. Won’t resize object if changed.

• Dimensioning

– Chain dimension: Used when tolerances between adjacent features is more

important than the overall tolerance of the feature.

– Baseline dimension :used when the location of features must be controlled from a

common reference point or plane.

– Direct Dimensioning: Applied to control specific features

– Dimension largest dimension to the outside of the inner dimensions.

– Crossing dimension lines with arrow should be avoided.

– Guidelines for Witness Lines

• Witness lines are extension lines

– Visible gap exists between the Extension line and the visible line.

– Extension line extends 1.5 mm beyond the Dimension line .

Copyright 2003 Joseph Greene All Rights Reserved

17

ANSI/ASME Y14.5-1994 Standards

• Tolerancing

–

–

–

–

Parts typically are made in part of an assembly that has to fit together.

Parts are not made to exact dimensions but are made to plus/minus.

Exact dimensions would be expensive to make.

Higher precision = higher costs

• Gage blocks are made to very precise dimensions but are used to check parts.

• Parts are made to varying degrees of accuracy depending on part requirements.

– Some parts are required to be built with low precision (+/- 0.05 in)

– Some parts are required to be built with medium precision (+/- 0.005 in)

– Some parts are required to be built with high precision (+/- 0.0005 in)

– Major terms

– Nominal size is designation for general ID, e.g. 9/32 drill or 2 by 4

– Basic size is size from which limits of size are derived by application of

allowances and tolerances. Basic size of 9/32 drill is 0.28125 in.

– Limits are the extreme allowable sizes for a feature. +/- dim Fig 16-11

– Tolerance is permissible variation in dimension. (Big – Small) Fig 16-12

Copyright 2003 Joseph Greene All Rights Reserved

18

ANSI/ASME Y14.5-1994 Standards

• Tolerancing

– Major terms

• Allowance is minimum clearance between mating parts. (Big – Small) Fig 16-12

• Maximum material condition (MMC) is condition of a part when it contains the

MOST amount of material. MMC of an external feature of size (e.g., shaft) is

the upper limit. MMC of an internal feature of size (e.g., hole) is the lower limit.

• Least Material Condition (LMC) is the condition of a part when it contains the

LEAST amount of material. LMC of an external feature of size (e.g., shaft) is

lower limit. LMC of an internal feature of size (e.g., hole) is the upper limit.

• Limit dimensioning is the maximum and minimum sizes of a feature are

1.885

specified as shown in Fig 16-13.

1.875

• Unilateral tolerances is a basic size followed by plus/minus that variaion is

allowed only toward one side, usually from the smaller size. E.g., 1.88 +/- 0.001

• Bilateral tolerances is a basic size followed by plus/minus tolerance that is

directed toward both directions from nominal size. 1.88 +- .001

.001

– Criteria to determine tolerance for dimension

• Tolerance should be chosen to permit the assembly of randomly selected parts

• Tolerance should be as large as possible

Copyright 2003 Joseph Greene All Rights Reserved

19

ANS International Tolerance (IT) Grade

http://www.qfm.uni-erlangen.de/gps/content/Chapters/chapter_6.htm

• Tolerances Grades

Tolerance of a size as function of nominal size and tolerance grade

– Tolerance interval: replaces tolerance zone

• Relates the size tolerance to the nominal size of a feature,

• The tolerance interval comprises values of the size between the limits of

size, its position with respect to the nominal size defines the limits of the

size, and its width defines the value of the size tolerance.

– Example: A piston and a piston ring with the tolerance intervals of

the groove width of the piston and the width of the piston ring itself

Fig.6.1.

Scheme of a piston and piston ring and corresponding tolerance intervals.

Copyright 2003 Joseph Greene All Rights Reserved

20

ANS International Tolerance (IT) Grade

http://www.qfm.uni-erlangen.de/gps/content/Chapters/chapter_6.htm

• Tolerances Grades

Tolerance of a size as function of nominal size and tolerance grade

– Tolerance interval

– The horizontal axis of the scheme is the zero line, representing the nominal

size to which the deviations and tolerances refer.

– Above the zero line there are shown positive deviations, below the zero line

– the negative ones.

– The scheme is drawn to scale and deviations are presented in micrometers.

– As drawings are composed in millimeters, the scales of these two images

differ by at least three orders of magnitude also.

– The nominal size can be shown on the tolerance scheme by a sole

arrowhead; the other head would never fit into the scheme done to scale.

– Here, these images are shown side-by side, in order to emphasize the

physical meaning of the tolerance interval.

– Dispersion of actual sizes at processing depends among other factors on the

total size of the part processed. The bigger the size being processed, the

bigger are deviations arising at processing and inspection.

Copyright 2003 Joseph Greene All Rights Reserved

21

ANS International Tolerance (IT) Grade

• Tolerances Grades

http://www.qfm.uni-erlangen.de/gps/content/Chapters/chapter_6.htm

– In order to secure the same level of accuracy for different

nominal sizes the concept of tolerance grade is used as a

measure of accuracy. The tolerance value for a given size

equals to

IT = a x I

(6.1)

• where: i – tolerance unit

a –tolerance grade factor.

– The tolerance unit depends only on the nominal size and the

tolerance grade factor – only on the tolerance grade selected.

– The series of standard tolerances obtained in this way (IT–

International Tolerance) are universal and regular depending on

the nominal size

– Selecting tolerance grades enables the designer to get different

levels of accuracy.

• This sort of system of standardization of tolerances gives to the level of

accuracy characterized by the tolerance grade a certain economic and

technological meaning.

– The tolerance unit is used not as a continuously variable

quantity but as a set of discrete numbers.

Copyright 2003 Joseph Greene All Rights Reserved

22

ANS International Tolerance (IT) Grade

http://www.qfm.uni-erlangen.de/gps/content/Chapters/chapter_6.htm

• Tolerances Grades

– For this purpose, all the values of a dimension used are divided up into

ranges and for the whole of each range only one value of the tolerance unit

applies, which is calculated by the average size of the given range.

– The number of such ranges, covering dimensions up to 3150 mm, is only 21.

As a result, a slight difference arises between the calculation value of the

tolerance unit and the value that is used as a base for the standard tolerance

(up to 8%), but, in return, the number of different standard tolerances sharply

diminishes.

• This makes it possible to limit considerably the list of necessary cutting tools and

measuring instruments with a substantial consequent economic impact.

– The ISO system of tolerances and fits (ISO 286-1) comprises 20 different

groups (levels of accuracy), which are characterized by the standard

tolerance grades, general designation - IT.

• The tolerance grade is specified by numbers 01, 0, 1, 2, ... 18 in order of

decreasing accuracy, i.e. increasing tolerance.

• Thus, the designation of an ISO standard tolerance would be, respectively to the

tolerance grade, IT01, IT3, and IT12 etc.

– Table 6.1. An excerpt of values of standard tolerance grades.

–

Copyright 2003 Joseph Greene All Rights Reserved

23

ANS International Tolerance (IT) Grade

http://www.qfm.uni-erlangen.de/gps/content/Chapters/chapter_6.htm

• Tolerances Grades

– Table 6.1. An excerpt of values of standard tolerance grades.

–

Copyright 2003 Joseph Greene All Rights Reserved

24

American National Standard Holes and Fits

• Fits

– Fit signifies type of clearance that exists between mating parts.

• Clearance Fits provide some gap between mating parts.

• Interference Fits have no clearance between mating parts.

• Transition fits are listed to result in either a clearance or interference

– American National Standard and metric sizes for holes and shafts

• Set of classes of fits based on the basic hole system.

• Basic hole system used from reamers and drills to produce standard size holes.

• Types of fit covered

– RC - running and sliding fits

– LC - clearance locational fits.

– LT – transition locational fits.

– LN – interference locational fits.

– FN force and shrink fits.

• Tables and standards are organized on hole basis, thus basic shaft size and type

of fit are needed to determine the dimension and tolerance for mating parts.

• Example, RC4 is close running fit and RC 9 is a loose running fit

• Standard tables are in Machinery’s Handbook

Copyright 2003 Joseph Greene All Rights Reserved

25

ANSI/ASME Y14.5-1994 Standards

• GD&T Standards

– According to ANSI Y14.5-1994 standards, the following rules

should be observed:

• Each dimension must have a tolerance, either applied directly or indicated

by a general note.

– Identified as reference, basic, or maximum dimensions are exceptions.

• Dimensions for size, form, and location of features should be complete to

the extent that there is full understanding of the characteristics of each

feature.

– Scaling (measuring from drawing) of the print is not allowed.

– Assumption of a distance or size is not allowed.

• Dimensions should be shown between points, lines, or surfaces having

necessary and specific relationship to each other.

• Dimensions must be selected and arranged to avoid accumulation of

tolerances and more than one interpretation.

Copyright 2003 Joseph Greene All Rights Reserved

26

ANSI/ASME Y14.5-1994 Standards

• GD&T Standards

– According to ANSI Y14.5-1994 standards, the following rules

should be observed:

• Multiview display should define a part without specifying manufacturing

methods (CAM).

– Thus, only the diameter of the hole is given and not whether it is

reamed, punched, drilled, etc.

• Finish allowance and shrinkage allowance can be added.

• Dimensions should be selected for display to provide required information.

• Wires, cables, sheets, or rods, and other display items must be specified by

linear dimension, indicating the diameter or thickness.

• Surfaces or centerlines shown on displays at right angles to each other are

implied to be 90° apart.

Copyright 2003 Joseph Greene All Rights Reserved

27

ANSI/ASME Y14.5-1994 Standards

• GD&T Standards

– Geometric Dimensioning and Tolerancing (GD&T) establishes the

standard by which designers can communicate the intended

function of the part to the machinist making the part and the

inspector checking the part.

– This standard lets the designer inform the machinist, toolmaker or

fabricator what are the important features of the design when they

are making the part.

– The standard also lets the inspector know what are the important

features to inspect form.

• GD&T uses symbols to communicate the information to those involved in

making the part to eliminate any misunderstanding.

• Word explanations can be confusing especially with the global market and

the translations of words into different languages.

– A simple layout of the symbols used in GD&T can be found as

follows

Copyright 2003 Joseph Greene All Rights Reserved

28

ANSI/ASME Y14.5-1994 Standards

• GD&T Standards

– Feature Control Frames

Geometric ToleranceGeometric Characteristic Symbol

• The feature control frame helps to organize the various symbols, see

Appendix A or sections 3b-3h, into a sentence. This sentence communicates

the information in an organized manner. Figure 3a-1 shows a simple

sentence with the geometric symbol and the geometric tolerance that is

applied to the intended feature.

Geometric Characteristic

Geometric Tolerance

[|.

Symbol

005]

• The simple sentences can be expanded to contain a greater amount of

information. A couple notes about the feature control frames that are

important in understanding they’re meaning. The first is the Geometric

Tolerance is the total tolerance band for that feature. This means that it is

not a +/- tolerance. An example of this is if we have a dimension of 1.00 and

a Geometric tolerance of .005, we can interpret this as 1.000 +/-.0025.

Copyright 2003 Joseph Greene All Rights Reserved

29