polar_power

advertisement

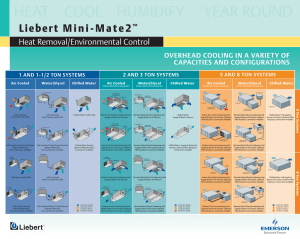

Project Title: Polar Power You Tube video: How Polar Power Works Summary of Project: Provide a general summary of the project. Make sure to include a rationale for why this idea has strategic importance at this time. Why use electricity to power mechanical, compressor-based refrigeration systems when cold, fresh air can cool a refrigerated space for free? The Freeaire Polar Power® system’s components monitor outside and inside temperatures and bring, fresh, filtered outside air into a cooler during the winter. When outside air is used for cooling, conventional mechanical refrigeration system components are shut off and do not consume any energy. The savings in energy, reduced wear and tear on system components and money are significant. Introduction and Background: Describe in detail the background, context, importance, and value of this project. Polar Power® allows the use of cold outside air to cool a space for approximately 120 to 130 days a year in Burlington. Like wind and solar energy, this “polar energy” is a natural and endlessly renewable source of energy. Polar Power® is appropriate for any refrigerated space of 1,000 cubic feet or more. Refrigeration has a significant energy footprint on UVM’s campus and a lot of the refrigeration is in campus dining, with a total of 44 coolers and freezers. Dining Services already prioritizes energy efficient equipment but is excited about the innovative Freeaire technology that can increase efficiency of refrigerators new and old. The Freeaire system can reduce energy use up to 50% per cooler. Methodology and Timeframe: How will the idea be carried out? Which individuals and offices will be involved? How long with the project take to complete, and what is the timeframe for each key phase? Include information on long-term maintenance and accountability. A walk-through assessment of existing walk-in coolers on campus and their eligibility for a retrofit was completed on 10/25/13. The retrofit itself only takes one week per cooler. Although the work can be done without shutting down the system, it would be safer and easier to schedule the work during the summer or a break period when the dining unit is not operational. Installation would be completed by Green Tech Refrigeration. Preventative maintenance would be included in KC Mechanical’s regular schedule. Below are the three eligible coolers in order of eligibility: 1. Davis Center Marketplace: This cooler is on the second floor, is the appropriate size and is against an exterior brick wall facing Main Street. The cooler has two evaporator units. 2. Given Atrium: This location will be undergoing renovations May-July 2014. The refrigeration/ freezer combo is located close to an exterior wall but is currently <1000 ft3. The two coolers could possibly be expanded during renovation to make Polar Power® practical. However, Given is a historic building so there may be difficulties with altering an exterior wall. 3. Waterman: This cooler is appropriately sized but is located in the basement of Waterman and it is unclear what the exterior access to the unit looks like. If outdoor access is feasible, this unit 1 would be an ideal candidate. However, like Given, Waterman is also a historic building which may be a challenge. Benefits and Results: Describe the educational, environmental, and economic benefits this project will provide (for example, energy savings, return on investment, reductions in greenhouse gas emissions, learning opportunities and outcomes, or any other broader impacts on the university community). Investigating innovative ways to decrease the energy use of our campus food system is a step in the right direction to food security for our university. The payback for the system is usually 1-5 years depending on the complexity of installation. The return can be 2-10 times the initial investment, or save 50-90% in operating costs. Freeaire provides detailed information quantifying reduced greenhouse gas emissions, energy savings, etc. Case studies show an average of 25-50% energy savings. Student Engagement: How, specifically, will this project provide opportunities for student engagement? Engineering classes offered at the graduate and undergraduate level could partner with Green Tech Refrigeration for the installation, evaluate the success of the upgraded system, or conduct a feasibility study for other locations on campus (ex: labs or server rooms). Suggested Project Champion(s): Include the names, phone numbers, email addresses, roles, and departmental affiliations of individuals who may be interested in developing this idea into an implemented project. The individuals below have all expressed interest and strong support for this project and/or were involved in the campus walk-through. Kevin Casey, KC Mechanical, President Phone: (802) 878-0800 Email: kevinc@kcmechanical.com Caylin McKee, UVM Dining, Sustainability Coordinator Phone: (802) 656-7911 Email: Caylin.McKee@uvm.edu Michelle Smith, UVM Green Building Coordinator Phone: (802) 656-2219 Email: michellem.smith@uvm.edu Michael Levengood, Green Tech Refrigeration, Installer Phone: (802) 272-5271 Email: freeaire@greentechrefrigeration.com Michelle Keller, Burlington Electric Dept, Energy Services Phone: (802) 865-7371 Email: MKeller@burlingtonelectric.com Projected Budget and Budget Justification: Outline the project budget, justifying the need for all expenditures. 2 Below is an estimated budget for the most eligible walk-in unit, in the Davis Center Marketplace. Costs should be similar for additional units with variation in installation cost depending on building exterior and location of cooler. Equipment costs should stay consistent. Cost & Energy Savings Worksheet names addresses contact persons phone# fax# email addresses etc. Freeaire Refrigeration/R. H. Travers Company, 167-8 Mad River Canoe Road, Waitsfield, VT 05673 USA, Phone: 877-305-3733, web site: www.freeaire.com, Richard H. Travers, president, 802-496-5205, cell: 802-989-9558 email: manufacturer richard@freeaire.com installer Green Tech Refrigeration - Michael Levengood 16 Dimetro Road Warren, VT 05674 802-272-5271 - 802-496-4042 - freeaire@gmavt.net customer UVM Davix Center installation BED- Michelle Keller - Efficiency Manbager utilities account# utility rate class average (blended) cost of electricity Date ###### cooler? yes freezer? no walk-in use food and beverages length Condensing unit outside? yes meter readings? no On outside wall? yes concrete walls? no width pumpdown sytem? yes access through ceiling and wall? yes access through roof? no height compressor type reciprocating evaporator fan diameter 12" evaporator fan rotation cw volume other info No electrical permit included hi temp. # of unit power # fans # doors amps equipment brand model# s volts phase factor /unit /unit /unit evaporators Peerless LSC160AMC2J 1 120 1 50% 4 4.8 condensing unit compressor Tecumseh AV 144ET 1 240 1 14.2 condensing fans 240 1 85% 1 1.3 door heaters Anthony TJ-3 0 0 1 100% 1 0 INSTALLED COST Qty 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Item# Item 70100 All Climate System 70200 All Climate System w/Polar Power Pkg. 70400 All Climate w/Polar Pwr Pkg. & Hum. Cntl. 70300 Additional Polar Power Package 30100 Additional Adjustable Circ 20200 Additional Wallcap 40800 2"x16"x16" disposable Carbon Filter 30200 summer plug 30250 BreezeShooter adjustable elbow 30600 Stocking Switch 70201 All Climate Sys. w/Large Polar Power Pkg. 70450All Climate Sys.w/Large Polar Pkg. & Hum. 70350 Addl. Large (Industrial) Polar Power Pkg. 30160 Additional Large Circ Fan 40801 2"x24"x24" disposable Carbon Filter 14100 Web Interface Box $/ea. $2,558 $4,335 $4,735 $1,840 $355 $110 $43 $50 $75 $50 $8,300 $8,700 $5,500 $900 $95 300 subtotal 6% tax (VT shipments only) shipping labor other materials & costs total installed cost of Freeaire system estimated utiity rebate: NET COST (after rebate) ALL CLIMATE & POLAR PKGS: TOTAL INSTALLED COST TOTAL ESTIMATED UTILITY REBATE NET COST (AFTER REBATE) $0.13000 /kwh 16 feet 10 feet 8 feet 1,280 cubic feet 40 °F Coefficient of Performance 2.8 ENERGY AND COST SAVINGS total Item $0 total # of evaporator fans $4,335 watts/each fan $0 evaporator fan runtime without Freeaire system $0 annual evaporator fan energy use without Freeaire system $0 expected reduction in evaporator fan runtime $0 hours/year evaporator fan operation will be reduced $0 total kilowatt reduction when circ fans are on $0 annual energy saved directly by controlling evap. fans $0 annual energy saved indirectly by condensing unit $0 total annual energy saved by controling evap fans $0 annual evaporator energy cost savings $0 condensing unit kilowatts $0 ave. annual condensing unit runtime before Freeaire $0 annual condensing unit energy use before Freeaire $0 condensing unit runtime in winter before Freeaire $0 days/yr outside air takes over refrigeration $4,335 outside air system kilowatts $0 outside air system cold weather runtime $0 annual condensing unit energy saved by outside air $1,800 hours/year evap fan operation will be reduced $100 annual evaporator fan energy saved by outside air $6,235 total annual energy saved by All Climate & Polar Pkgs. $1,800 annual cost savings from using All Climate & Polar Pkgs. $4,435 ALL CLIMATE & POLAR PKGS PAYBACK PERIOD $6,285 $1,800 $4,485 TOTAL ENERGY SAVINGS % REDUCTION IN ENERGY USE TOTAL ANNUAL COST SAVINGS PAYBACK PERIOD (IF ELECTRICITY GENERATED BY COAL) CARBON REDUCTION value 4 72 100% 2,525 50% 4,383 0.27 1,161 415 1,576 $205 3.16 50% 13,859 30% 125 0.17 40% 2,638 990 262 4,477 $582 7.62 unit fans watts 4,477 27% $582 7.7 8,954 KWH kwh/yr hours KW kwh kwh kwh kw kwh/yr days kw kwh hours kwh kwh years YEARS LB/YR Justification for use of student-supported, CEF Funds: Why is this project appropriate for the Clean Energy Fund, as opposed to another funding source? What complementary in-kind or monetary support does this project have? UVM is responsible for the purchase, renovations and maintenance of equipment for Dining Services. Without support from the Clean Energy Fund, this effort could be stalled in stalemate. Improving the energy efficiency in dining helps UVM reduce its carbon footprint, lowers overall costs to UVM operations and provides an innovative technology for students to monitor and study. Success with one installation on campus could lead to campus-wide support of Polar Power®! 3