Prezentace aplikace PowerPoint

advertisement

Transport processes in liquid

steel : challenge for chemical

engineers

Kamil Wichterle

VSB – Technical University of Ostrava, Czech Republic

Classical image of iron metallurgy:

Reduction of iron oxides

FeO(s) + CO(g) Fe(?) + CO2(g)

• (?)=(s) … Direct reduction - smelting

• (?)=(l) … Blast furnace reduction

Iron ore

Charcoal

CO2

,N2

Smelting furnace, T<1000oC

Gas - Solid reaction

Air

Iron bloom (solid Fe)

hammering, forging,

carburization, quenching

Steel

IRONWORKS

(Technical museum of Brno)

1st milenium

18th century

http://www.technicalmuseum.cz/pamatky.html

Genesis

1. Adam

2. Cain

3. Enoch

4. Irad

…Tubalcain, an instructor

5. Mehuajel

6. Methushael

of

every

artificer

in

brass

7. Lamech

and iron …

8. Tubalcain

9. …

Genesis 4:22

10. …Noah

THE GREAT FLOOD

IRON BLOOM

English Heritage Archaeology Day 22 June 2002

http://www.brad.ac.uk/acad/archsci/depart/resgrp/amrg/Rievaulx02/Rievaulx.htm

HAMMERING

http://www.cassovia.sk/stm/v3.php3

Iron ore

Coke

CO, CO2 ,N2

o

T>1500 C

Blast furnace,

Gas – Liquid - Solid reaction

Hot air

Pig iron (liquid Fe – Fe3C)

Molding

Cast iron (high carbon %)

STEEL

(wrought iron) less than 2% C

ductile, malleable

CAST IRON

more than 2% C

brittle

STEEL - CAST IRON

Prague 1891

Petřín tower

Hannau Pavillon

MAIN REASON FOR

STEELMAKING

Removing of

carbon

Steel – less than 2% C

Special steels 99.9% Fe

liquid steel process

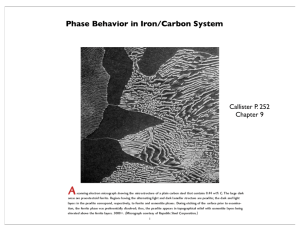

LIQUID STEEL

Fe – C

Temperature oC

1638oC

Lowest melting point

STEEL

Fe

1153oC

CAST IRON

Weight Percent Carbon

Fe3

C

PUDDLING - Henry Cort 1780

•The Crucible Steel Furnace

•Melted high carbon iron (pig iron)

+ air + flue gas

•Reaction:

Fe-C(ℓ) + O2 (g) → Fe(s) + Fe-C(ℓ) + CO(g)

or:

[Fe-C] + {O2 } → <Fe> + [Fe-C] + {CO }

•Mechanical separation of solid steel

lumps from the „puddle“

The Crucible Steel Furnace Shop at Abbeydale

http://www.woodberry.org/acad/hist/irwww/Metallurgy/Biography/Henry_Cort.htm

CONVERTER – Sir Henry Bessemer 1856

•The Converter

•Melted high carbon iron (pig iron)

+ bottom injected air

•Fast reaction:

[Fe-C] + {O2 } → [Fe] + {CO }

Minor reaction

[Fe] + {O2 } → (FeO)

•Liquid steel product

•SiO2 lining (acidic)

Sir Henry Bessemer 1813 - 1898

http://www.history.rochester.edu/ehp-book/shb/illus.htm

EFFECT OF THE LINING - 1875

Sidney Gilchrist Thomas and Percy Gilchrist

Dephosphorization in the converter

MgO, CaO lining (basic)

The lining enters following reactions:

[Fe-P] + {O2 } + <CaO> → [Fe] + (Ca3(PO4)2)

metal melt

gas

solid non-metal metal melt non-metal melt (slag)

slag => fertilizer „Thomas powder“

Other reactions:

[Fe-S] + {O2 } + <CaO> → [Fe] + (CaS)

[Fe-Si] + {O2 } + <CaO> →[Fe] + (CaSiO3)

CONVERTER

CONVERTER 1936

1936

OPEN HEARTH FURNACE - 1863

Sir Charles William Siemens

Émile et Pierre Martin

•Melted iron (pig iron + scrap)

+ hot air

+ flue gas

+ magnesite lining

+ CaO powder

Slower process than this in the converters

However higher quality of the product

1950

• Iron- and steelworking - fully matured

industry, using proven processes

• Limited demand for a scientific

approach to the technology

Revolution in steelworking

since 1960

• Basic oxygen process

• Continuous casting

• Environmental issues

Revolution in steelworking

CONTINUOUS CASTING

Revolution in steelworking

OXYGEN PROCESS

FURNACES

Oxygen in steelmaking

• Prof. Robert Durrer

(pilot-plant experiments Gerlafingen,

Switzerland 1948)

• The first industrial oxygen converter

(VOEST Linz-Donawitz 1952)

Advantage of pure Oxygen

Absence of inert nitrogen:

•

•

•

•

Faster reaction than with air

More efficient employment of heat

Higher temperature

Suppressed formation of nitrides

BOS - Basic Oxygen Steelmaking

BOP - Basic Oxygen Process

BOF - Basic Oxygen Furnace

[Fe-C] + {O2 } → [Fe] + {CO }

[Fe-P-S-Si] + {O2 } + <CaO> → [Fe] + (P,S,Si in slag)

Source of iron for steelworking

• Liquid pig iron from blast furnace 30-40%

(higher content of C, Si, P, S,…)

• Steel scrap

60-70%

(variable composition - also Cu, Zn, Pb, Cd,…)

• Iron from direct reduction process < 10%

(bloom, sponge, briquettes – quite pure Fe)

Scrap

BOS

Liquid

steel

Ladle

Oxygen

Lance

Steel batch 200 000 kg

O2 : 500 normal m3/min

20 min

Superficial velocity 1.5 m/s

250 vvm

Gas power input 60 kW/m3

(or 8 W/kg)

Mixing time 10-100 s

Whole cycle 50 min

Oxygen tuyere

http://www.bhpsteel.com.au/bhp/steel/steelenv/steelpath/steelbos.cfm

Steel

Slag

OXYGEN INTRODUCTION

•

•

•

•

Tuyere above the liquid bath (L-D)

Tuyere under the liquid level (Quiet)

Bottom blown ladles (converters)

Introduction of CaO powder in the

oxygen stream

• Water cooled lance

• Hydrocarbon gas cooled lance

Production of Oxygen

cryogenic process and liquid air distillation

Largest facilities in steelworks

•

•

•

•

•

•

consumption 50-60 normal m3 per ton of steel

delivery rates 500-800 normal m3/min

pressure of 1.5 MPa

99.5% O2; the major impurity is Argon

byproducts: Argon and Nitrogen

energy consumption 0.45 kWh per normal m3

OTHER AIMS OF

STEELMAKING

•

•

•

•

•

Removing of P, S, Si

Removing of metals Zn, Cu, Pb, Cd, Al, …

Removing of diluted gases N, CO, H, O

Removing of solid non-metal particles

Addition of alloying metals (e.g. Ni, Cr, Co,

Mo, Mn, Si, V, …)

REFRACTORY LINING

•

•

•

•

•

•

Up to 1 m thickness

Errosion, abrasion, thermal cycling

Losses 0.5-1 mm per run

Laser controlled thickness

Slower wall dissolution when CaO added

Life more than 1000 runs

(classical converters 100 runs)

• Regeneration of walls by slag spray ;

(up to 10 000 runs)

LIQUID IRON FOR STEELMAKING

•

•

•

•

•

BLAST FURNACE

TORPEDO LADLE

ELECTRIC ARC

GAS - OXYGEN COMBUSTION

HEAT OF OXIDATION C, Si, … (Fe)

BLAST FURNACE

TORPEDO LADLE

(up to 100 km from the blast furnace)

ELECTRIC ARC FURNACE

ALSO WITH OXYGEN

GAS COMBUSTION

WITH OXYGEN

• less expensive (40%) than the electric arc

• lower temperature than with the electric arc

- limited heavy metal emissions

• can be combined with the electric heating

SECONDARY METALLURGY

ARGON – VACUUM LADLE

• Desorption of diluted gases N, CO, H, O

• Sedimentation - floating of slag particles

• Addition of alloying metals

• De-oxidation

• Homogenization

TUNDISH

• Removing of solid non-metal particles

• Homogenization of temperature and

composition

ARGON –VACUUM TREATMENT

• Argon gas-lift for agitation (10-300 W/m3)

• Vacuum for desorption of soluble gases

Superficial gas

velocity:

0.001 m/s … bottom

> 1 m/s … level

(CO, O2, H2, N2)

Atmospheric pressure:

1420 mm Fe

RH

Ruhrstaal - Heraeus

DH

Dortmund-Hoerde

ENVIRONMENTAL:

• Gas emissions (CO)

• Airborn particles

(Fe,Zn,Pb,Cd,Cu, …)

• Slag

TUNDISH

• Batch input

continuous output

• Turbulence suppression

• Argon agitation

• Argon inert atmosphere

• Last slag separation

particles < 50μm

• Tundish refractories

steel quality

tundish

mold

solidification

cooling

HYDRODYNAMICS

MULTIPHASE FLOW

HEAT TRANSFER

CFD

Transformation of Metallurgy:

• Material engineering – merging with

polymer science, ceramics,

electronics materials …

• Process engineering – adoption of

chemical engineering method

(chemical reactors gas-liquid-solid, non-isothermal

processes, mechanical separation, transport

phenomena, scale-up methods, modelling,

simulation, CFD, …)

Our contribution

Department of Chemistry

Faculty of Metallurgy and

Material Engineering

Technical University of

Ostrava

BUBBLE BEHAVIOR IN LIQUID STEEL

• From the viewpoint of two-phase

hydrodynamics

(density, viscosity and surface tension),

water and liquid steel are quite similar !

density

ρ

Liquid

oC

kg/m3

dynamic

kinematic surface

Laplace

Laplace

viscosity

viscosity tension

length

velocity

μ

ν

σ

(σ/(ρg))1/2 (σg/ρ)1/4

Pas

m2/s

N/m

m

m/s

molten steel 1500

7200

5*10-3

0.7*10-6

1.4

4.5*10-3

0.21

water

25

1000

1.0*10-3

1.0*10-6

0.073

2.7*10-3

0.16

mercury

25

13500

1.5*10-3

1.1*10-6

0.46

1.8*10-3

0.14

Wood metal

80

10600

3*10-3

0.3*10-6

0.4

1.9*10-3

0.14

hexane

25

650

0.35*10-3

0.5*10-6

0.018

1.6*10-3

0.13

DECREASING PRESSURE - INCREASING VOLUME

BREAK-UP

HIGH HYDROSTATIC ("FERROSTATIC")

PRESSURE AT THE LADLE BOTTOM

SMALL SINGLE ARGON BUBBLES

DECREASING PRESSURE - INCREASING VOLUME

BREAK-UP

FAST DECREASE OF PRESSURE

INCREASING BUBBLES

RETARDED BREAKUP

Experimental

History of Metallurgical

Engineering

DE RE METALLICA

LIBRI XIIGeorgius

Chemnitz

Agricola (Georg Bauer)

(1494-1555)

Glauchau

Leipzig

Jáchymov

(Joachimsthal)

Basel

Padova

Bologna

Dukedom Saxony

Czech Kingdom

Georgius Agricola

(Georg Bauer)

(1494-1555)

Agricola

1556

Cascade of

CSTR

Impeller

manufacture

Metallurgy

Chemical

Engineering

Transformation of one journal:

• 1902 Electrochemical Industry

• 1905 Electrochemical and Metallurgical Engineering

• 1910 Metallurgical and Chemical Engineering

• 1913 Chemical and Metallurgical Engineering

• 1946 Chemical Engineering

CONCLUSIONS

• At the end of 20th century

steelmaking became a fast

developing chemical technology

• Chemical engineering education

should also turn its attention to the

processes in liquid steel

• In metallurgy, there are challenging

jobs for chemical engineers

Thank you for the attention

Financial support by the Grant Agency of the Czech Republic

(grants No.106/98/0050 and No. 104/01/0547)

is greatly appreciated