Drilling Systems

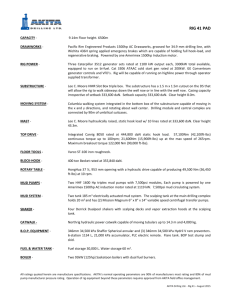

advertisement

Drilling Systems Various Types of Drilling Rigs Steel Jacket Platform - Most common type of fixed offshore structure - Most suitable to soft soil regions. Where piles can be driven in deeply to hold the structure Gravity Platform - In regions where hard soil conditions exist and piling driving is more difficult - The structure relies on its weight to hold it - It has large foundations base - It is normally constructed with reinforced concrete Jack-up Rig - It has a floating, barge-like hull which supports a platform on which drilling equipment and crew quarters are located - Three or more legs fit vertically or slant - The legs are lowered by hydraulic jacks until they penetrate the mud of the seabed - Anchoring of the rig is by means of piles which are driven down through tubes in the legs Jack-up Rig Two Types of Jack-up Rig Independent Leg Jack-up Rig Mat-supported Jack-up Rig Semi-Submersible Drilling Rig - A platform deck supported by columns which are connected to a large underwater displacement hulls - The hull is flooded on site to reduce wave forces by locating the major buoyancy members beneath wave action - It is towed or self-propelled - It is best suited for severe weather condition - Most units are positioned with conventional mooring systems, some have dynamic positioning systems Drill Ships A sea-going vessel with an opening through its hull for passage of the drill string Self-contained and self-sufficient, requiring little or no assistance from support vessels The operating depth is limited by mooring requirements As water depths exceed 300m, the weight and complexity of mooring lines and machinery become prohibitive For great depths, to use dynamic positioning system, which requires a means of locating the ship hull with respect to the well hole Sensors at the well opening and ship bottom, coupled with computer, activate the ship’s propeller and side thrusters which compensate for movement thereby keeping the ship in station A drill ship Positioning Tension Leg Platform A hull structure which is anchored to the seabed floor by means of permanently tension tethers The hull may be of steel or concrete, and the tethers of steel wire core or structural steel pipes The hull structure design is not affected by water depth, so the cost increase is probably not as high as traditional fixed structure The horizontal motion will be greater Drilling Rig and Its Components Basic rig components Drill floor and derrick Drawworks and hoist system Swivel, kelly, rotary hose , rotary table Circulation system Three tasks of rotary rig The lowering drill pipe and casing into hole and hoisting the drill string and tools out of the hole The rotation of the drill string to turn the bit on bottom of the hole The forced circulation of a drilling fluid to remove cuttings from the bottom of the hole, to cool and lubricate the bit, to control downhole pressure Derrick Providing the ability to lift tools in and out of the well Supporting the weight of the drill pipe string Being capable of over pull – pull the drill pipe through a tight spot in the hole The derrick must withstand the wind load Drill Floor DRAWWORK - It is a driven winch. Drilling line (thick wire) is wound around it. - The line unwinds from the drum up through the pulleys or sheaves in crown block and down to the sheave in the traveling block when lowering the pipes into the hole Drill Line Swivel Swivel hangs from hook by a Thick steel looped handle or bail Swivel does not actually rotate But it suspends the whole weight of the drill string by means of internal bearing, allow its free rotation Gooseneck pipe A leak-proof entry point to the inside of drill string Drilling fluid is pumped down Kelley It is a long steel tube Suspended from swivel It is hexagon or square-sectioned hollow pipe, usually 12 m long Purpose to transmit torque to the drill string from power-driven rotating device (rotary table) in the drill floor Kelly is free to slide up and down Rotary Table Fitted below the level of the drill floor Look like a large rectangular steel box with a drive shaft Weighs about 11 tons Functional Diagram of a Rotary Drilling Rig Circulating Mud System Main functions of drilling fluids Clean, cool and lubricate the drill bit Suspend cuttings when circulation is stopped Remove cuttings from the hole Control sub-surface pressure Keep the hole walls from collapsing Provide information about the formation penetration Protect potential pay zones from damage Drilling System Drilling Mud System Types of Drilling Fluids - Water-base Used most frequently - Oil-base - Air/foam More than one of these types of fluids may be used In a single well Water-base muds - Various muds are added into water - Fresh water and low-solids brines - A number of salts as sodium chloride, calcium chloride or potassium chloride may be added to fresh water - Salts can increase the weight of drill mud for pressure control purposes without adding solids -Salts often help reduce formation damage and hole problems in clay and other formation -Sea water is often used in offshore drilling Water-in-oil emulsion muds - Water and oil (crude or diesel oil) are emulsified by suitable emulsifiers, e.g. soaps and by agitation - Agitation is required to break water into small droplets - The ratio of oil/water determines the final properties of emulsion and its stability - Higher oil/water ratios give increased resistance to contamination and increased temperature stability - Such muds are used to drill holes with severe shale problems and to reduce torque and drag problems - More stable at high temperatures than water-base muds Mud properties 1). Solids control The amount of solids in mud must be controlled If not, the rate of drilling is reduced the drilling problems (lost circulation) is increased Two sources of mud solids - Solids are added at the surface for controlling density and other properties - The formation being drilled 2). Density Weight of drilling mud is controlled for controlling Pressure in zones penetrated by the bit 3). Drilling fluid density can be ranged from 1000kg/m3 to 2400kg/m3 4). The most common material used to control weight is Barite (barium sulphate) s.g. 4.2-4.3 Ilmenite (s.g. 4.58) can be used to increase mud density Mud must be monitored constantly to detect the change. That may reduce drilling rates or cause other hole Problems Some key properties that are monitored : - Density (as mentioned above) - Fluid loss (if lost water, solids in drilling fluid build up on wall of hole, causing stuck pipe and others) - Viscosity (describes thickness of mud in motion. If it increases the pressure drop in the circulating system increases) - Yield point (influenced by concentration of solids, their electrical charges and other factors. If not at proper value, it can reduce drilling efficiency by cutting penetration rate, increasing circulating pressure, and posing the danger of lost circulation) - Gel strength (proper value helps suspend solids in hole and allow them in settle on the surface) - Filtrate (the rate at which filtrate will invade a permeable zone and thickness of the filter cake that will be deposited on the wall as filtrations are important keys to trouble-free drilling) Drilling Fluid Solids Removal - Settling tanks - Mud pumps - Shale shakers - Hydrocyclone desander - Hydrocyclone desilter - Centrifuge Mud circulation and cleaning system A large reciprocating pump used to circulate the mud (drilling fluid) on a drilling rig. Mud circulation and cleaning system Classification of solids treatment equipment Mechanical solids control Settling Tanks - Mud pits are required for holding an excess volume of mud at the surface - The volume mud in the circulating system is usually Between 300 and 700 barrels - Mud pits are made of steel, with 5 x 40 x 3 feet size 3 pits are required - They are coupled together with conduits of 12 – 18” pipe - Mud is pumped into these tanks to allow sand to settle and any trapped gas bubbles in the mud to escape - At the edge of mud pits, mud guns are mounted for jetting down onto the surface of the mud - Mud guns are usually operated by an auxiliary mud-mixing pump Mud Pumps Function: To circulate the drilling fluid at desired pressure and volume Positive displacement piston pumps must be used - Large delivery rates at high pressure Two types mud pumps: -Two cylinder double-acting (duplex) -Three cylinder single-acting (triplex) Capable of delivering up to 5600 psi and 560 gallons per minute Shale Shakers -Vibratory screen shakers are the first stage devices - To trap large solid particles on a screen - The gyratory vibration frequency about 20 cycles per minute Different types of Shale Shakers Desanders -Commonly described as cyclone centrifuge separator - Rely on separation of large density particles from lower density liquids by centrifugal effect - Mud is pumped into the large end of a conical container - The small end is below the inlet and a turbulent whirling flow pattern is established within the cyclone - A short cylindrical tube at the top of the cone projects downwards into the body of the cone and acts as a “vortex-finder” for the inner (and lighter) components which make their exit via the top or overflow - The denser, solid particles are ejected, normally via an orifice at the lower end of the cone. - Cyclones are available in 6 “ (150mm) and 12” cone diameter - The capacities: with a feed pressure 35 psi (2.5 kg/cm2), 125 gallons/ min (0.47 m3/min) for 6” cone 500 gallons/ min (1.9m3/min) for 12” cone Desilters - Similar to desanders - But generally have smaller cone diameters (3-4” compared to 6-12”) - Have finer cone angles Frequently desilter cones are operated in an angle nearer to the vertical desanders - Desanders and desilters are operated in series with the desilter in sequence after the desander - Desilters may be used as a means of saving barite and is returned to the active stream while the overflow contains unwanted dispersed clays and this is discarded DESILTERS MUD CLEANER Centrifuge When solids of less than 20um, cyclone devices tend to be less effective, rotary centrifugal separators are used - A helical screw conveyor rotates inside a conical bowl on a horizontal axis - Bowl rotates at a slightly higher speed than screw conveyor and in the same direction (1800 rpm compared to 1775 rpm) - High rotational speed creates very high centrifugal accelerations thereby throwing heavy particles to the outside of the bowl, from which they are scraped towards the narrow end by the inner screw conveyor - The lighter liquids and dispersed clays move to the wide end and are discharged - The heavier particles discharged at the “solids” end are regarded as barite and are frequently returned to the active mud line to maintain density - At the other end, mud clay and bentonite may have to be discarded as the best means of controlling mud properties - In which case bentonite may require to be added immediately after the centrifuge Ancillary Equipment Most mud circulation and solids control system must necessarily Include some of the flowing bits of ancillary equipment - Mud tank agitators or mixer - Chemical and additions-mixing equipment - Degassers - Wash and cuttings cleaners for oil-bas Mud tank agitators Active and reserve tanks require continuous agitation Otherwise suspended solids settle out forming substantial deposits which can greatly reduce The effective volume of mud tanks Two main types 1) Paddle-type - Driven by electrical motor - Impeller is mounted about 1/3 of the depth of the depth of the mud above bottom - Baffles are used to provide a “butterfly “ circulation pattern which penetrates well into corners of mud tanks - Power consumption is about 5 hp (3.75 kW) - One can provide adequate agitation for 9.1 x 2.3 x 1.83 m tank Mud Agitator 2) Jet guns - Direct either high pressure (100 -125 psi) (7 kg/cm2 – 9 kg/cm2) or low pressure (40 - 60 psi) (3 kg/cm2 – 4.3 kg/cm2) - Recirculate mud within a tank - Being fed with mud via a centrifugal pump pressurized manifold system - Jets range in sizes from about ½” (13 mm) up to 3” (75 mm) - Mud flow rate 50 – 1500 grams per minute - Jet guns use about 2 hp (1.5 kW) each Jet Gun Mixing Devices - Mixing, chemical addition or blending devices operate on a jet-driven injector principle - Dry powders are fed to a hopper pass to a venturi mix with water or drilling fluid supplied at a pressure and highvelocity - The jet is supplied at pressure of 30 – 100 psi (2 kg/cm2 to 7kg/cm2) - Can mix dry powder 200 – 800 lb per min (90 – 360 kg per min) Degasser - Be fitted to a mud system immediately after the shale shaker and before mud is admitted to desander or desilter cones - A vacuum degasser is a one-stage liquid separator - Gas-cut mud is drawn into a cylindrical vessel by vacuum - The mud passes along a trough or baffle which spreads mud in a thin layer over a large surface - The exposed surface at reduced pressure allows gas to be released from solution - The gas being evacuated via a top discharge line to a safe area where it may be burnt off - The gas-free mud falls to the base of the cylindrical vessel from which it is ejected by a jet ejector - A ball float valve controls the flow to maintain mud at acceptable level - Such degasser can extract gas from heavy mud flows up to 900 gallons per minute (3.4 m3) - A 3 hp electric motor drives a vacuum pump to provide a vacuum 8 inch (203 mm) to 15 inch (381 mm) of mercury - The maximum lift to inlet is about 10 feet - The jet extractors utilize 5/8 inch (16 mm) jets (high pressure) or 1 ½ inch (38 mm) jets (low pressure) with volumetric feed rates of up to 500 gallons per minute (1.9 m3 per minute) to the jet Bulk Mud and Cement System - Bulk mud is in a form of powder - The powder is usually a mixture of bentonite and barite material. It is mixed with drill water to make drilling mud which is used as circulation fluid during drilling operation. - Bulk mud is loaded from the main deck side shell port and starboard filling station to the storage tank (“P” tank). - It is purged down by using low pressure air, known as bulk air. - When the bulk mud is required for mixing mud, it is purged from the “P” tank to the surge tank and fed into a mixing hopper. - The mixture is then transferred to the mud pit by circulating of mud fluid. - Bulk cement on a rig is similar to the cement used in other types of construction. - The filling, storing and transferring is similar to the bulk mud system. - The cement is purged from the storage tank to the surge tank and discharged to mixing hopper. - It is then mixed with fluid and pump via the cementing unit to the well. - Drill water is used mainly to mix with bulk mud to make a drilling fluid. - The mixture is processed in the mud pits. - Drill water does not have to be potable water. It can be river or industrial water. - Drill water is stored in designated double bottom tanks in the rig - Drill pump is fitted for transferring the water from the storage tank to the mud pits. - This system may also be modified to work as a wash down, machinery cooling, and equipment services or bilge sys Drilling Water System Low Pressure Mud System - Low pressure mud is the fluid which is mixture of bulk mud and drill water - It is used as circulation fluid when drilling an oil well. - The low pressure mud is mixed in the mud hopper by mixing drill water with bulk mud. - The mud mixing pump circulates the mixture from the mud pits through the mud hoppers and back to the pits until the required mud density is achieved. - Mud agitators in each pit keep the liquid mud from settling down prior to use. - The low pressure mud is sucked by the supercharging pump which discharges the mud into the suction header of the mud pump to maintain a constant inlet volume. - Overboard discharge line is provided for clean mud discharge. - If oil based mud is used for drilling operation, used mud will be stored in a waste oil mud holding tank before being loaded to another vessel through the port/starboard discharge station or a waste oil mud tank. - The low pressure mud can also be piped to the cementing unit for high pressure pumping requirement for the cement manifold High Pressure Mud and Cement - The high pressure mud is created after well mixed low pressure mud - It is being sucked to the slush pump. - There is a piston type pump which creates a discharge pressure up to 5,000 psi working pressure. - Relief valves are installed on each pump so that normal working pressure cannot exceed the system design pressure. - The high pressure mud is discharged via the discharge manifold to the drill floor stand pipe manifold, from stand pipe to the kelly connector down the drill string for mud circulation and returns via the mud return system. - The high pressure cement is pumped to the drill floor using the cementing unit. - There is also a high pressure piston pump, which is capable of developing 10,000 psi – 15,000 psi. - High pressure cement is used to stabilize the outside of the drill string by forming a concrete jacket between the bore hole and the casing. - The cement unit can also be used to pump high pressure mud or cement down the well to stabilizing the blow out. Mud Processing System - To clean drilling mud, which has been pumped down the well with the high pressure mud pumps to aid in circulation. - The mud is returned from the mud return line and must be cleaned of other particles, which are mixed with the mud during the drilling process. - The mud returning from the well through the casing flows into the flow line to the shale shaker. - The mud passing through the shale shaker mud will be reprocessed and the cuttings will be discharged overboard. Preload Filling and Dumping System - The preload (ballast) filling is the use of sea water through the raw water tower pump to fill the preload (ballast) tanks of a rig (typically jack-up rig). - Normally, the jack-up is preloaded before elevating the hull. - After elevating with the preload, the ballast water is discharged over board through the preload dump valve. Spud Can Leg Jetting System - A drilling jack up rig is equipped with a jetting system. - Along one side of the truss of each leg, two 6” pipeline are led to the spud can. - Each pipeline has connection branches distributed over the length. - At the spud can, the 2 jetting supply pipe penetrates the spud can top and continues with a ring header inside the spud can. - A total of 12 jetting nozzles each is provided for the can’s bottom plating and top plating are branched off from the ring headers. - Any of the two jetting lines or nozzle header can accommodate high pressure jetting. - Water is supplied to the jetting system from seawater system and high-pressure mud pump with maximum working pressure of 2000 psi. - The connection between the jetting pipes along the legs to the manifold outlet near the leg well by means of flexible hoses - The flooding line is located at the spud can with shut off valve that has an extended spindle operable from the top of the entrance trunk. - Before flooding the can, the cover for the entrance trunk is to be opened to allow for venting. - The flood valve is then opened for fill the can. - A 1 ½” air blow down line is provided for clearing the flooding line if the flood line is clogged up. - The flood valve must be closed after the spud can is filled. - To empty the can, the flood valve is closed and seawater is driven out by an eductor located in the can. - The seawater pump drives the eduactor. The eductor discharge pipe is led outside the can for discharge to the sea Spud Can Leg Jetting System