chapter 7 angle measurement

advertisement

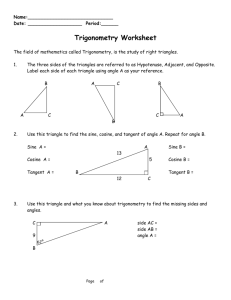

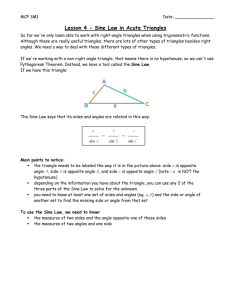

CHAPTER 7 ANGLE MEASUREMENT DPT 312 METROLOGY ROSHALIZA HAMIDON ANGLE From division of the circle, all of angular measurement is derived and provable Angle deal with direction – not space Angle is a relationship between two lines We can measure this relationship if we extend the lines until they intersect The intersection is called the vertex, and the lines are sides See figure 7.1 Figure 7.1 The angle is defined as AOB. It refers to the directions of the sides, not to the space between them Angle (cont’) Right angle – one-fourth of circle or one quadrant Acute angle - an angle measures less than 90o Obtuse angle - an angel measure more than 90o See figure 7.2 Figure 7.2 A right angle is 90.if smaller, it is acute; if larger, it is obtuse The level One of the most useful measurement instruments is the level These ‘bubble instrument’ are widely use in engineering metrology For precision measurement Precision levels Clinometers Theodolites Use in the shop (less precision measurement) Bench level Mechanic’s level All of these instruments use bubbles in fluid filled tubes Figure 7.4 The longer the radius of curvature, the more precise the level will be Figure 7.5 Figure 7.6 Reading level Figure 7.7: the readings are the number of divisions that the bubble moves Level adjustment First, orient the level on the surface until the bubble is centered Then clamp the straightedge to the surface along one side of the level Reverse the level and read the error Repeat this process, orienting to a new location on the surface until you have achieved the desired accuracy * If the level is so far out of calibration that the bubble is off the scale, it may take long and tedious adjustment to make it usable again. Level adjustment Clinometer The block level is restricted to relatively small angles This restriction is removed in the clinometer It is a level mounted in a frame so that the frame may be turned at any desired angle to the horizontal reference Figure 7.8 A few of many types of clinometers Measuring with clinometer Place the base against the surface with the circle clamp in the free position Rotate the level until it is approximately level Clamp the circle, then use the fine adjustment to center the bubble Turn the micrometer knob first until you have a reading on the degree scale in line with the fiducial arrowhead Add the reading on the top scale to the degree scale In clinometer, you read the bubble only to provide reference plane; you must read the angle from another scale Disadvantage of levels There are four principal disadvantage of levels 1. 2. 3. 4. General ignorance about their proper use and application The time required to settle down Their single sensitivity characteristic They do not produce any output that can be used as loading for a measurement system THE PROTRACTOR For measuring angles, the simple protractor is equivalent to the rule for measuring length Like a steel rule, the simple protractor has limited use. But mechanical additions to the rule resulted in the versatile combination square (e.g: vernier caliper & height gage) We make similar modifications on the simple protractor, we get universal bevel protractor Figure 7.9 Figure 7.9 Figure 7.10 Degrees are read directly, but minutes are read with the vernier scale Care must be used to read the minutes from the correct pair of lined-up graduation 12o 50’ Figure 7.11 Always read the vernier in the same direction from zero that the dial is read and add the vernier minutes to the scale degrees Application for vernier protractor We can determine the angle or degrees in any arc with the universal bevel protractor When protractor is set at 90, (figure 7.12B), all four angles are as read If you turn the blade counterclockwise (figure 7.12A) which happens in two position as shown. If you turn the blade clockwise (figure 7.12C), the angle read will be formed only in two places, which are always from the blade to the base rotating clockwise Figure 7.12 & 7.13 Figure 7.12: When reading from 90, these are positions where the angle and its supplement are found Figure 7.13: when reading from 0, there is little danger of confusing the angle and its supplement Care of the universal bevel protractor TRIGONOMETRIC FUNCTIONS The trigonometric functions, formed by the sides of triangles For elementary angle computation, we simply use the natural functions Sine Cosine Tangent Sine bars and plate The sine bar, a steel bar that has a cylinder near each end, forms a hypotenuse The instrument is designed with a distance between the cylinder that make computation easy When one of the cylinders is resting on a surface, you can set the bar at any desired angle by simply raising the second cylinder You obtain the desired angle when the height difference between the cylinder id equal to the sine angle multiplied by the distance between the centers of the cylinders Figure 7.14 The sine bar is a hypotenuse of triangle frozen in steel with a length selected to minimize computations Comparison measurement with sine bars We use gage blocks for measurement of angles with high amplification instrumentation and measure by comparison The sine bar is used to construct an angle equal to angle that we need to measure, but the constructed angle is in opposite direction of the actual angle Part is supported by sine bar The deviation can be detected by measuring the parallelism between the part feature and the reference surface (using dial indicator) See figure Figure 7.15 For comparison measurement, the sine bar is used to cancel out the angle being measured Sine blocks, sine plates and sine tables Sine blocks are wide sine bar (a sine instrument wide enough to stand unsupported) Sine plates are wider sine blocks (a sine instrument rest on an integral base) Sine tables are still wider (a sine instrument is an integral part of another device, such as machine tool) Figure 7.16 Sine block Sine plate MECHANICAL ANGLE MEASUREMENT Another method of angle measurement, called mechanical indexing and its related tools The dividing head, indexing head or index head Were developed specifically for machining rather than measurement There are three principal classes of index head Dial index head Plain index head Universal The dial index head The lowest amplification, the dial index head is one power (1X). Therefore, it has a limited practical application today. It consist of horizontal spindle mounted on the base that rests on a reference surface The plate which also an index plate, contains holes with a plunger that engages the stationary housing The typical plate has 24 holes, which provides 360o rotation in 15o increment Figure 7.17 The dial index head quickly divides rotations into 24 divisions 15 part Figure 7.17 Plain index head The plain index head, which start at a 2X amplification, can provide a discrimination of 40X when we add worm and a gear One third of the index plate turns of the index plate turns the spindle 9 degrees; therefore if we are using the 24-position index plate, the discrimination increases to 0o2’15” Figure 7.18