Angular Measurement

advertisement

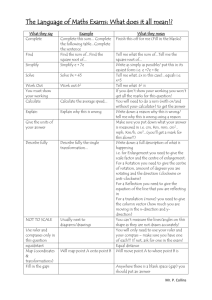

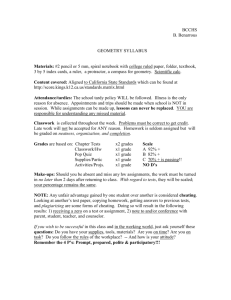

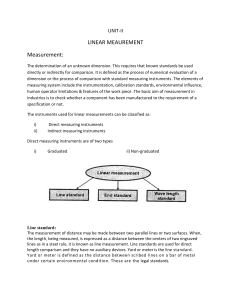

IQC PRESENTATION 1 Contents • • • • • • • Angular Measurement Angular Tools Types Of Tools Sine Bar Try square Dial Gauge Clinometers 2 Angular Measurement • Circles are divided into 360 equal parts, each being a degree. • Each of these degrees can be evenly divided into 60 equal parts. These parts are called minutes. • These minutes can be evenly divided into 60 equal parts. These parts are called seconds. 3 Types Of Tools:• Most common tools:• • • • Simple Protractor Multi-Use Gauge Combination Set Universal bevel protractor 4 Angular Measure Tools 5 Protractor Whole degree increments 6 Multi-Use Gauge Pre-set positions for 45 and 90 degrees, 59 degree drill point angle, and whole degree increments. 7 Multi-Use Gauge Pre-set position for 90 degrees. 8 Multi-Use Gauge Pre-set position for 45 degrees. 9 Multi-Use Gage Measuring 59 degree drill point angle. 10 11 Protractor Head Whole degree increments 12 Protractor Built-in Spirit Level 13 Protractor Angular Measure with Protractor Head 14 Transfer-type Protractors 15 Universal Bevel Protractor • Precision angles to within 5' (0.083º) • It Consists of :• Base • • • • Vernier scale Protractor dial Sliding blade Dial clamp nut 16 Vernier Protractor • Used to measure obtuse angle (90º-180º) • Acute-angle attachment fastened to protractor to measure angles less than 90º • Main scale divided into two arcs of 180º • Scale divided into 12 spaces on each side of 0 • If zero on vernier scale coincides with line on main: reading in degrees 17 Reading a Vernier Protractor • Note number of whole degrees between zero on main scale and zero on vernier scale • Proceeding in same direction, note which vernier line coincides with main scale line • Multiply number by 5' and addFourth to degrees on protractor dial 50º 4 x 5'= 20' Reading = 50º 20' 18 Sine Bars • Used when accuracy of angle must be checked to less than 5 minutes • Consists of steel bar with two cylinders of equal diameter fastened near ends • Centers of cylinders exactly 90º to edge • Distance between centers usually 5 or 10 inches and 100 or 200 millimeters. • Made of stabilized tool hardened steel 19 Sine Bar 20 Sine Bars 21 TRY SQUARE • A try square is a wood working or a metal working used for marking and measuring a piece of wood. The square refers to the tool's primary use of measuring the accuracy of a right angle (90 degrees); to try a surface is to check its straightness or correspondence to an adjoining surface. A piece of wood that is rectangular, flat, and has all edges (faces, sides, and ends) 90 degrees is called four square. 22 23 Dial Gauge • The dial gauge also known as the indicating gauge and used for checking concentricity of rods, holes and flatness of surfaces to accuracy of 0.01mm. These gauges are widely used on lathe. 24 Clinometer • A clinometer is an instrument used for measuring angle relative to the horizontal plane. 25 Type Of clinometer • • • • • Vernier Clinometer Micrometer Dial Pendulum Optical 26 THANKS 27