Lab 5 Angular Measurement

advertisement

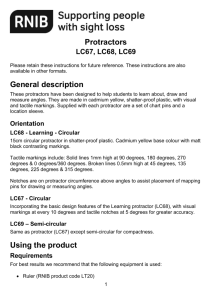

DPT 312/3 METROLOGY LAB 5: ANGULAR MEASUREMENT OBJECTIVES 1. To expose student about angular measurement technique and its purpose using Sine Bar. 2. To measure the angle using Sine Bar, Dial Gauge Indicator and Gauge Block. 3. To measure the angle using Vernier Bevel Protractor. INTRODUCTION 1. Level A spirit level measures small angular displacements relative to horizontal datum, the level of liquid at rest. It is used for setting surface level. Levels which have a displacement of 2.5 mm for a tilt of 0.025 mm in 250 mm are representative of the precision class of the inexpensive and very useful piece of equipment. The principal use of spirit level is that of testing straightness and flatness. The accuracy of a spirit level can be checked by placing it on any flat surface, marking the bubble's position and rotating the level 180°. The position of the bubble should then be symmetrical to the first reading. Both levels have a "vee" groove machined along the base which enables the level to sit on a round bar while remaining parallel with the bar's axis. They also have a smaller cross level to enable the second axis to be roughly checked or corrected. (a) (b) Figure 1: Level; a) Engineering Spirit Level; b) Acrylic spirit level 1 School of Manufacturing Engineering DPT 312/3 METROLOGY 2. Vernier Bevel Protractor A protractor is an instrument for measuring and for laying out angles. There are many different types of protractors, but they all embody the same general principles. The type generally used by machinists and toolmakers is known as the bevel protractor. The simple bevel protractor can be extended in its accuracy by the application of a circular vernier scale and this instrument is known as vernier level protractor. A vernier level protractor has a straight blade, which can be set at any angle with the base ; the angle for any position is shown by degree graduations on the disk, which is graduated from 0 to 90 degrees in each direction. V is the circular vernier scale. The main scale on the disk is graduated in degrees of arc. The vernier scale has 12 divisions on each side of the centre zero. These are marked 0-60 minutes of arc, so that each division equals 1\12 of 60, that is 5 minutes of arc. These12 divisions occupy the same space as 23 degrees on the main scale. Therefore each division of the vernier is equal to1\2 of 23 degree or 1 11\12 degree. Since two divisions on the main scale equal 2 degrees of arc, the difference between two divisions on the main scale and one division on the vernier scale is 2degree -1 11\12 degree=1\12degree=5 minutes of arc. Figure 2: Vernier Protractor 3. Trigonometric functions For accurate work in connection with angles, the sine bar possesses advantages over the protractor when conditions are favourable for its use. A Sine bar is used either for accurately measuring angles or for locating work to a given angle. A sine bar consists of an accurately ground bar on which two accurately ground pins or plugs, of the 2 School of Manufacturing Engineering DPT 312/3 METROLOGY same diameter, are mounted an exact distance apart. The distances are usually either 125 or 250 mm. essential conditions for accuracy are that the plugs or rollers must be of the same diameter with their axes parallel and lying in the plane parallel with the upper or working surface of the sine bar. Measurements of angles are made by using the principle that the sine of a given angle is the ratio of the opposite side of the angle to the hypotenuse of a right-angled triangle. The sine bar is set using gauge blocks in a way that the to plugs of the sine bar rest on gauge blocks wrung to such heights that the bottom of the sine bar rests perfectly over the surface of workpiece whose inclination is to be found out. 3 School of Manufacturing Engineering DPT 312/3 METROLOGY Figure 3: Sine Bar PROCEDURES i. Vernier Bevel Protractor 1. Take a warkpiece, and measure the angel that labeled. 2. place the base on reference plane and move the blade to the plane that want to measure. Take a reading (Main scale + Vernier scale). 3. Repeat step No. 1 to complete 5 readin ii. Trigonometric functions 1. Get the sine bar information before starting set up (length and rollers diameter). 2. Set up the sine bar, workpiece (part), gauge block and dial indicator as in Figure 4 below. Figure 4 3. Move the indicator along the surface of part. If the indicator is in horizontal plane (0), calculate the angle of the combination set using trigonometric function. 4. Repeat step No. 2 to 3 with the other workpiece. 4 School of Manufacturing Engineering DPT 312/3 METROLOGY REPORT FORMAT 1. Title. 2. Objectives. 3. Procedures and drawing. 4. Results. 5. Discussion and recommendation. (Base on result) 6. Conclusion. (Base on Objective and Discussion) 5 School of Manufacturing Engineering DPT 312/3 METROLOGY RESULT i. Vernier Bevel Protractor Item No. Angle () Table 1: Result ii. Trigonometric functions Item No. Angle () Table 2: Result 6 School of Manufacturing Engineering DPT 312/3 METROLOGY 7 School of Manufacturing Engineering