Midterm Presentation - Final

advertisement

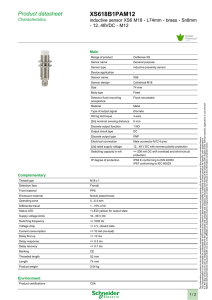

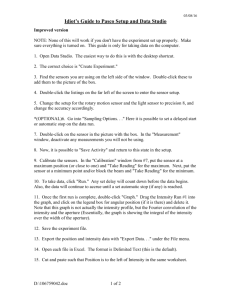

Contactless Angular Position Sensor Mid-Semester Design Presentation Senior Design Presentation October 8, 2009 Team Members Eugene Sandberg Computer Engineer Christine Bratton Electrical Engineer Matt Landry Electrical Engineer Tasks: -Construct Test Setup -Program Microchip -Website Tasks: -Research Magnets and Sensors -Program Microchip -Output Stage Tasks: -Research Magnets and Sensors -Output Stage -Packaging Aram Lee Electrical Engineer Jeremy Lewis Computer Engineer Tasks: -Research Magnets and Sensors -Program Microchip Tasks: -Construct Test Setup -Packaging -Layout Outline • Problem Statement • Solution Diagram • Constraints – Technical – Practical • Alternatives to Original Solution • Progress – Timeline Problem A-Arm Endcap/Sensor Problem With Current Design The current sensor fails often. The Army believes that it is due to the mechanical contact. Solution - Hall Effect Sensor Overview of Proposed Solution Magnet • Generates a magnetic field. Sensor • Outputs a signal relative to angular position of magnetic field. Microprocessor • Processes the signal from the sensor. DAC/Amp • Outputs analog voltage. (0-24V) Constraints •Technical Constraints •Practical Constraints Technical Constraints •The CAPS must be driven by a 24 volt input and output a linear DC voltage ranging from 0 to 24 V. •The CAPS must draw less than 24 mA. •The CAPS must have a response time of less than 20ms or less. Technical Constraints •The CAPS must operate between -40 to 70 degrees Celsius •The CAPS must be accurate to .1 degrees and measure an angle of 90 degrees. Practical Constraints • Problem • Sustainability – The CAPS must be contactless. Practical Constraints • Problem • Compatibility – Must Fit in End Cap – Same Casing Alternatives for Angular Position Sensing •Optical -Grease Interference -Outside of Vehicle -Particle Interference Alternatives for Angular Position Sensing •Hall Effect Sensor -No particle interference -Operates in Endcap -Sensitive to Magnetic field Alternatives Angular Position Sensors MLX90316 KMA200 • Hall Technology • Magnetoresistive • Digital SPI Output • Analog and Digital SPI Output • Specify Default Mode when Ordering • Default Mode is Analog • Currently Being Tested • Will be used for Initial Testing, • 360 Degree Range Calibration of Test Setup • 180 Degree Range Progress - Parts MAX5312EAE • DAC • 0V-8V Output • 12Bit Percision PIC24 • Process Sensor Signal • Talks to the MAX5312EAE LM7321MA • OP AMP • 3 to 1 Amplification • Will output voltage of 0- 24 • 24V supply Progress-Test Setup Test Setup Progress Magnet Evaluation Magnet A (Largest Magnet) Voltage at 45 Degrees Voltage at 90 Degrees Voltage at 135 Degrees 5mm 1.08 2.5 3.64 10mm 1.07 2.49 3.67 15mm 1.08 2.52 3.66 20mm 1.09 2.48 3.62 25mm 1.09 2.48 3.61 30mm 1.1 2.4 3.61 Progress Timeline 8/18 Research Sensor and Magnets Construct Test Setup Evaluate Angle Sensor 1 Output Stage Investigate 3D CAD Packaging Evaluate Angle Sensor 2 Interface with Microprocessor Package Design 8/28 9/7 9/17 9/27 10/7 10/17 10/27 References •Karahalis, Alex. “Contacless Angular Position Sensor.” August 11, 2009. •SPG Media Group Ltd. “Stryker 8-Wheel Drive Armoured Combat Vehicles, USA.” 2009. [Online]. Available: http://www.army-technology.com/projects/stryker/ [Accessed: August 30, 2009]. • Quasdorf, Joachim. “A Case Study: MR vs. Hall Effect for Position Sensing.” [Online]. Available: http://www.sensorsmag.com/sensors/article/ [Accessed: October 2009]. Questions ?????